Lithium ion battery negative electrode single-side pre-lithiation method using three-dimensional foil

A lithium-ion battery, pre-lithiation technology, applied in the direction of battery electrodes, electrode manufacturing, electrode carrier/collector, etc., can solve the problems of silicon carbon/graphite electrode expansion and powder loss life, low capacity, etc., to achieve the required time for operation Effects of shortening, improving cycle life, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

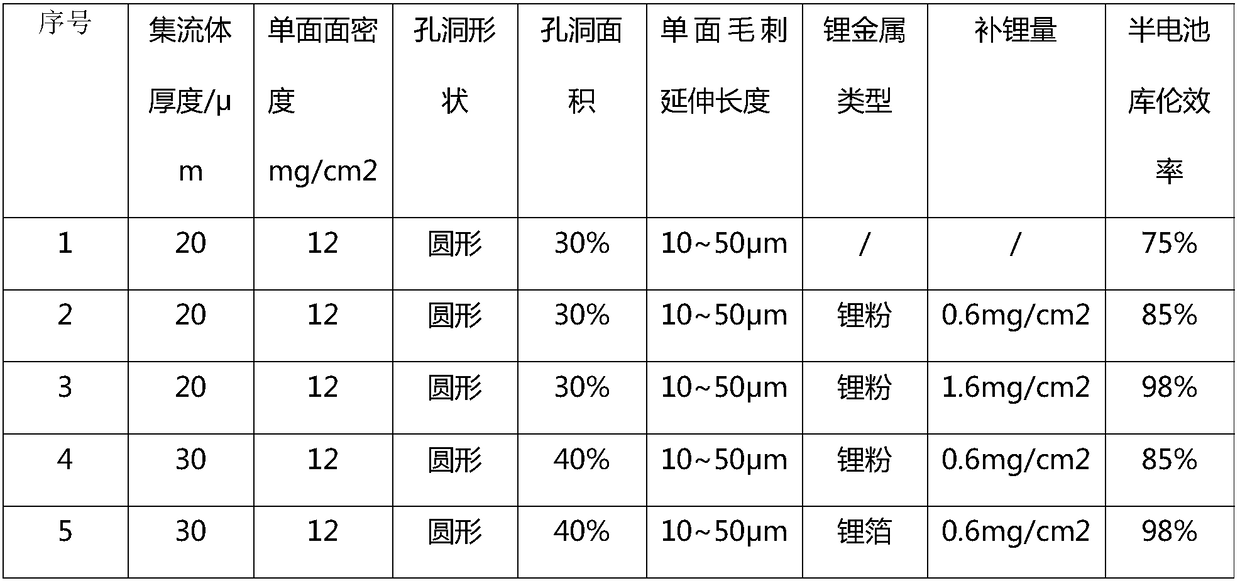

[0036] Embodiment one, silicon oxide, lithium metal powder, composite amount is at 0.6mg / cm2

[0037] 1) Using a double planetary mixer, according to the ratio of silicon oxide / graphite / conductive agent / binder = 7% / 83% / 5% / 5%, prepare negative electrode slurry;

[0038] 2) Using roller coating equipment, according to the single surface density of 12mg / cm2, the above-mentioned negative electrode slurry is coated on a three-dimensional current collector with circular holes with a diameter of 0.5mm, a hole ratio of 30%, and a thickness of 20μm, and rolled to 170μm ;

[0039] 3) using pre-lithiation composite equipment, coating 0.6mg / cm2 of lithium metal powder on the surface of the above-mentioned pole piece, that is, obtaining the negative electrode pole piece after pre-lithiation;

[0040] 4) Assemble the above-mentioned lithium metal powder-composited pole piece, positive electrode, and diaphragm, inject an appropriate amount of electrolyte solution after baking, and form it t...

Embodiment 2

[0042] Embodiment two, silicon oxide, lithium metal powder, composite amount is at 1.6mg / cm2

[0043] 1) Using a double planetary agitator, according to the ratio of silicon oxide / graphite / conductive agent / binder = 30% / 60% / 5% / 5%, prepare negative electrode slurry;

[0044] 2) Using roller coating equipment, according to the single surface density of 7.5mg / cm2, the above-mentioned negative electrode slurry is coated on a three-dimensional current collector with a circular hole in diameter of 0.5mm, a hole ratio of 30%, and a thickness of 20μm, and rolled to 127μm;

[0045]3) using pre-lithiation composite equipment, coating 1.6mg / cm2 of lithium metal powder on the surface of the above-mentioned pole piece to obtain the negative electrode pole piece after pre-lithiation;

[0046] 4) Assemble the above-mentioned lithium metal powder-composited pole piece, positive electrode, and diaphragm, inject an appropriate amount of electrolyte solution after baking, and form it to obtain a...

Embodiment 3

[0048] Embodiment three, silicon, lithium metal powder, composite amount is at 0.6mg / cm

[0049] 1) Using a double planetary mixer, according to the ratio of silicon / graphite / conductive agent / binder = 2.5% / 87.5% / 5% / 5%, prepare negative electrode slurry;

[0050] 2) Using roller coating equipment, according to the single surface density of 12mg / cm2, the above-mentioned negative electrode slurry is coated on a three-dimensional current collector with circular holes with a diameter of 0.5mm, a hole ratio of 30%, and a thickness of 20μm, and rolled to 170μm ;

[0051] 3) using pre-lithiation composite equipment, coating 0.6mg / cm2 of lithium metal powder on the surface of the above-mentioned pole piece, that is, obtaining the negative electrode pole piece after pre-lithiation;

[0052] 4) Assemble the above-mentioned lithium metal powder-composited pole piece, positive electrode, and diaphragm, inject an appropriate amount of electrolyte solution after baking, and form it to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com