Preparation method of high-solid-content aqueous polyurethane for leather

A water-based, polyurethane technology, used in textiles and paper making, etc., can solve the problems of mechanical properties (tensile strength, elongation at break and modulus, poor oxidation resistance of toluene diisocyanate, poor coating performance, etc.) Excellent performance, increased solid content, good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

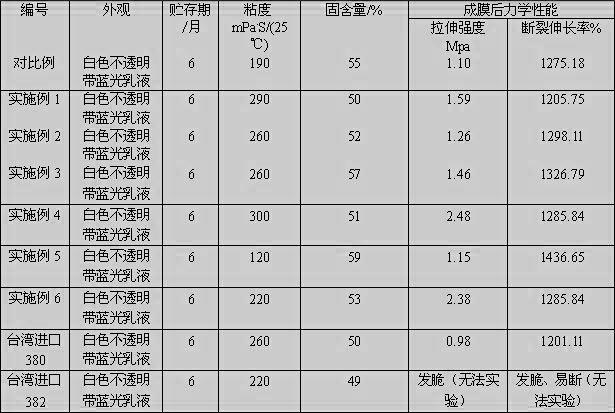

[0027] Example 1: Under the operating conditions of the comparative example, replace part of the polyethylene adipate (the sum of the OH moles of which is the same as that of the comparative example) with 0.4kg polyneopentyl glycol adipate, and replace half of the IPDI with HDI (NCO mol number), the prepolymerization reaction time is 3h, all the other conditions are the same as the comparative example, finally obtain a white translucent band bluish emulsion, the solid content is 50%.

Embodiment 2

[0028]Example 2: Under the operating conditions of the comparative example, polyethylene adipate was replaced with 1.0kg polytetrahydrofuran glycol and 0.255kg polyethylene glycol (M=1000), the prepolymerization reaction time was 2.5h, neutralization The concentration is 90%, and all the other conditions are the same as those of the comparative example, finally a white translucent band bluish emulsion is obtained, and the solid content is 52%.

Embodiment 3

[0029] Example 3: Under the operating conditions of the comparative example, replace part of polyethylene adipate with 0.5kg polytetrahydrofuran diol (the sum of its OH moles is the same as that of the comparative example), and add IPDI prepolymerization reaction time according to R=1.3 for 2.5 hours, and the rest of the conditions were the same as those of the comparative example, and finally a white translucent emulsion with bluish light was obtained, with a solid content of 57%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com