Controllable method for preparing orthogonal-phase stannous sulfide two-dimensional monocrystalline nanosheet

A single crystal nano, stannous sulfide technology, applied in chemical instruments and methods, single crystal growth, single crystal growth and other directions, can solve the problems of uneven SnS morphology, reduced carrier mobility, and small nanosheet area. , to achieve the effect of low synthesis cost, easy development and application, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

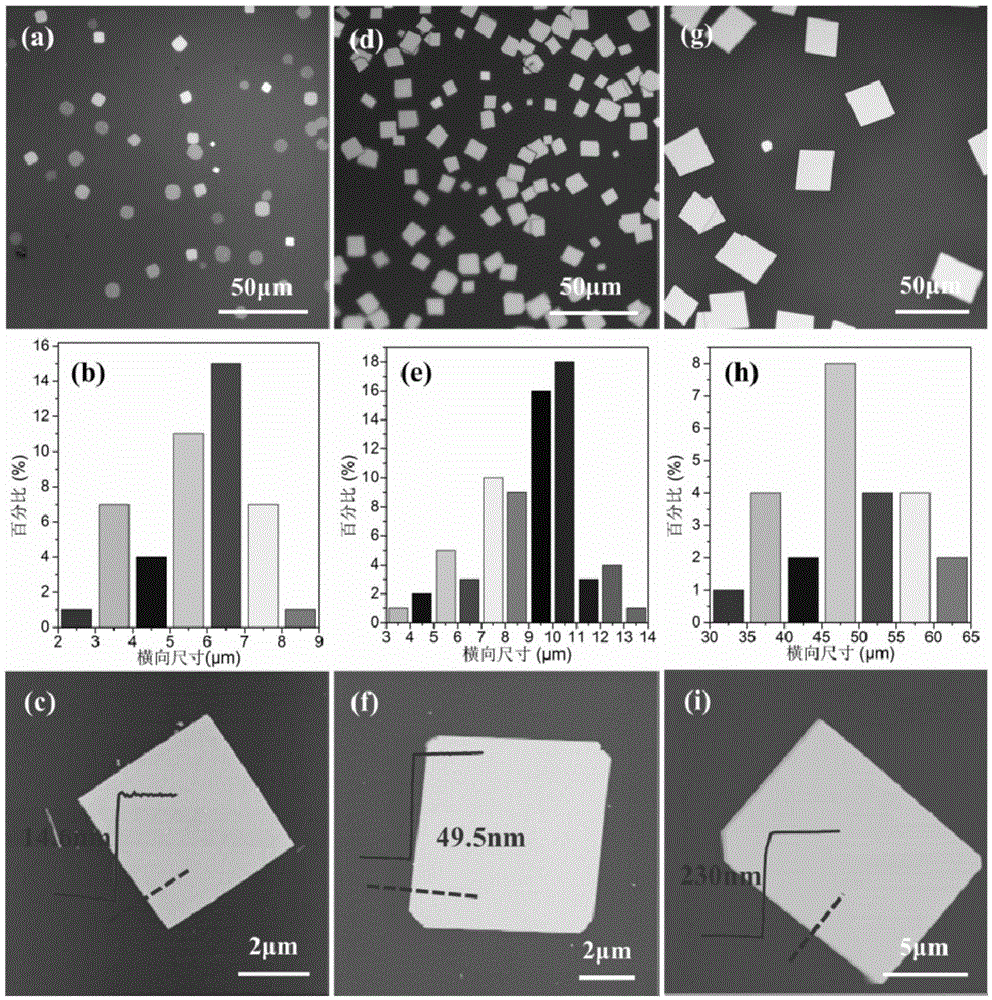

Embodiment 1

[0039] (1) Preparation of fluorine phlogopite sheet substrate:

[0040] 1) Use scissors to cut the mica sheet into small rectangular pieces with a size of 2cm*4cm.

[0041] 2) Cleavage the fluorophlogopite sheet naturally into two pieces from the middle with fine tweezers, and use the newly split side as the growth substrate.

