Method for manufacturing square power polymer lithium ion battery

A lithium-ion battery and power-type technology, which is applied in the field of square-shaped power-shaped polymer lithium-ion battery production, can solve the problems affecting the manufacturing yield and safety of polymer lithium-ion batteries, the increase of battery automatic discharge rate, and the change of battery working time. Short and other problems, to achieve the effect of reducing design cost, strong horsepower, and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Such as Figure 1-Figure 8 As shown, the present invention is achieved in this way, a method for making a square power type polymer lithium ion battery is characterized in that the method steps are as follows:

[0037] (1) Batching; the batching process is the same as the conventional battery batching process, and the positive and negative electrode powders are compacted by continuous rolling equipment to improve the bonding performance of the powder and reduce the thickness of the dressing

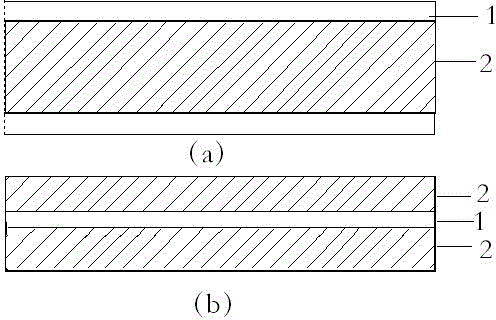

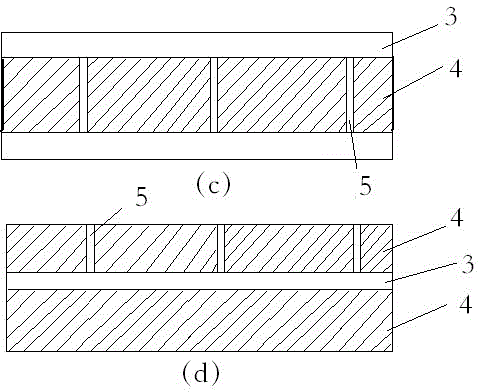

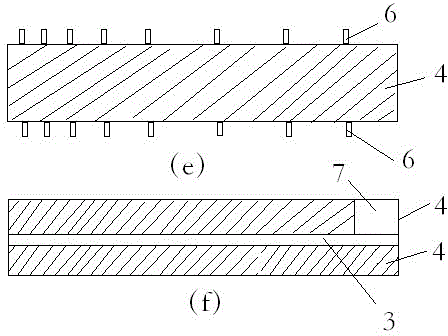

[0038] (2) Coating: Coating is carried out according to the battery design process. The positive electrode is coated with aluminum foil 1 with a thickness of 20um, and the positive electrode material 2 is evenly coated on both sides of the aluminum foil 1 through a coating machine; The material 4 is evenly coated on both sides of the copper foil 3 by the coating machine;

[0039] (3) Positive and negative electrode roll pressing: After the positive and negative electrodes are coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com