Nail removing device

A technology of roller shaft and chassis, applied in the direction of nail pullers, manufacturing tools, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

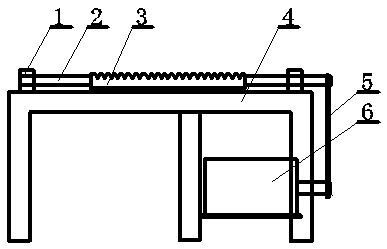

[0010] As shown in the figure, a horizontal roller shaft 2 is installed on a cuboid chassis 4, and an axial rack 3 is installed on the roller shaft 2. The two ends of the roller shaft 2 are connected with the chassis 4 by the shaft seat 1. The bottom of the gear box is equipped with a speed reducer 6, and a transmission belt 5 is housed between the speed reducer 6 and the roller shaft 2.

[0011] During work, first start the reducer 6 to drive the roller shaft 2 and the rack 3 to rotate, then insert the nails on the wooden parts into the tooth spaces of the rack 3 and hold the wooden parts, the nails will be pulled out by the rotating rack 3 out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com