A kind of preparation method of multi-different composite nylon 6 fiber

A nylon and fiber technology, which is applied in the field of preparation of polyiso-composite nylon 6 fibers, can solve the problems such as the inability to produce high-end functional nylon products, improve the style and performance, expand the application space and field, and improve the network degree. and the effect of network fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

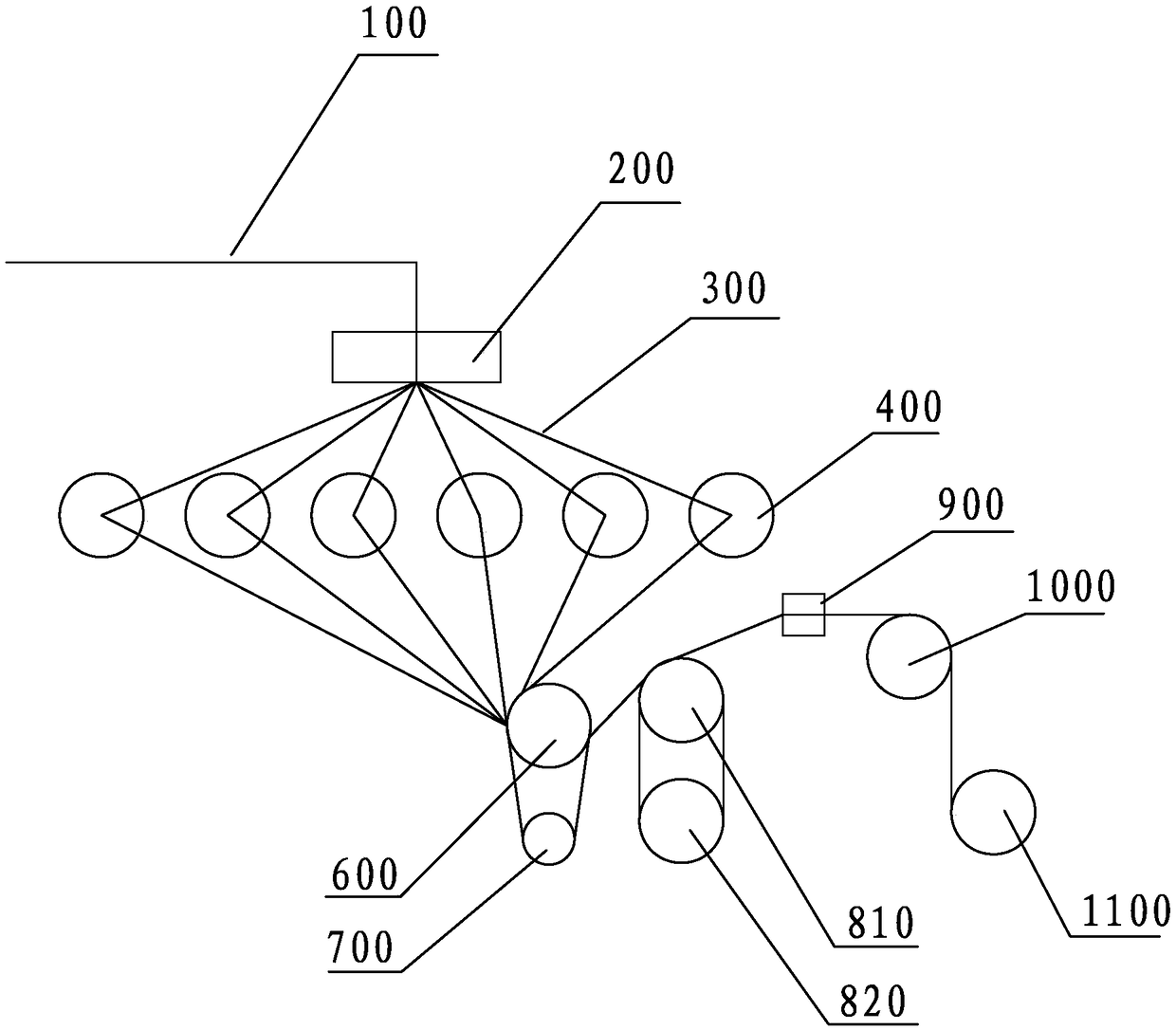

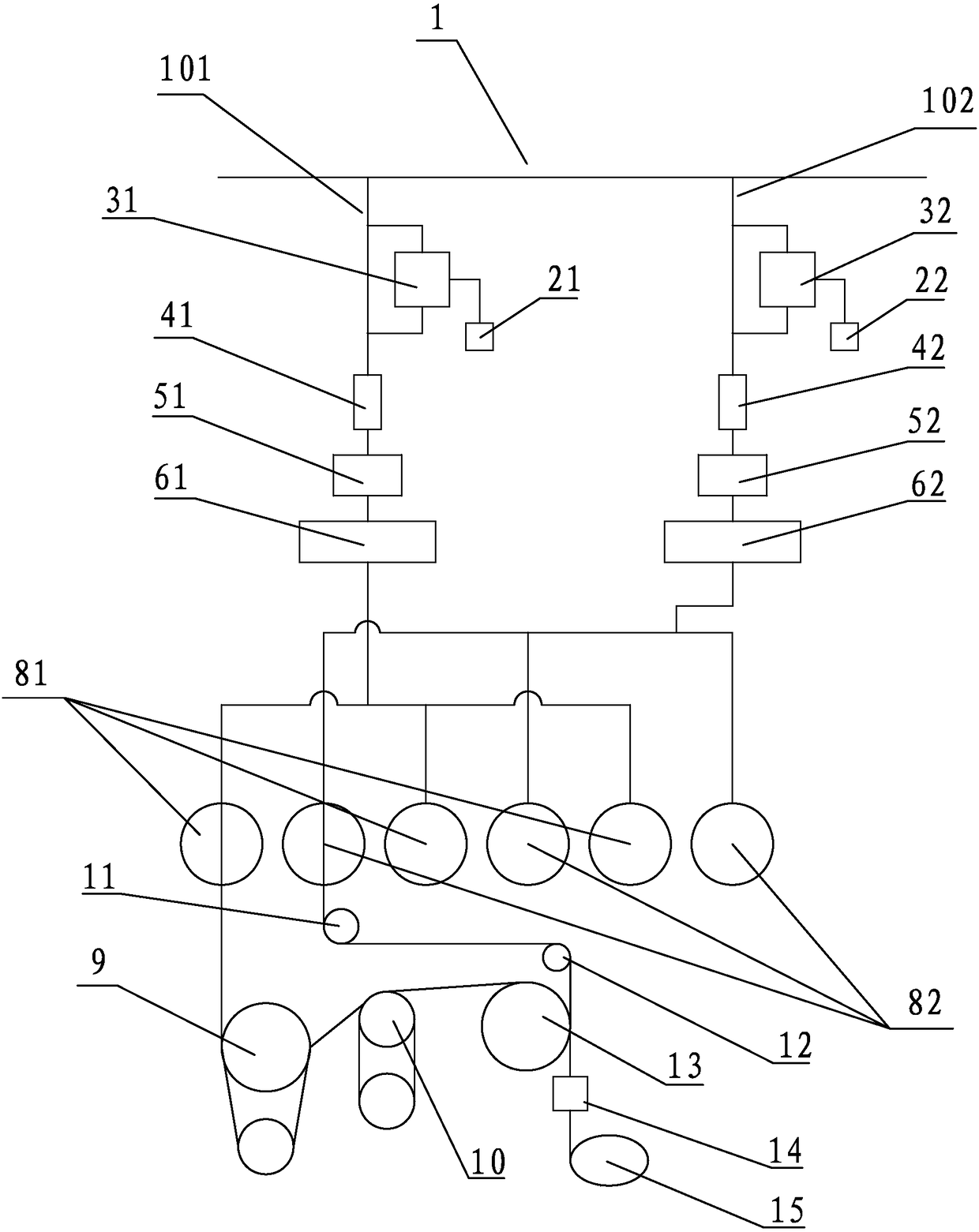

[0032] A method for preparing polyisotropic composite nylon 6 fibers, including the preparation of FDY and POY.

[0033] The preparation steps of the FDY are as follows:

[0034] 1) Mixing: FDY spinning solution is transported to FDY feeding pipe through the total melt pipe, and the FDY feeding pipe is equipped with FDY modified mixing tank, FDY static mixer, FDY dynamic mixer and FDY metering in sequence Pump, wherein the FDY modified mixing tank is connected with the FDY modified masterbatch storage tank; black masterbatch is housed in the FDY modified masterbatch storage tank. The metering pump controls 6 silk cakes.

[0035] 2) Spinning: the FDY spinning solution is discharged from the FDY metering pump and enters the FDY spinning device for spinning to obtain FDY precursors; the FDY precursors have a circular cross section.

