Antibacterial and antiviral modification method of electret melt-blown non-woven fabric

A melt-blown non-woven fabric, anti-virus technology, applied in textiles and papermaking, biochemical fiber treatment, fiber type, etc. Air permeability and hand feeling of spray non-woven fabrics to achieve the effect of improving adsorption efficiency and adsorption fastness, high-efficiency load, important market economic value and application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

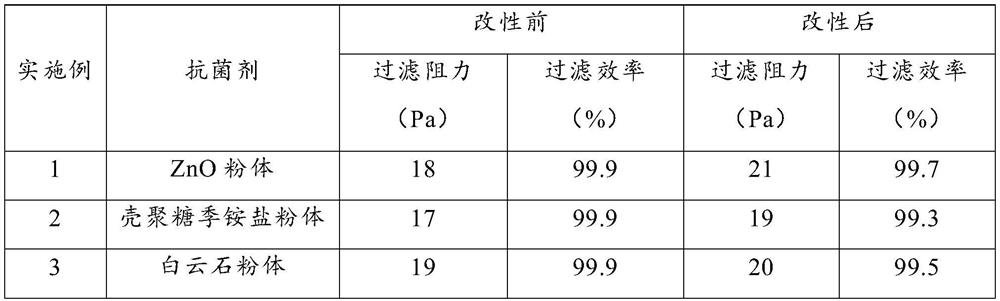

Examples

Embodiment 1-3

[0042] An antibacterial and antiviral modification method of an electret melt blown nonwoven fabric, the method is carried out in the following steps:

[0043] a) Preparation of powder type antibacterial agent airflow

[0044] The powder-type antibacterial agent is dispersed by high-pressure jet airflow, the initial pressure of the high-pressure jet airflow is 0.5Mpa, and the dispersed powder-type antibacterial agent is centrifugally screened to form a powder with a gas-solid ratio of 1:1-4:1 type antibacterial agent airflow, wherein the dispersion temperature is 25°C, the centrifugal speed is 10000 rpm, and the centrifugal temperature is 25°C;

[0045] b) Electropolarization of powder-type antibacterial agent airflow

[0046] Pass the airflow of the powder-type antibacterial agent obtained in step a through the middle of two parallel electrode plates for electric polarization, one of the electrode plates is grounded, and the other electrode plate is connected to the positive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com