Composite material of nitrogen-doped porous carbon-wrapped carbon nano tube as well as preparation method and application of material

A nitrogen-doped porous carbon and composite material technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of unfavorable catalyst large-scale production, inability to obtain catalytic activity, low heteroatom content, etc. The effect of large-scale production, easy control of feeding amount and high nitrogen atom content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

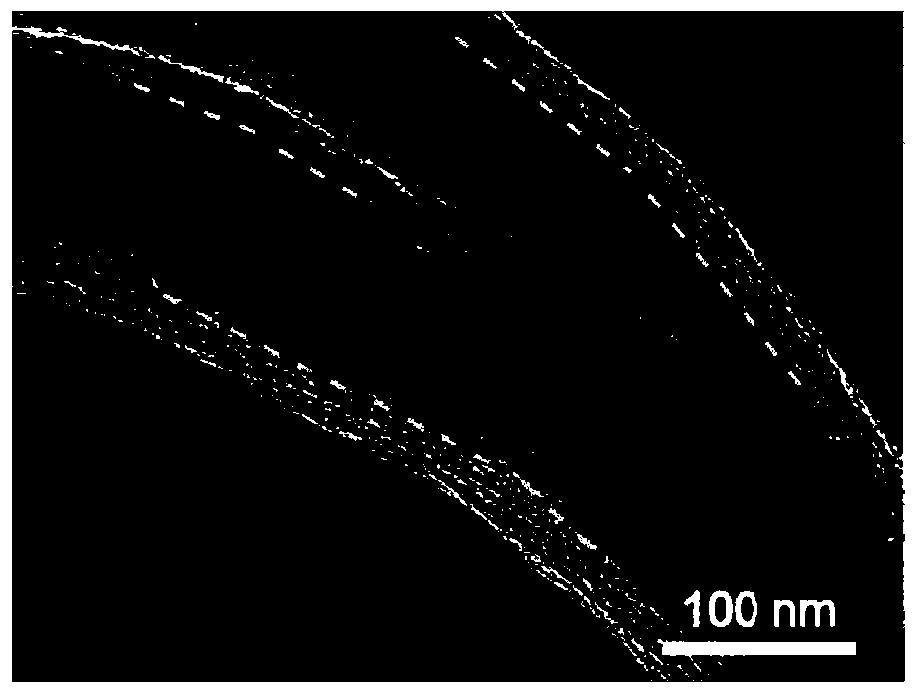

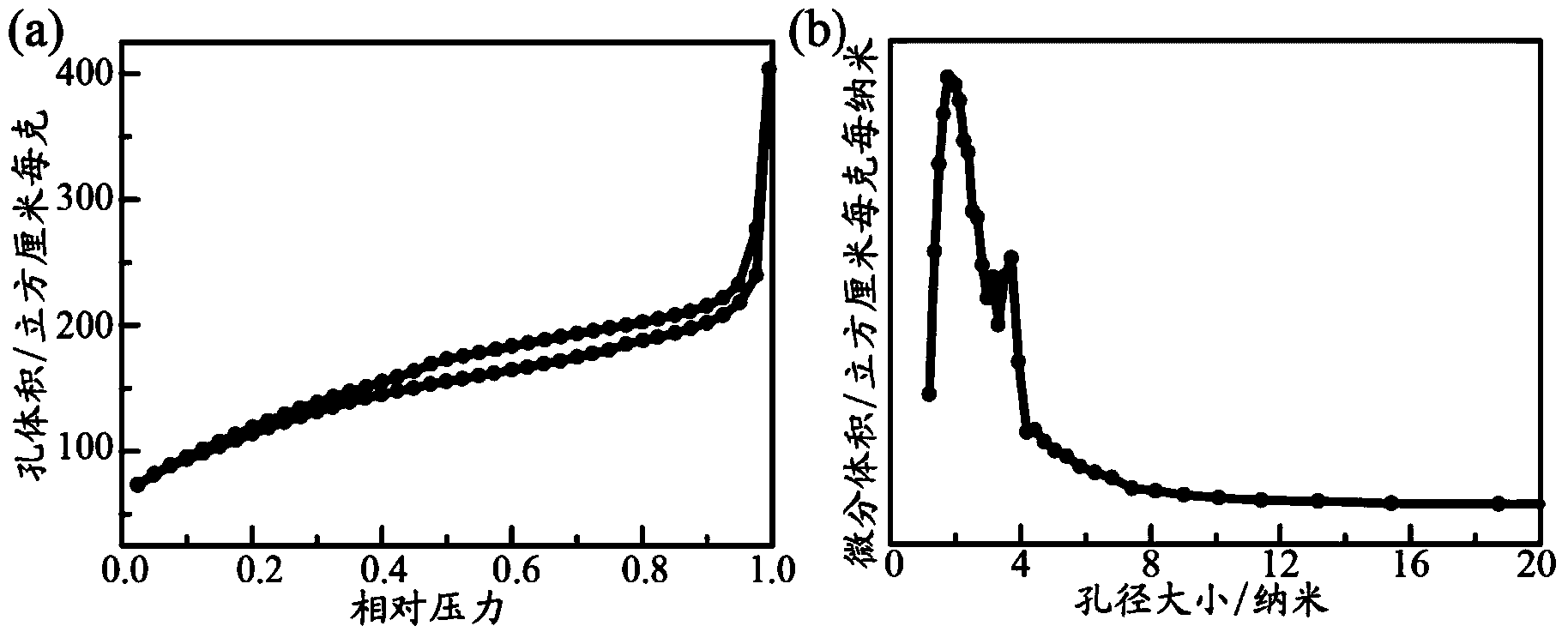

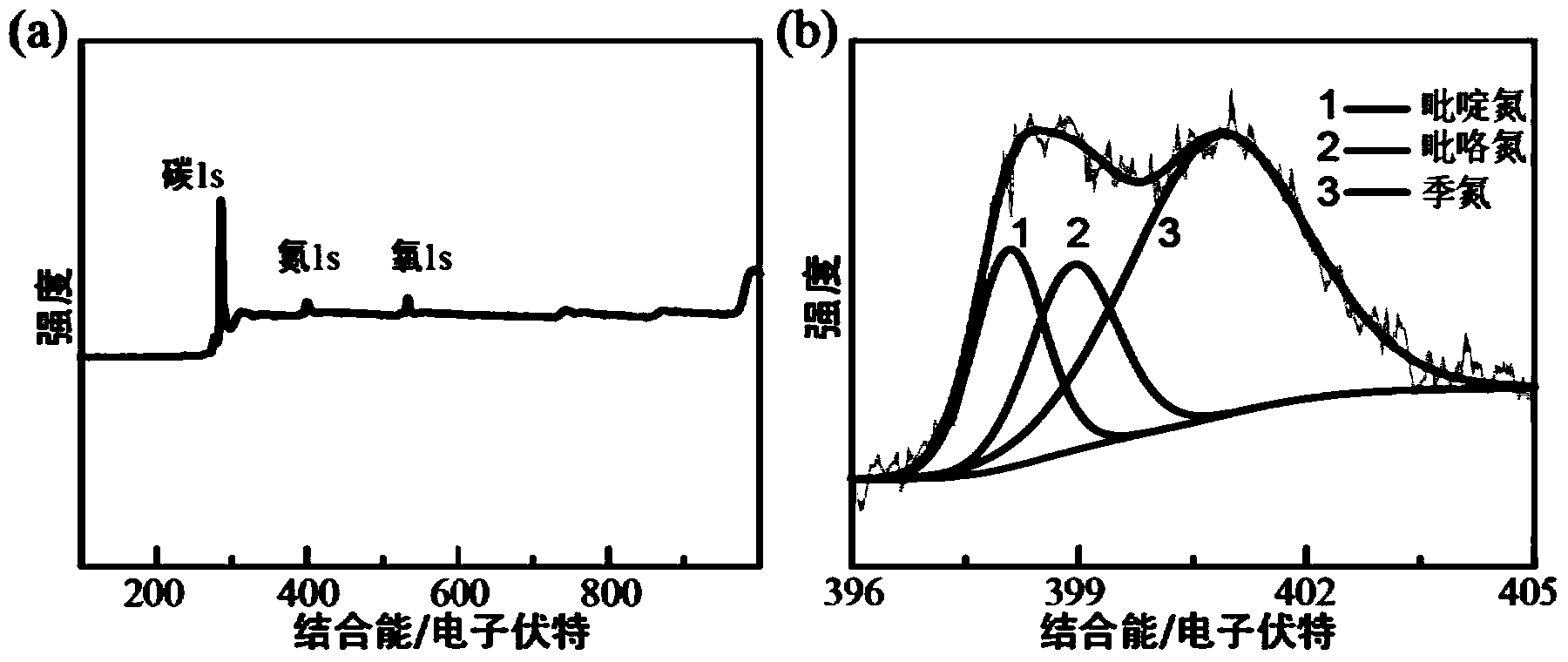

[0039] After ultrasonically dispersing 20mg of carbon nanotubes (40nm to 60nm in diameter and 5μm to 15μm in length) in 10mL of water for 1 hour, add 800mg of glucose and transfer it to a 25mL high-pressure tank lined with polytetrafluoroethylene after it is completely dissolved. In the reaction kettle, then carry out hydrothermal reaction at a temperature of 180°C for 15 hours, wash with water and ethanol several times, and filter with suction to obtain a solid, which is dried at 60°C overnight to obtain a surface coated with a thickness of about 25 to 35 The carbon nanotube of nano carbonaceous layer; After the carbon nanotubes and melamine that the obtained surface is covered with carbonaceous layer are mixed with the ratio of 1:10 with mass ratio, transfer to porcelain boat, and put into the tube furnace In the quartz tube, deair with argon for half an hour, then raise the temperature to 900° C., and perform heat treatment for two hours under the protection of argon to obta...

Embodiment 2

[0052] Prepare the composite material of nitrogen-doped porous carbon-coated carbon nanotubes basically according to the same method as Example 1, the difference is that the 900 ° C used in the heat treatment is changed to 800 ° C, the specific surface area of the obtained composite material is 101m 2 / g, wherein the thickness of the nitrogen-doped porous carbon-coated shell is about 30-40 nanometers, and the content of nitrogen atoms is 15.76%.

Embodiment 3

[0054] Prepare the composite material of nitrogen-doped porous carbon-coated carbon nanotubes basically according to the same method as Example 1, the difference is that the 900 ° C used in the heat treatment is changed to 1000 ° C, and the specific surface area of the obtained composite material is 479m 2 / g, wherein the thickness of the nitrogen-doped porous carbon-coated shell is about 10-20 nanometers, and the content of nitrogen atoms is 3.54%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com