Preparation method of silver-bearing antibacterial polypropylene fiber

An antibacterial polypropylene, polypropylene fiber technology, applied in the direction of single-component polyolefin rayon, can solve the problems of antibacterial, anti-spill and processing performance to be improved, and achieve no effect on spinnability and mechanical properties , easy to operate, uniform and lasting effect of antibacterial agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 90 parts by weight of polypropylene slices and 10 parts by weight of sodium silver zirconium phosphate were uniformly mixed, then mixed and extruded into pellets through a twin-screw extruder, and the extrusion temperature was 170°C to obtain silver-containing antibacterial masterbatches. 20 parts by weight of the obtained antibacterial masterbatch and 80 parts by weight of polypropylene chips are blended and spun, the spinning temperature is 230°C, the metering pump specification is 0.6ml / r, the metering pump revolution is 10r / min, the spinneret hole diameter is 0.4mm, and the hole The number is 18, the winding speed is 400m / min, and the tow after winding is carried out 2 times of thermal drawing to obtain the silver-containing antibacterial polypropylene fiber with an antibacterial agent content of 2%.

[0025] The antibacterial polypropylene fiber of this embodiment is tested, and the result shows: this fiber fineness 4.0dtex, intensity 5.8cN / dtex, elongation at break...

Embodiment 2

[0027] 90 parts by weight of polypropylene slices and 10 parts by weight of sodium silver zirconium phosphate were uniformly mixed, then mixed and extruded into pellets by a twin-screw extruder, and the extrusion temperature was 180°C to obtain silver-containing antibacterial masterbatches. 2 parts by weight of the obtained antibacterial masterbatch and 98 parts by weight of polypropylene chips are blended and spun, the spinning temperature is 230°C, the metering pump specification is 0.6ml / r, the metering pump rotation speed is 10r / min, the spinneret hole diameter is 0.4mm, the hole The number is 18, the winding speed is 400m / min, and the tow after winding is carried out 4.0 times of thermal drawing to obtain the silver-containing antibacterial polypropylene fiber with an antibacterial agent content of 0.2%.

[0028] The antibacterial polypropylene fiber of this embodiment is tested, and the result shows: this fiber fineness 2.0dtex, intensity 7.5cN / dtex, elongation at break 1...

Embodiment 3

[0030] 90 parts by weight of polypropylene slices and 10 parts by weight of sodium silver zirconium phosphate were uniformly mixed, then mixed and extruded into pellets through a twin-screw extruder, and the extrusion temperature was 200°C to obtain silver-containing antibacterial masterbatches. 10 parts by weight of the obtained antibacterial masterbatch and 90 parts by weight of polypropylene chips are blended and spun, the spinning temperature is 220°C, the metering pump specification is 0.6ml / r, the metering pump revolution is 15r / min, the diameter of the spinneret hole is 0.4mm, the hole The number is 18, the winding speed is 400m / min, and the tow is drawn 3.5 times hot after winding to obtain a silver-containing antibacterial polypropylene fiber with an antibacterial agent content of 1%.

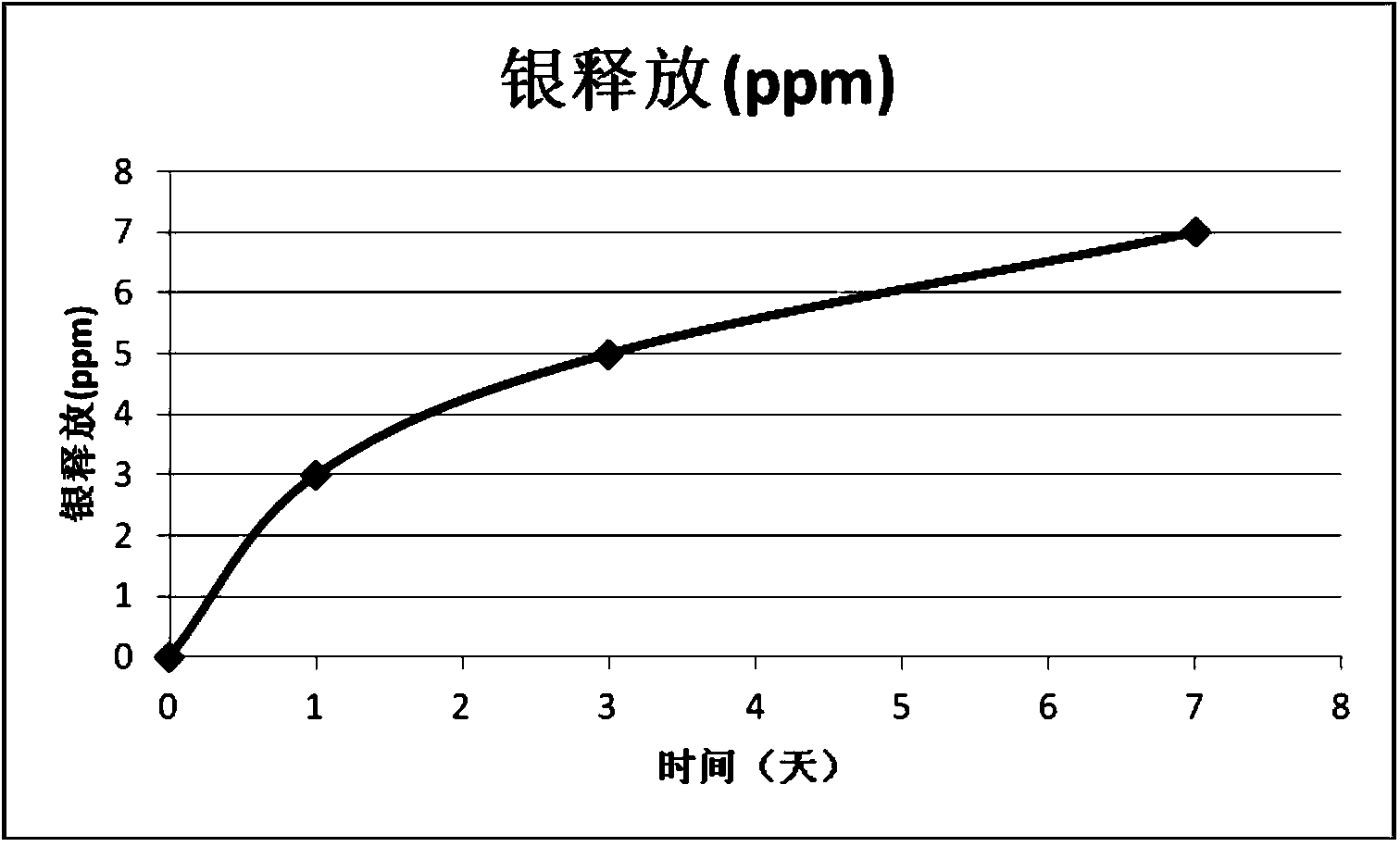

[0031] The antibacterial polypropylene fiber of this embodiment is tested, and the result shows: this fiber fineness 3.5dtex, intensity 6.1cN / dtex, elongation at break 15.0%, silver con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com