Forming method for metal gate

A technology of metal gates and gate trenches, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve problems such as gaps in metal gates and difficulties in the fill process, so as to reduce resistance and solve the manufacturing process The effect of the puzzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

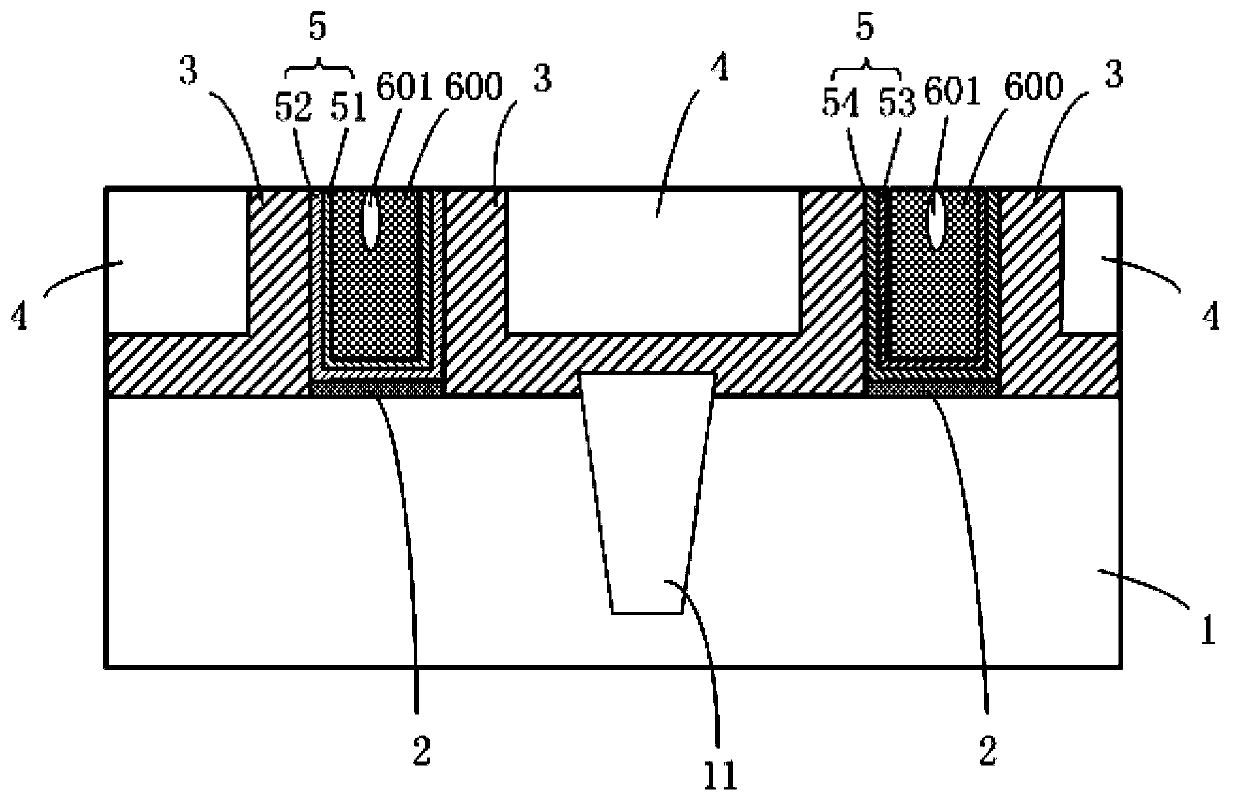

[0048] In this embodiment, NMOS transistors and PMOS transistors are formed by using the first method for forming metal gates, and this embodiment will be described in detail below with reference to the accompanying drawings.

