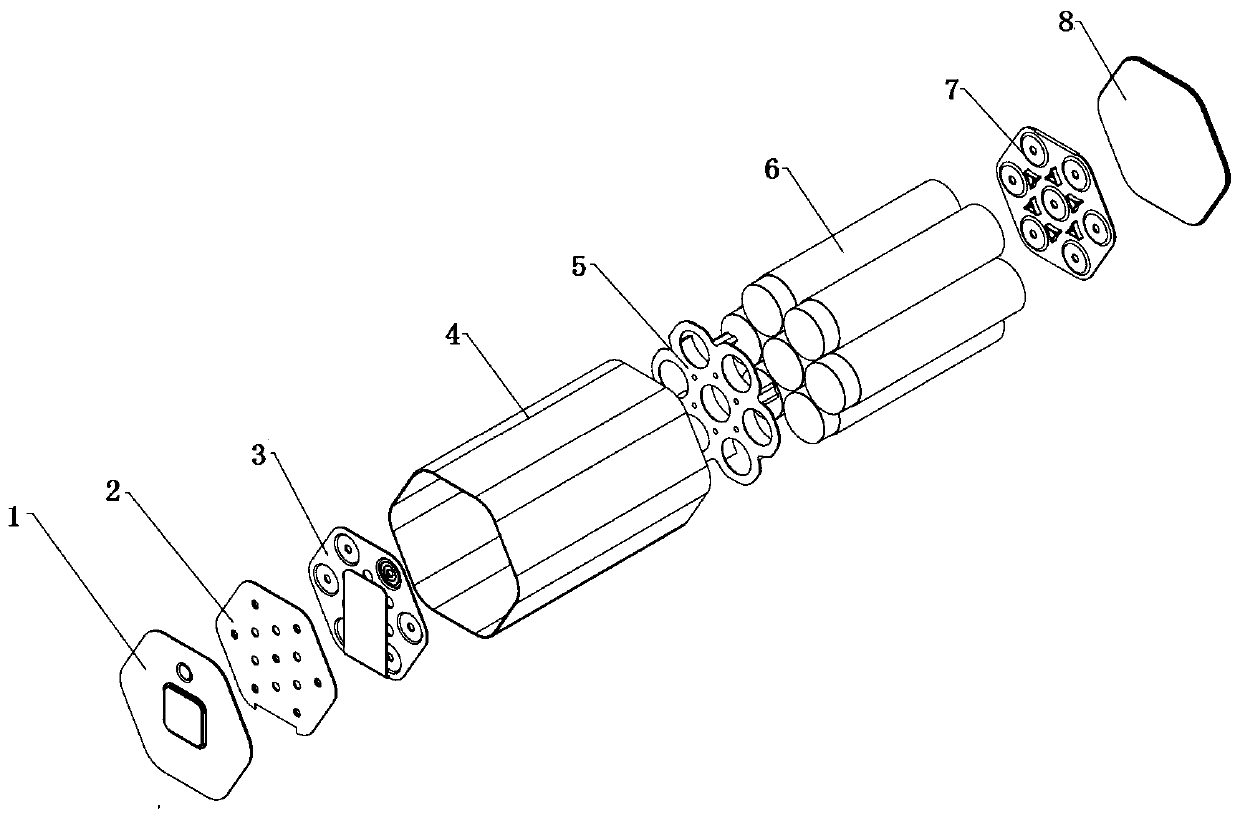

High-capacity battery and manufacturing method thereof

A production method and high-capacity technology, applied in the manufacture of secondary batteries, secondary batteries, cylindrical shell batteries/batteries, etc., can solve the problems of poor insulation and thermal conductivity, inability to improve heat dissipation, rate performance life, poor heat dissipation, etc. , to achieve the effect of improving heat dissipation, shortening the welding path, and reducing the internal resistance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

