Synthetic-resin laminated bottle body, injection molding device and method for forming laminated preform

A synthetic resin, preform technology, applied in packaging, bottles, wrapping paper, etc., can solve the problems of interlayer peeling, damage to appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

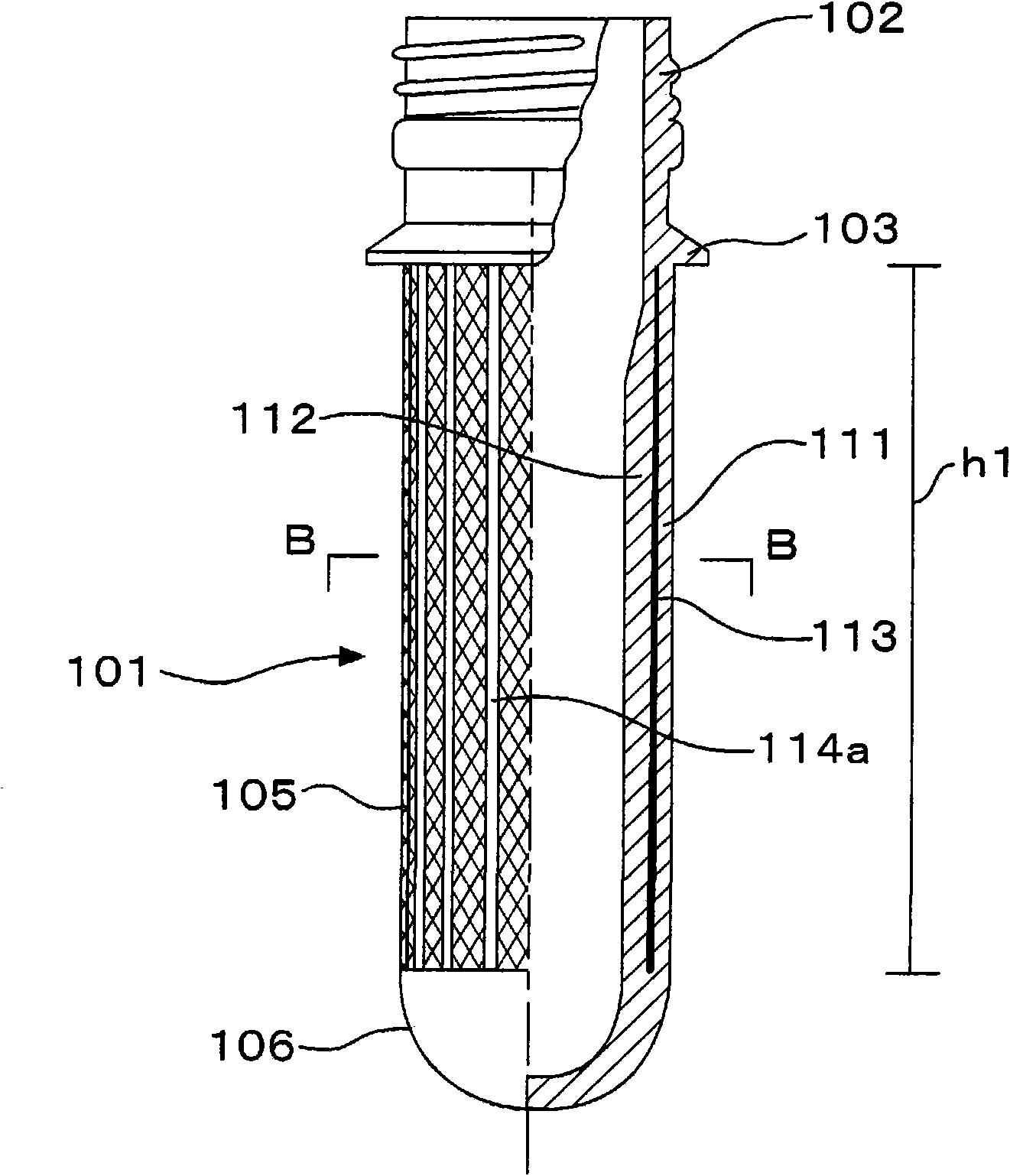

[0076] Hereinafter, a biaxial stretch blow molding synthetic resin laminated bottle body, an injection molding device, and a method of molding a laminated preform using the injection molding device according to the present invention will be described with reference to the drawings.

