Water-soluble three-dimensional network type electrode binding agent and preparation method thereof, electrode piece and preparation method thereof, and electrochemical devices

A three-dimensional network, water-soluble technology, applied in electrode manufacturing, battery electrodes, circuits, etc., can solve the problems of long-term cycle performance and high-rate charge-discharge performance of batteries, poor mechanical properties of electrode sheets, and poor long-distance connectivity. , to achieve the effect of small irreversible capacity loss, small side reaction and high specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

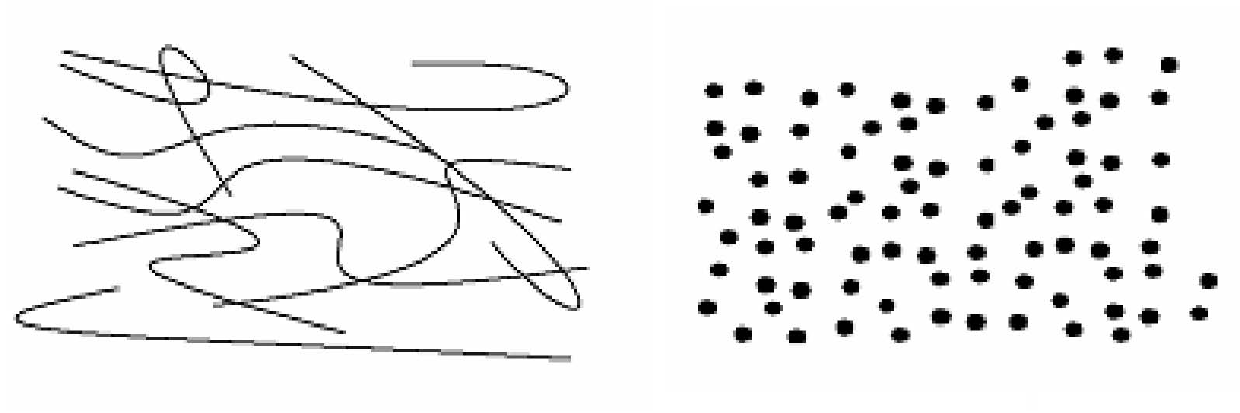

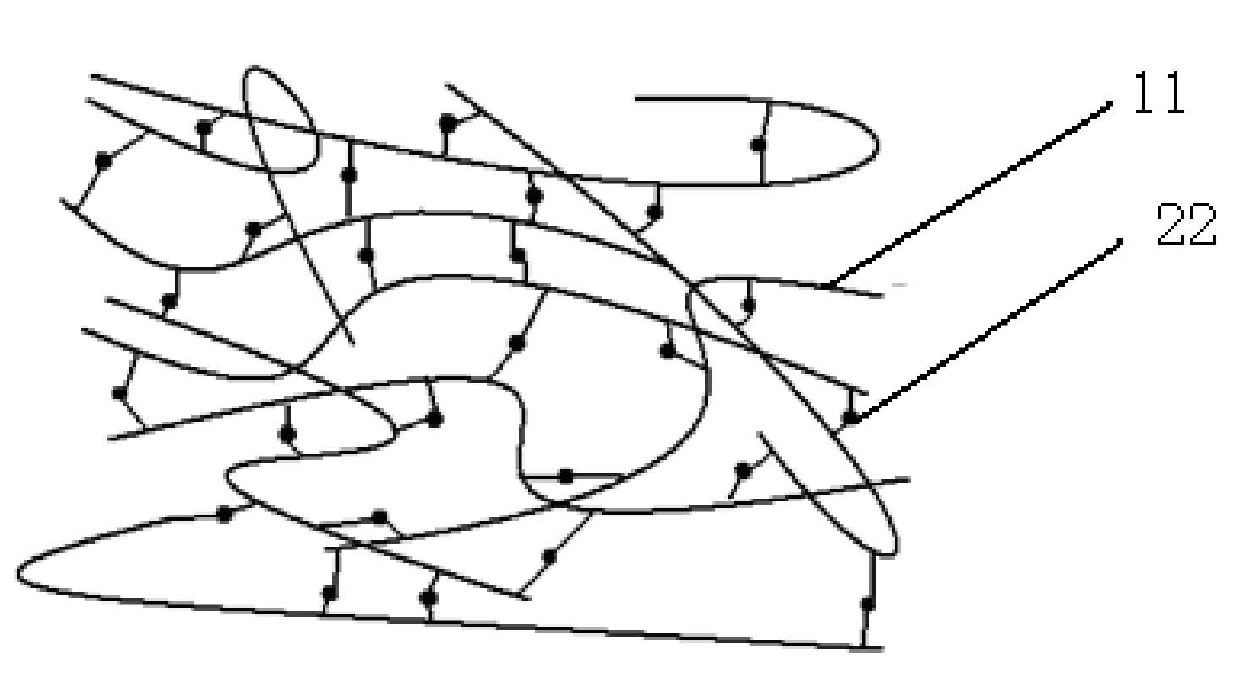

Problems solved by technology

Method used

Image

Examples

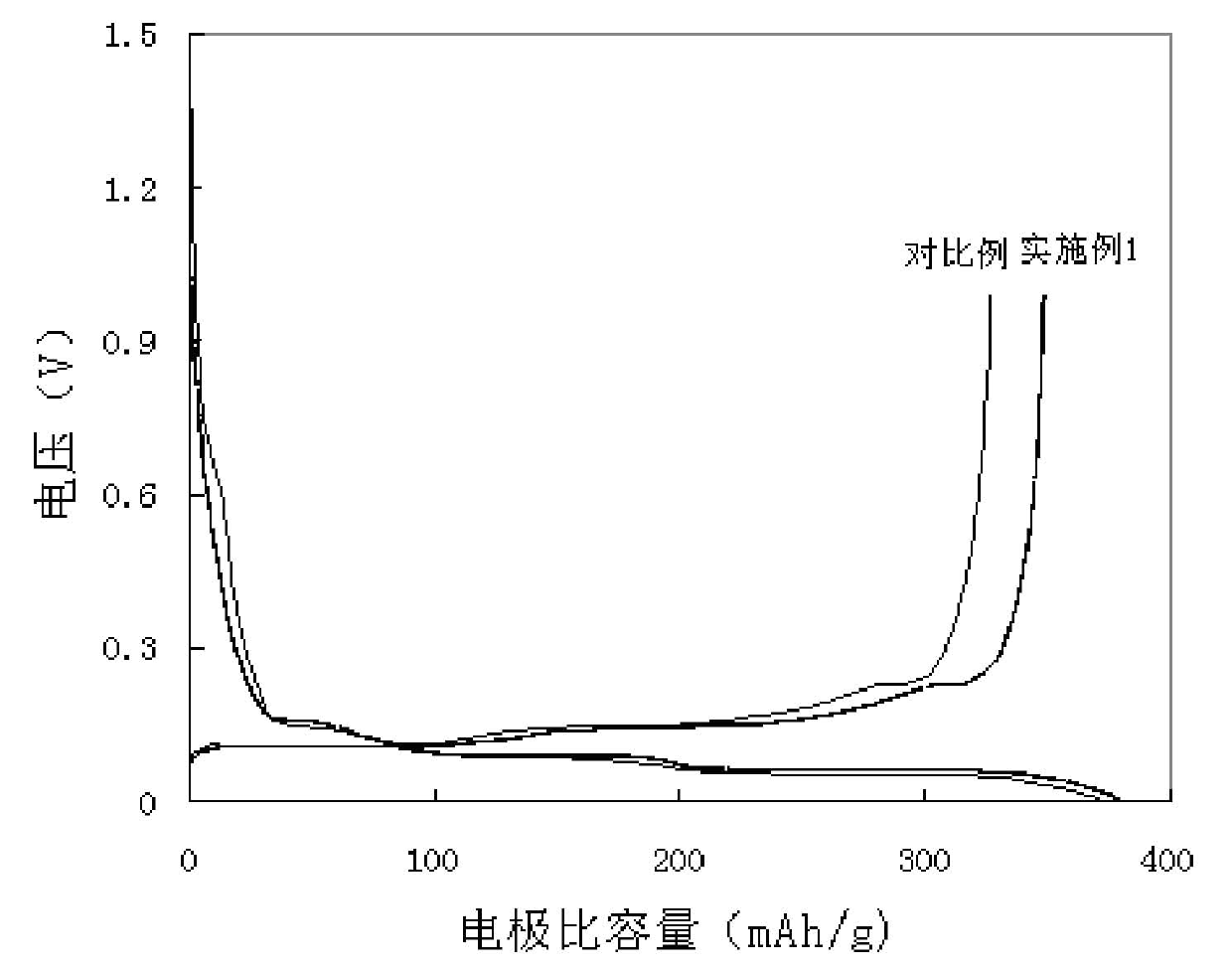

Embodiment 1

[0045](1) Sodium alginate polyelectrolyte is dissolved in water, the concentration is 2%, fully stirred to obtain uniform water-soluble polyelectrolyte aqueous solution;

[0046] (2) In the aqueous solution of sodium alginate, add Ca 2+ aqueous solution, such as CaNO 3 , CaCl 2 Aqueous solution, where Ca 2+ The molar ratio to the carboxyl group in sodium alginate is 0.08, stir for 2 to 4 hours to make Ca 2+ By building bridges between polyelectrolyte molecular chains, the viscosity of the system increases by 2 to 3 times;

