Method for compounding graphene and metallic oxide/metallic compound and composite material thereof

A technology of metal compounds and oxides, which is applied in the field of synthesis and compounding of nanomaterials, to achieve the effects of good dispersion, lower impedance and uniform compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

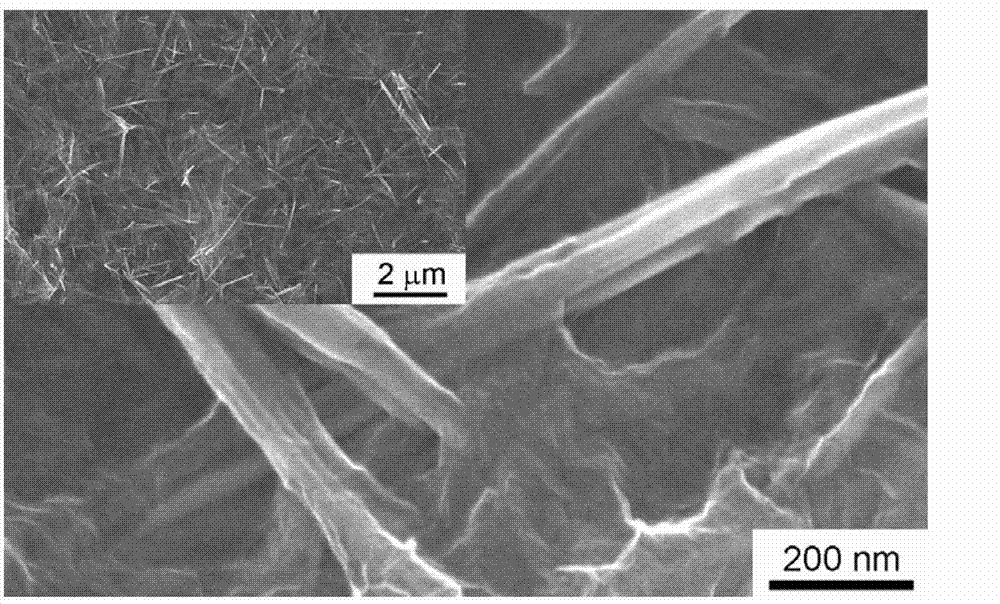

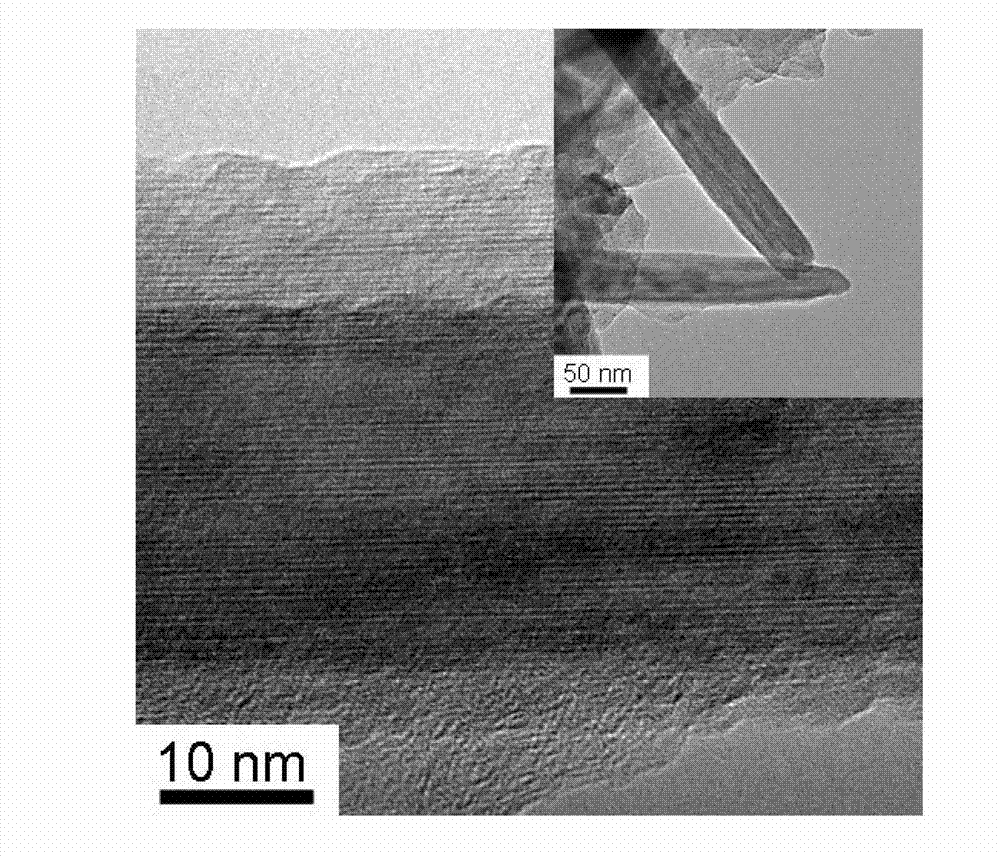

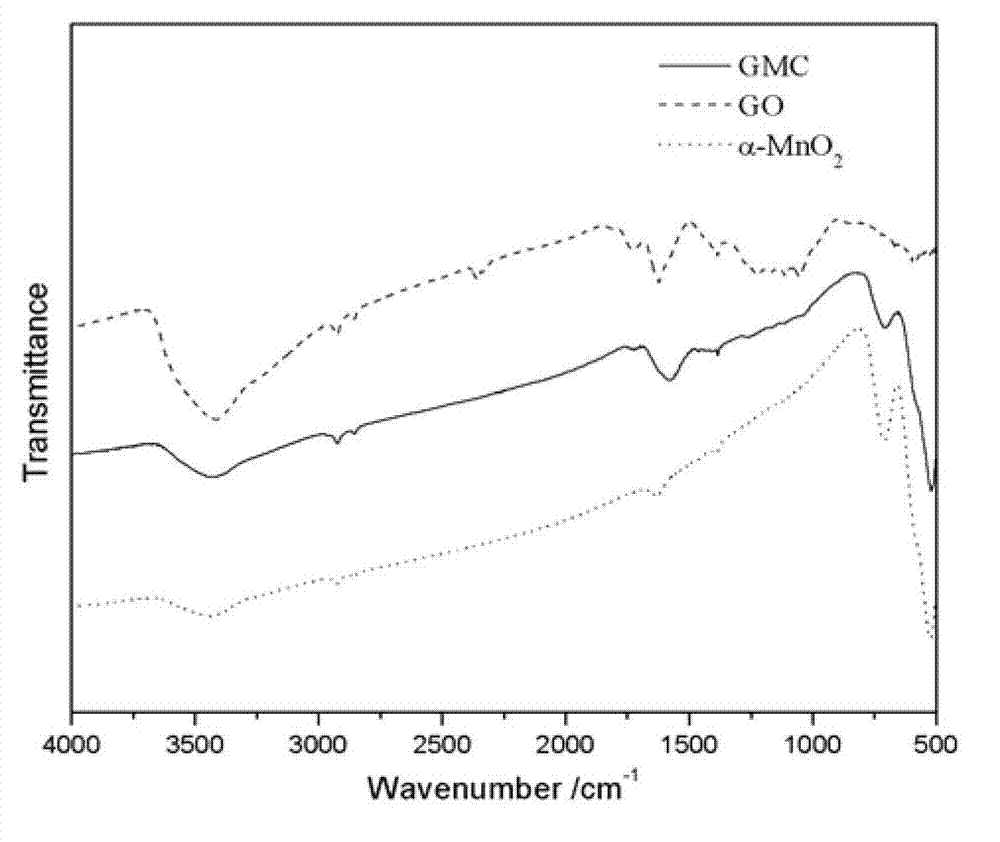

[0029] a. graphene oxide is dissolved in deionized water to make a pH value of 6.5 (to ensure the solubility of graphene in solution), and the concentration is a graphene oxide solution of 1 mg / mL;

[0030] b. Put 0.01g of manganese oxide nanowires into 20ml of graphene oxide aqueous solution with a concentration of 1mg / mL, mix the mixture ultrasonically for 2 hours (to ensure sufficient dispersion of manganese oxide in graphene aqueous solution) and put the mixed solution into Put into a hydrothermal kettle, react at 90° C. for 36 hours, filter with suction after the reaction, wash, then dry at 60° C. to obtain graphene and metal oxide / metal compound composite material.

[0031] In this embodiment, replacing deionized water with one or more mixtures of ethylene glycol and isopropanol can achieve the purpose of the invention.

[0032] In this embodiment, manganese oxide is replaced by manganese hydroxide, cobalt oxide, cobalt hydroxide, iron oxide, iron hydroxide, zinc oxide, ...

Embodiment 2

[0034] a. graphene oxide is dissolved in ethylene glycol to make a pH value of 6.5, and the concentration is a graphene oxide solution of 0.5 mg / mL (to ensure the solubility of graphene in the solution);

