Preparation method of graphene-titanium dioxide composite material

A composite material, titanium dioxide technology, applied in the directions of titanium dioxide, graphene, titanium oxide/hydroxide, etc., can solve the problems of difficult control of product size, uneven thickness of graphene film, and inability to meet industrial production, and achieve excellent electrical properties. Chemical properties, scale up preparation, and ensure the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific steps. Embodiment 1 mainly describes the reduction of pure graphene oxide film by hydrothermal vapor phase method.

[0026] Step 1, the preparation of graphene oxide

[0027] First prepare graphene oxide according to prior art, and its preparation method is as follows:

[0028] Get 0.5g graphite powder (Bay carbon, SP-1), 0.5g sodium nitrate (NaNO 3 ), 23ml sulfuric acid (H 2 SO 4 ) Stir in an ice bath; slowly add 3g of potassium permanganate (KMnO 4 ), and mix thoroughly for 1.5h in an ice bath environment. After mixing completely, transfer to a 35±5°C environment and stir for about 1 hour. Transfer the sample to an environment of 90±5°C, add 40ml of water, and stir for 30min. Maintain ambient temperature, add 100ml of water, then slowly add 3ml of 30% hydrogen peroxide (H 2 o 2 ), the color of the solution changed from dark brown to yello...

Embodiment 2

[0038]This embodiment mainly describes the hydrothermal vapor phase preparation method of graphene oxide / titanium oxide composite material, including the following steps:

[0039] Step 1 is the same as in Example 1.

[0040] Step 2. Hydrothermal Vapor Phase Reduction of Graphene and Titanium Oxide Composite Films

[0041] 1. Dissolve 0.74ml of tetraisopropyl titanate in 30ml of absolute ethanol and stir for 5 minutes to make solution A; add 357μL of deionized water and 14.1μL of concentrated nitric acid to 30ml of absolute ethanol to make solution B; Stir solution B, drop solution A into it, and stir to form a uniform solution C.

[0042] 2. Take 3ml of the graphene oxide solution prepared in step 1 and pour it into solution C, and stir thoroughly for 12 hours to obtain a uniform solution D.

