Application of alginate as a binder in the preparation of electrode sheets

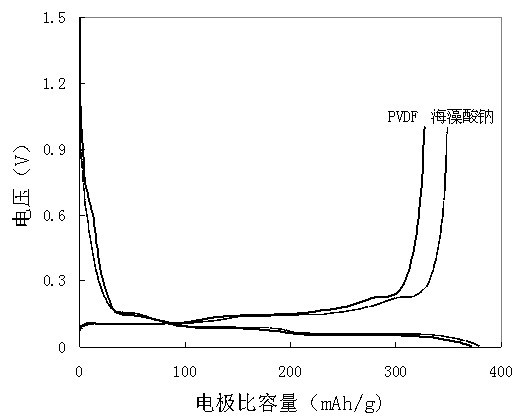

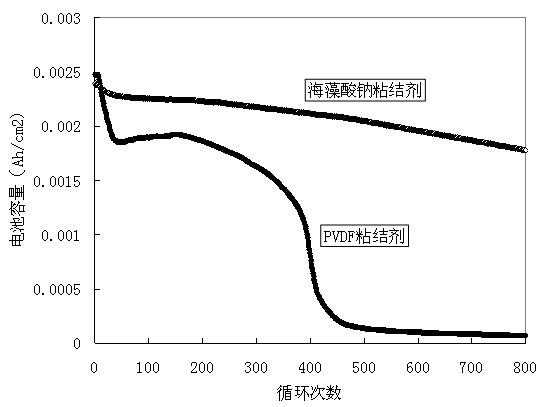

A technology for preparing electrodes from alginate, which is applied to battery electrodes, circuits, electrical components, etc., to achieve the effects of small irreversible capacity loss, good cycle stability, and extended cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Application of sodium alginate as a binder in the preparation of electrode sheets. Utilize sodium alginate binding agent to prepare electrode sheet, comprise the steps:

[0031] (1) Get 2 grams of sodium alginate and dissolve it in 98 grams of water, fully stir to obtain a 2% uniform and viscous sodium alginate aqueous solution;

[0032] (2) Mix the prepared sodium alginate aqueous solution with 33.3 grams of spherical natural graphite electrode material (at this time, the dry weight of the sodium alginate binder is 6% of the dry weight of the electrode), 4000 rpm Stir fully at high speed to make the slurry fully mixed evenly;

[0033] (3) Control the viscosity of the slurry at 800~1000 centipoise;

[0034] (4) The prepared slurry is evenly coated and dried on a coating machine, and the thickness of the electrode after drying is between 40 and 120 mm;

[0035] (5) Use a pair of roller presses to control the pressure of 10 to 20 atmospheres to press the prepared elect...

Embodiment 2

[0053] Application of lithium alginate as a binder in the preparation of electrode sheets. Utilize lithium alginate binding agent to prepare electrode sheet, comprise the steps:

[0054] (1) Get 4 gram lithium alginate and be dissolved in 96 grams of water, fully stir and make 4% uniform viscous lithium alginate aqueous solution;

[0055] (2) Mix the prepared lithium alginate aqueous solution with 66.7 grams of spherical natural graphite electrode material (at this time, the dry weight of the lithium alginate binder is 6% of the dry weight of the electrode), 4000 rpm Stir fully at high speed to make the slurry fully mixed evenly;

[0056] (3) Control the viscosity of the slurry to be 800~1000 centipoise;

[0057] (4) The prepared slurry is evenly coated and dried on a coating machine, and the thickness of the electrode after drying is between 40 and 120 mm;

[0058] (5) Use a pair of roller presses to control the pressure of 10 to 20 atmospheres to press the prepared electr...

Embodiment 3

[0060] Application of potassium alginate as a binder in the preparation of electrode sheets. Utilize potassium alginate binding agent to prepare electrode sheet, comprise the steps:

[0061] (1) Get 3 grams of potassium alginate and dissolve it in 97 grams of water, fully stir to obtain 3% evenly viscous potassium alginate aqueous solution;

[0062] (2) Mix the prepared potassium alginate aqueous solution with 50 grams of spherical natural graphite electrode material (at this time, the dry weight of the lithium alginate binder is 6% of the dry weight of the electrode), 4000 rpm Stir fully at high speed to make the slurry fully mixed evenly;

[0063] (3) Control the viscosity of the slurry to be 800~1000 centipoise;

[0064] (4) The prepared slurry is evenly coated and dried on a coating machine, and the thickness of the electrode after drying is between 40 and 120 mm;

[0065] (5) Use a pair of roller presses to control the pressure of 10 to 20 atmospheres to press the prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com