A kind of preparation method of nylon 6 fiber with high strength and low elongation

A high-strength, low-stretch, nylon technology, applied in fiber processing, stretch spinning, fiber type, etc., can solve the problems of functional masterbatch not functioning effectively, easy to react and influence each other, and influence of spinning fiber performance. , to achieve significant economic and social benefits, dimensional stability, and improved application performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of high-strength low-stretch nylon 6 fiber, comprising the following steps:

[0034] 1) Melting: Melting the pre-dried nylon 6 slices to obtain spinning solution.

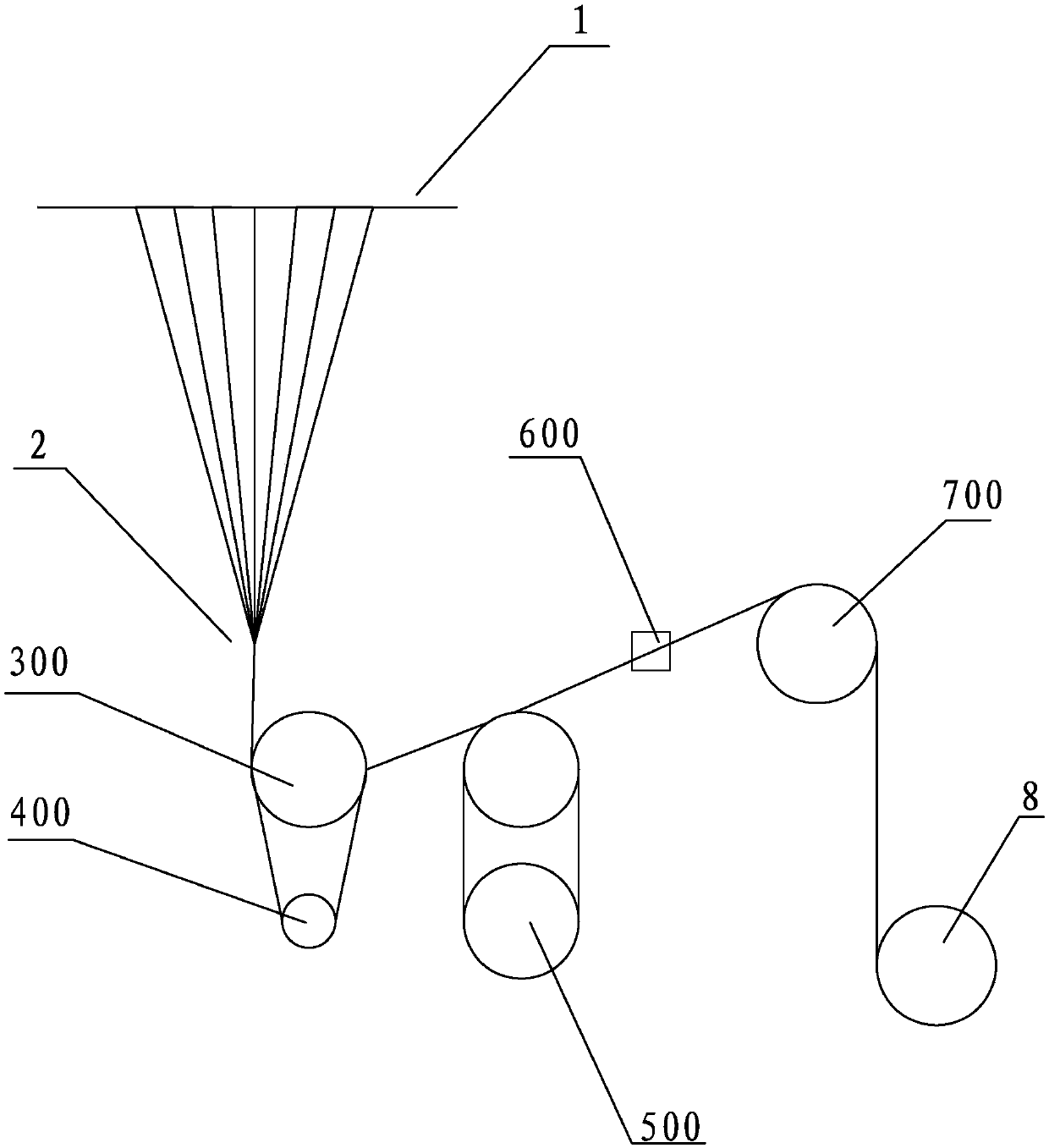

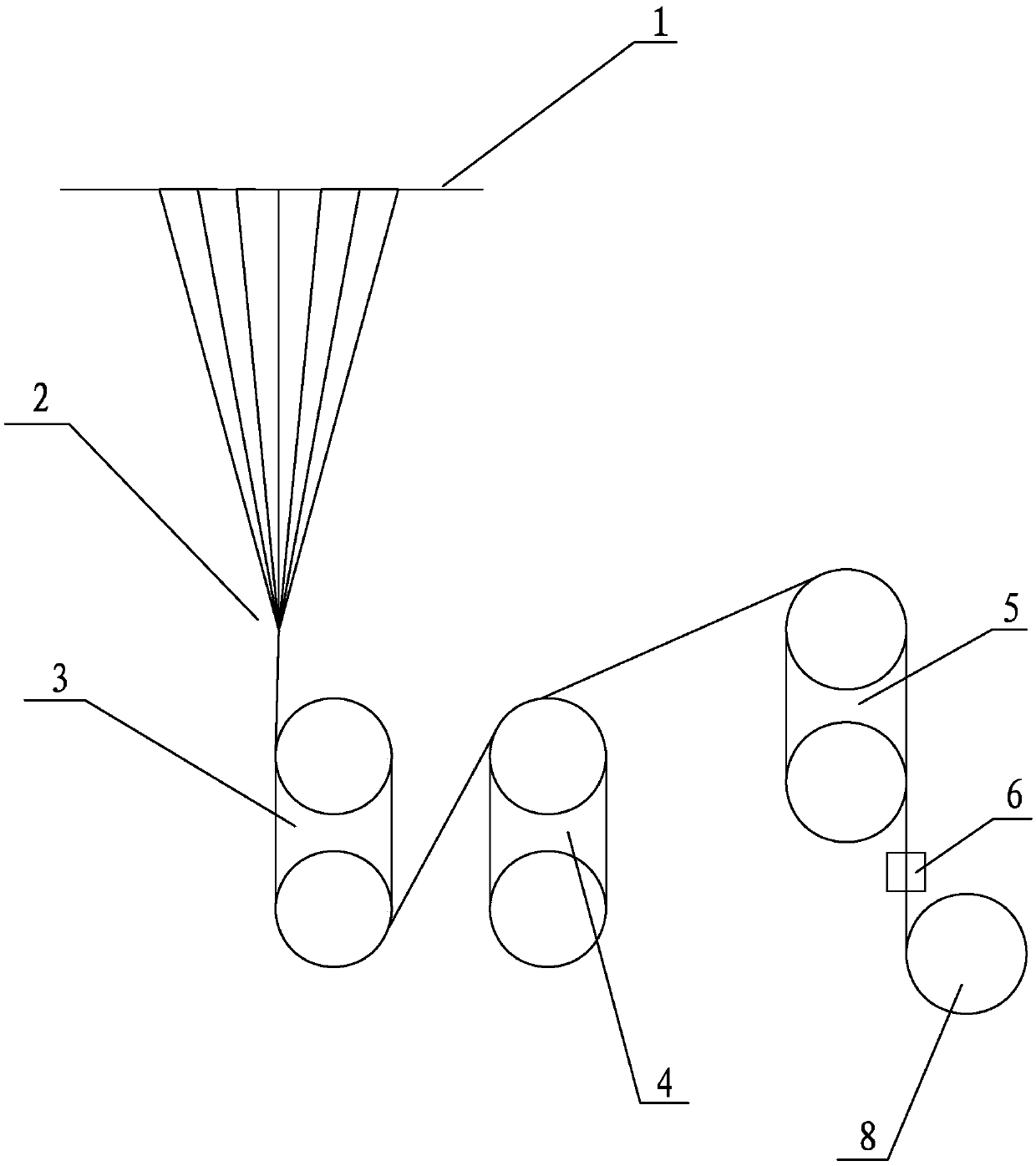

[0035] 2) Spinning: The spinning solution enters the spinning assembly for spinning, and the monofilament is ejected from the spinneret.

[0036] 3) Bundle oiling: the monofilaments are bundled at the bundle oiling point and oiled on the surface of the filament bundle, wherein the spinning oil contains a mixture of nano-titanium dioxide and nano-zinc oxide and polymethylmethacrylate. Wherein, the addition amount of polymethacrylate is 0.05% of the fiber mass, and the addition amount of the anti-ultraviolet agent is 0.15% of the fiber mass.

[0037] 4) Thermal stretching: the oiled tow is thermally stretched through No. 1 combined roll, No. 2 combined roll, and No. 3 combined roll in sequence. Wherein, the draw ratio of the No. 1 combined roll is 1.05, the draw ratio of the No. 1 combin...

Embodiment 2

[0041] A preparation method of high-strength low-stretch nylon 6 fiber, comprising the following steps:

[0042] 1) Melting: Melting the pre-dried nylon 6 slices to obtain spinning solution.