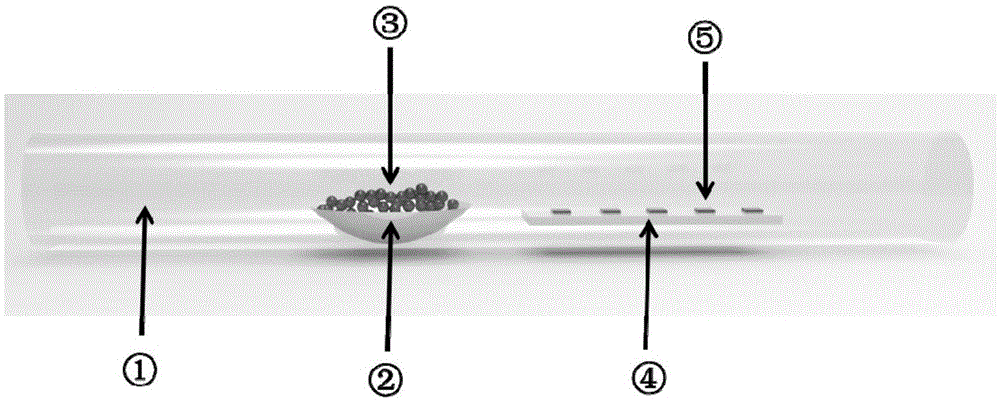

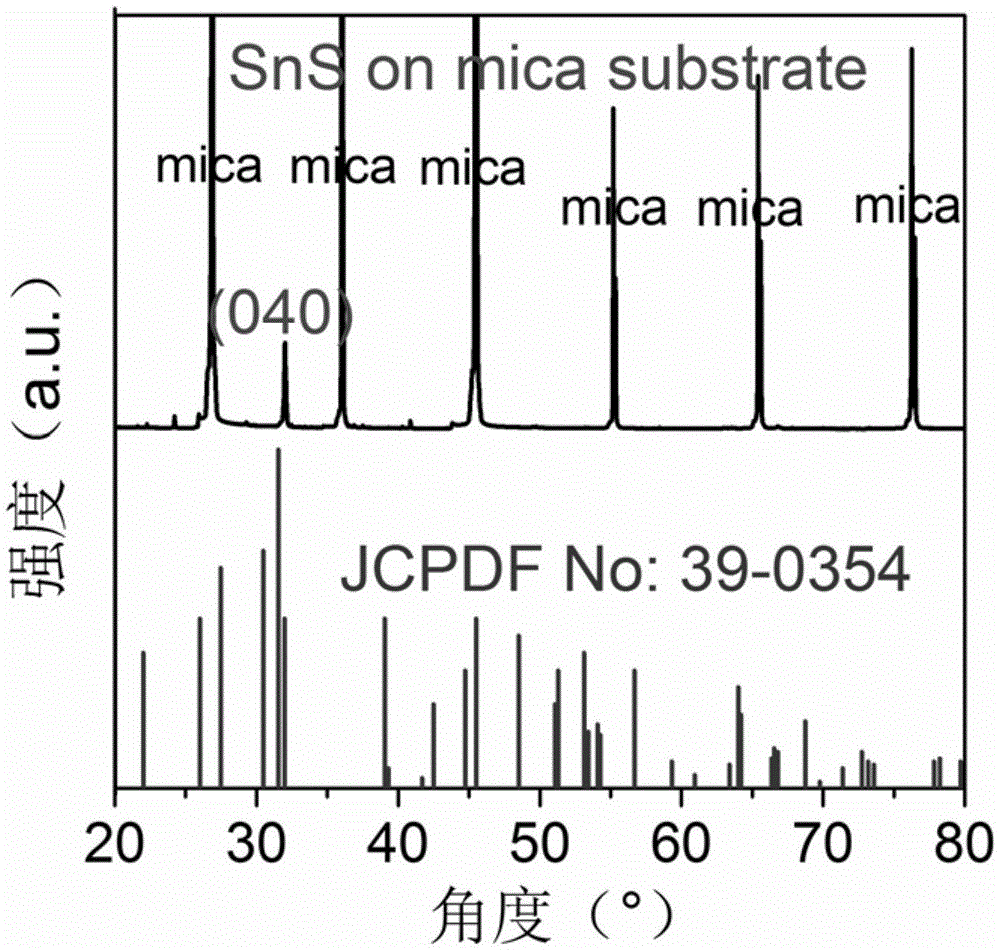

[0042] (2) Place the fluorine phlogopite sheet substrate sequentially on the downstream of the heating center of the tube furnace, 8-20cm away from the center of the heating source. Weigh 0.1 g of high-purity SnS powder (purity not less than 99%) into a ceramic boat, and then place the ceramic boat in the heating zone of the tube furnace.

[0043] (3) Turn on the mechanical pump to evacuate. When the pressure in the tube furnace cavity drops to 0.1Pa, fill in high-purity argon to bring the pressure in the tube furnace cavity back to 80 Torr, and keep the argon flow rate at 60 sccm.

[0044] (4) The heating center of the tube furnace is heated to 600° ...

Embodiment 2

[0052] (1) Preparation of fluorine phlogopite sheet substrate:

[0053] 1) Use scissors to cut the mica sheet into small rectangular pieces with a size of 2cm*4cm.

[0054] 2) Cleavage the fluorophlogopite sheet naturally into two pieces from the middle with fine tweezers, and use the newly split side as the growth substrate.

[0055] (2) Place the fluorine phlogopite sheet substrate sequentially on the downstream of the heating center of the tube furnace, 8-20cm away from the center of the heating source. Weigh 0.1 g of high-purity SnS powder (purity not less than 99%) into a ceramic boat, and then place the ceramic boat in the heating zone of the tube furnace.

[0056] (3) Turn on the mechanical pump for vacuuming. When the pressure in the tube furnace chamber drops to 0.1 Pa, fill in high-purity argon to bring the pressure in the tube furnace chamber back to 80 Torr, and keep the argon flow rate at 60 sccm.

[0057] (4) The heating center of the tube furnace is heated to ...

Embodiment 3

[0061] (1) Preparation of fluorine phlogopite sheet substrate:

[0062] 1) Use scissors to cut the mica sheet into small rectangular pieces with a size of 2cm*4cm.

[0063] 2) Cleavage the fluorophlogopite sheet naturally into two pieces from the middle with fine tweezers, and use the newly split side as the growth substrate.

[0064] (2) Place the fluorine phlogopite sheet substrate sequentially on the downstream of the heating center of the tube furnace, 8-20cm away from the center of the heating source. Weigh 0.1 g of high-purity SnS powder (purity not less than 99%) into a ceramic boat, and then place the ceramic boat in the heating zone of the tube furnace.

[0065] (3) Turn on the mechanical pump to evacuate. When the pressure in the tube furnace chamber drops to 0.1Pa, fill in high-purity argon to bring the pressure in the tube furnace chamber back to 300 Torr, and keep the argon flow rate at 80 sccm.

[0066] (4) The heating center of the tube furnace is heated to 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com