Soft insulating optical fiber insulator

An insulator and software technology, applied in the coupling of optical waveguides, etc., can solve the problems of short service life, complex processing, large optical loss, etc., and achieve the effect of improving insulation performance and service life, simplifying processing technology, and reducing optical loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

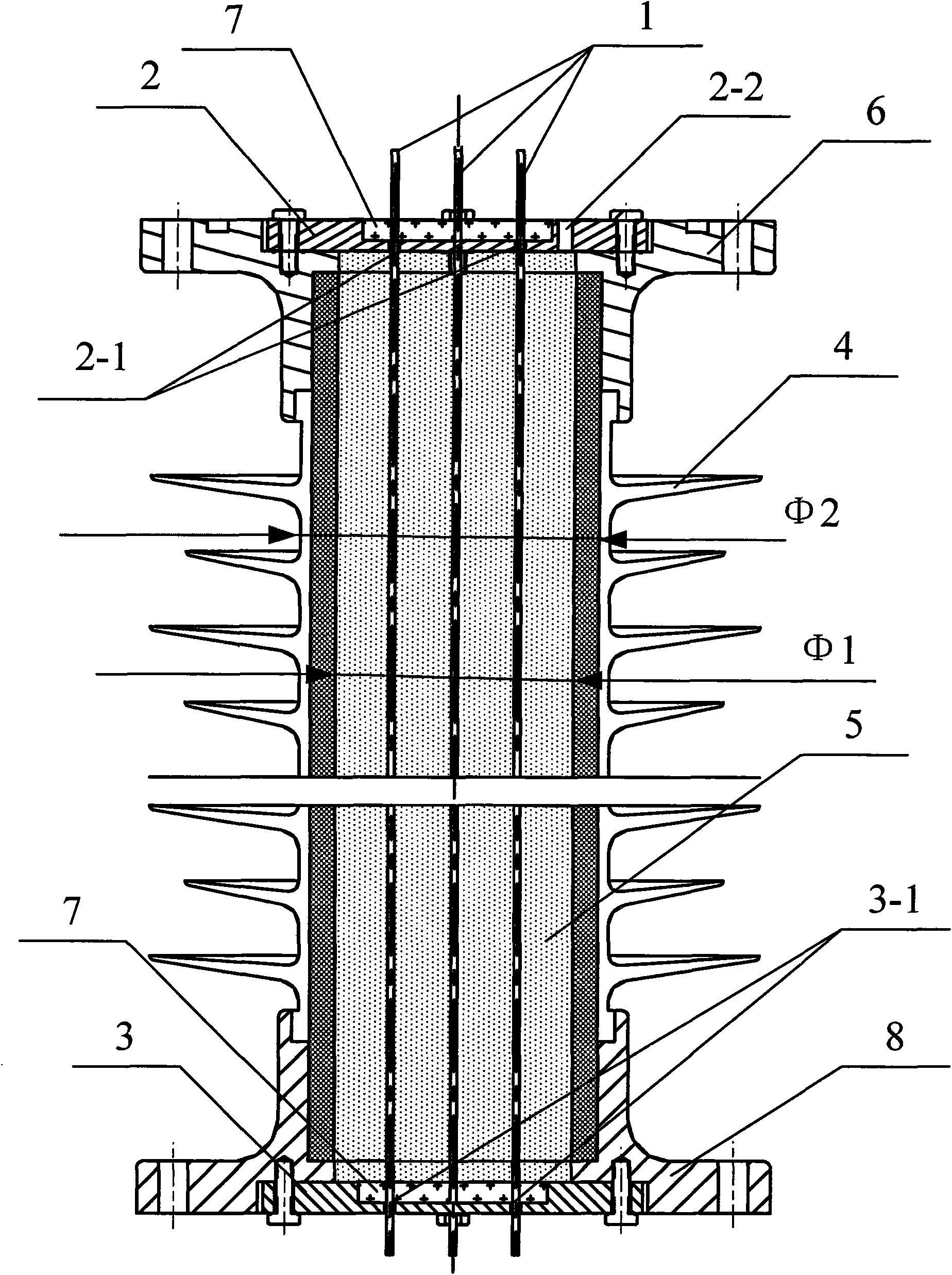

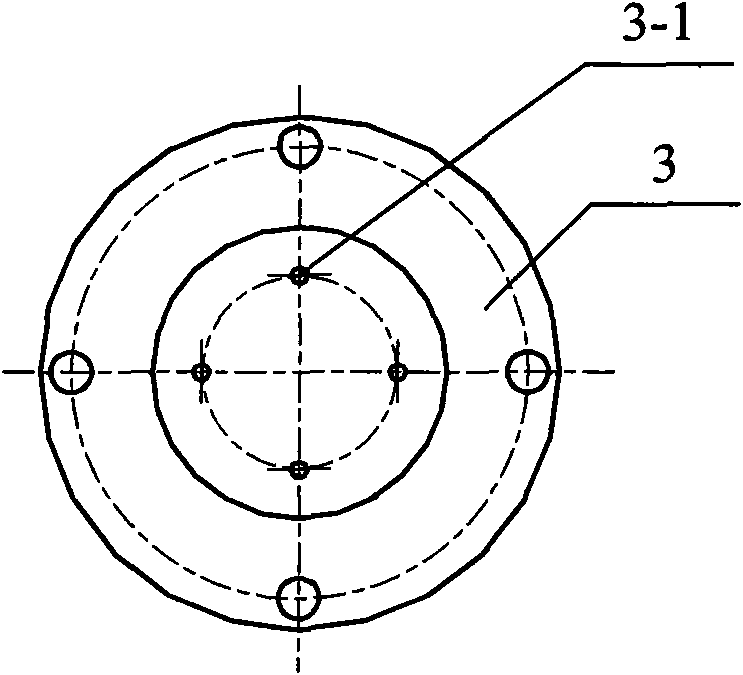

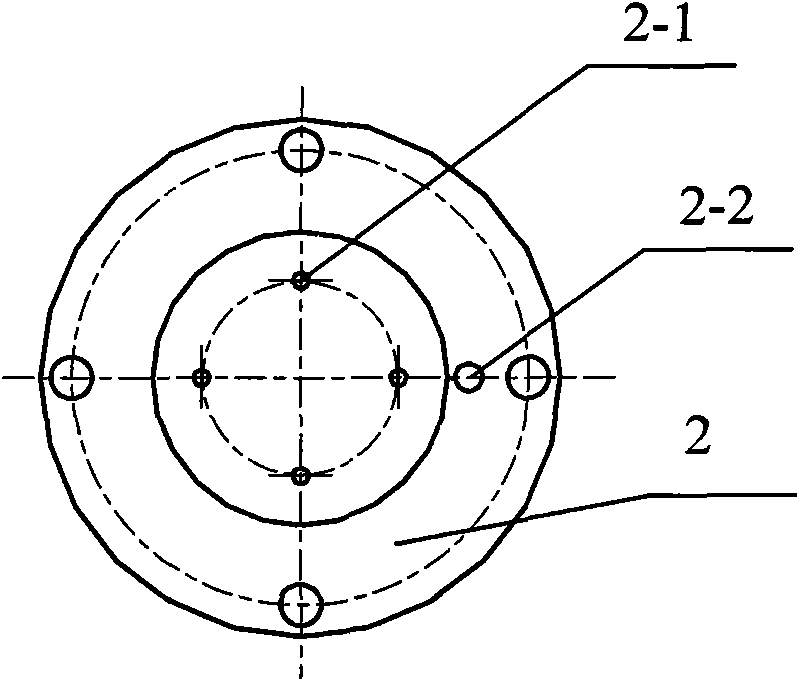

[0009] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe this embodiment, the soft insulated optical fiber insulator of this embodiment consists of multiple optical fiber jumpers 1, an upper metal end cap 2, a lower metal end cap 3, an upper metal flange 6, a lower metal flange 8, a hollow insulator 4, a software Glue 5 and two layers of sealant 7, the upper end of the hollow insulator 4 is fixed to the upper metal end cover 2 through the upper metal flange 6, and the lower end of the hollow insulator 4 is connected to the lower metal end cover through the lower metal flange 8 3 fixed connection, the upper metal end cover 2 has a plurality of through holes 2-1 and a glue injection hole 2-2, the lower metal end cover 3 has a plurality of through holes 3-1, and the upper The plurality of through holes 2-1 on the metal end cover 2 correspond to the plurality of through holes 3-1 on the lower metal end cover 3, and the plurality of optical fiber jumpers 1 pen...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 The present embodiment will be described. The hollow insulator 4 of the present embodiment is a hollow composite insulator with a silicone rubber outer insulation. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 The present embodiment will be described. The ratio of the inner diameter φ1 to the outer diameter φ2 of the hollow composite insulator with silicone rubber outer insulation in this embodiment is ≤0.66. In this way, the flexural and compressive modulus of the hollow composite insulator with silicone rubber outer insulation is greater than that of the solid state, which meets the mechanical performance requirements of the hollow composite insulator with silicone rubber outer insulation. During the implementation of the process, the inner wall of the hollow composite insulator with the outer insulation of silicone rubber is machined once to ensure its smoothness. Other compositions and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com