High-yield cultivation method for sugarcanes

A cultivation method and technology of sugarcane, applied in cultivation, plant cultivation, botany equipment and methods, etc., can solve problems such as increased resistance of weeds or pests, soil compaction and barrenness, and pesticide residues in sugarcane plants, so as to promote the absorption of nutrients , Ensure loose soil and promote germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

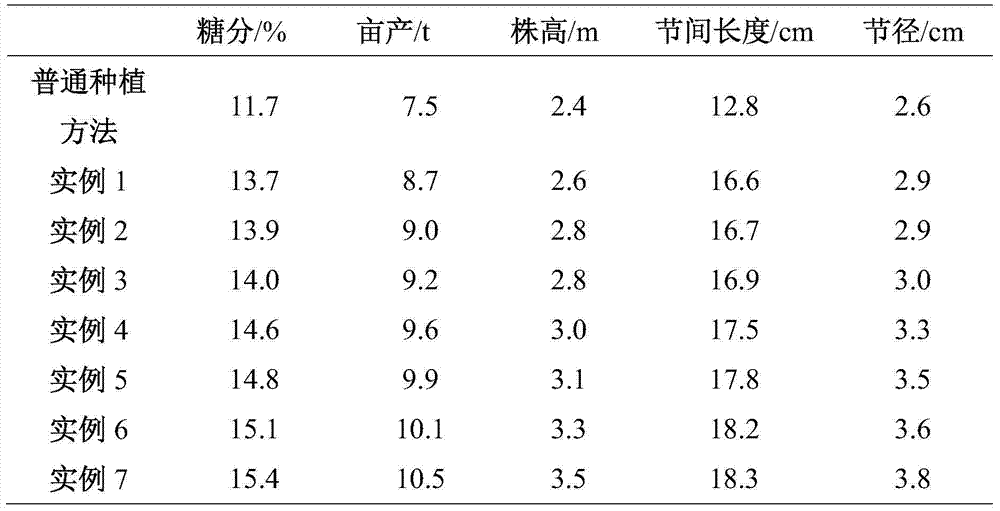

Examples

example 1

[0043] A high-yield cultivation method for sugarcane, comprising the following steps:

[0044] A. Soil preparation and planting of sugarcane ditches

[0045] Plow the field 20 days before planting sugarcane, expose it to the sun for 3 days after plowing, level it, and plant cane furrows with a depth of 40 cm, a width of 60 cm, and a row spacing of 100 cm;

[0046] B. Base fertilizer application

[0047] Apply unfermented green manure raw materials directly to sugarcane ditch, apply 2000 kg of said green manure raw material per mu, use plastic film to cover sugarcane ditch after said green manure raw material is applied, and use soil compaction on both sides of plastic film to make said green manure raw material airtight fermentation After 15 days, the mulch film was lifted to one side, and compound fertilizer was added, and 80 kilograms of the compound fertilizer was applied per mu. After applying the compound fertilizer, it was covered with fine soil, covering a thickness of...

example 2

[0063] A high-yield cultivation method for sugarcane, comprising the following steps:

[0064] A. Soil preparation and planting of sugarcane ditches

[0065] Plow the field 25 days before planting sugarcane, expose it to the sun for 4 days after plowing, level it, and plant cane furrows with a depth of 50 cm, a width of 70 cm, and a row spacing of 120 cm;

[0066] B. Base fertilizer application

[0067] Apply unfermented green manure raw materials directly to the sugarcane ditch, apply 2500 kg of the green manure raw material per mu, use plastic film to cover the sugarcane ditch after the green manure raw material is applied, and use soil compaction on both sides of the plastic film to make the green manure raw material airtight fermentation After 20 days, lift the plastic film to one side, add compound fertilizer, apply 100 kilograms of compound fertilizer per mu, cover with fine soil after applying the compound fertilizer, and cover with a thickness of 7.5cm. The green manu...

example 3

[0083] A high-yield cultivation method for sugarcane, comprising the following steps:

[0084] A. Soil preparation and planting of sugarcane ditches

[0085] Plow the field 30 days before planting sugarcane, expose it to the sun for 5 days after plowing, level it, and plant cane furrows with a depth of 60 cm, a width of 80 cm, and a row spacing of 140 cm;

[0086] B. Base fertilizer application

[0087] Directly apply unfermented green manure raw materials into the cane ditch, apply 3000 kg of the green manure raw materials per mu, cover the cane ditch with plastic film after the green manure raw materials are applied, and compact the two sides of the plastic film with soil to make the green manure raw materials airtight fermentation After 25 days, lift the plastic film to one side again, add compound fertilizer, apply 120 kilograms of compound fertilizer per mu, cover with fine soil after applying the compound fertilizer, cover thickness 10cm, and the green manure raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com