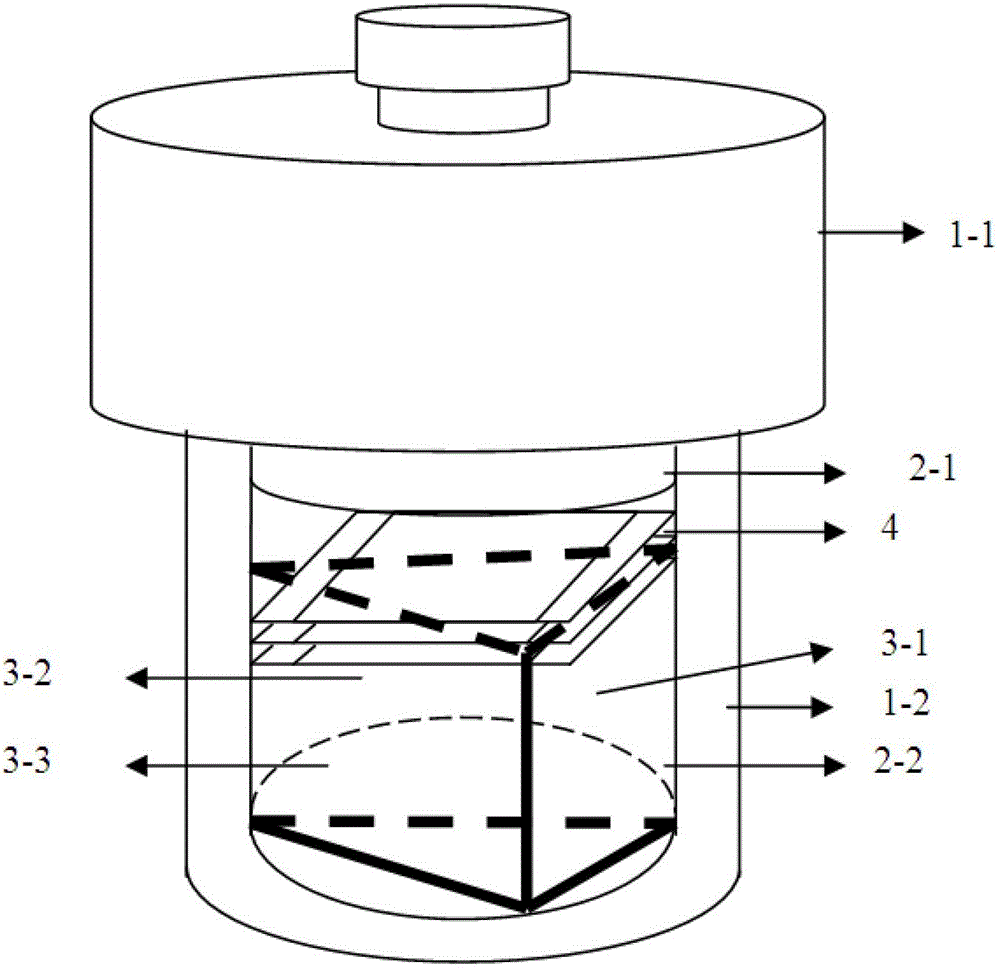

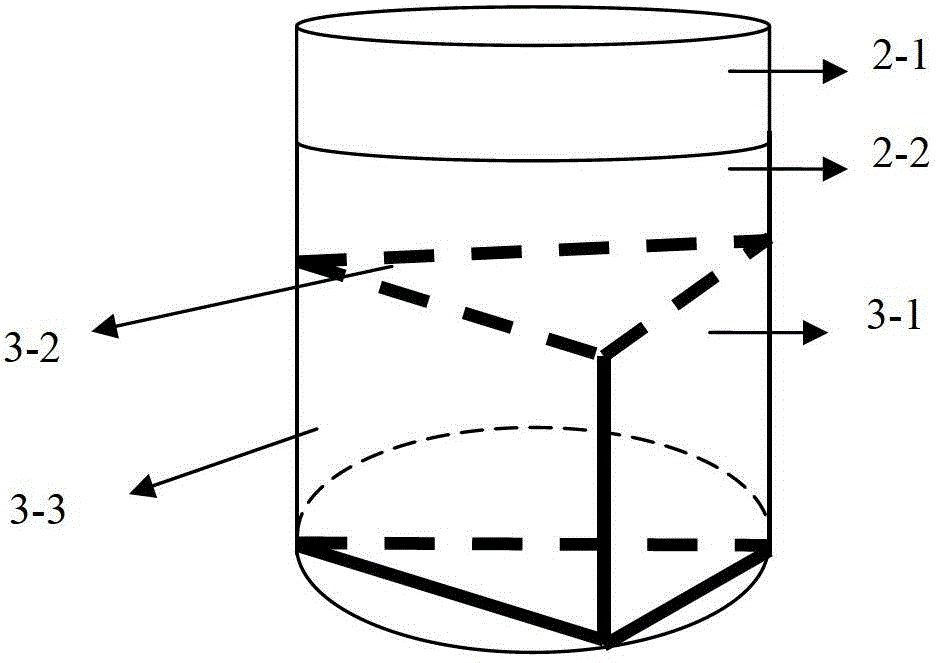

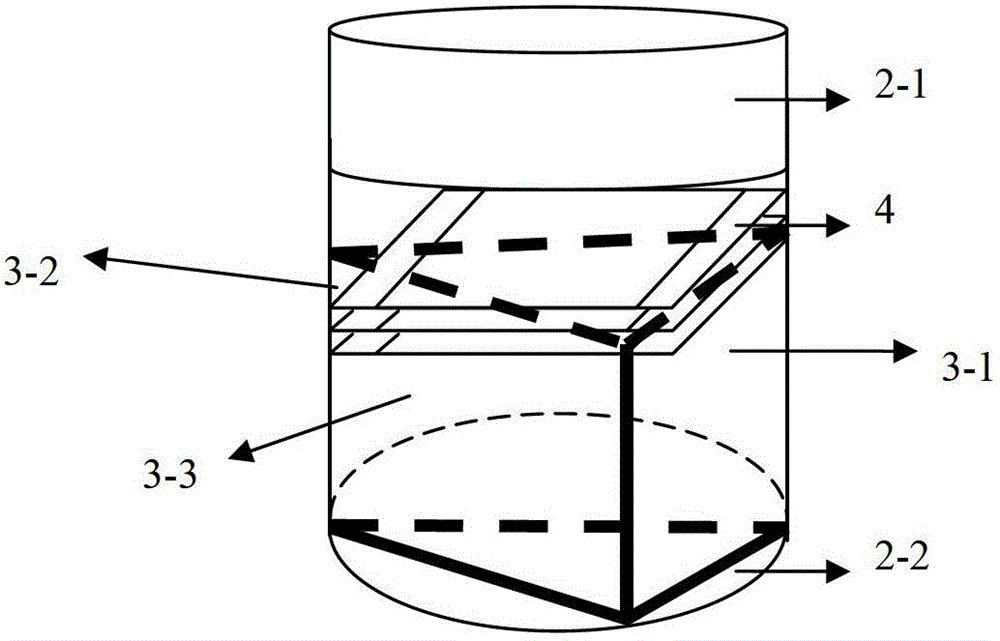

[0043] 3. Centrifuge solution D at 10,000 rpm for 15 minutes, scrape off the sediment and apply it on a glass slide ( figure 1 4) above.

[0044] 4. Put the glass sheet into a 40ml a...

Embodiment 3

[0046] The steps are the same as in Example 2, except that the volume of the graphene oxide solution added in the second small step in step two is changed to 12ml.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com