Patents

Literature

46results about How to "Does not affect spinnability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acidic dyeable polyester and method for preparing acidic dyeable polyester and fiber thereof

ActiveCN101450990AUniform dyeingAffinityMonocomponent copolyesters artificial filamentDyeing processFiberFormate

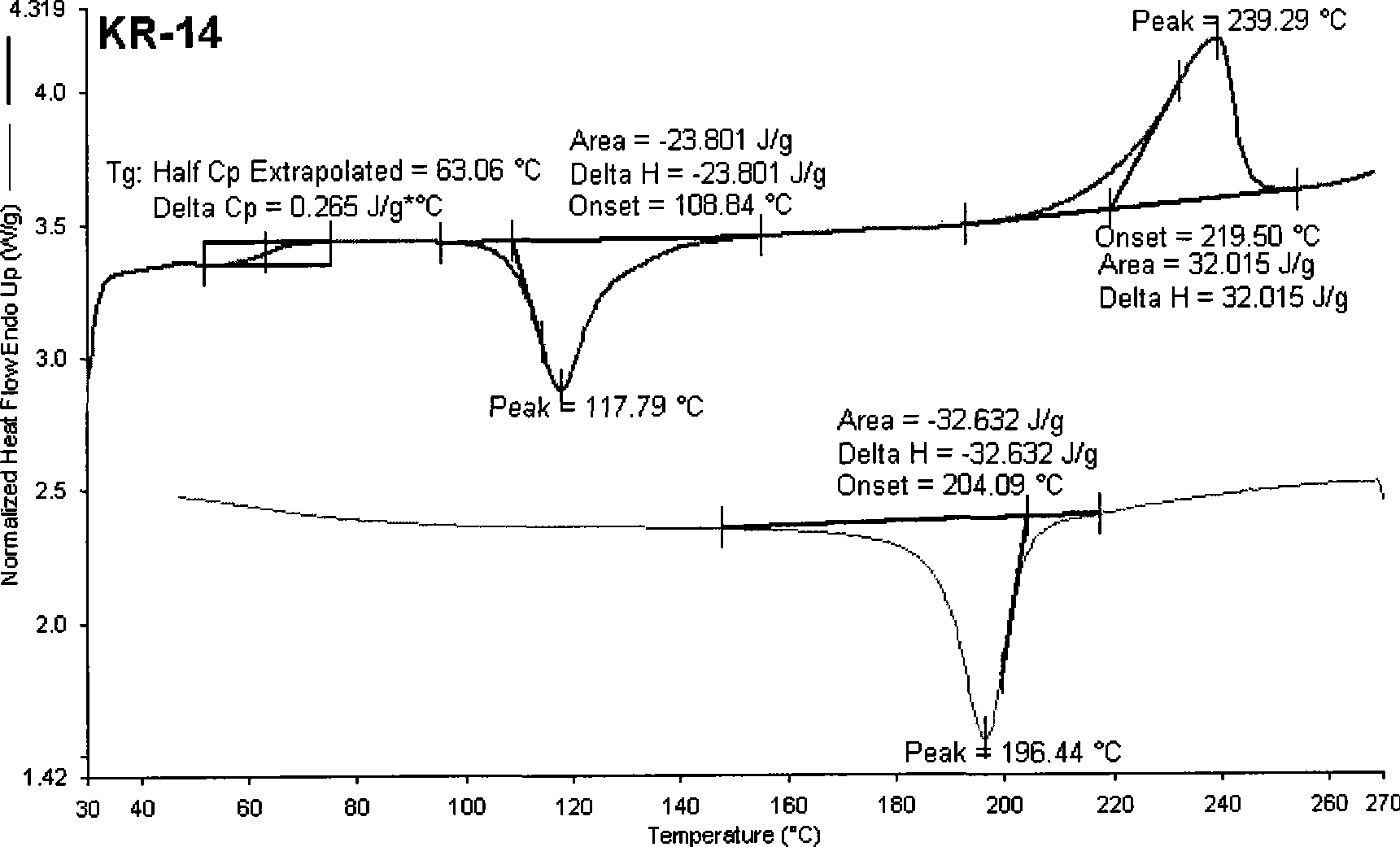

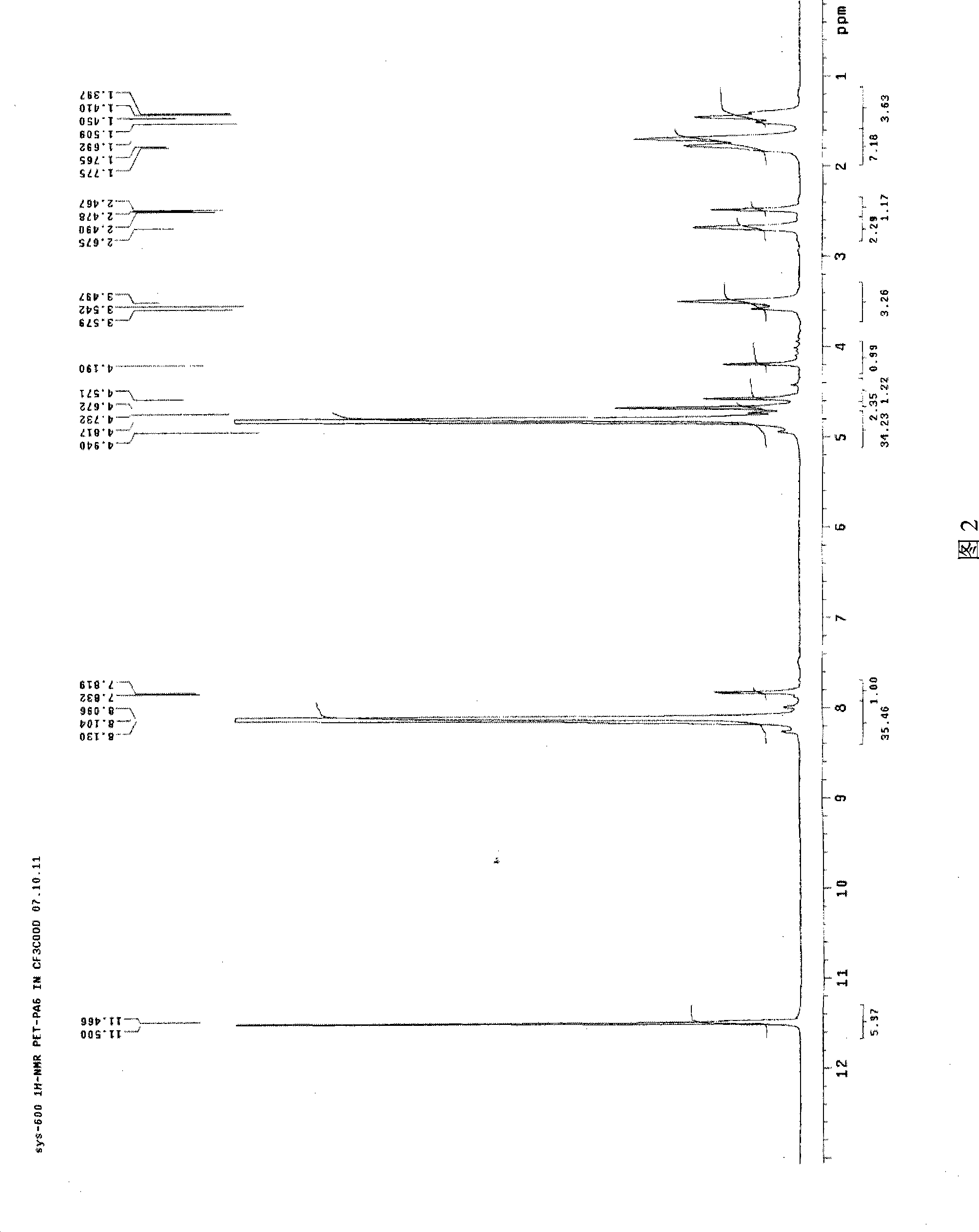

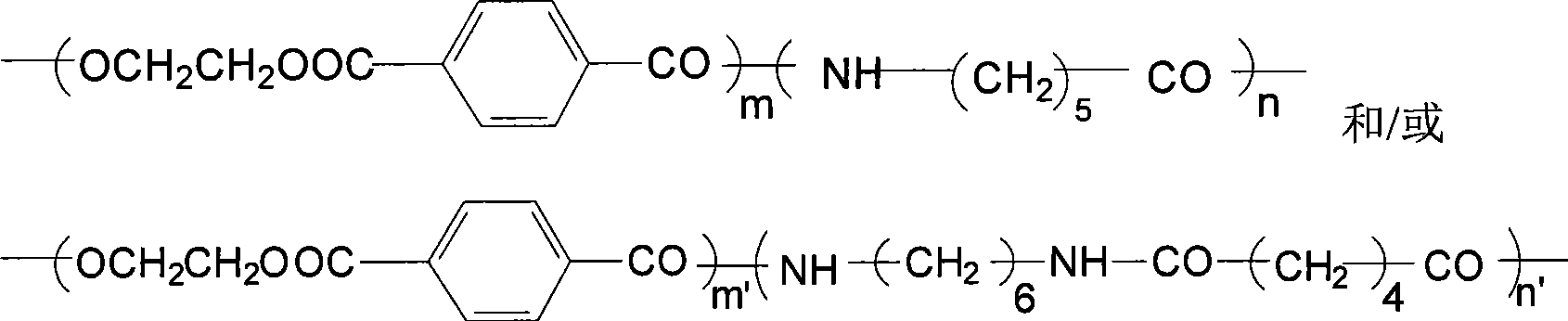

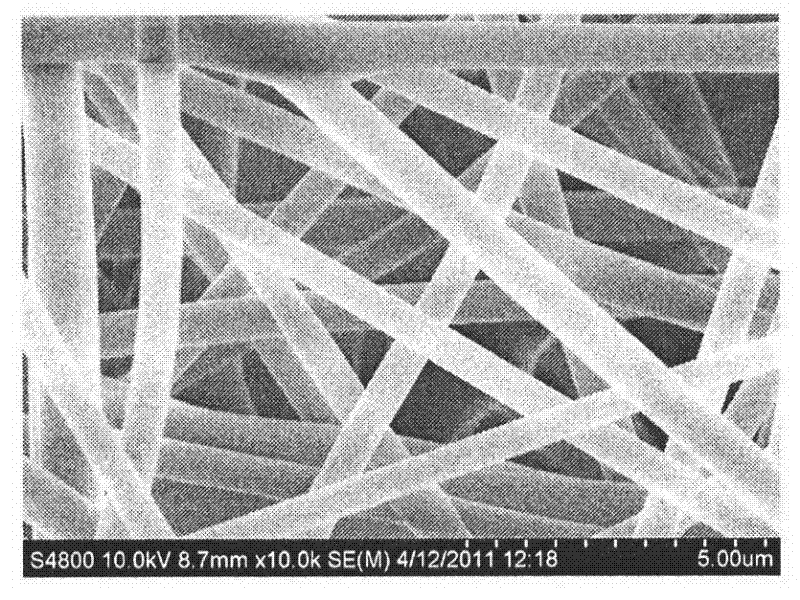

The invention relates to acidic dyeable polyester and a method for preparing acidic dyeable polyester chip and fiber. The method comprises the steps of performing transesterification or esterification to p-phenyl dimethyl formate or p-phenyl dicarboxylic acid and glycol, adding polyamide such as nylon 6 and / or nylon 66 during polyester polymerization so as to prepare polyester chip, drying the polyester chip and using a conventional spinning machine to spin so as to prepare the polyester fiber used for the dyeing of acid dye. The polyester fiber thoroughly solves the problem that polyester and polyamide are not compatible, ensures uniform dyeing of acid dye, and enables spinning workstage to proceed smoothly. In addition, as the preparation of the polymer adopts a process similar to polyester polymerization for polymerization on a common polyester polymerization device, the method is simple to operate, easy to perform industrial production and low in cost.

Owner:CHINESE TEXTILE ACAD

Stock solution for spinning phenolic fibers (PFs) and preparation method for stock solution

ActiveCN102532444AGood dispersionSynthetic conditions are mild and controllableMonocomponent synthetic polymer artificial filamentFiberTO-18

The invention relates to a stock solution for spinning phenolic fibers (PFs). The stock solution comprises the following raw materials: phenol, a 30 to 40 weight percent formaldehyde solution, a 6 to 18 weight percent polyvinyl alcohol (PVA) solution and a catalyst in a mass ratio of 100:(90-200):(40-250):(8-40). The stock solution has the advantages that: spinnability is high, the spinnable viscosity interval is wide, and the intrinsic properties of the PFs are not influenced by an additive.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

UV-resistant polyester fiber of nano titanium nitride

InactiveCN100503910CIncrease reflectionImprove the scattering effectMelt spinning methodsMonocomponent polyesters artificial filamentMasterbatchPolyester

The invention discloses a nano-titanium nitride anti-ultraviolet polyester fiber. The fiber contains nano-titanium nitride with a concentration of 0.5%-2% by weight and has an anti-ultraviolet function. The fiber is made of nano-titanium nitride, other additives and carriers to make a masterbatch, and the masterbatch is added to polyester chips and melt-spun. The addition of nano-titanium nitride makes the polyester fiber have good anti-ultraviolet function; and does not affect its spinnability; the average ultraviolet shielding rate of the spun anti-ultraviolet functional polyester fiber is above 85%; at the same time, it does not affect people's health. Nano-titanium nitride anti-ultraviolet polyester fiber can be widely used in outerwear, sportswear, trousers and other fields.