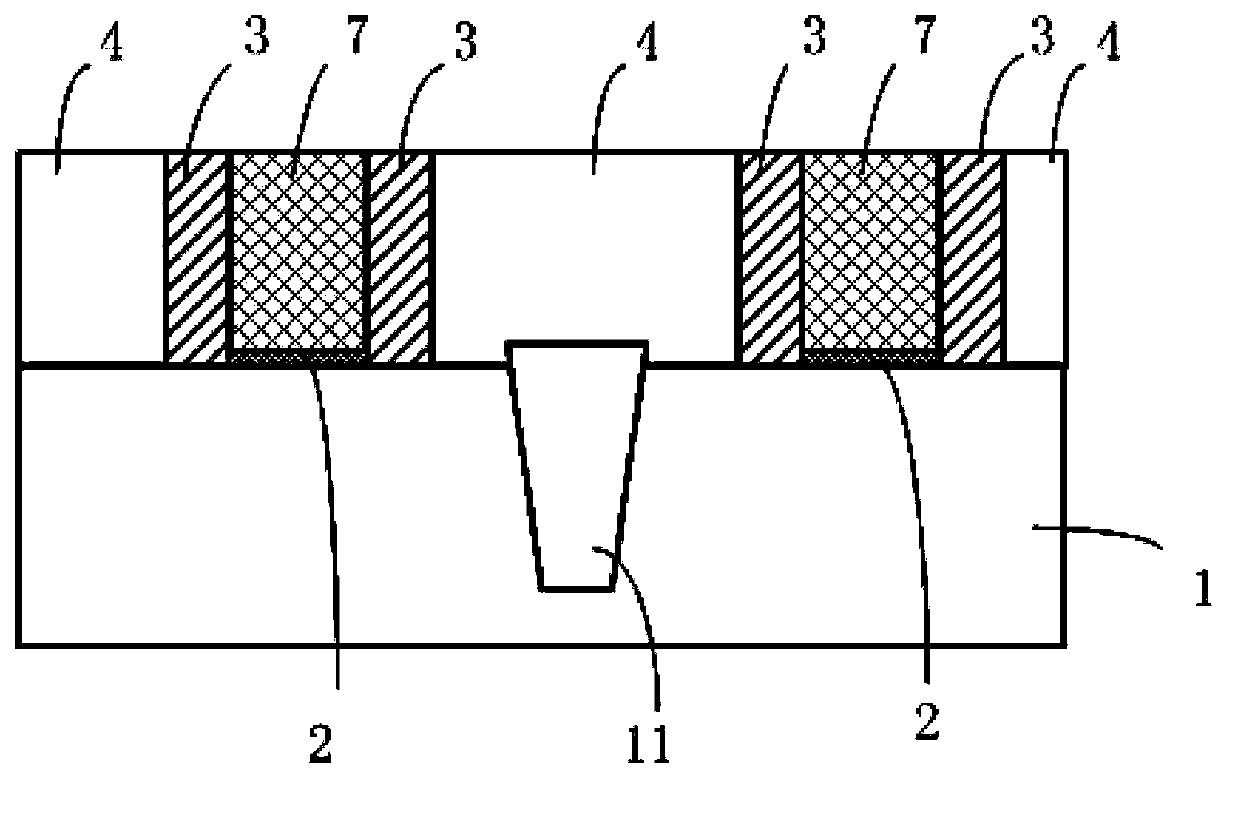

[0049] Please refer to figure 2 Firstly, a dummy gate layer 7 is formed on the substrate 1 , and spacers 3 are formed on both sides of the dummy gate layer 7 .

[0050] The substrate 1 in this embodiment may typically be a silicon substrate, such as a wafer. The silicon substrate can be made of silicon that reaches the purity of the semiconductor industry, or a silicon substrate doped with a small amount of elements such as germanium and / or carbon. The substrate 1 may also be doped with impurity dopant elements such as boron, phosphorus or arsenic. In other embodiments, alternative materials may be used to form the substrate 1, and the alternative materials may or may not be combined with silicon, including but not limited to germanium, indium antimo...