[0043] 2) Spinning: The spinning solution enters the spinning assembly for spinning, and the monofilament is ejected from the spinneret.

[0044] 3) Cluster oiling: the monofilaments reach the cluster oiling point for clustering and oiling on the surface of the filament bundle, wherein the spinning oil contains a mixture of micron titanium dioxide and micron zinc oxide and polymethylmethacrylate. Wherein, the addition amount of polymethacrylate is 0.10% of the fiber mass, and the addition amount of anti-ultraviolet agent is 0.12% of the fiber mass.

[0045] 4) Thermal stretching: the oiled tow is thermally stretched through No. 1 combined roll, No. 2 combined roll, and No. 3 combined roll in sequence. Wherein, the draw ratio of the No. 1 combined roll is 1.02, the draw ratio of the No....

Embodiment 3

[0049] A preparation method of high-strength low-stretch nylon 6 fiber, comprising the following steps:

[0050] 1) Melting: Melting the pre-dried nylon 6 slices to obtain spinning solution.

[0051] 2) Spinning: The spinning solution enters the spinning assembly for spinning, and the monofilament is ejected from the spinneret.

[0052] 3) Bundle oiling: the monofilaments are bundled at the bundle oiling point and oiled on the surface of the filament bundle, wherein the spinning oil contains a mixture of nano-titanium dioxide and nano-zinc oxide and polymethylmethacrylate. Wherein, the addition amount of polymethacrylate is 0.15% of the fiber mass, and the addition amount of anti-ultraviolet agent is 0.05% of the fiber mass.

[0053] 4) Thermal stretching: the oiled tow is thermally stretched through No. 1 combined roll, No. 2 combined roll, and No. 3 combined roll in sequence. Wherein, the draw ratio of the No. 1 combined roll is 1.03, the draw ratio of the No. 1 combined r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com