Owner:DONGHUA UNIV

Far infrared bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556275AImprove antibacterial propertiesSignificant far infrared health functionArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceFar infrared

The invention discloses provides a far infrared bamboo charcoal viscose fiber and a preparation method thereof, in order to make up for the blank of the conventional far infrared bamboo charcoal viscose fiber and solve the problem of poor spinnability of the bamboo charcoal viscose fiber. The far infrared bamboo charcoal viscose fiber is characterized in that the fiber comprises 1-10 percent by weight of far infrared ceramic powder and 0.1-10 percent by weight of bamboo charcoal, wherein the far infrared emissivity is greater than 80 percent, the ammonia absorption rate is greater than or equal to 50 percent, the permeability is greater than or equal to 500 mm / s, and the color fastness to washing is class 4-5. The far infrared bamboo charcoal viscose fiber has a heat insulation effect; the radiated far infrared also has the health-care functions of activating cell tissues and promoting the blood circulation.

Owner:YIBIN HIEST FIBER +1

Extinction bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556261ASignificant shielding rateGood deodorizing functionArtificial filaments from viscoseWet spinning methodsChemistryComposite material

The invention provides an extinction bamboo charcoal viscose fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The extinction bamboo charcoal viscose fiber is characterized by comprising the components by weight percent: 0.01-10 percent of titanium dioxide and 0.1-10 percent of bamboo charcoal, wherein the ammonia absorption rate is more than or equal to 50 percent, the air permeability is more than or equal to 500mm / s, and the color fastness to washing is of 4-5 level. The extinction bamboo charcoal viscose fiber disclosed by the invention is a novel product, has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and moisture absorption, has soft handfeel and has an extinction function.

Owner:YIBIN HIEST FIBER +1

Bamboo charcoal viscose fiber rich in nano-copper and preparation method of bamboo charcoal viscose fiber

ActiveCN103556272AImprove breathabilityHigh strengthArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceSpinning

The invention provides a bamboo charcoal viscose fiber rich in nano-copper and a preparation method of the bamboo charcoal viscose fiber in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The bamboo charcoal viscose fiber rich in nano-copper is characterized by being prepared by mixing a nano-copper bamboo charcoal solution with viscose throug injection before spinning, and carrying out wet spinning and post-treatment; the nano-copper bamboo charcoal solution is formed by mixing masterbatches containing the nano-copper and a bamboo charcoal solution. The fiber comprises the components by weight percent: 0.01-5 percent of nano-copper and 0.1-10 percent of bamboo charcoal; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The bamboo charcoal viscose fiber rich in the nano-copper has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the antibacterial effect of the bamboo charcoal viscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