Embodiment 2

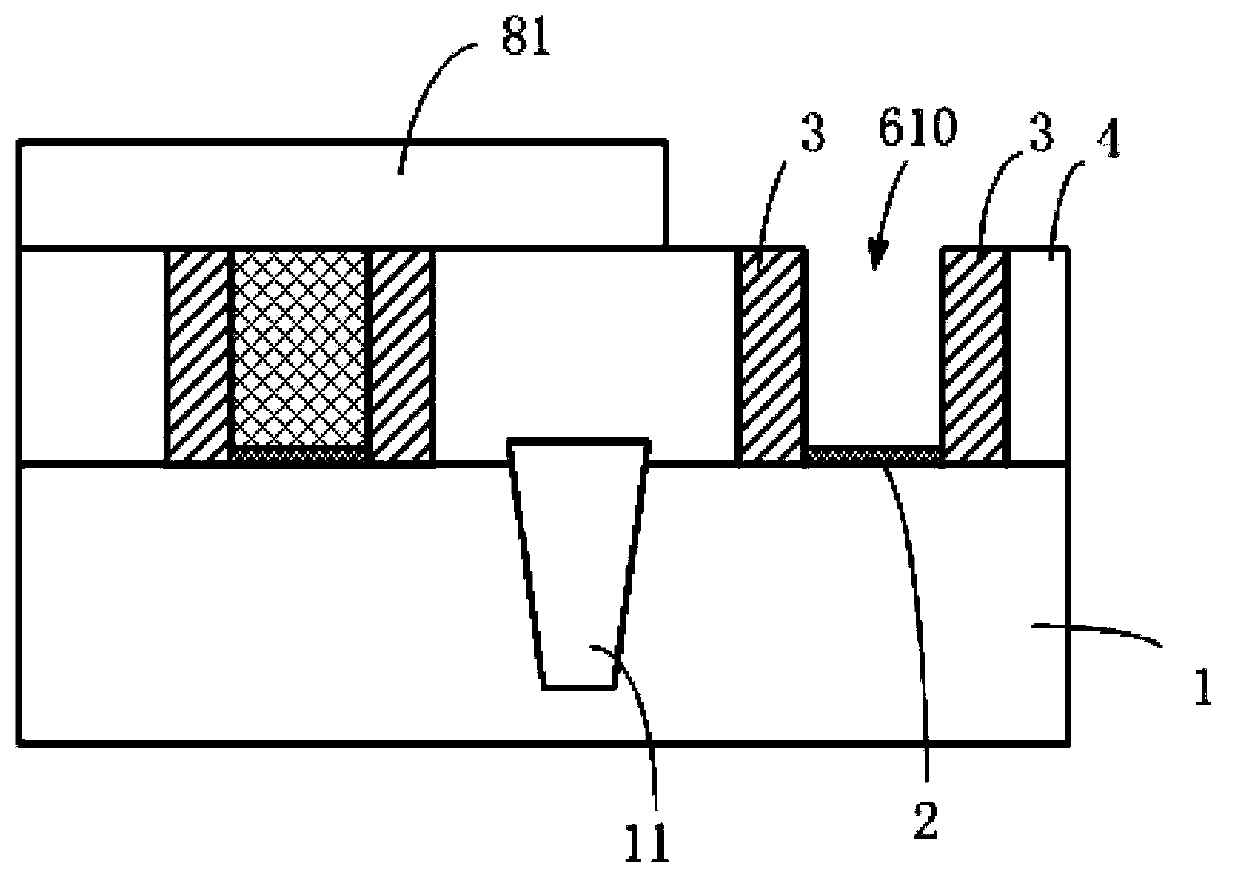

[0093] In this embodiment, NMOS transistors and PMOS transistors are fabricated using a method similar to that of Embodiment 1. Most of the steps in this embodiment are the same as those in Embodiment 1. This specification mainly describes the special steps in this embodiment. For other parts, please refer to Embodiment 1. For the content of this embodiment, you can refer to the corresponding figures in Embodiment 1, and at the same time refer to Figure 14 to Figure 16 .

[0094] This embodiment firstly provides the figure 2 The structure shown, then according to embodiment one from Figure 3 to Figure 5 Each step is processed. in getting Figure 5 After the structure shown, what follows is not as Figure 6 Shown to etch the work function metal layer, but take the Figure 5 The first protective mask layer 81 is removed for the structure in , and a third protective mask layer is formed to cover the structures on the right side of the shallow trench isolation region 11 (...

Embodiment 3

[0100] In this embodiment, a method similar to that of Embodiment 1 is used to fabricate a MOS transistor, and for the same part as the previous forming method, reference may be made to the content of the above corresponding part of this specification. The differences will be described in detail below. Please refer to the corresponding figures of the metal gate formation method in the first embodiment, and Figure 17 to Figure 23 .

[0101] This method includes steps S1 to S7, each step will be described in detail below.

[0102] S1 , forming a dummy gate layer 7 on the substrate 1 , and forming sidewalls 3 on both sides of the dummy gate layer 7 .

[0103] The substrate 1 in this embodiment may typically be a silicon substrate 1 such as a wafer. The silicon substrate 1 can be made of silicon with the purity of the semiconductor industry, or a silicon substrate 1 doped with a small amount of elements such as germanium and / or carbon. The substrate 1 may also be doped with i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com