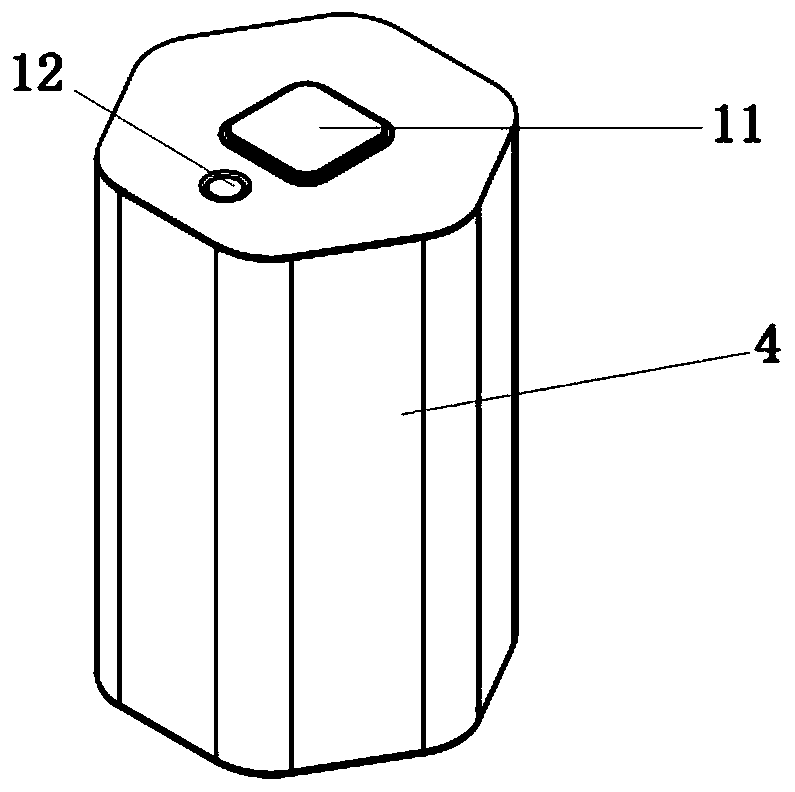

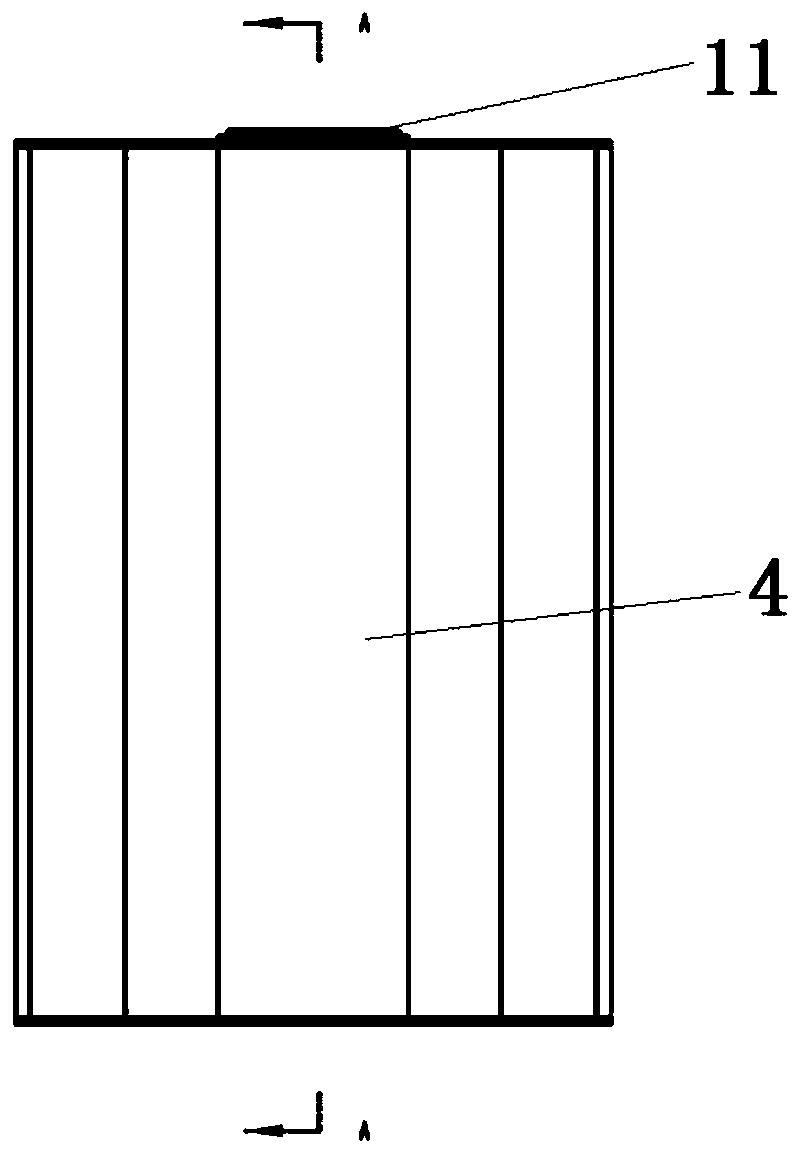

Embodiment 1

[0078] The electrodeless cylindrical core inside the large-capacity battery of the present invention is composed of positive and negative electrodes of the same system, such as lithium iron phosphate-graphite core, lithium manganate-graphite core, nickel-cobalt lithium manganate-graphite core, cobalt Lithium oxide-graphite core, lithium cobaltate-lithium titanate core, lithium manganate-lithium titanate core, supercapacitor core, metal hydride-nickel core, cadmium-nickel core, zinc-nickel coil Any of chemical power sources such as cores, and are not limited to the above systems.

Embodiment 2

[0080] The tabless cylindrical winding core inside the large-capacity battery of the present invention can be combined with winding cores of different material systems, such as the combination of lithium manganese oxide-graphite winding core and nickel-cobalt lithium manganese oxide-graphite winding core, power-type super capacitor winding core Combination with energy-type lithium-ion winding cores of similar positive electrode materials, etc. Two types of winding cores with different characteristics are combined in parallel to form a large-capacity battery, which improves performance while reducing costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com