Preparation method of lithium iron phosphate cathode material pole piece

A technology of lithium ferrous phosphate and cathode material, applied in electrode manufacturing, battery electrode, vapor deposition manufacturing, etc., can solve the problem of low tap density, low volume specific energy of lithium ferrous phosphate material, hindering lithium ion and electron transfer rate and other problems, to achieve the effects of convenient preparation, simple structure and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

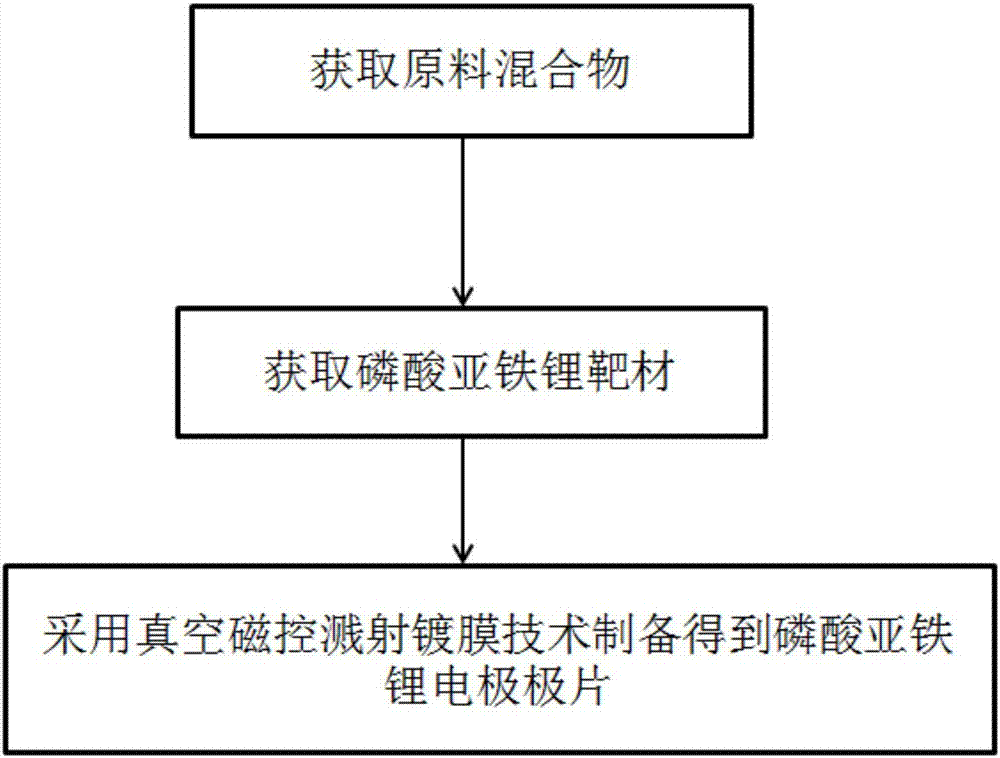

[0025] Such as figure 1 As shown, the preparation method of a lithium iron phosphate cathode material pole piece of the present embodiment comprises the following steps:

[0026] (1) Using lithium carbonate, ferrous oxalate and ammonium dihydrogen phosphate as raw materials and mixing them uniformly by grinding to obtain a raw material mixture;

[0027] (2) The raw material mixture was pre-calcined at 350°C for 2 hours in an inert atmosphere, ground into powder, and made into a circular green body with a diameter of 65mm and a thickness of 5mm under a pressure of 20MPa, and then calcined at 600°C for 10h under an inert atmosphere, and It was lowered to room temperature in 1 hour, and finally a lithium iron phosphate target was obtained;

[0028] (3) Place the prepared lithium iron phosphate target and graphite target in a high-vacuum magnetron sputtering coating equipment, using vacuum magnetron sputtering coating technology, specifically radio frequency magnetron sputtering ...

Embodiment 2

[0032] Such as figure 1 As shown, the preparation method of a lithium iron phosphate cathode material pole piece of the present embodiment comprises the following steps:

[0033] (1) Using lithium carbonate, ferrous oxalate and ammonium dihydrogen phosphate as raw materials and mixing them uniformly by grinding to obtain a raw material mixture;

[0034] (2) Pre-calcine the raw material mixture under an inert atmosphere at 320°C for 1 hour, grind it into powder, and make a circular green body with a diameter of 60 mm and a thickness of 3 mm under a pressure of 10 MPa, and then calcinate it at an inert atmosphere at 580°C for 9 hours, and Take 0.5h to cool it down to room temperature, and finally get the lithium iron phosphate target;

[0035] (3) Place the prepared lithium iron phosphate target and graphite target in a high-vacuum magnetron sputtering coating equipment, using vacuum magnetron sputtering coating technology, specifically radio frequency magnetron sputtering meth...

Embodiment 3

[0039] Such as figure 1 As shown, the preparation method of a lithium iron phosphate cathode material pole piece of the present embodiment comprises the following steps:

[0040] (1) Using lithium carbonate, ferrous oxalate and ammonium dihydrogen phosphate as raw materials and mixing them uniformly by grinding to obtain a raw material mixture;

[0041] (2) The raw material mixture was pre-calcined at 370°C for 3 hours in an inert atmosphere, ground into powder, and made into a circular green body with a diameter of 70mm and a thickness of 8mm under a pressure of 30MPa, and then calcined at 620°C for 11h under an inert atmosphere, and Take 1.5h to cool it down to room temperature, and finally get the lithium iron phosphate target;

[0042] (3) Place the prepared lithium iron phosphate target and graphite target in a high-vacuum magnetron sputtering coating equipment, using vacuum magnetron sputtering coating technology, specifically radio frequency magnetron sputtering method...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com