Semiconductor wafer protective member and semiconductor wafer grinding method

A technology for protecting components and single wafers, which is used in semiconductor/solid-state device manufacturing, workpiece support grinding, grinding/polishing equipment, etc., and can solve the problems of peeling off the protective tape, which are prone to cracks, fractures, and the peripheral part is not firmly fixed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

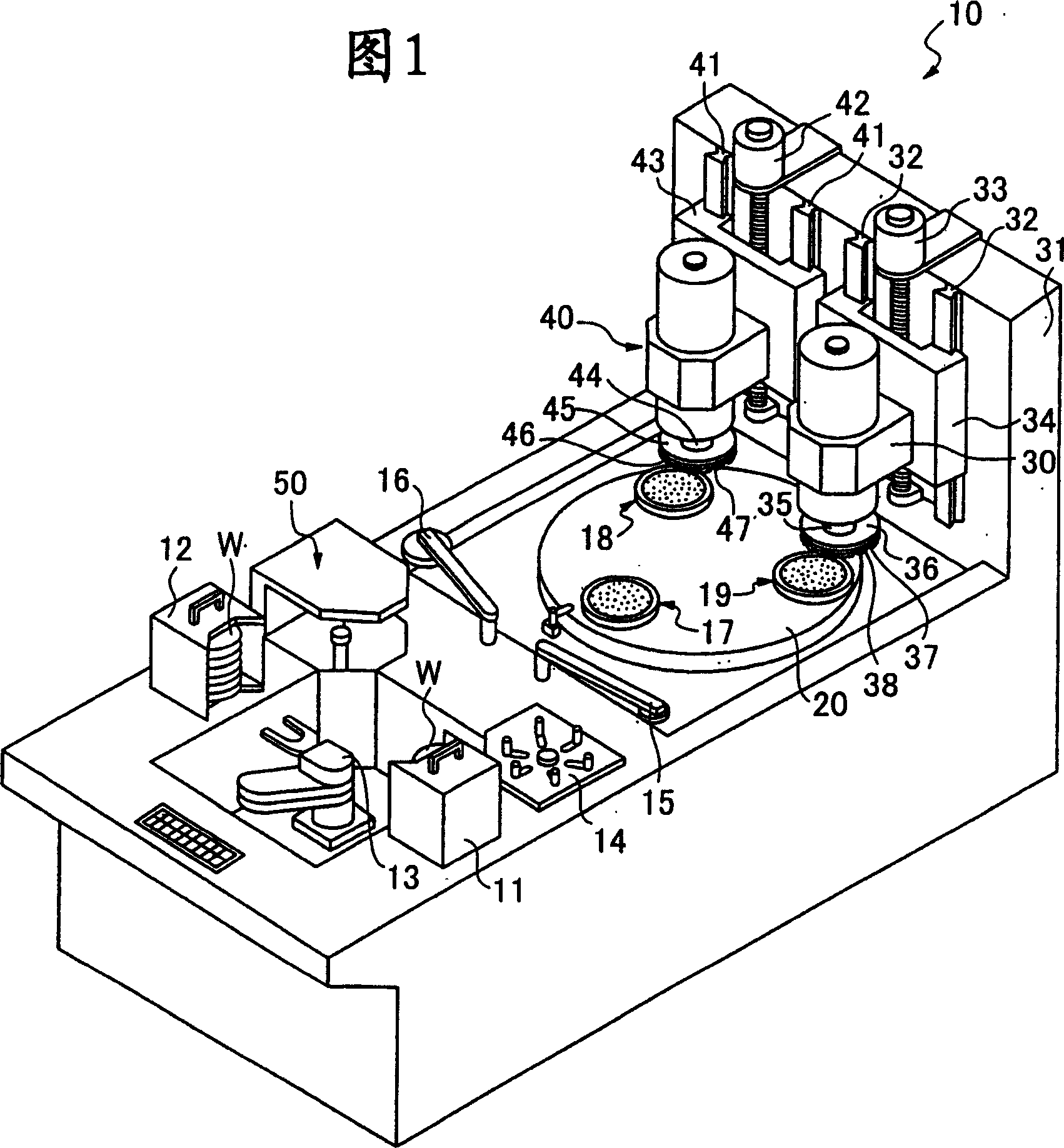

[0022] As an example of an embodiment of the present invention, a case where the back surface of a semiconductor single wafer is ground by the grinding apparatus 10 shown in FIG. 1 will be described.

[0023] The grinding apparatus 10 includes: cassettes 11 and 12 for accommodating semiconductor single wafers W, and a carrying-in / out device 13 for carrying out semiconductor single wafers W from the cassettes 11 or carrying semiconductor single wafers W into the cassette 12, and performing grinding on the semiconductor single wafers W. The aligning device 14 for alignment, the first conveying device 15 and the second conveying device 16 for conveying the semiconductor single wafer W, the three suction cups 17 to 19 for attracting and holding the semiconductor single wafer W, and supporting the suction cups in a rotatable manner The turntable 20 rotating ground, the grinding units 30, 40 for grinding the semiconductor single wafer W held on each chuck, and the cleaning device 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com