Compound lithium cobaltate cathode material, preparing method and application thereof

A technology for compounding lithium cobalt oxide and cathode materials, which is applied in electrode manufacturing, battery electrodes, and final product manufacturing, etc., can solve the problems of poor rate cycle performance and poor electrochemical performance of lithium cobalt oxide, etc. Chemical properties, high volume specific energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

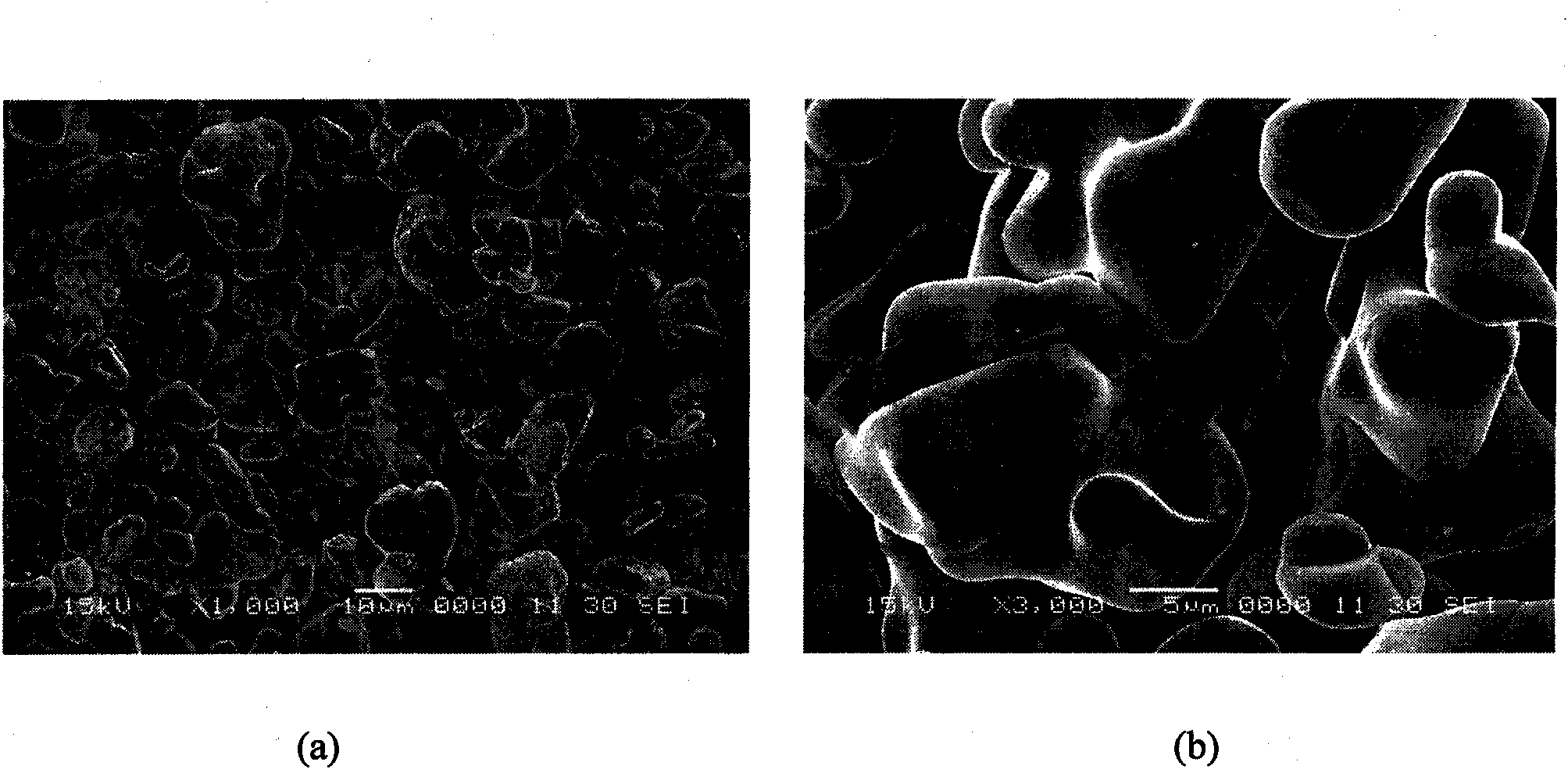

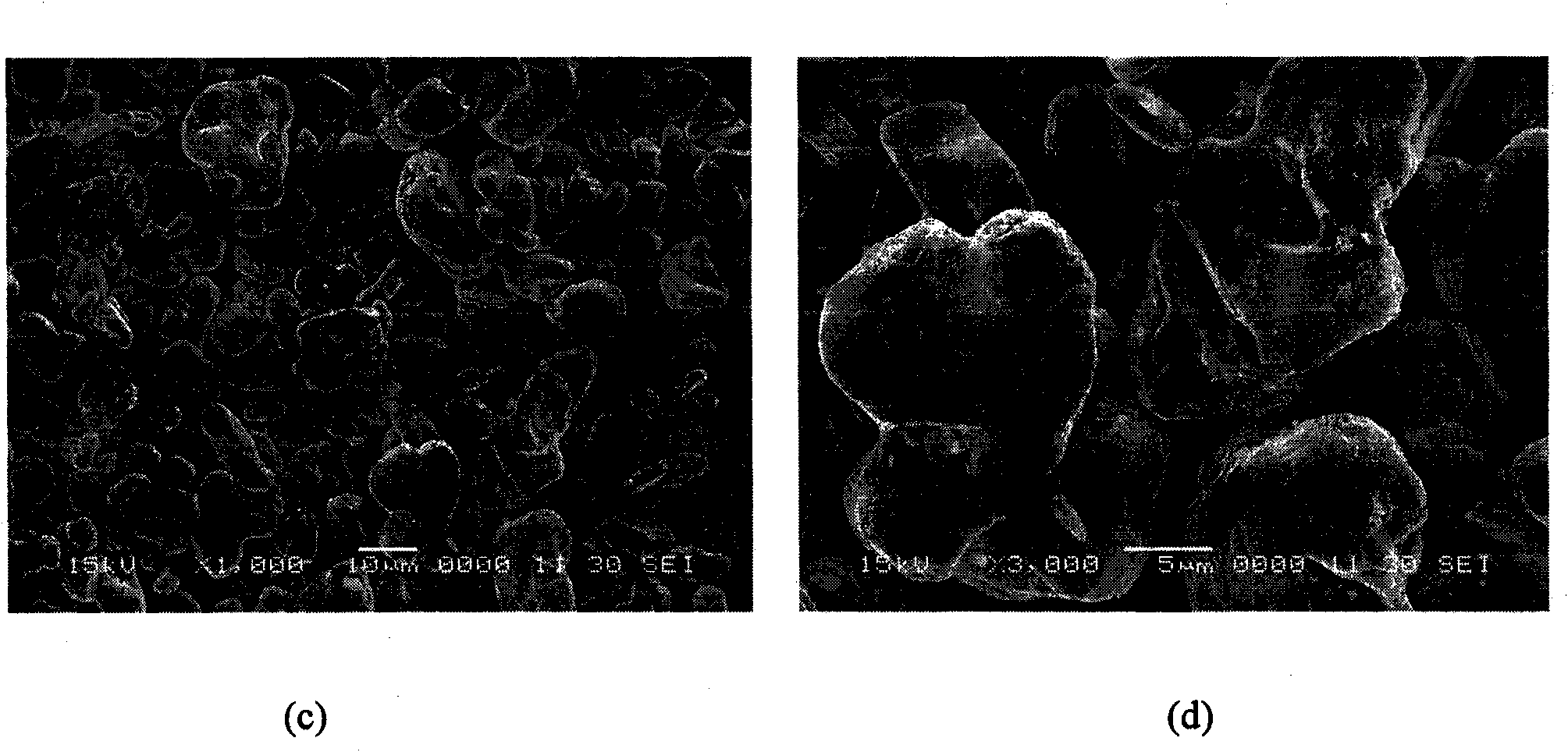

[0018] Mix tricobalt tetroxide and lithium carbonate in an appropriate amount, sinter at 850°C for 24 hours in an air atmosphere, and then use a mortar to crush it into a lithium cobalt oxide material with a particle size of about 14 microns, and then mix it with ternary nickel cobalt manganese oxide (including nickel cobalt manganese The ratio is 1:1:1) and then sintered at 850° C. for 8 to 16 hours after mixing to make an active material for positive electrode. The ternary nickel-cobalt-manganese can be prepared by the following method: mix the hydroxide containing nickel-cobalt-manganese and lithium carbonate in an appropriate amount, sinter at 800°C for 24 hours in an air atmosphere, and then crush it into particles with a particle size of about 3 microns.

[0019] Copper foil is used as the current collector of the negative electrode, aluminum foil is used as the current collector of the positive electrode, the sintered lithium cobaltate is used as the positive electrode a...

Embodiment 2

[0021] Make 053048 prismatic lithium-ion battery according to the above method, the battery active material used is lithium cobaltate, wherein the content of ternary nickel-cobalt-manganese oxide lithium (wherein the ratio of nickel-cobalt-manganese is 1:1:1) is 0.6%, then The arithmetic average result of the battery capacity shows that the capacity of the battery 0.2C5A is 690 mAh, and the volume specific energy is 354Wh / l. The 100-cycle retention rate was 94.5%.

Embodiment 3

[0023] Make 053048 square lithium-ion battery according to the above method, the battery active material used is lithium cobaltate, wherein the content of ternary nickel-cobalt-manganese oxide lithium (wherein the ratio of nickel-cobalt-manganese is 1:1:1) is 1.5%, then The battery has a capacity of 682mAh and a volume specific energy of 350Wh / l. The 100-cycle retention rate was 94.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com