Wooden chair top end transverse plate scraping device

A technology of wooden chairs and horizontal boards, which is applied to wood processing equipment, processing machines for manufacturing flat surfaces, manufacturing tools, etc., can solve the problems of inability to plan and scrape horizontally, labor intensively, and low operating efficiency, and achieve Simplify the step-by-step operation process, reduce the operation intensity, and achieve high planing and scraping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

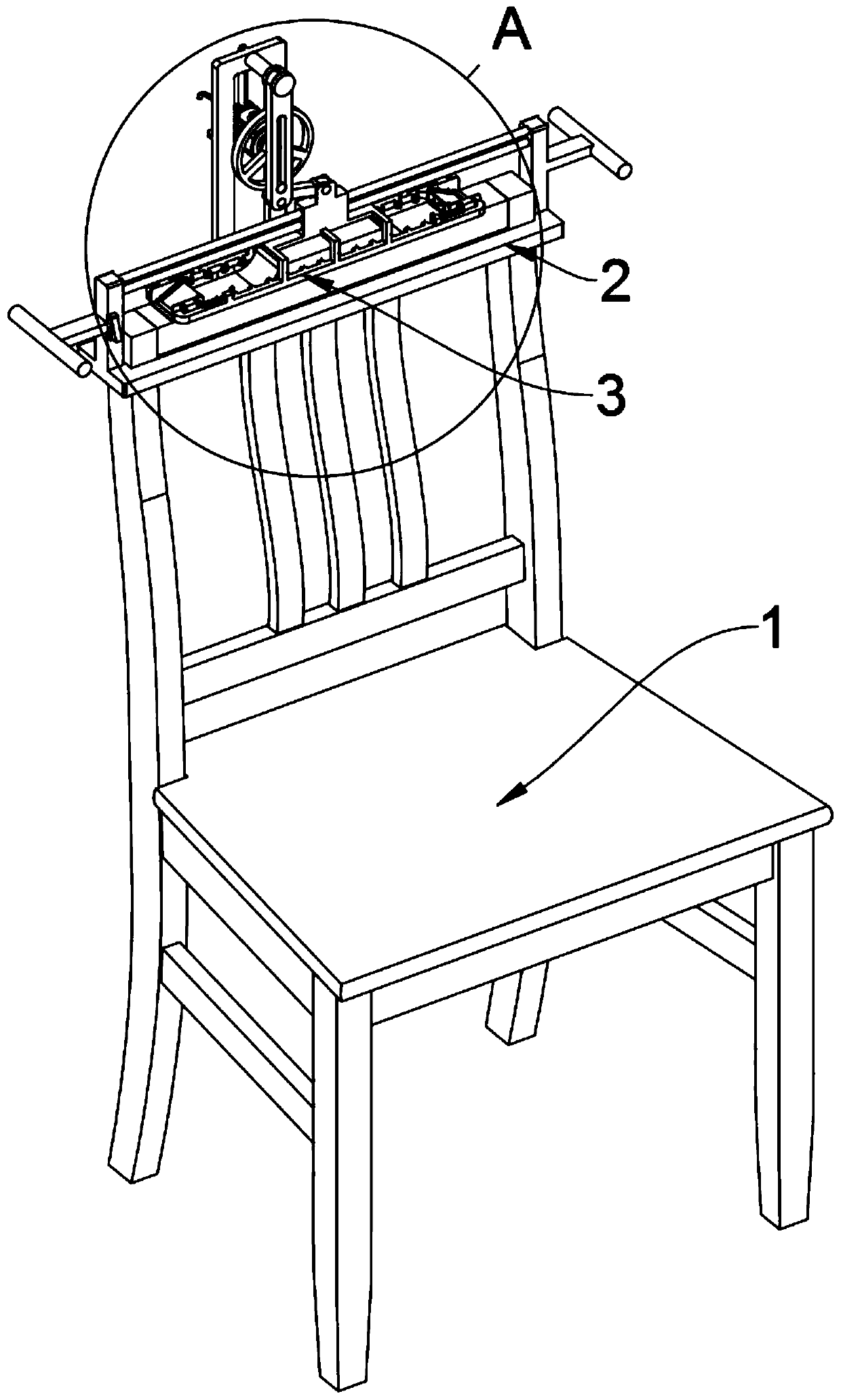

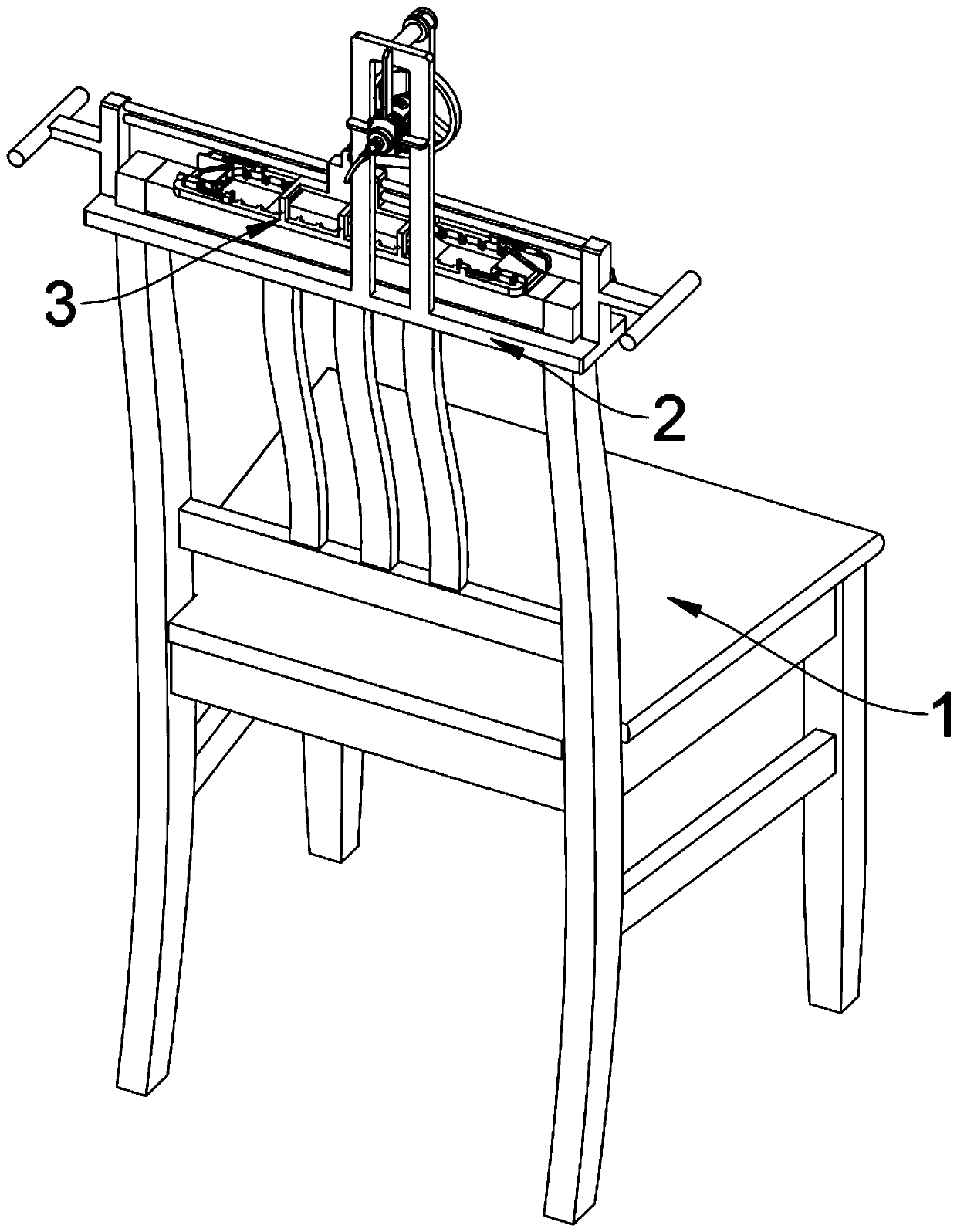

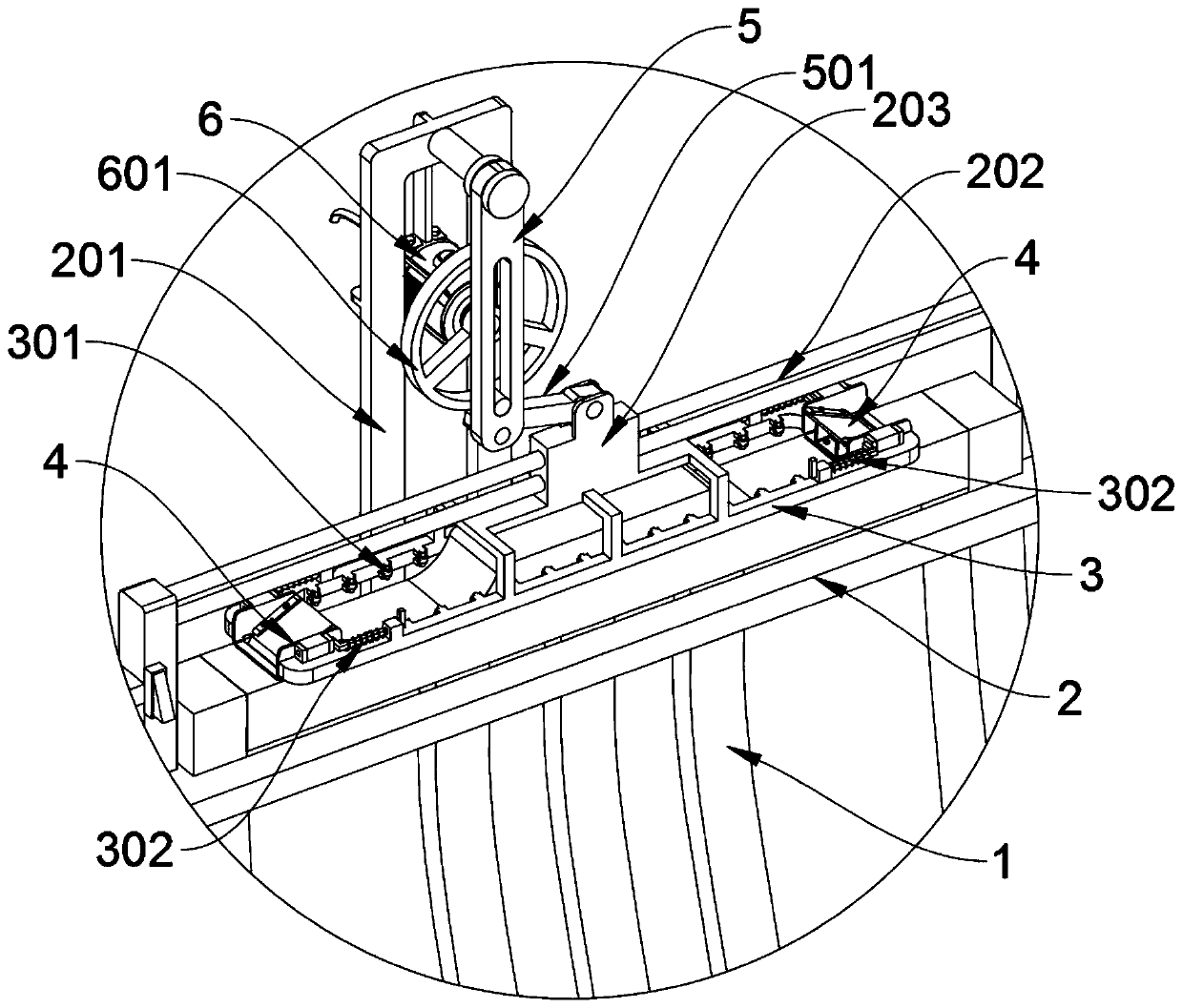

[0030] see Figure 1 to Figure 11 , an embodiment provided by the present invention: a wooden chair top horizontal board scraping device, including a sliding scraping frame 3, a swing rod 5, a motor 6 and a T-shaped handle 7, and the left and right ends of the sliding scraping frame 3 are welded Woodworking planer 4, two woodworking planers 4 are arranged symmetrically, a chute is provided on the swing rod 5, and the chute runs through the swing rod 5; the sliding scraping frame 3 includes a guide wheel 301, an insertion rod 302, a support frame 303 and a positioning plate 304, A sliding scraping frame 3 is connected to the cross brace push rod of the backrest of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com