[0047] (3) form three-dimensional network type alginic acid polymer hydrosol by cross-linking, that is, the water-soluble three-dimensional network type binder of the present invention and spherical graphite electrode active material are mixed and pulped, and the dry weight of the control cross-linked alginic acid macromolecule is electrode 5% of the total weight, fully stirred to make the slurry fully mixed evenly;

[0048] (4) adjust the viscosity of...

Embodiment 2

[0052] (1) sodium pectate polyelectrolyte is dissolved in water, concentration is 4%, fully stirs to obtain uniform water-soluble polyelectrolyte aqueous solution;

[0053] (2) Add Cu containing Cu to the aqueous solution of sodium pectate 2+ aqueous solution, such as CuNO 3 , CuCl 2 aqueous solution, wherein the molar ratio of Cu ions to pectinic acid active groups is 0.12, stirred for 2 to 4 hours to make Cu 2+ By building bridges between polyelectrolyte molecular chains, the viscosity of the system increases by 2 to 3 times;

[0054] (3) form three-dimensional network type sodium pectate macromolecular hydrosol by crosslinking namely water-soluble three-dimensional network type binding agent of the present invention and spherical graphite electrode active material mix pulping, control crosslinking sodium pectate macromolecule The dry weight is 6% of the total weight of the electrode, stir well to make the slurry fully mixed evenly;

[0055] (4) adjust the viscosity of s...

Embodiment 3

[0059] (1) Sodium gellan gumate polyelectrolyte is dissolved in water, the concentration is 3%, fully stirred to obtain a uniform water-soluble polyelectrolyte aqueous solution;

[0060] (2) Add polydimethyldiallyl ammonium chloride in the aqueous solution of sodium gellan gum acid, the molar ratio of polydimethyldiallyl ammonium chloride and sodium pectate active group is 0.05, stir For 2 to 4 hours, the polydimethyldiallylammonium chloride bridges the polyelectrolyte molecular chains, and the viscosity of the system increases by 2 to 3 times;

[0061] (3) cross-linking to form a three-dimensional network type sodium gellanate macromolecule hydrosol and spherical graphite electrode active material mixed slurrying, control the dry weight of the crosslinked sodium gellanate macromolecule to be 5% of the total weight of the electrode, fully Stir to fully mix the slurry evenly;

[0062] (4) adjust the viscosity of slurry, control the viscosity of slurry at 900 centipoise;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com