Stock solution for spinning phenolic fibers (PFs) and preparation method for stock solution

A technology of phenolic fiber and spinning dope, applied in the fields of fiber chemical characteristics, textiles and papermaking, single-component synthetic polymer rayon, etc., can solve the problems of phenolic fiber flame retardancy, thermal insulation performance and strength, and meet the synthesis conditions Mild and controllable, short synthesis cycle, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

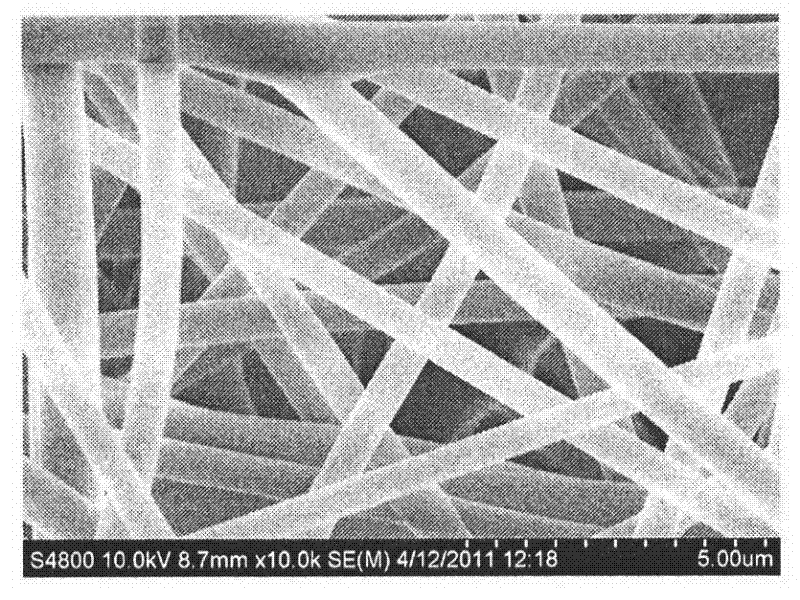

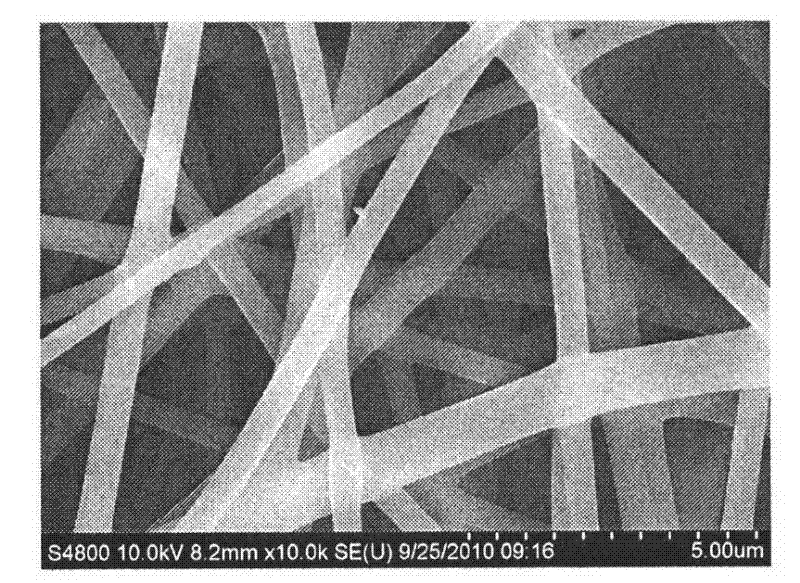

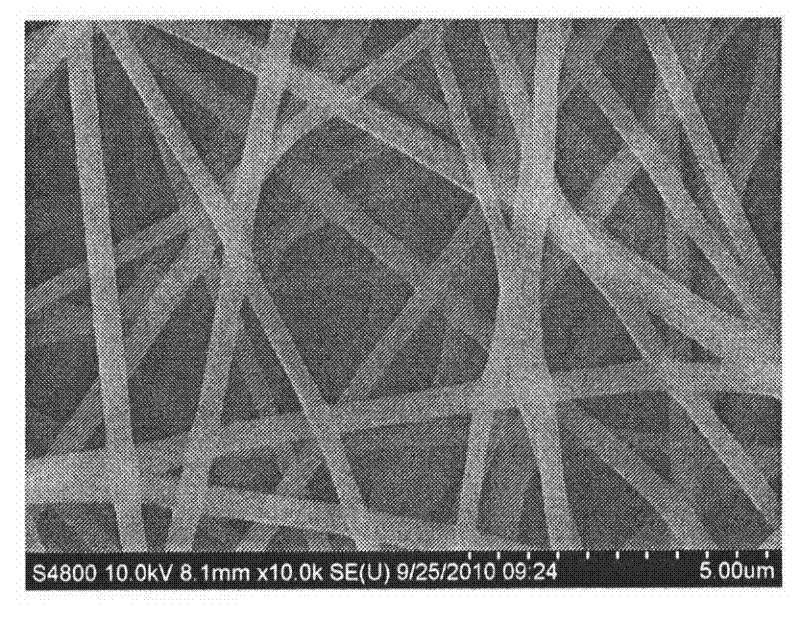

Image

Examples

Embodiment 1

[0021] Embodiment 1: 60g phenol, 210gPVA solution (12wt%) and 5gNaOH are put into reactor, under the stirring of 300r / min, temperature is raised to 90 ℃, then add 74g formaldehyde solution (30wt%), temperature is raised to 95 ℃, add 18.5g formaldehyde solution (30wt%) after reacting for 60min, adjust the temperature to 95℃, react for 100min and cool to room temperature within 1min to obtain a stock solution with a viscosity of 12000mPa.s.

Embodiment 2

[0022] Embodiment 2: 60g phenol, 835gPVA solution (18wt%) and 4.8g KOH are put into reactor, under the agitation of 800r / min, temperature is raised to 80 ℃, then add 44.5g formaldehyde solution (40wt%), lower temperature Raise to 90°C, add 11g of formaldehyde solution (40wt%) after reacting for 100min, adjust the temperature to 92°C, react for 40min and then cool to room temperature within 5min to obtain a stock solution with a viscosity of 25000mPa.s.

Embodiment 3

[0023] Embodiment 3: with 60g phenol, 640gPVA solution (6wt%) and 20g NH 3 ·H 2 O is put into reactor, under the stirring of 500r / min, temperature is raised to 85 ℃, then add 84g formaldehyde solution (37wt%), temperature is raised to 96 ℃, add 36g formaldehyde solution (37wt%) after reaction 40min, will Adjust the temperature to 100°C, react for another 120 minutes, and then cool to room temperature within 3 minutes to obtain a stock solution with a viscosity of 10,000 mPa.s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com