Laser taking perovskite quantum dot microcrystalline glass as gain medium

A glass-ceramic and gain medium technology, applied in the field of lasers, can solve the problems of poor wavelength tunability, poor reliability and mechanical stability of all-solid-state lasers, and high cost of electrically pumped lasers, and is suitable for mass production and performance. Excellent, environmentally stable and mechanically stable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

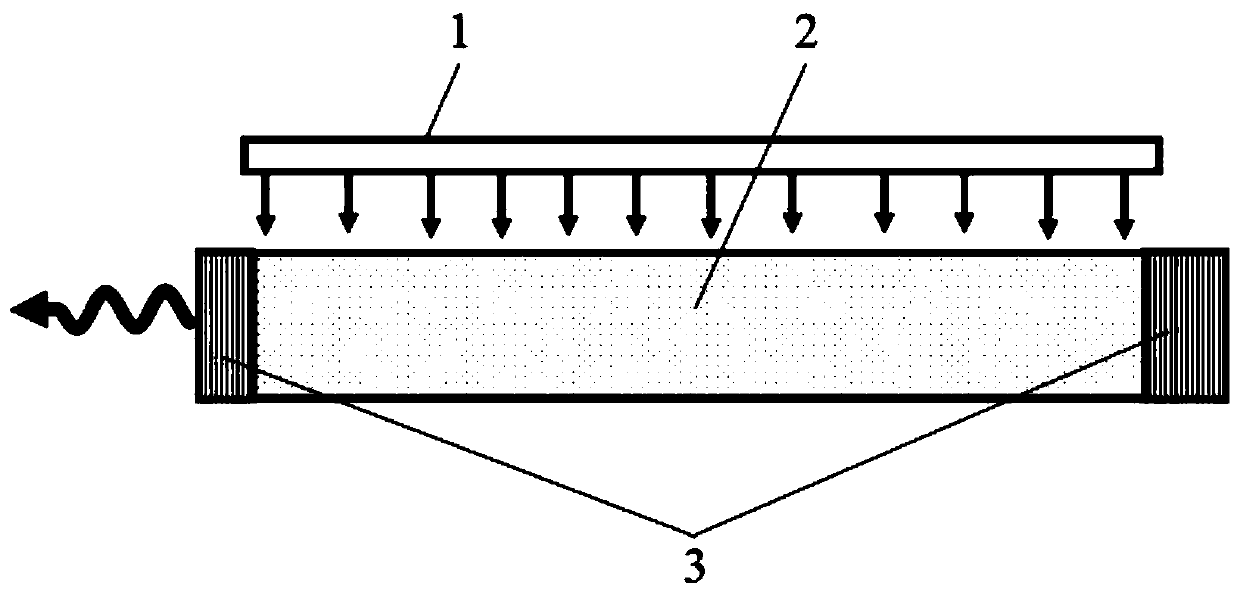

[0043] Such as figure 1 Shown is a schematic diagram of a laser with a perovskite quantum dot glass ceramic whose resonant cavity structure is Fabry-Perot (FP) as the gain medium in the present invention. Such as figure 1 As shown, in this embodiment, the laser with perovskite quantum dot glass ceramics as the gain medium includes:

[0044] The pump source 1 is used to excite the laser gain medium 2 so that the laser gain medium 2 emits photons;

[0045] The laser gain medium 2 is used to receive the radiation of the pump source 1 and emit photons;

[0046] The resonant cavity 3 is used to amplify the photons emitted by the laser gain medium 2 to output continuous laser or pulsed laser.

[0047] The perovskite quantum dot glass ceramic material of the laser gain medium 2 is CsPbX 3 (X=Cl,Br,I), or CsPb(Cl x Br 1-x ) 3 (x=0-1), or CsPb(Br x I 1-x ) 3 (x=0-1), or CsPb 2 Br 5 The Pb ions in the perovskite quantum dot glass-ceramic material can be replaced in whole or in part with tin ion...