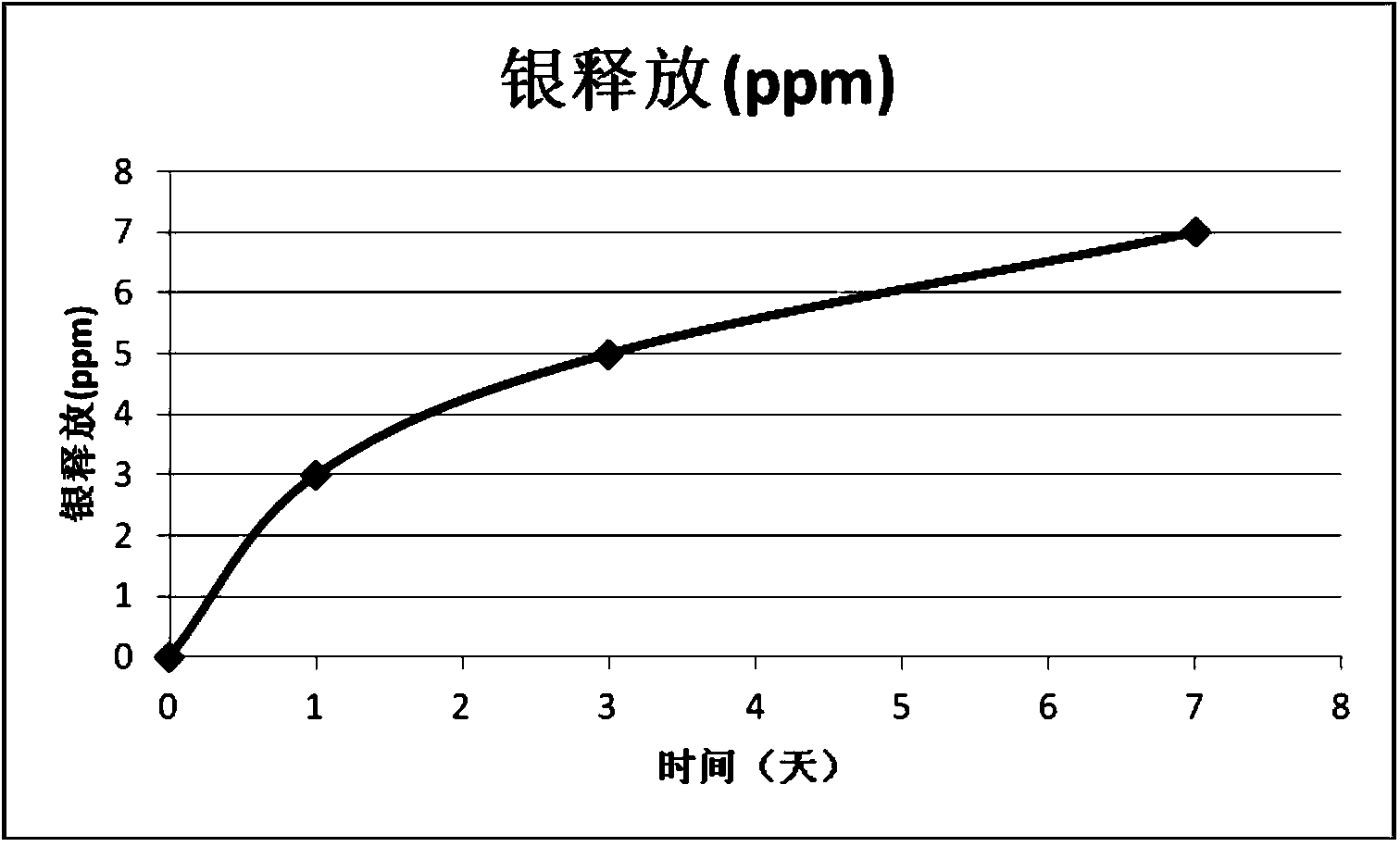

Preparation method of silver-bearing antibacterial polypropylene fiber

InactiveCN104372432ANo biological toxicityEvenly dispersedMonocomponent polyolefin artificial filamentArtifical filament manufactureEscherichia coliPolymer science

The invention discloses a preparation method of a silver-bearing antibacterial polypropylene fiber. The preparation method is characterized by comprising the following steps: mixing 80-90 parts by weight of polypropylene slices and 10-20 parts by weight of silver-bearing antibacterial agent in a twin-screw extruder for extruding and granulating, thereby obtaining silver-bearing antibacterial master batch; evenly mixing 2-20 parts by weight of the obtained antibacterial master batch and 80-98 parts by weight of polypropylene slices and preparing the silver-bearing antibacterial polypropylene fiber by use of a common melt spinning method, wherein the linear density of the obtained fiber is controlled within the range of 2.0-10.0dtex, the strength of the fiber is 5.0-7.5cN / dtex, the breaking elongation of the protofilament is 10%-25%, the mass fraction of the silver-bearing antibacterial agent is 0.2%-4%, and the silver content is 100-3000ppm; the obtained silver-bearing antibacterial polypropylene fiber has the sterilizing rate of more than 98% to escherichia coli and staphylococcus aureus and is an ideal material for wound dressing bases.

Owner:SICHUAN UNIV

Anti-ultraviolet bamboo charcoalviscose fiber and preparation method thereof

ActiveCN103556252AGood antibacterial effectGood deodorizing functionArtificial thread manufacturing machinesArtificial filaments from viscoseBamboo charcoalViscose fiber

The invention provides an anti-ultraviolet bamboo charcoalviscose fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoalviscose fiber is poor in spinning property. The anti-ultraviolet bamboo charcoalviscose fiber is characterized by being obtained by mixing an anti-ultraviolet bamboo charcoal solution with mucilage glue through spinning before injection, and carrying out wet spinning and post-treatment, wherein the anti-ultraviolet bamboo charcoal solution is formed by mixing an anti-ultraviolet masterbatches and a bamboo charcoal solution; the anti-ultraviolet masterbatches contain an anti-ultraviolet agent. The fiber comprises the components by weight percent: 0.01-10 percent of the anti-ultraviolet agents and 0.1-10 percent of bamboo charcoal; the ultraviolet shielding rate is more than or equal to 95 percent, the ammonia absorption rate is more than or equal to 50 percent, and the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The anti-ultraviolet bamboo charcoalviscose fiber has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the anti-ultraviolet effect of the anti-ultraviolet bamboo charcoalviscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

High-conductivity wool top fiber and preparation method thereof

InactiveCN110318119ALow volume specific resistanceImprove conductivityElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsElastomerFiber

The invention discloses a high-conductivity wool top fiber. The high-conductivity wool top fiber comprises an inner layer and an outer layer, wherein the cross section of the inner layer is triangular, the outer layer wraps the outer circumference of the inner layer, and the cross section of the outer layer is circular; the inner layer is prepared from, by weight, 65-75 parts of polyamide-6, 15-22parts of poly-p-benzoyl hexamethylenediamine, 10-14 parts of an elastomer, 4.5-6.5 parts of graphene, 6-10 part of carbon black and 6.5-10.5 parts of a nanofiller; the outer layer is prepared from 6-100 parts of polyamide by weight. The high-conductivity wool top fiber is formed by finely selecting raw materials, and the contents of various raw materials are optimized, so that the prepared high-conductivity wool top fiber has low volume resistivity, good electrical conductivity, long-lasting electrical conductivity and good antistatic performance, the high-conductivity wool top fiber also hasthe advantages of soft hand feeling, elasticity, higher strength, good wear resistance and weather resistance and the like, and therefore, the high-conductivity wool top fiber is suitable for being prepared into various conductive fabrics, is comfortable to wear, and is especially suitable for places sensitive to static electricity.

Owner:海宁泰尔欣新材料有限公司

Aromatic bamboo charcoal fiber and production process thereof

ActiveCN103541035AGood deodorizing functionGood air permeabilityArtificial filaments from viscoseWet spinning methodsAnti bacterialBamboo charcoal

The invention aims at meeting market customer demands of a product, solving the problem of poor spinnability of bamboo charcoal viscose fiber and providing aromatic bamboo charcoal fiber and a production process thereof. The aromatic bamboo charcoal fiber is characterized in that the fiber contains 0.01-10% by weight of aromatic fragrance and 0.1-10% of bamboo charcoal, the ammonia absorption rate is not less than 50%, the air permeability is not less than 500mm / s, and the color fastness to washing is level 4-5. The aromatic bamboo charcoal fiber provided by the invention has not only anti-bacterial, anti-ultraviolet and deodorizing functions, but also good air permeability and absorption, and can effectively and continuously emit aroma and realize the effects of relieving stress and refreshing people.

Owner:YIBIN HIEST FIBER +1

Antibacterial bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556278AImprove breathabilityImprove antibacterial propertiesArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceAnti bacterial

The invention provides an antibacterial bamboo charcoal viscose fiber and a preparation method thereof, which meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The antibacterial bamboo charcoal viscose fiber is characterized by being obtained by mixing an antibacterial bamboo charcoal solution with viscose through injection before spinning, and carrying out wet spinning and post-treatment, wherein the antibacterial bamboo charcoal solution is formed by mixing an antibacterial solution and a bamboo charcoal solution. The fiber comprises the components by weight percent: 0.01-10 percent of an antibacterial agent and 0.1-10 percent of bamboo charcoal; the bacteriostasis rate is more than or equal to 90 percent; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The antibacterial bamboo charcoal viscose fiber has functions of ultraviolet prevention and deodorization and is high in air permeability and absorptivity; furthermore, the antibacterial effect of the antibacterial bamboo charcoal viscose fiber is better than that of the common bamboo charcoal fiber; the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

Mosquito-dispelling polyamide 6 fiber and preparation method thereof

InactiveCN102618959ASmall particle sizeLarge specific surface areaMelt spinning methodsArtifical filament manufactureFiberPolyamide

The invention provides a mosquito-dispelling polyamide 6 fiber and a preparation method thereof. The preparation method comprises the following steps of: after adsorbing mosquito-dispelling ester to attapulgite, adding an additive and polyamide 6 resin; extruding in a double-screw extruder and granulating to prepare mosquito-dispelling polyamide 6 master batch, wherein the mosquito-dispelling polyamide master batch comprises the following materials in percentage by weight: 60-70 percent of fiber-scale polyamide 6 resin, 15-30 percent of attapulgite, 0.1-1 percent of antioxidant, 0.1-1 percent of light stabilizer 78300 and 5-15 percent of mosquito-dispelling ester, wherein the antioxidant is a composition of MD 697 and one of a hindered phenolic antioxidant, a phosphite ester antioxidant and thiodipropionate antioxidant; and performing blended spinning on polyamide 6 slices and the mosquito-dispelling polyamide 6 master batch according to the weight ratio of80-90:10-20 to prepare the mosquito-dispelling polyamide 6 fiber. The mosquito-dispelling polyamide 6 fiber has the advantages of lasting mosquito-dispelling effect, simple process, low cost, wide application and the like.

