Long-acting antibacterial polyester and preparation method thereof

A polyester and long-acting technology, which is applied in the field of long-acting antibacterial polyester and its preparation, can solve the problems of high cost, poor antibacterial durability, and poor washing resistance, and achieve high safety, stable performance, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method of long-acting antibacterial polyester, concrete steps are as follows:

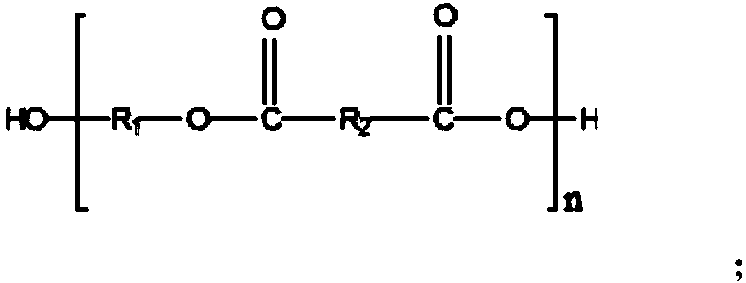

[0034] (1) p-hydroxybenzoic acid and polyethylene terephthalate (PET) are dried, the water content of the dried p-hydroxybenzoic acid is 20ppm, and the water content of the dried PET is 20ppm, wherein the water content of PET The structural formula is as follows:

[0035]

[0036] In the formula, R 1 for x=2;R 2 for n=100~120; the number average molecular weight is 16000, and the content of terminal carboxyl group is 30.0mmol / t;

[0037] (2) P-hydroxybenzoic acid is added in PET melt and carries out reactive blending and makes long-acting antibacterial polyester, and reactive blending refers to the blending process that esterification takes place, and when reactive blending starts, to The mass ratio of hydroxybenzoic acid to PET was 13:1000, the temperature of reactive blending was 270°C, the pressure was -0.05MPa, and the time was 30min.

[0038] Finally, the...

Embodiment 2

[0042] A kind of preparation method of long-acting antibacterial polyester, concrete steps are as follows:

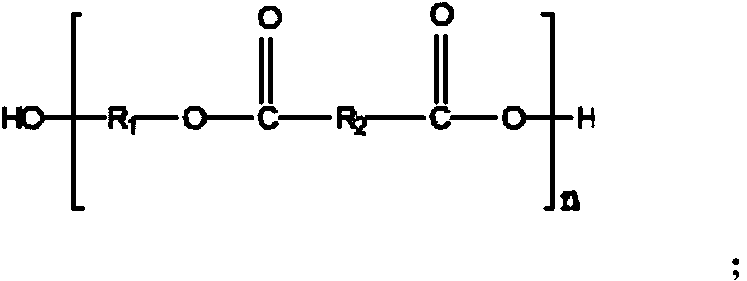

[0043] (1) Methyl p-hydroxybenzoate and polytrimethylene terephthalate (PTT) are dried, the water content of the dried methyl p-hydroxybenzoate is 30ppm, and the water content of the dried PTT is 30ppm, wherein The structural formula of PTT is as follows:

[0044]

[0045] In the formula, R 1 for Among them, x=3; R 2 for n=100~120; the number average molecular weight is 11000, and the content of terminal carboxyl group is 29.4mmol / t;

[0046] (2) After blending methyl p-hydroxybenzoate and PTT slices, melt and carry out reactive blending to obtain long-acting antibacterial polyester. Reactive blending refers to the blending process in which esterification occurs. Reactive blending begins , the mass ratio of methyl p-hydroxybenzoate to PTT was 15:1000, the temperature of reactive blending was 230°C, the pressure was -0.05MPa, and the time was 25min.

[0047] F...

Embodiment 3

[0051] A kind of preparation method of long-acting antibacterial polyester, concrete steps are as follows:

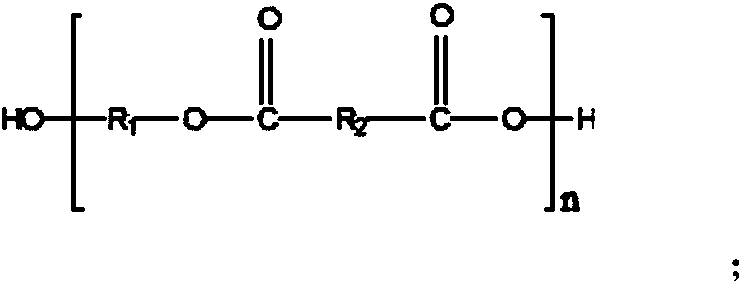

[0052] (1) Ethyl p-hydroxybenzoate and polybutylene terephthalate (PBT) are dried, the water content of the dried ethyl p-hydroxybenzoate is 20ppm, and the water content of the dried PBT is 20ppm , wherein the structural formula of PBT is as follows:

[0053]

[0054] In the formula, R 1 for Among them, x=4; R 2 for n=80~100; the number average molecular weight is 15000, and the content of terminal carboxyl group is 29.8mmol / t;

[0055] (2) Ethyl p-hydroxybenzoate is added to the PBT melt for reactive blending to obtain long-acting antibacterial polyester. Reactive blending refers to the blending process in which transesterification occurs. When reactive blending begins , the mass ratio of ethyl p-hydroxybenzoate to PBT was 17:1000, the temperature of reactive blending was 275°C, the pressure was -0.05MPa, and the time was 29min.

[0056] Finally, the ester g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com