Embodiment 2

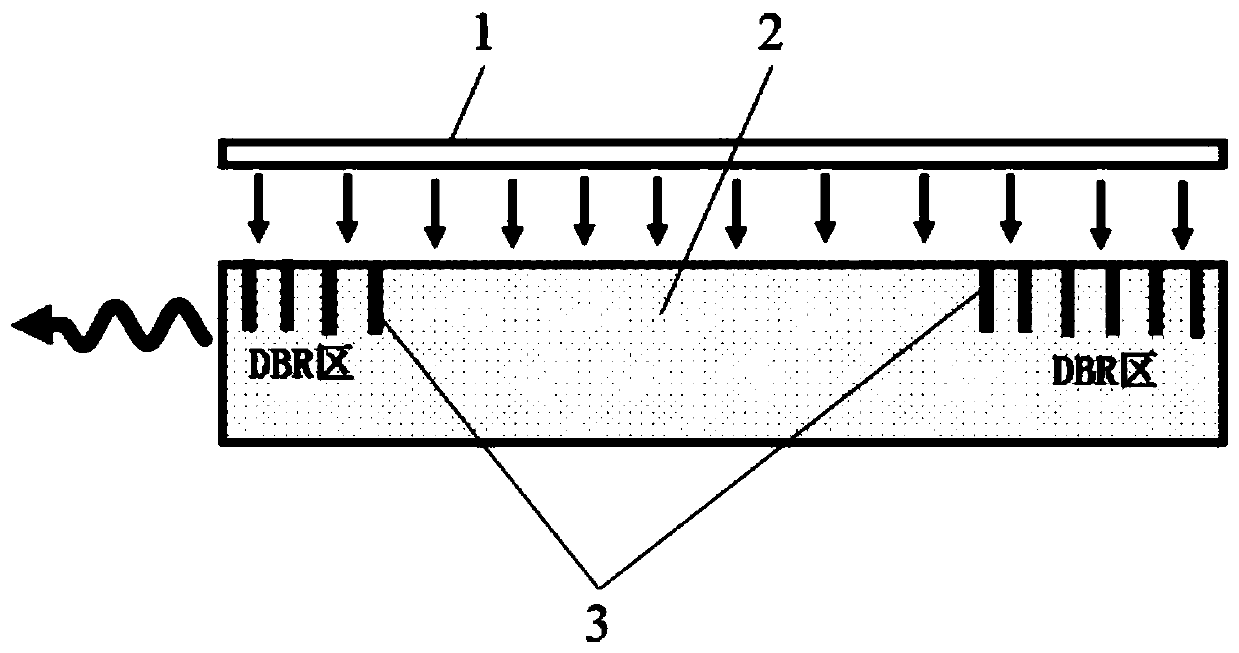

[0054] figure 2 It is a schematic diagram of a laser with a perovskite quantum dot glass ceramic whose resonant cavity structure is a distributed Bragg reflector (DBR) as a gain medium in the present invention. Such as figure 2 As shown, in this embodiment, the laser with perovskite quantum dot glass ceramics as the gain medium includes:

[0055] The pump source 1 is used to excite the laser gain medium 2 so that the laser gain medium 2 emits photons;

[0056] The laser gain medium 2 is used to receive the radiation of the pump source 1 and emit photons;

[0057] The resonant cavity 3 is used to amplify the photons emitted by the laser gain medium 2 to output continuous laser or pulsed laser.

[0058] The difference from Embodiment 1 is that in the laser with the perovskite quantum dot glass ceramics of Embodiment 2 as the gain medium, the resonator 3 is a distributed Bragg reflector (DBR) structure resonator in a periodic structure resonator. . The laser gain medium 2 is formed b...

Embodiment 3

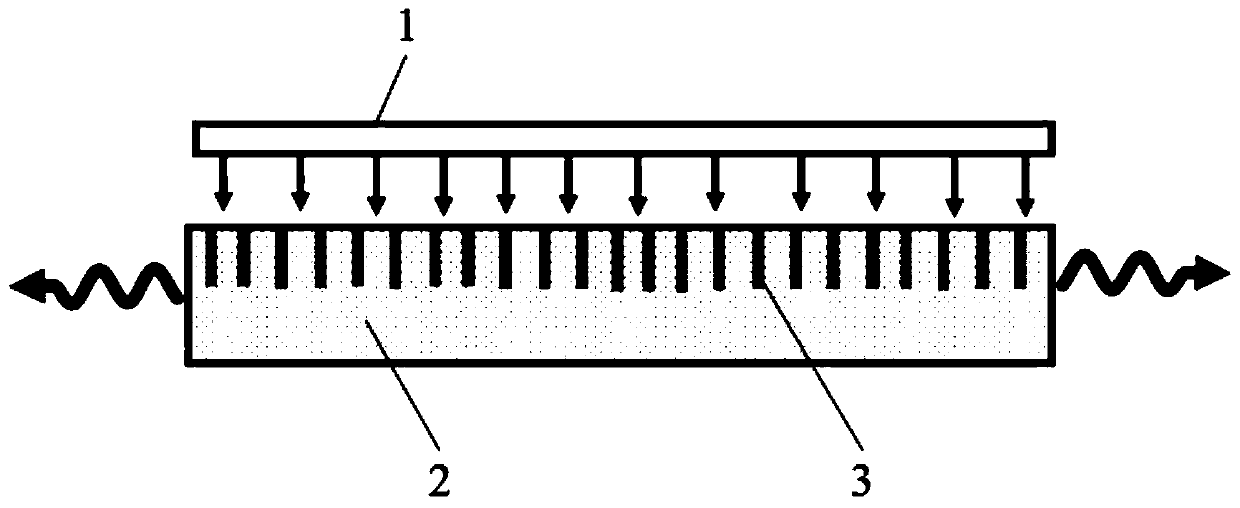

[0061] image 3 It is a schematic diagram of the laser with the perovskite quantum dot glass ceramics as the gain medium with the distributed feedback (DFB) cavity structure in the present invention. Such as image 3 As shown, in this embodiment, the laser with perovskite quantum dot glass ceramics as the gain medium includes:

[0062] The pump source 1 is used to excite the laser gain medium 2 so that the laser gain medium 2 emits photons;

[0063] The laser gain medium 2 is used to receive the radiation of the pump source 1 and emit photons;

[0064] The resonant cavity 3 is used to amplify the photons emitted by the laser gain medium 2 to output continuous laser or pulsed laser.

[0065] The difference from Embodiment 1 is that in the laser with the perovskite quantum dot glass ceramics of Embodiment 3 as the gain medium, the resonator 3 is a distributed feedback (DFB) structure resonator in a periodic structure resonator. Make the laser emit laser light in both directions.

[0066...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com