Owner:HANGZHOU XINFU TEXTILE

Aromaticity bamboo charcoal fiber and preparation method thereof

ActiveCN103556264AImprove breathabilitySignificant shielding rateArtificial filaments from viscoseWet spinning methodsSpinningPulp and paper industry

The invention provides an aromaticity bamboo charcoal fiber and a preparation method thereof in order to meet demands of clients in a product market and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The aromaticity bamboo charcoal fiber is characterized in that a finished product is obtained by taking cellulose fiber pulp as a raw material, mixing an aromaticity bamboo charcoal solution and viscose through injection before spinning and performing wet spinning and post-treatment, wherein the aromaticity bamboo charcoal solution is prepared by mixing fragrant masterbatches and a bamboo charcoal solution; the fragrant masterbatches contain perfumes; the fragrant perfume content of the fiber is 0.01-10 percent; the bamboo charcoal content is 0.1-10 percent; the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s; the color fastness to washing is of 4-5 level. The aromaticity bamboo charcoal fiber disclosed by the invention has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and hygroscopicity, can effectively and continuously scatter fragrance and has the effects of relieving pressure and enabling people to be invigorating.

Owner:YIBIN HIEST FIBER +1

Antistatic bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556280ASignificant far infrared health functionSignificant UV shielding rateArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceMoisture absorption

The invention provides an antistatic bamboo charcoal viscose fiber and a preparation method thereof, which fill up the blank of the conventional antistatic bamboo charcoal viscose fiber and solve the problem that the conventional bamboo charcoal viscose fiber is poor in spinning property. The antistatic bamboo charcoal viscose fiber is characterized by comprising 1-10 percent of graphite and 0.1-10 percent of bamboo charcoal, wherein the volume resistivity is lower than 1,010 ohm.cm, the ammonia absorption rate is more than or equal to 50 percent; the air permeability is more than or equal to 500mm / s, and the color fastness to washing is of 4-5 level. The antistatic bamboo charcoal viscose fiber disclosed by the invention has the functions of bacterium and ultraviolet prevention and deodorization, is high in air permeability and moisture absorption and has soft handfeel; the antistatic effect is obvious and lasting.

Owner:YIBIN HIEST FIBER +1

Bamboo charcoal pulp suitable for bamboo charcoal fiber production

ActiveCN103556265AHigh viscosityIncrease alkalinityArtificial filaments from viscoseMaterials scienceBamboo charcoal

The invention provides bamboo charcoal pulp suitable for bamboo charcoal fiber production in order to solve the problem that the conventional bamboo charcoal fibers are poor in spinning property. The bamboo charcoal pulp is characterized by comprising the following raw materials by weight percent: 10-50 percent of bamboo charcoal powder, 1-2 percent of a bubble-free dispersing agent, 1-5 percent of a thickening agent, 4-6 percent of alkaline and the balance being deionized water. Bamboo charcoal fibers prepared from the bamboo charcoal pulp for the bamboo charcoal fiber production is high in spinning property, and bamboo charcoal is high in dispersibility in the fibers.

Owner:YIBIN HIEST FIBER +1

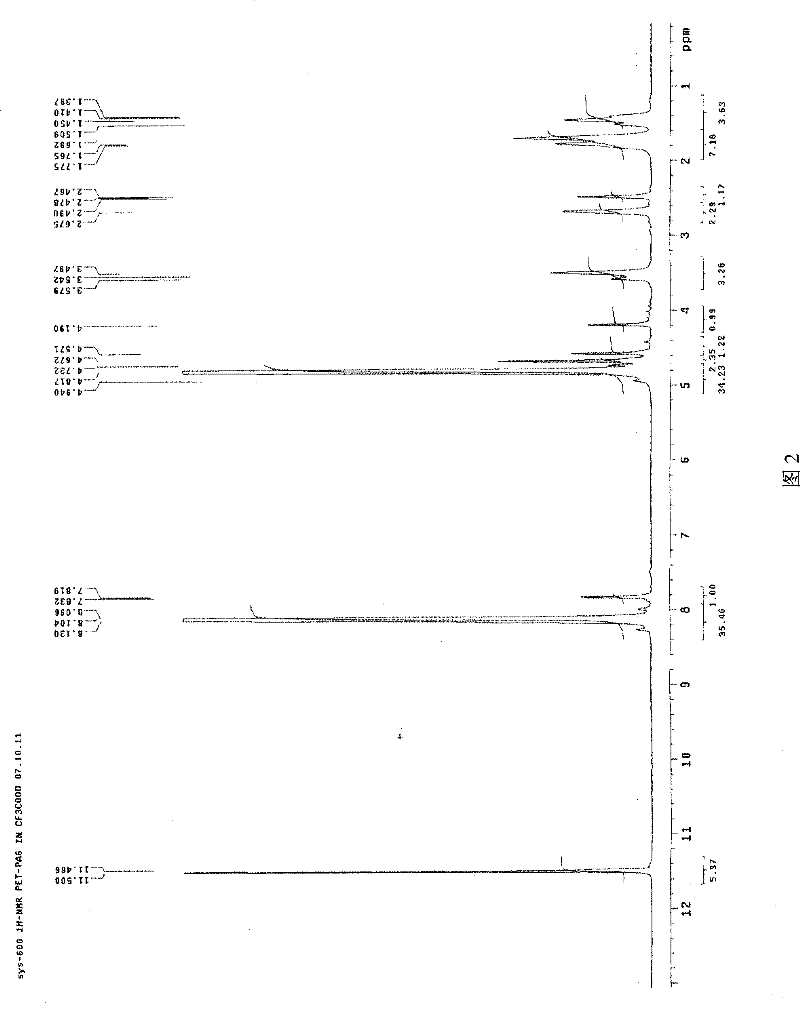

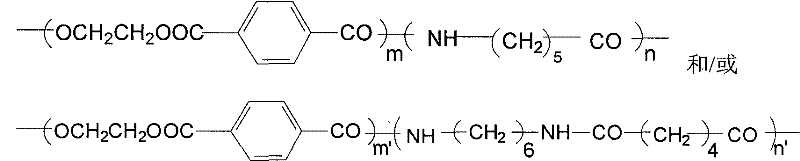

Acidic dyeable polyester and method for preparing acidic dyeable polyester and fiber thereof

ActiveCN101450990BDoes not affect spinnabilityUniform dyeingMonocomponent copolyesters artificial filamentDyeing processFiberFormate

The invention relates to acidic dyeable polyester and a method for preparing acidic dyeable polyester chip and fiber. The method comprises the steps of performing transesterification or esterification to p-phenyl dimethyl formate or p-phenyl dicarboxylic acid and glycol, adding polyamide such as nylon 6 and / or nylon 66 during polyester polymerization so as to prepare polyester chip, drying the polyester chip and using a conventional spinning machine to spin so as to prepare the polyester fiber used for the dyeing of acid dye. The polyester fiber thoroughly solves the problem that polyester and polyamide are not compatible, ensures uniform dyeing of acid dye, and enables spinning workstage to proceed smoothly. In addition, as the preparation of the polymer adopts a process similar to polyester polymerization for polymerization on a common polyester polymerization device, the method is simple to operate, easy to perform industrial production and low in cost.

Owner:CHINESE TEXTILE ACAD

A kind of bamboo charcoal viscose fiber rich in nano copper and preparation method thereof

ActiveCN103556272BImprove breathabilityHigh strengthArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceSpinning

In order to meet the needs of customers in the product market and solve the problem of poor spinnability of the bamboo charcoal viscose fiber, the invention provides a nano-copper bamboo charcoal viscose fiber and a preparation method thereof. It is characterized in that: the nano-copper bamboo charcoal solution is mixed with viscose by pre-spinning injection, and the finished product is obtained through wet spinning and post-processing. By weight, the nano-copper content in the fiber is 0.01~5%, the bamboo charcoal content is 0.1~10%, the ammonia absorption rate is ≥50%, the air permeability is ≥500mm / s, and the color fastness to washing is 4~5. The nano-copper bamboo charcoal viscose fiber of the present invention not only has anti-ultraviolet and deodorizing functions, but also has good air permeability and absorbency, and the antibacterial effect is stronger than that of ordinary bamboo charcoal fiber, the fiber has high breaking strength and low cost.

Owner:YIBIN HIEST FIBER +1

Regenerated cellulose fiber containing Binchotan and preparation method of regenerated cellulose fiber

InactiveCN108486673AGood antibacterialExcellent excitation of negative ionsArtificial filaments from viscosePolymer scienceCellulose fiber

The invention relates to regenerated cellulose fiber containing Binchotan and a preparation method of the regenerated cellulose fiber. The regenerated cellulose fiber containing the Binchotan, provided by the invention, is characterized in that Binchotan powder, regenerated celluloses and the like are adopted as raw materials, Binchotan dispersing liquid is formed by uniformly dispersing the Binchotan powder in water, a viscose spinning solution is prepared simultaneously, and a pre-spinning injection method is adopted to add the Binchotan dispersing liquid into the viscose spinning solution for spinning, thereby obtaining a finished product. The regenerated cellulose fiber containing Binchotan and the preparation method of the regenerated cellulose fiber provided by the invention have thebenefits: in the regenerated cellulose fiber containing the Binchotan, the adding amount of the Binchotan is 1.5-10 percent by weight of alpha-celluloses, the ammonia absorption rate is more than orequal to 50 percent, the air permeability is more than or equal to 600 mm / s, the washing resistance is realized, and the color fastness is grade 4-5. The regenerated cellulose fiber provided by the invention has an antibacterial rate of 95 percent, a remarkable antibacterial effect, a far infrared emissivity of 88.5 percent, a remarkable far infrared emission function, an ammonia adsorption rate of more than or equal to 50 percent and a remarkable deodorization function; a prepared textile product has the characteristics of being smooth, fine and good in hygroscopicity.

