Solar module and manufacturing method thereof

A technology of solar cells and solar cells, which is applied in the field of solar cells, can solve problems such as easy delamination and easy damage of solar cells, and achieve the effects of preventing delamination and aging, improving sealing performance, and preventing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

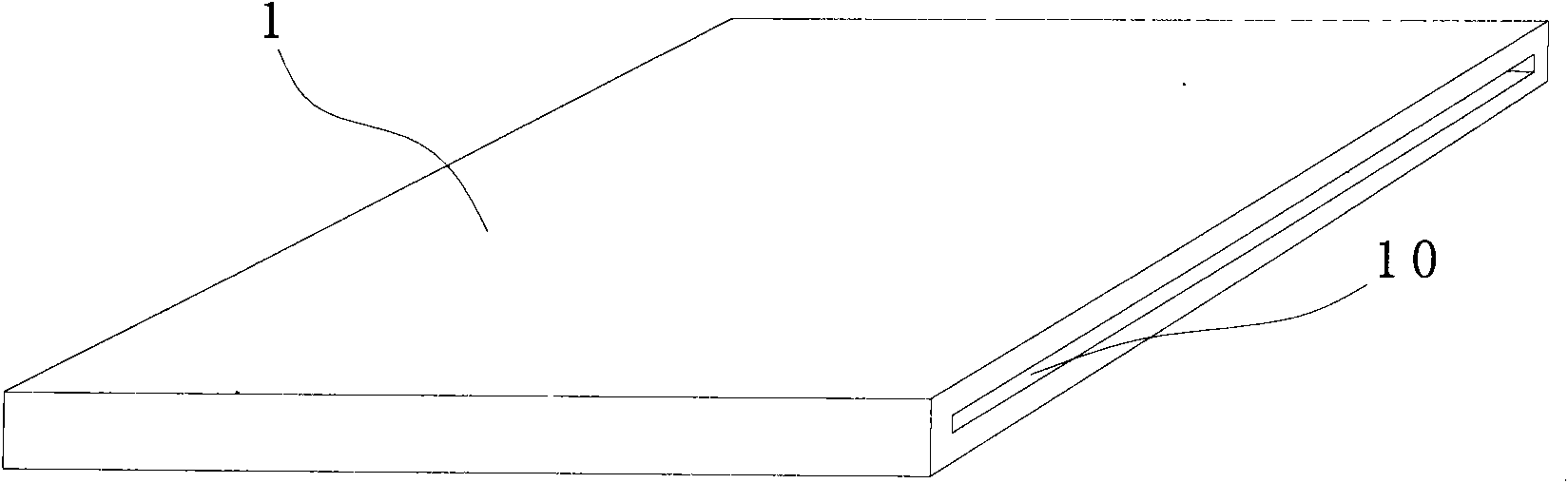

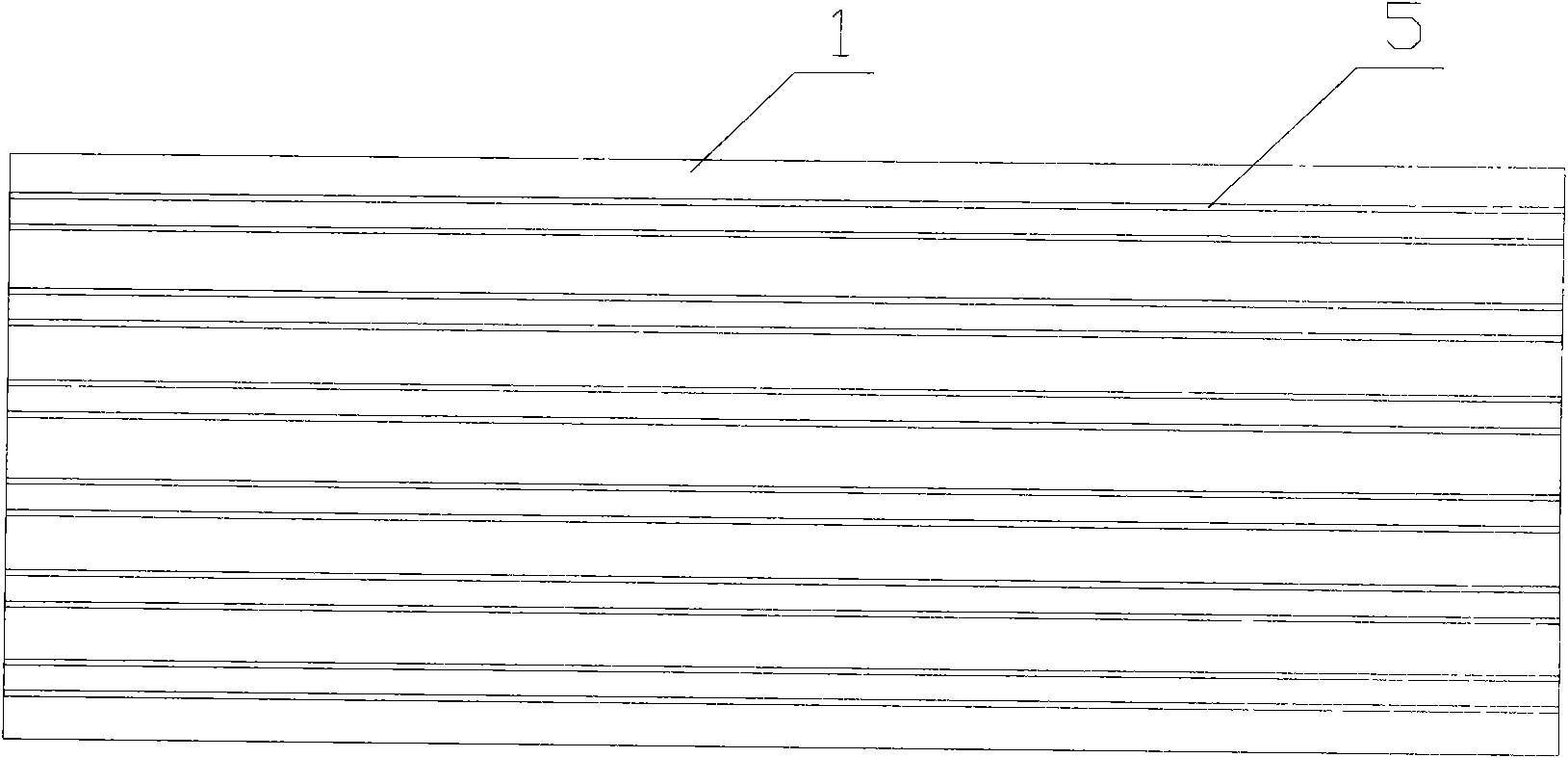

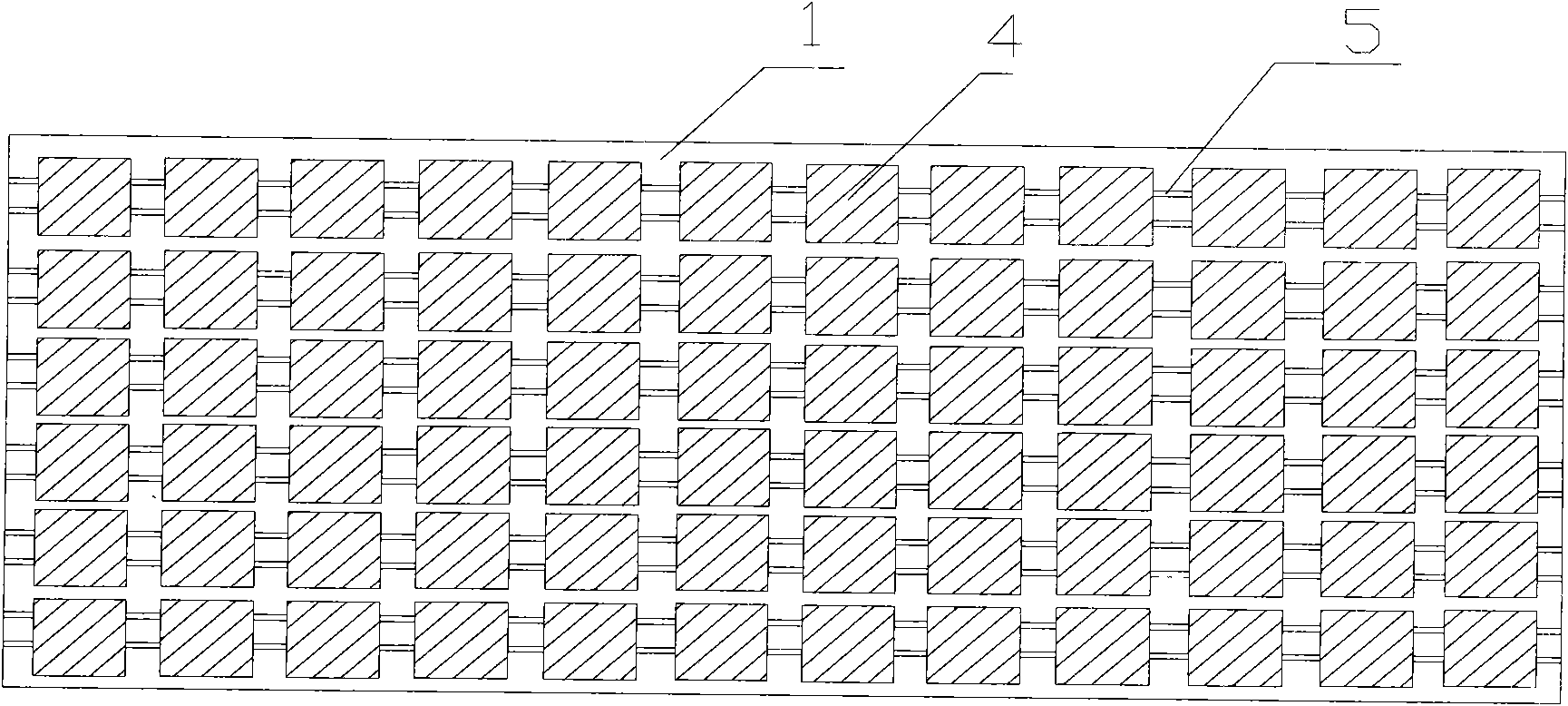

[0028] As shown in the figure, a solar battery module includes a battery array, and the battery array is formed by connecting a plurality of solar battery pieces 4 in series or in parallel through welding ribbons 3, and also includes a flat plate with a cavity inside, a lead post, and a side opening The glass model 1, sealing material 2 and