Mounting method using thermocompression head

A technology of hot-pressed joint and installation method, which is applied in the direction of assembling printed circuits, presses, and printed circuits with electrical components, can solve the problems of reduced connection reliability, insufficient heating, and installation takes a long time, and achieves high reliability. Sexual connection, the effect of preventing the generation of voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] [0013] Hereinafter, an embodiment of the installation method of the thermocompression joint according to the present invention will be described in detail with reference to the accompanying drawings.

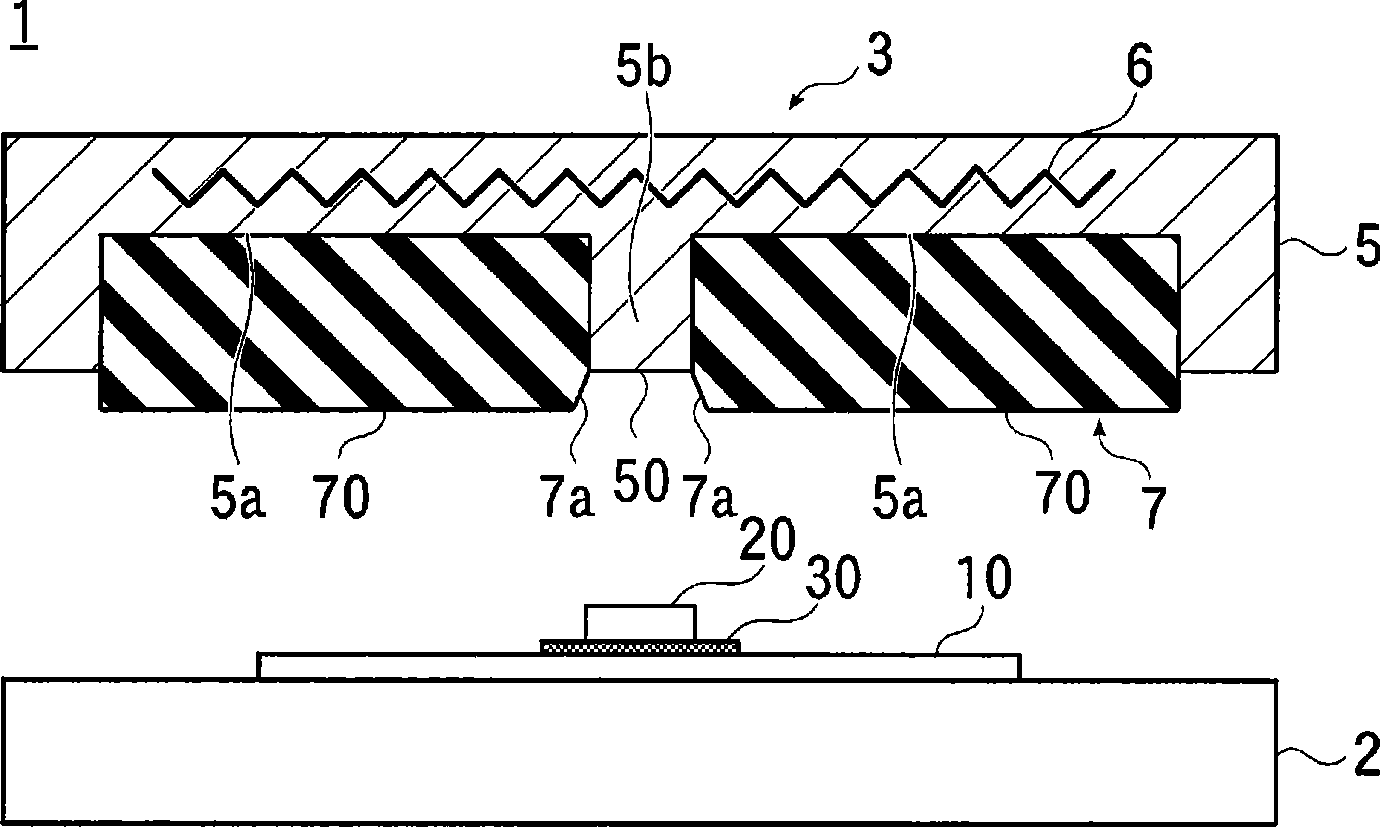

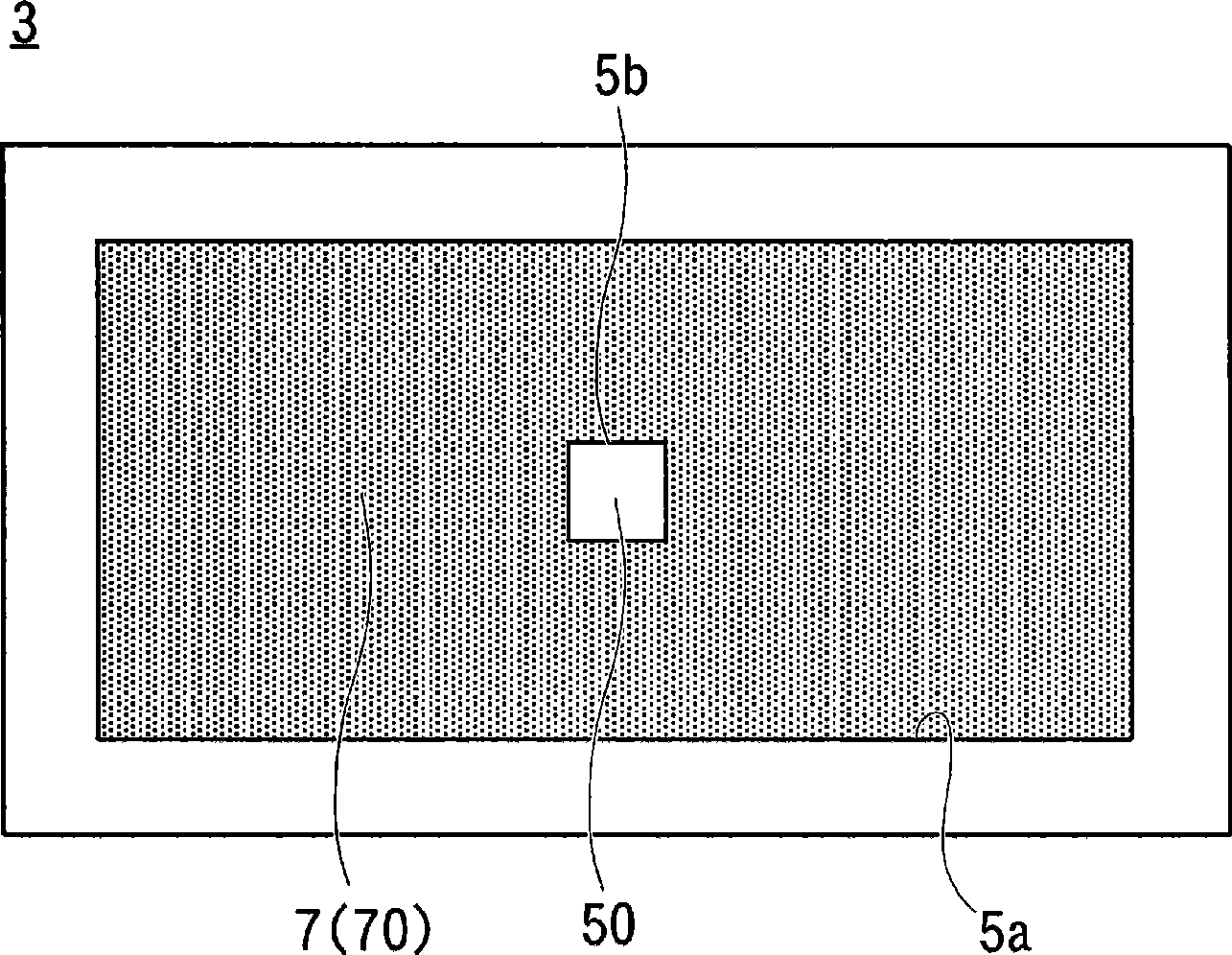

[0038] [0014] FIG. 1(a) is a schematic partial sectional view showing a mounting device according to the present invention, and FIG. 1(b) is a view showing a pressing side portion of a thermocompression joint in the mounting device.