Owner:杭州优标纺织有限公司

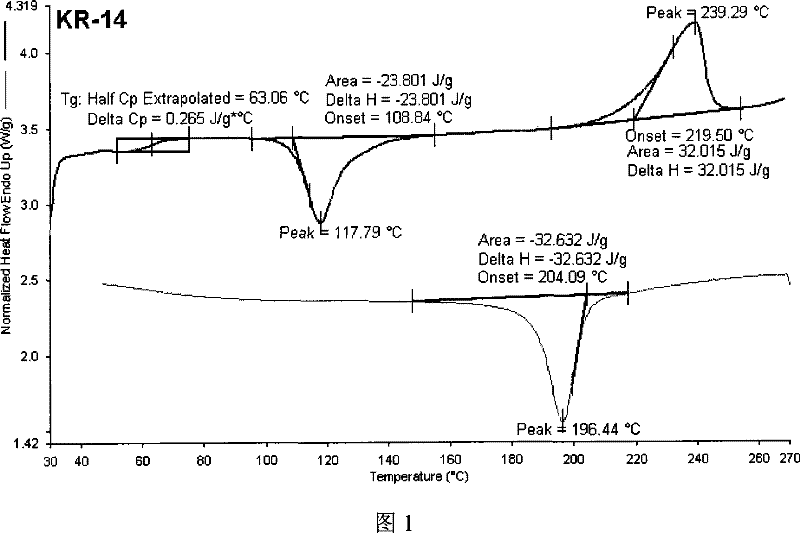

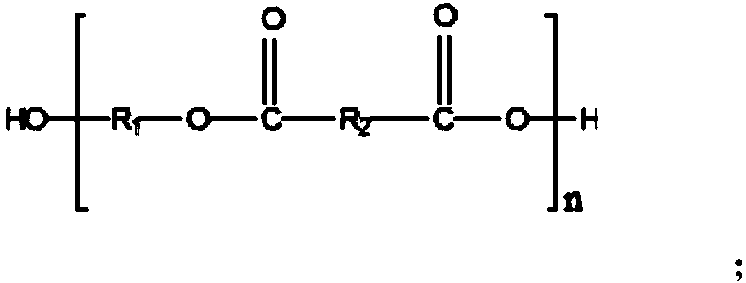

Long-acting antibacterial polyester and preparation method thereof

The invention relates to long-acting antibacterial polyester and a preparation method thereof. According to the invention, an antibacterial agent and polyester are reactively mixed in a molten state to obtain the long-acting antibacterial polyester, wherein the structural formula of the polyester is as shown in the specification. In the formula, R1 and R2 are aromatic rings, cyclic hydrocarbons oraliphatic hydrocarbons; and n= 80-180. The molecular structure of the prepared long-acting antibacterial polyester contains both a polyester segment and an antibacterial terminal group, wherein the antibacterial terminal group is a group formed after a reaction of the antibacterial agent. The antibacterial agent is hydroxybenzoic acid and / or hydroxybenzoate. The 24-hour inhibition rate of Staphylococcus aureus and Escherichia coli by the antibacterial agent is greater than or equal to 99%, the 24-hour inhibition rate of Staphylococcus aureus and Escherichia coli is greater than 95% after 50 times of washing, and the 24-hour inhibition rate of Staphylococcus aureus and Escherichia coli is greater than 98% after 12 hours of irradiation by ultraviolet rays of 70 muW / cm<2>. The preparation method is simple and low-cost; and the prepared polyester has good quality and good antibacterial property, and has a considerable application prospect.

Owner:DONGHUA UNIV

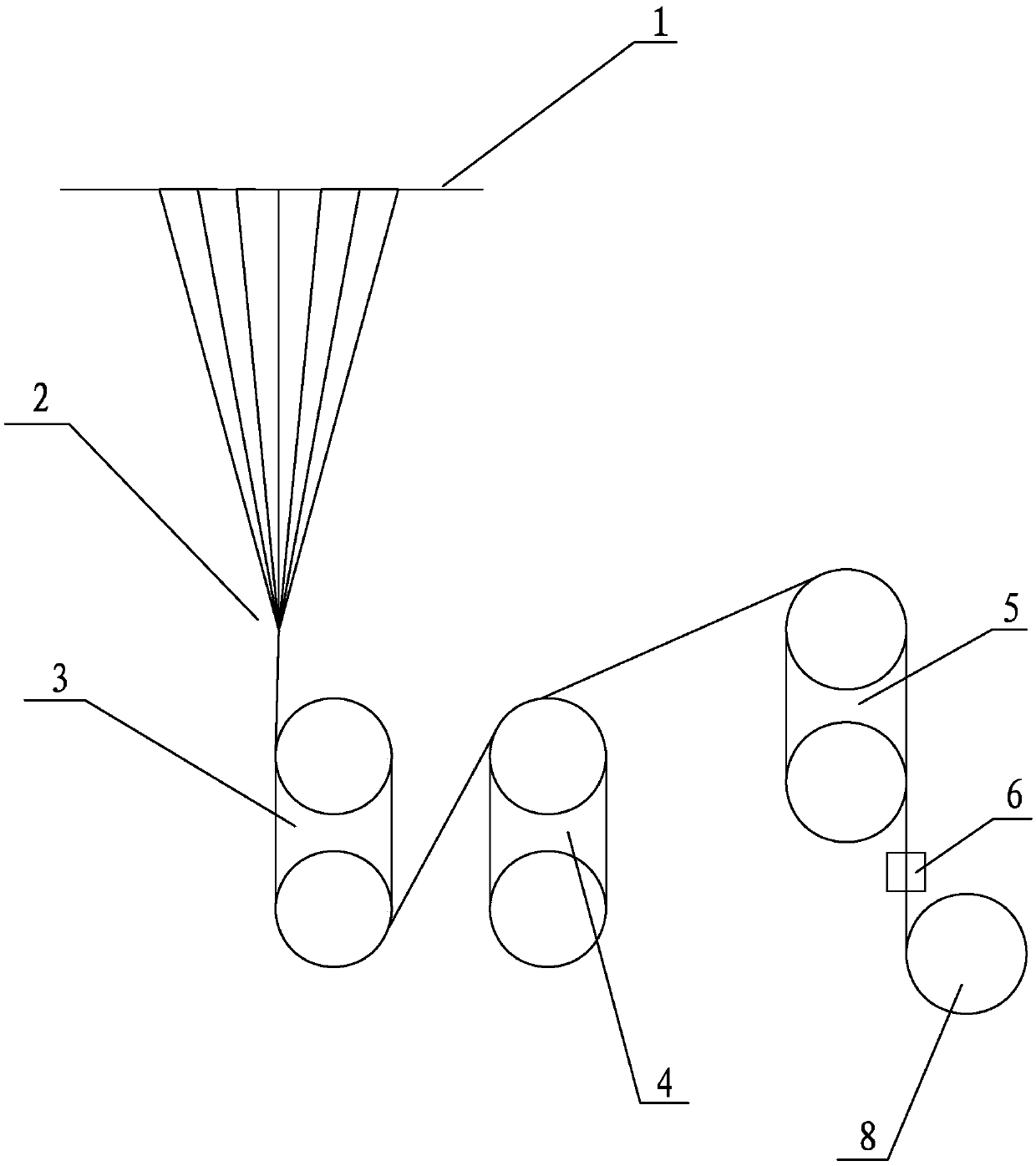

A kind of preparation method of nylon 6 fiber with high strength and low elongation

ActiveCN106400156BDoes not affect spinnabilityImprove uniformityFibre typesArtificial filament heat treatmentFiberPolymer science

The invention relates to a method for preparing high-tenacity low-elongation polyamide 6 fibers. The method for preparing high-tenacity low-elongation polyamide 6 fibers comprises the following steps of: 1) fusion: sliding pre-dried polyamide 6 and performing fusion to obtain spinning solution; 2) spinning: performing spinning by enabling the spinning solution to enter a spinning component, wherein monofilaments are sprayed out from a spinneret plate; 3) bundling and oiling: bundling the monofilaments reaching a bundling and oiling point and oiling the surface of a bundle, wherein spinning oil contains polyamide chain extender and ultraviolet screening agent; 4)hot drawing: enabling oiled bundle to sequentially pass through No.1 combined rollers, No.2 combined rollers and No.3 combined rollers to perform hot drawing; 5) winding: enabling the bundle after hot drawing to pass through a separate interlacer and winding at a winding head to obtain high-tenacity low-elongation polyamide 6 fibers. The polyamide 6 fibers prepared by adopting the method disclosed by the invention has the characteristics of high tenacity and low elongation, the addition of functional additives does not influence the spinnability and fiber performance of the spinning solution, and the sunlight resistance, high temperature resistance and oxidation aging resistance of the fibers can be effectively improved.