sealant 6; the battery array is placed in the cavity of the glass model 1, the sealing material 2 fills the space outside the battery array in the cavity, and the sealant 6 is used to seal the glass The side opening of Model 1.

[0029] Such as image 3 As shown, the battery array is formed by connecting multiple solar cells 4 in series or in parallel, and the connection mode of the battery array is selected according to the required current and voltage. The solar cells 4 can be monocrystalline silicon, polycrystalline silicon, or amorphous silicon solar cells , the specific principle and structure of the solar battery sheet 4 are well kno...

Embodiment 2

[0041] The specific method for manufacturing the solar cell module of the present invention will be described in detail below.

[0042] Including the following steps:

[0043] 1) Make a battery array: according to the needs, select solar cells 4 of appropriate size, form a plurality of solar cells 4 by welding in series or in parallel with ribbons 3, and lead out positive and negative electrode wiring and bypass diode wiring; specifically Weld the single / double-sided light-receiving solar cell 4 with the ribbon 3, then place the welded single cell in the mold and orderly weld the solar cell string, and weld the solar cell string with the ribbon 3 to form a solar cell array .

[0044] 2) Making glass model 1: Select low-iron ultra-clear glass as the material, make a mold according to the design structure during production, complete the casting and molding of glass parts according to the glass preparation process, and perform subsequent tempering treatment.

[0045] Step 1) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com