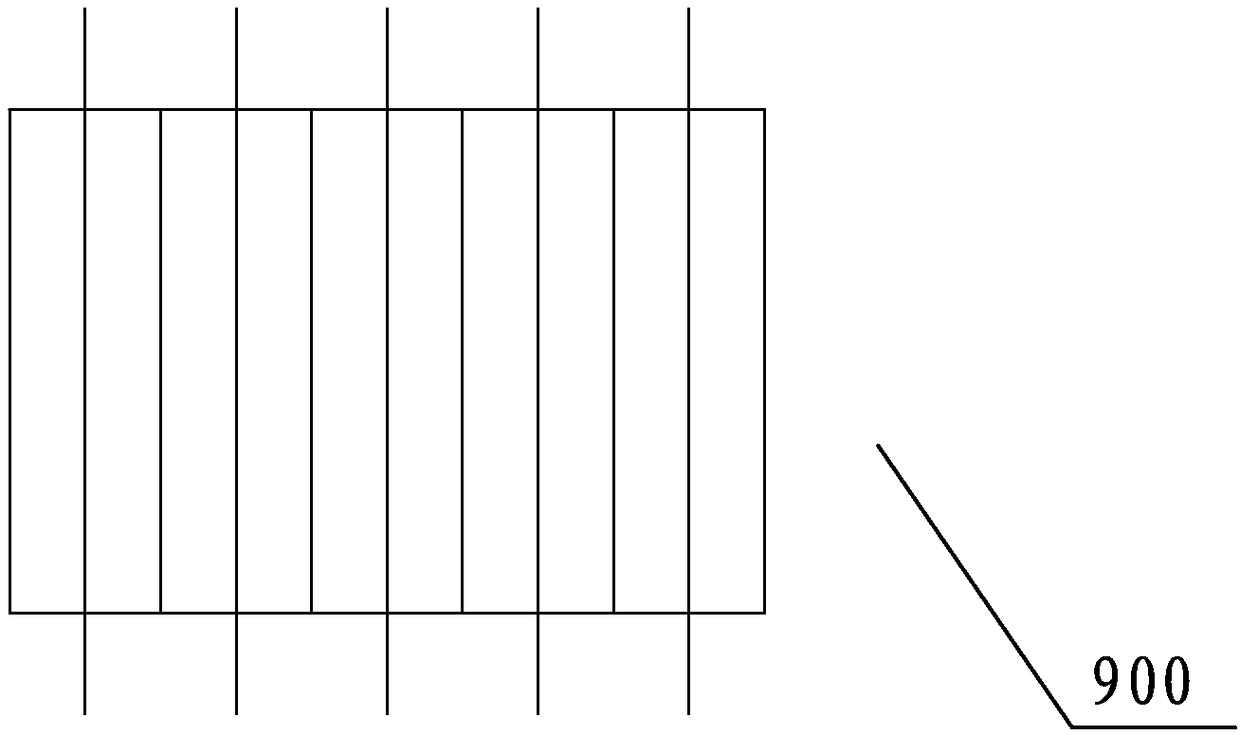

[0036] 3) Stretching: After the FDY raw yarn is heated by the No. 1 drawing hot roller and the No. 2 drawing hot roller in turn, it reaches the No...

Embodiment 2

[0043] A method for preparing polyisotropic composite nylon 6 fibers, including the preparation of FDY and POY.

[0044] The preparation steps of the FDY are as follows:

[0045] 1) Mixing: FDY spinning solution is transported to FDY feeding pipe through the total melt pipe, and the FDY feeding pipe is equipped with FDY modified mixing tank, FDY static mixer, FDY dynamic mixer and FDY metering in sequence pump, wherein the FDY modified mixing tank is connected with the FDY modified master batch storage tank; the antibacterial agent master batch is housed in the FDY modified master batch storage tank. The metering pump controls 4 silk cakes.

[0046] 2) Spinning: the FDY spinning solution is discharged from the FDY metering pump and enters the FDY spinning device for spinning to obtain FDY precursors; the FDY precursors have a cross-shaped cross-section.

[0047] 3) Stretching: After the FDY raw yarn is heated by the No. 1 drawing hot roller and the No. 2 drawing hot roller i...

Embodiment 3

[0054] A method for preparing polyisotropic composite nylon 6 fibers, including the preparation of FDY and POY.

[0055] The preparation steps of the FDY are as follows:

[0056] 1) Mixing: FDY spinning solution is transported to FDY feeding pipe through the total melt pipe, and the FDY feeding pipe is equipped with FDY modified mixing tank, FDY static mixer, FDY dynamic mixer and FDY metering in sequence pump, wherein the FDY modified mixing tank is connected with the FDY modified master batch storage tank; the negative ion modified master batch is housed in the FDY modified master batch storage tank. The metering pump controls 6 silk cakes.

[0057] 2) Spinning: the FDY spinning solution is discharged from the FDY metering pump and enters the FDY spinning device for spinning to obtain FDY precursors; the FDY precursors have a hollow cross section.

[0058] 3) Stretching: After the FDY raw yarn is heated by the No. 1 drawing hot roller and the No. 2 drawing hot roller in tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com