Owner:YIWU HUADING NYLON

Bamboo charcoal viscose flat yarn and production process thereof

ActiveCN103556266AMeet diverse needsSignificant far infrared health functionArtificial filaments from viscoseWet spinning methodsYarnPolymer science

The invention provides a bamboo charcoal viscose flat yarn and a production process thereof, in order to meet the requirements of clients on product markets. The bamboo charcoal viscose flat yarn is characterized by being prepared through the following steps: mixing the bamboo charcoal pulp with viscose through injection before spinning and performing wet spinning and post-treatment, wherein the flatness of the yarn is (10-500):1, the content of the bamboo charcoal is 0.1-10 percent of the total weight of the fiber, the ammonia absorption rate is greater than or equal to 50 percent, the permeability is greater than or equal to 500mm / s, and the color fastness to washing is class 4-5. The bamboo charcoal viscose flat yarn is a new product, which has antibacterial, anti-ultraviolet and deodorization functions, also has good permeability and wet absorption and is a degradable environment-friendly fiber.

Owner:YIBIN HIEST FIBER +1

A kind of far-infrared bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556275BImprove antibacterial propertiesSignificant far infrared health functionArtificial thread manufacturing machinesArtificial filaments from viscoseFar infraredMechanical engineering

In order to make up for the blank of the current far -infrared bamboo charcoal sticky glue fiber and solve the problem of poor texture of bamboo charcoal sticky fiber, it provides a method of far -infrared bamboo charcoal sticky fiber and its preparation method.It is characterized by: according to the weight meter, the content of far -infrared ceramic powder in the fiber is 1 ~ 10%, the content of bamboo charcoal is 0.1 ~ 10%, the far -infrared emission rate is> 80%, the ammonia absorption rate is ≥50%, the breathability is ≥500mm / s, the water -resistant washing resistance is resistant to water washingSection 4 ~ 5.The far -infrared vibraous glue fiber of the invention not only has the effect of insulation, but also the radiation far -infrared rays also have a health care function of activating cell tissue and promoting blood circulation.

Owner:YIBIN HIEST FIBER +1

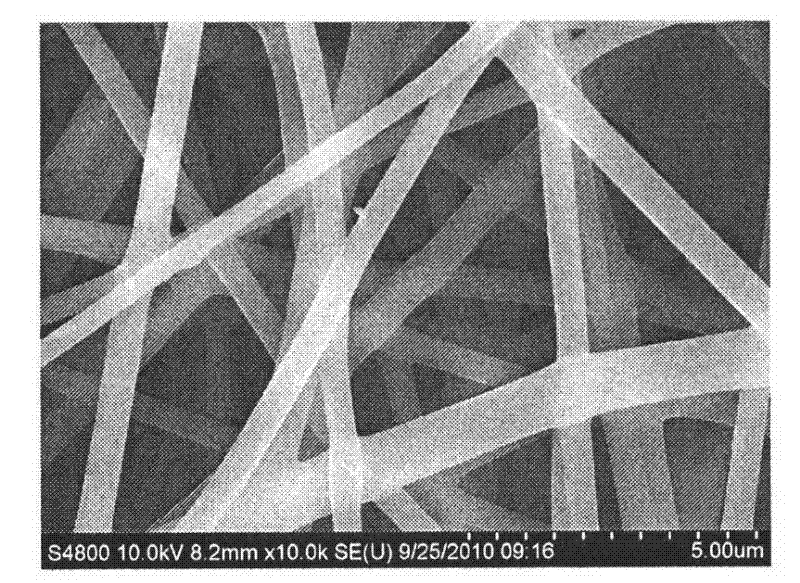

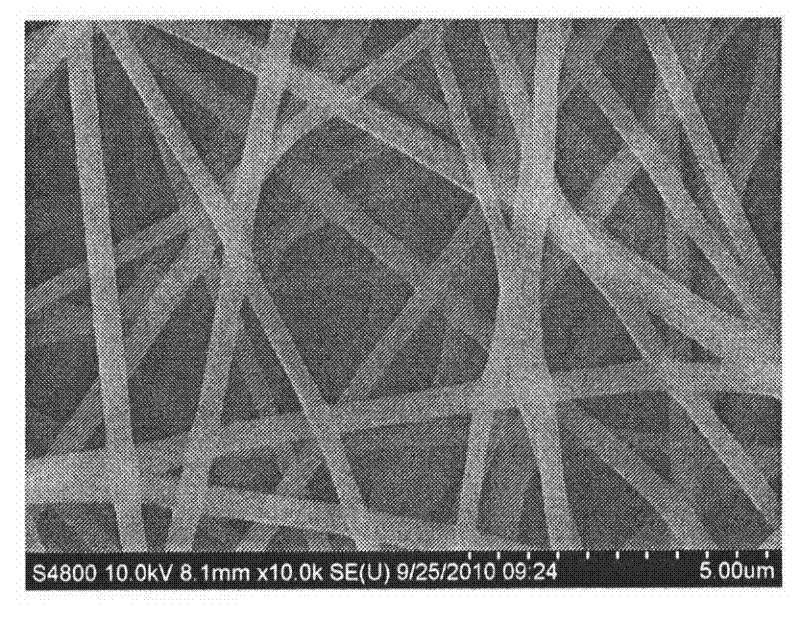

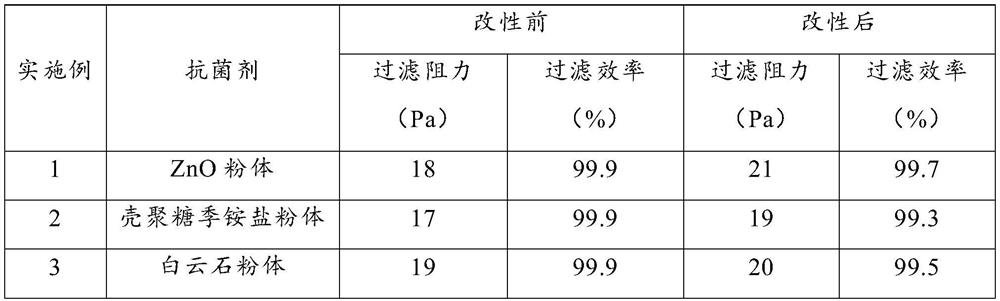

Antibacterial and antiviral modification method of electret melt-blown non-woven fabric

PendingCN114016284AImprove adsorption efficiencyHigh fastnessBiochemical fibre treatmentFibre typesPolymer scienceNonwoven fabric

The invention provides an antibacterial and antiviral modification method of an electret melt-blown non-woven fabric. Firstly, a powder antibacterial agent is subjected to high-voltage electric polarization, and then the powder antibacterial agent is filtered and adsorbed through an electret melt-blown non-woven fabric in a powder antibacterial agent airflow blowing mode, so that the powder nano-antibacterial agent is attached to the surfaces of fibers of the electret melt-blown non-woven fabric through an electrostatic adsorption effect, and the electret melt-blown cloth with excellent antibacterial and virus-killing performance is prepared. In the whole modification process, no harsh technical conditions are needed, the electrostatic adsorption effect of the melt-blown non-woven fabric is not changed or reduced, no adhesive covers, the antibacterial and virus-killing performance of the powder nano-antibacterial agent can be exerted to the maximum extent, and the antibacterial and virus-killing performance of the melt-blown non-woven fabric is improved. The electrostatic effect and filtering permeability of the electret melt-blown non-woven fabric are reserved to the maximum extent, and the electret melt-blown non-woven fabric has important market economic value.

Owner:WUHAN TEXTILE UNIV +1

A kind of antibacterial bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556278BImprove breathabilityImprove antibacterial propertiesArtificial thread manufacturing machinesArtificial filaments from viscosePolymer scienceAnti bacterial

In order to meet the needs of customers in the product market and solve the problem of poor spinnability of the bamboo charcoal viscose fiber, the invention provides an antibacterial bamboo charcoal viscose fiber and a preparation method thereof. It is characterized in that: the antibacterial bamboo charcoal solution is mixed with viscose by pre-spinning injection, and the finished product is obtained through wet spinning and post-treatment. The antibacterial bamboo charcoal solution is formed by mixing the antibacterial solution and bamboo charcoal solution. Antibacterial agent 0.01~10%, bamboo charcoal 0.1~10%, antibacterial rate ≥ 90%, ammonia absorption rate ≥ 50%, air permeability ≥ 500mm / s, color fastness to washing 4-5. The antibacterial bamboo charcoal viscose fiber of the present invention not only has anti-ultraviolet and deodorizing functions, but also has good air permeability and absorbency, and the antibacterial effect is stronger than ordinary bamboo charcoal fiber, the breaking strength of the fiber is high, and the cost is low.

