Hard asphalt granulation method and device thereof

A hard asphalt and granulation technology, which is applied in the direction of solidification/crushing and processing tar asphalt/petroleum asphalt/natural asphalt, etc., can solve the problems of low production efficiency, asphalt particles need to be dehydrated and dried, and achieve improved utilization rate and bright appearance , the effect of enhancing the heat transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The hard asphalt used for granulation is deoiled asphalt obtained by the butane solvent deasphalting process with a softening point of 95°C in the ring and ball method.

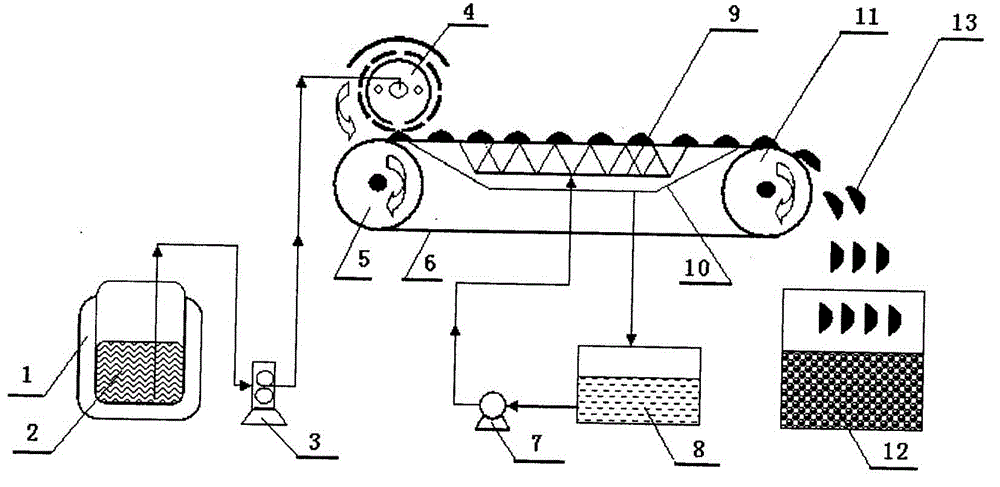

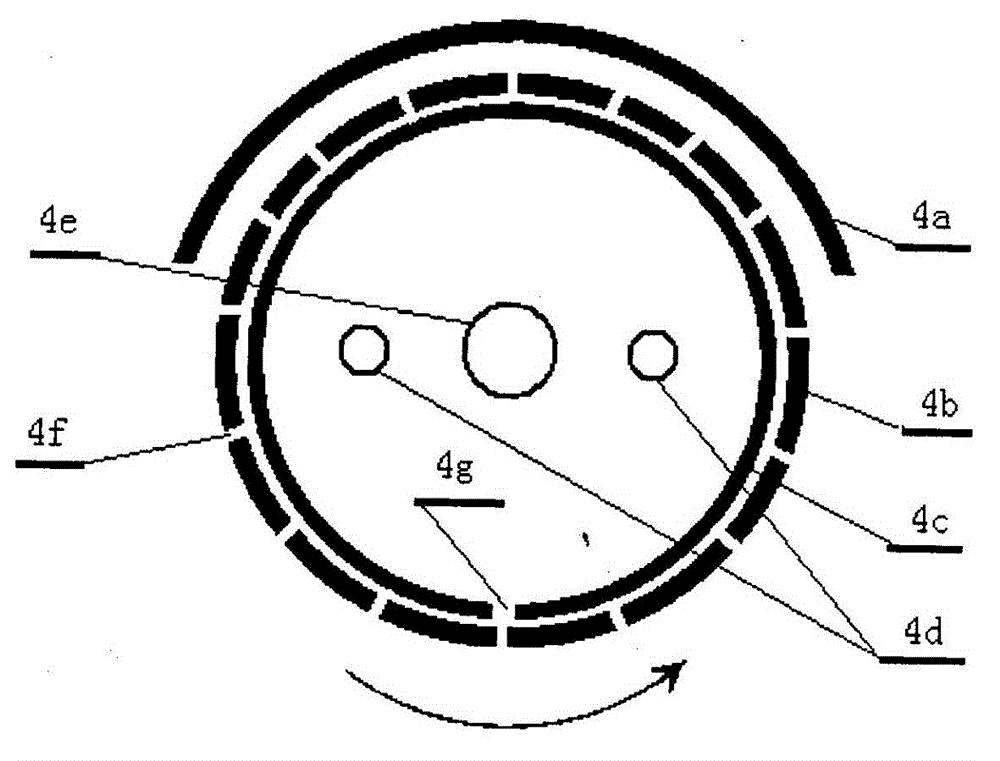

[0027] The deoiled asphalt is placed in a hard asphalt melting tank 2, heated with a heater 1 and kept at 200°C. Start the raw material pump 3, the deoiled asphalt in the molten state in the hard asphalt melting tank 2 is delivered to the internal member 4c of the distributor 4 by the molten hard asphalt inlet 4e, start the heat preservation heater 4d, and make the inside of the distributor 4 The temperature of the molten deoiled bitumen in the member 4c was kept constant at 200°C. Start the rotary steel belt system so that the rotary steel belt 6 runs along the rotors 5 and 11 at a speed of 0.15m / s, and the effective cooling length of the steel belt is 15m. Start the cooling water pump 7 to make the cooling water in the cooling water tank 8 cool down the rotating steel belt 6 through the cooling wate...

Embodiment 2

[0029] The hard asphalt used for granulation is deoiled asphalt obtained by the butane solvent deasphalting process with a softening point of 95°C in the ring and ball method.

[0030] The deoiled asphalt is placed in a hard asphalt melting tank 2, heated with a heater 1 and kept at 200°C. Start the raw material pump 3, the deoiled asphalt in the molten state in the hard asphalt melting tank 2 is delivered to the internal member 4c of the distributor 4 by the molten hard asphalt inlet 4e, start the heat preservation heater 4d, and make the inside of the distributor 4 The temperature of the molten deoiled bitumen in the member 4c was kept constant at 200°C. Start the rotary steel belt system so that the rotary steel belt 6 runs along the rotors 5 and 11 at a speed of 0.30m / s, and the effective cooling length of the rotary steel belt is 20m. Start the cooling water pump 7 to make the cooling water in the cooling water tank 8 cool down the rotating steel belt 6 through the cooli...

Embodiment 3

[0032] The hard asphalt used for granulation is deoiled asphalt obtained by the butane solvent deasphalting process with a softening point of 95°C in the ring and ball method.

[0033] The deoiled asphalt is placed in a hard asphalt melting tank 2, heated with a heater 1 and kept at 200°C. Start the raw material pump 3, the deoiled asphalt in the molten state in the hard asphalt melting tank 2 is delivered to the internal member 4c of the distributor 4 by the molten hard asphalt inlet 4e, start the heat preservation heater 4d, and make the inside of the distributor 4 The temperature of the molten deoiled bitumen in the member 4c was kept constant at 200°C. Start the rotary steel belt system so that the rotary steel belt 6 runs along the rotors 5 and 11 at a speed of 0.35m / s, and the effective cooling length of the steel belt is 28m. Start the cooling water pump 7 to make the cooling water in the cooling water tank 8 cool down the rotating steel belt 6 through the cooling wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com