Workbench lifting cushion block of three-dimensional (3D) laminating machine for carpenters

A technology of workbench and laminating machine, which is applied in the direction of layered products, laminating devices, lamination, etc., can solve the problems of low splicing efficiency, affecting work efficiency by splicing backing plates, restricting the development of 3D laminating machines, etc., and achieve structural Reasonable design, reduce labor intensity and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

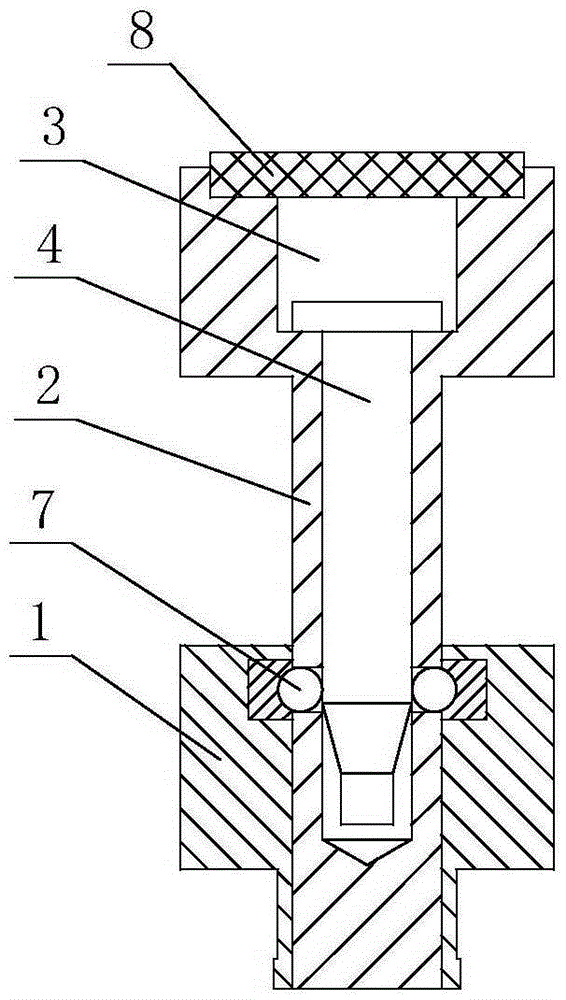

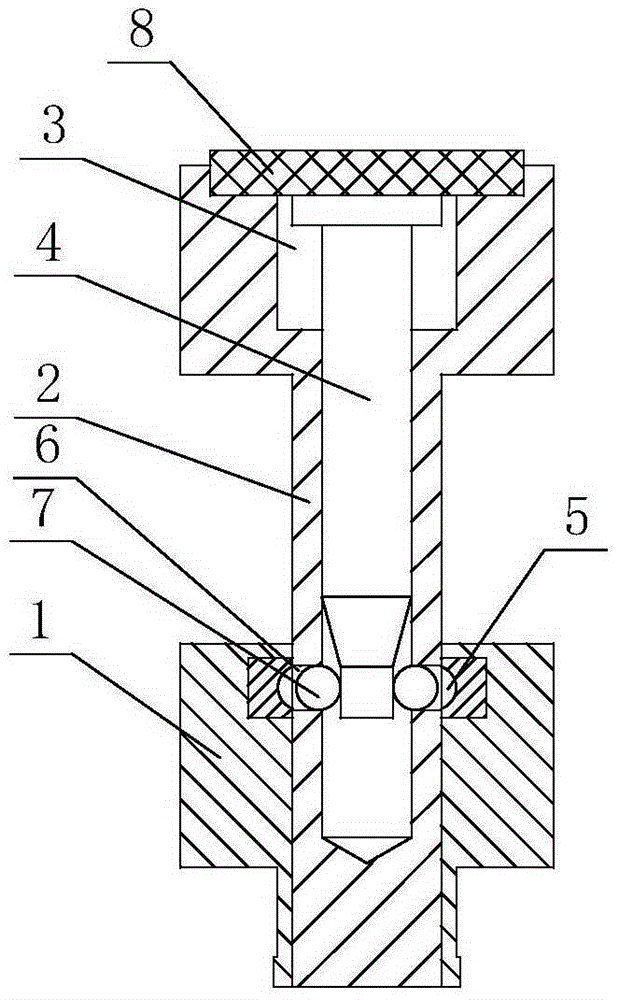

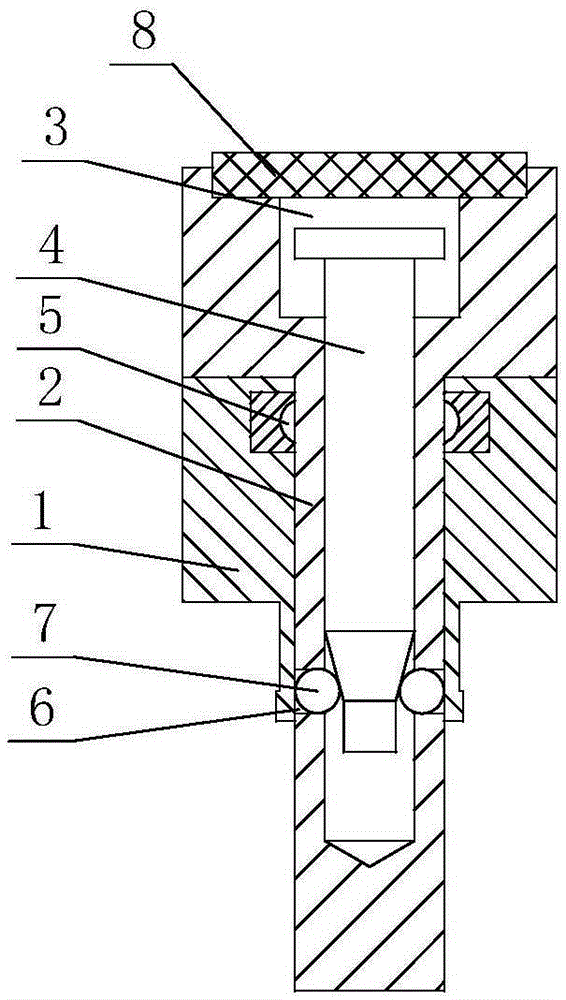

[0020] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0021] Such as Figure 1-4 As shown, a workbench lifting block for a woodworking 3D laminating machine includes a base 1, a vertical part of a T-shaped ejector rod 2 is movably inserted in the base 1, and inside the ejector rod 2 along the Its vertical portion length direction is provided with a cavity 3, is provided with a movable shaft 4 that can lift up and down along the inner wall of the cavity 3 under the action of magnetic force in the cavity 3, the bottom of the movable shaft 4 is funnel-shaped setting, on the base 1 The inner wall is provided with several arc-shaped grooves 5 along the circumference, and a steel ball installation hole 6 is respectively provided at the position corresponding to each arc-shaped groove 5 on the vertical part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com