Owner:YIBIN HIEST FIBER +1

A kind of aromatic bamboo charcoal fiber and preparation method thereof

ActiveCN103556264BImprove breathabilitySignificant shielding rateArtificial filaments from viscoseWet spinning methodsPolymer scienceSpinning

In order to meet the needs of customers in the product market and solve the problem of poor spinnability of bamboo charcoal viscose fiber, the invention provides an aromatic bamboo charcoal fiber and a production process thereof. It is characterized in that: using cellulose fiber pulp as raw material, the aromatic bamboo charcoal solution is mixed with viscose by pre-spinning injection, and the finished product is obtained through wet spinning and post-treatment. The aromatic bamboo charcoal solution is composed of aromatic masterbatch and Bamboo charcoal solution is mixed, aromatic masterbatch contains fragrance, aromatic fragrance content in fiber is 0.01~10%, bamboo charcoal content is 0.1~10%, ammonia absorption rate is ≥50%, air permeability is ≥500mm / s, color fastness to washing is 4 ~Level 5. The aromatic bamboo charcoal fiber of the present invention not only has antibacterial, anti-ultraviolet, and deodorizing functions, but also has good air permeability and absorbability, and can effectively and continuously emit aromatic odors, and has the effect of relieving stress and making people feel refreshed.

Owner:YIBIN HIEST FIBER +1

Preparation method of high-strength alkali-resistant polyacrylonitrile fiber and polyacrylonitrile fiber

PendingCN114481349AHigh strengthGood alkali resistanceArtificial filament washing/dryingArtificial filament heat treatmentPolymer scienceCarbon fibers

The invention relates to a preparation method of a high-strength alkali-resistant polyacrylonitrile fiber and the polyacrylonitrile fiber. The method comprises the following steps: carrying out spinning, solidification forming, solidification drafting, water washing, hot water drafting, primary oiling, dry densification, steam drafting, steam heat setting, secondary oiling, re-drying and fiber collection on a polyacrylonitrile spinning solution to obtain the polyacrylonitrile fiber, wherein the mass content percentage of acrylonitrile in a polyacrylonitrile copolymer in the polyacrylonitrile spinning solution is 99.2-99.8%; the micropore orientation angle of the fiber subjected to dry densification is less than or equal to 20 degrees by utilizing a small-angle X-ray scattering test. The polyacrylonitrile fiber obtained by the method has the characteristics of high fiber strength and good alkali resistance, and the pre-oxidized fiber and the carbon fiber prepared by taking the polyacrylonitrile fiber as the precursor have high performance, and can be used in industrial production of the polyacrylonitrile fiber.