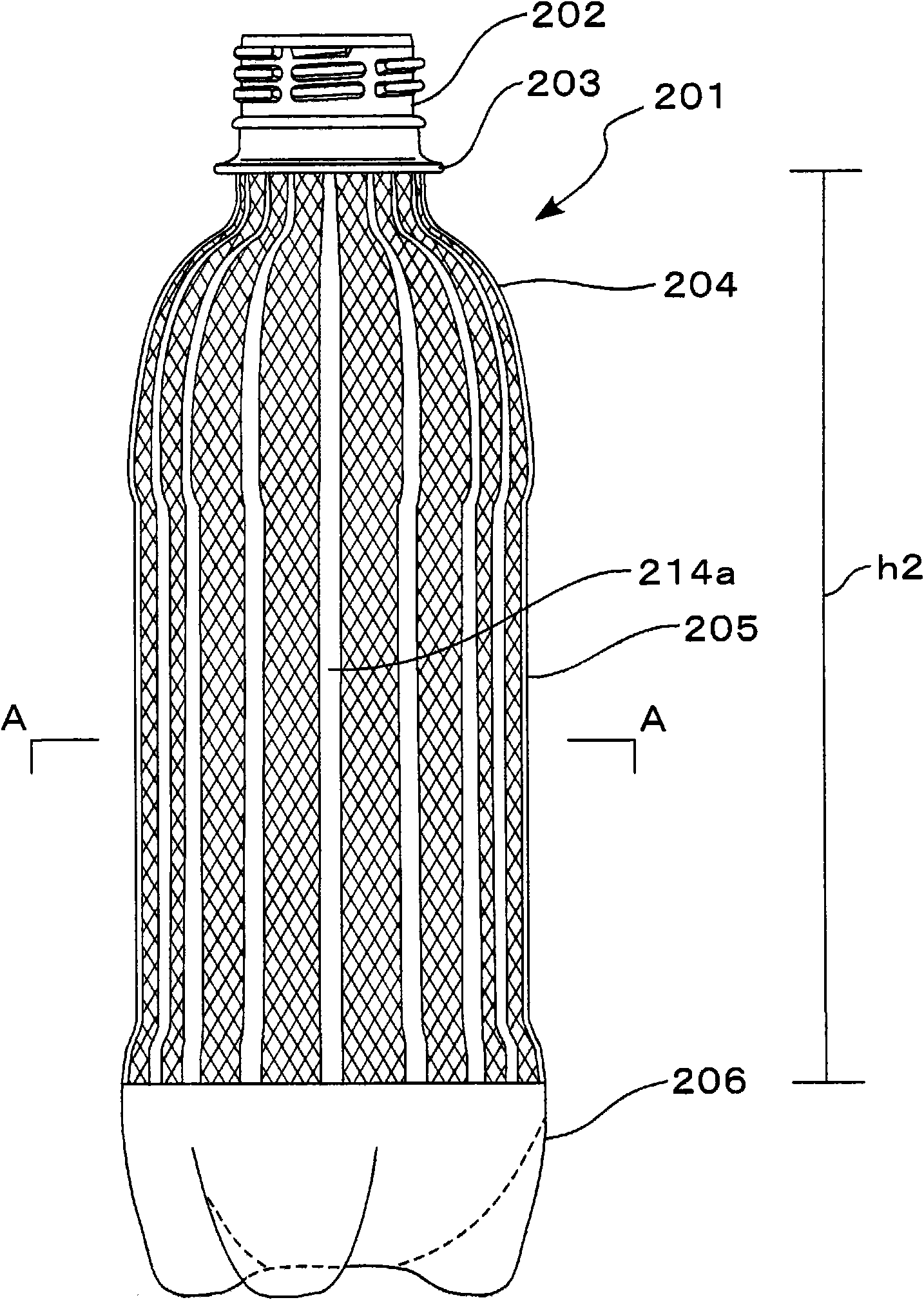

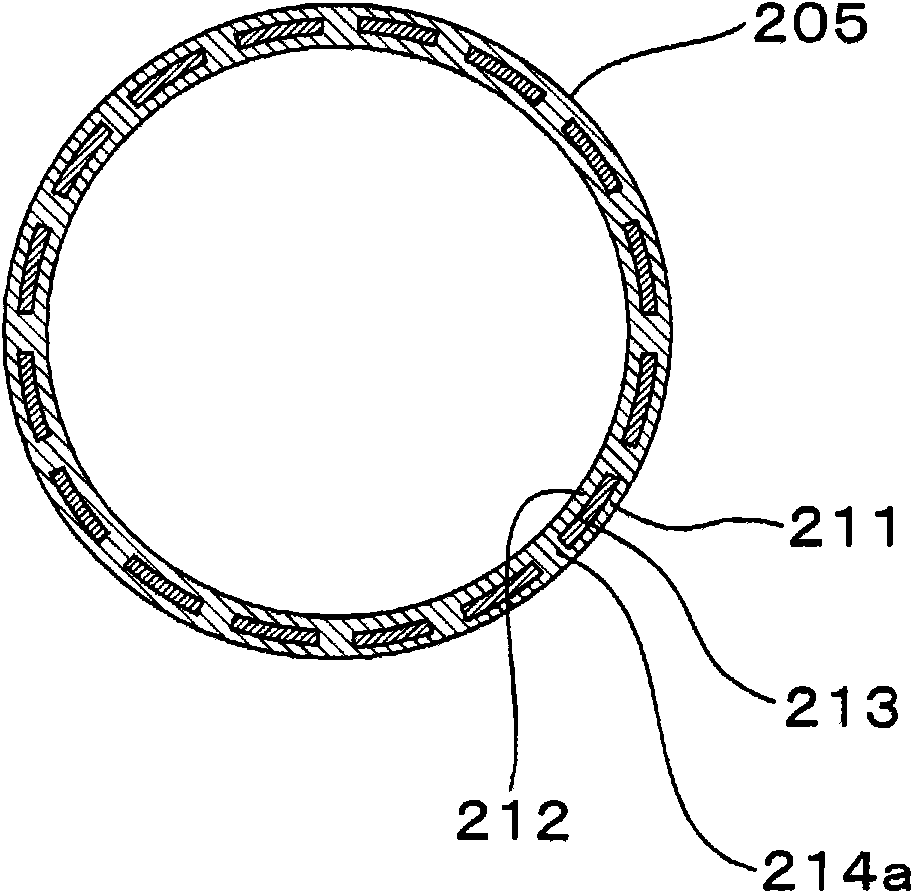

[0077] figure 1 , figure 2 It is a figure showing the first embodiment of the synthetic resin laminated bottle body of the present invention, figure 1 is the main view, figure 2 is along figure 1 The top sectional view indicated by the A-A line in . The bottle body uses PET resin as the main material resin, and is a so-called pressure-resistant PET bottle used for beverages containing carbonated components. A portion 205 and a bottom 206 protruding from a plurality of legs and formed in a so-called petal shape.

[0078] Such as figure 2 As shown in the top cross-sectional view of the bottle body 201, the bottle body 201 has the following stacked structure within a predetermined height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com