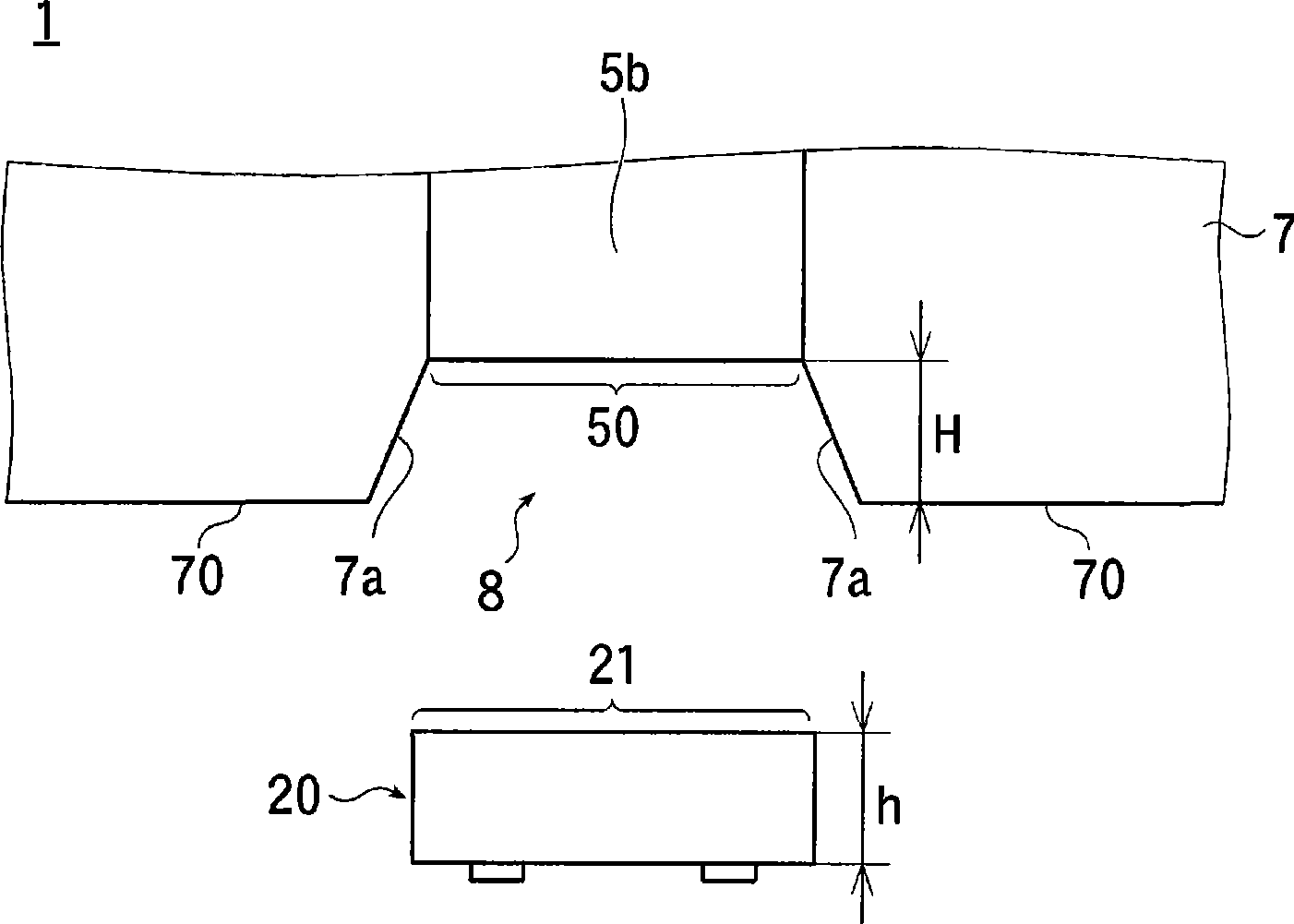

[0039] also, Figure 2(a) , 2(b) It is an explanatory diagram showing the dimensional relationship between the pressing surface of the thermocompression joint and the top area of the electrical component.

[0040] 【0015】if Figure 1(a) , 1(b) As shown, the mounting device 1 of the present embodiment has: a base 2 on which a wiring substrate 10 is mounted and a wiring pattern (not shown) is formed on the wiring substrate 10; Electric components 20 such as IC chips are pressurized and heated.

[0041] [0016] Here, the base 2 is formed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com