Owner:CHINA PETROLEUM & CHEM CORP +1

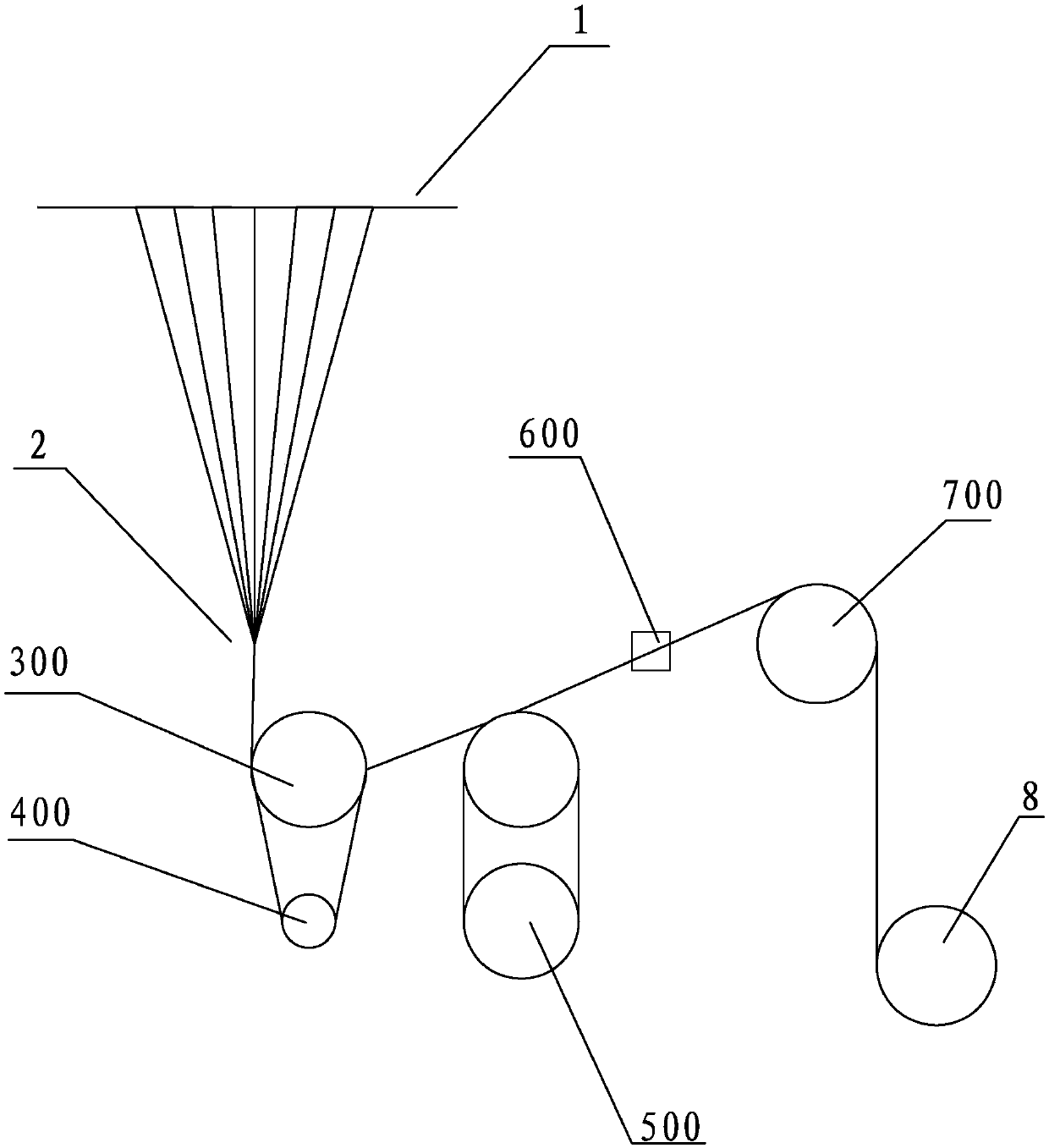

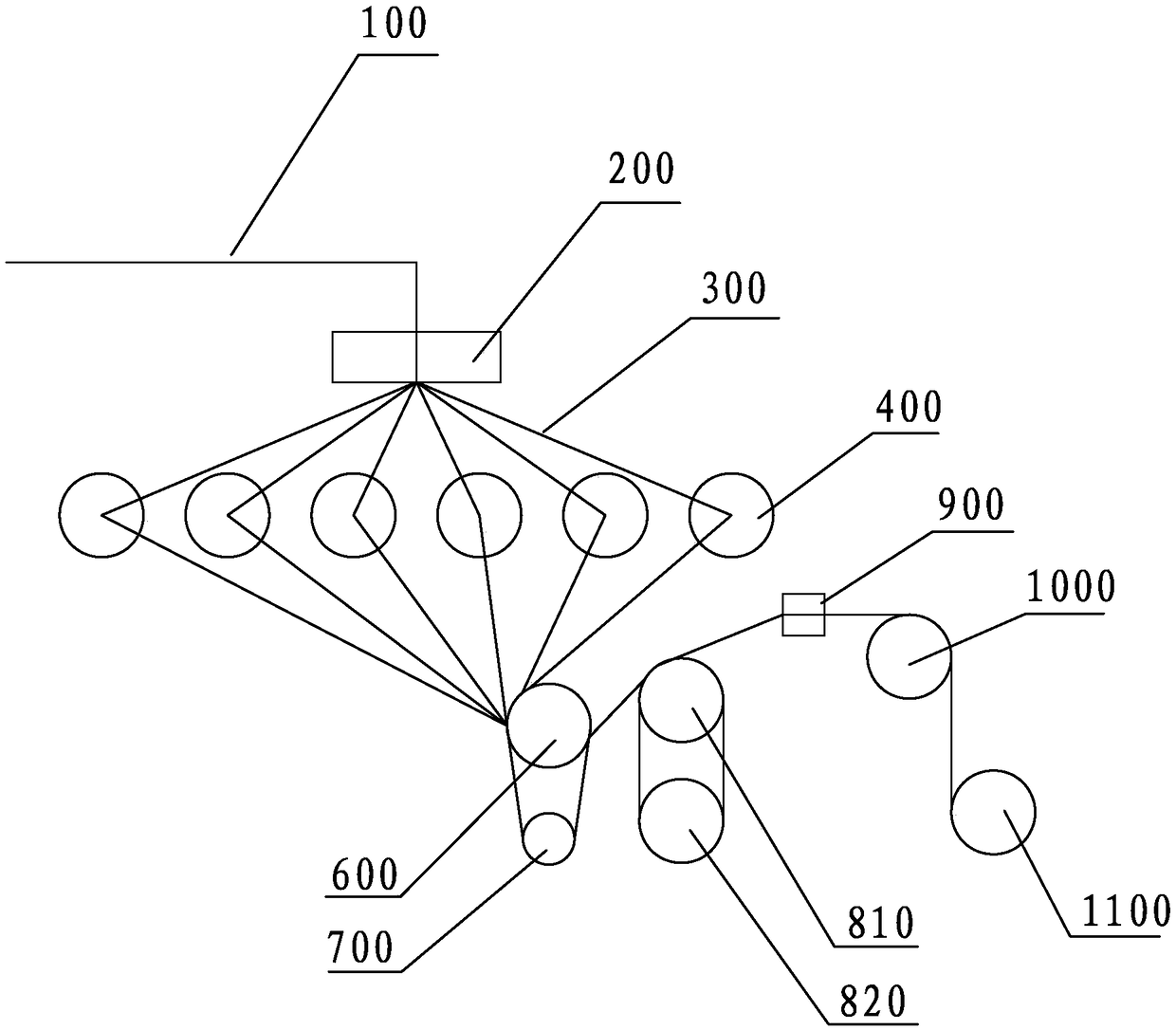

A kind of preparation method of multi-different composite nylon 6 fiber

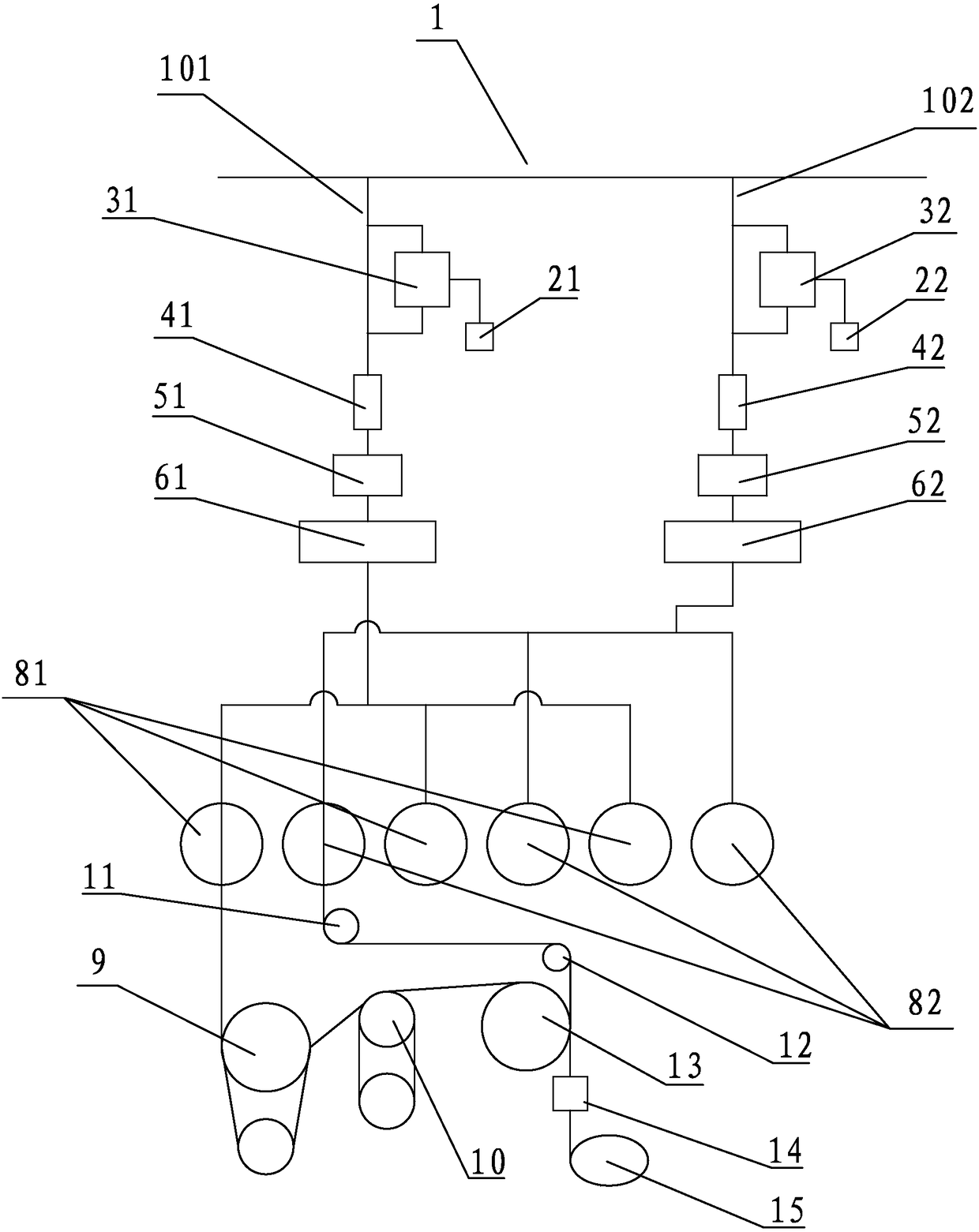

ActiveCN106337224BImprove network mixed-fiber composite stateImprove stylingSpinning head liquid feederArtificial filament supportProduction lineYarn

The invention relates to the field of spinning, and discloses a preparation method of multi-irregular composite nylon 6 fiber. The method comprises preparation of fully drawn yarn (FDY) and preparation of polyester pre-oriented yarn (POY). The preparation of the FDY comprises the following steps: (1) mixing; (2) spinning; (3) drawing. The preparation of the POY comprises the following steps: (1) mixing; (2) spinning; (3) guiding yarn. The multi-irregular composite nylon 6 fiber is prepared by merging the prepared FDY and the prepared POY on a guide roller No. 3, then compounding the mixed fiber on a subpackage type interlacer, and finally winding by using a winding device. By reforming and optimizing the existing production line for the nylon 6 fiber, the comprehensive compound modification such as multiple components, multiple functions, various colors and multiple irregular cross sections for the nylon fiber can be realized while not influencing the spinnability of fiber production, the types and styles of fiber and fabric can be greatly enriched, the application space and field of the fiber are expanded, and the application field of the product is improved. The preparation method is high in efficiency, low in cost and good in stability.

Owner:YIWU HUADING NYLON

Production method of PPS (poly(p-phenylene sulfide)) filter cloth

The invention relates to a production method of PPS (poly(p-phenylene sulfide)) filter cloth. The production method comprises the steps of adding a colloidal substance capable of being subjected to hot melting at a certain temperature into a PPS fiber melt spinning process to form modified PPS fibers, doubling and twisting the modified PPS fibers and ordinary PPS fibers, and preparing the filter cloth from doubling and twisting yarns. The filter cloth is influenced by the temperature during work; pin holes can be blocked by a small amount of the colloidal substance in the modified PPS fibers,so that the filtration efficiency is improved; and the method is simple in technology and easy to operate.

Owner:JIANGSU DINGSHENG FILTER BAG CO LTD

A kind of pupal protein bamboo charcoal viscose fiber and preparation method thereof

ActiveCN103556271BSignificant shielding rateSignificant far infrared health functionArtificial filaments from viscoseWet spinning methodsProtein solutionPolymer science

In order to make up the blank of the current pupa protein bamboo charcoal viscose fiber and solve the problem of poor spinnability of the bamboo charcoal viscose fiber, the present invention provides a pupa protein bamboo charcoal viscose fiber and a preparation method thereof. It is characterized in that: the bamboo charcoal slurry is mixed with pupa protein solution and viscose by injection before spinning, and the finished product is obtained through wet spinning and post-processing; by weight, the protein content in the fiber is 0.1-25%, and the bamboo charcoal content is 0.1-10%. , Ammonia absorption rate ≥ 50%, air permeability ≥ 500mm / s, color fastness to washing 4~5 grades. The pupal protein bamboo charcoal viscose fiber of the present invention not only has antibacterial, anti-ultraviolet and deodorizing functions, but also has good air permeability and hygroscopicity, and is soft to the touch, full of silk-like luster, and has very good wearability.

Owner:YIBIN HIEST FIBER +1

A kind of trilobal bamboo charcoal viscose fiber and its production process

ActiveCN103556270BImprove comfortFibrous cortex with large surface areaArtificial filaments from viscoseWet spinning methodsSpinningPulp and paper industry

In order to meet the needs of customers in the product market and solve the problem of poor spinnability of the bamboo charcoal viscose fiber, the invention provides a trilobal bamboo charcoal viscose fiber and a production process thereof. It is characterized in that: the bamboo charcoal pulp is mixed with viscose by pre-spinning injection, and obtained by wet spinning and post-treatment; the cross section of the fiber is trilobal, and the aspect ratio of the cross section is 10~200:1; the bamboo charcoal The content is 0.1~10% of the total weight of the fiber, the ammonia absorption rate is ≥60%, the air permeability is ≥500mm / s, and the color fastness to washing is 4~5. The trilobal bamboo charcoal viscose fiber of the present invention has a large surface area of the fiber cortex, and under the premise of maintaining the sterilization, deodorization, far infrared, and odor absorption effects of the bamboo charcoal viscose fiber, the hygroscopicity is better, and the additional value of the product can be greatly improved. , more comfortable to wear, and maximize the excellent characteristics of bamboo charcoal fiber.

Owner:YIBIN HIEST FIBER +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com