[0035] b. Put 0.005g of CoOOH nanoparticles into 20ml of graphene oxide aqueous solution with a concentration of 0.5mg / mL, mix the mixture ultrasonically for 1 hour (to ensure sufficient dispersion of CoOOH in the graphene aqueous solution), and then put the mixed solution into water In a hot kettle, react at 70°C for 32 hours, suction filter, wash after the reaction, and then dry at 55°C to obtain graphene and metal oxide / metal compound composites.

[0036] In this embodiment, replacing ethylene glycol with one or more mixtures of deionized water and isopropanol can achieve the purpose of the invention.

[0037] In this embodiment, manganese hydroxide is replaced by manganese oxide, cobalt oxide, cobalt hydroxide, iron oxide, iron hydroxide, zinc oxide, zinc hydroxide, titani...

Embodiment 3

[0039] a. graphene oxide is dissolved in isopropanol to make a pH value of 6 and a concentration of graphene oxide solution of 20mg / mL (to ensure the solubility of graphene in the solution);

[0040] b. Add 0.1g of cobalt oxide (Co 3 o 4 ) nanoparticles into 20ml concentration of 20mg / mL graphene oxide aqueous solution, the mixture was ultrasonically mixed for 3 hours (to ensure sufficient dispersion of cobalt oxide in the graphene aqueous solution) and then put the mixed solution into a hydrothermal kettle, React at 120°C for 40 hours, after the reaction, suction filter, wash, and then dry at 60°C to obtain graphene and metal oxide / metal compound composites.

[0041] In this embodiment, the purpose of the invention can be achieved by replacing isopropanol with one or more mixtures of ethylene glycol and deionized water.

[0042] In this embodiment, cobalt oxide is replaced by manganese hydroxide, manganese oxide, cobalt hydroxide, iron oxide, iron hydroxide, zinc oxide, zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com