Nitrogen-doped graphene-silicon composite negative pole material, preparation method thereof, and lithium ion battery

A technology of nitrogen-doped graphene and silicon composite materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of unfavorable lithium-ion battery cycle performance and poor graphite outer coating effect, so as to improve the first-time efficiency and reduce the Expansion rate and effect of improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

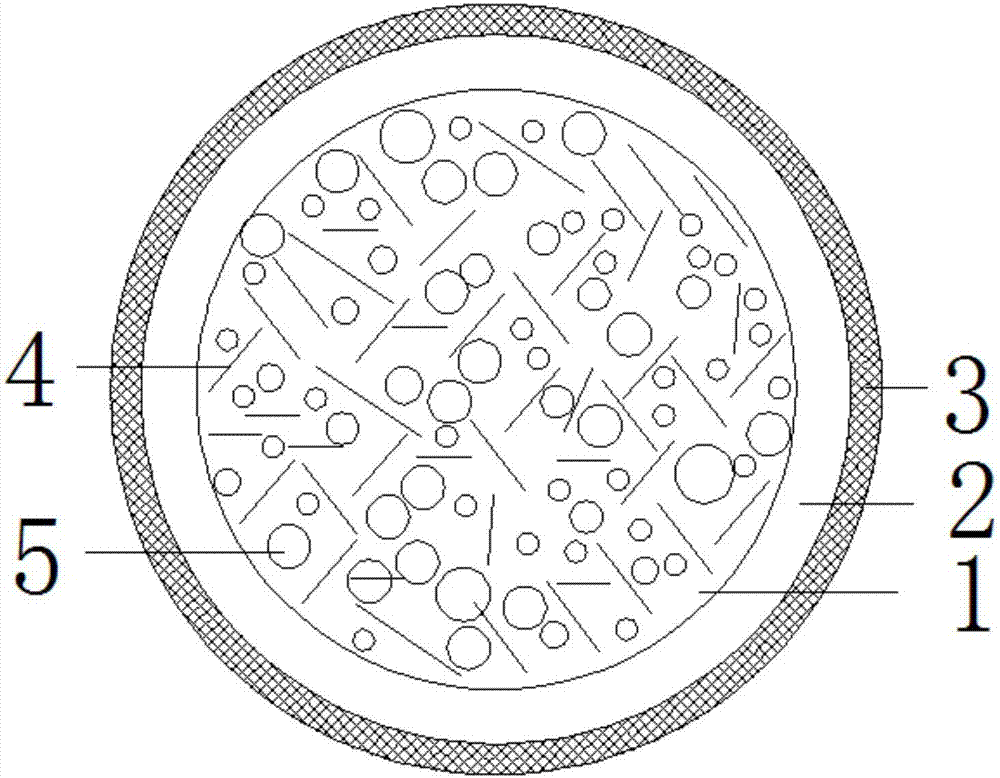

[0043] The nitrogen-doped graphene-silicon composite negative electrode material of the present embodiment, such as figure 1 As shown, it presents a core-shell structure, the inner core is a 1-nitrogen-doped graphene-silicon composite material, and the outer shell is a double-layer structure, which is followed by a 2-silane coupling agent layer and a 3-organolithium compound layer from inside to outside; The silane coupling agent layer is a silane coupling agent, and the silane coupling agent is γ-aminopropyltriethoxysilane; the nitrogen-doped graphene-silicon composite material is composed of 4-nanometer silicon material and coated nano-silicon material 5-Nitrogen-doped graphene, the mass ratio of nano-silicon material and nitrogen-doped graphene is 2:6; the organolithium compound layer is composed of organolithium compound and polyvinylidene fluoride, and the organolithium compound is positive Butyllithium; the thickness ratio of the nitrogen-doped graphene-silicon composite...

Embodiment 2

[0057] The nitrogen-doped graphene-silicon composite negative electrode material of this embodiment presents a core-shell structure, the inner core is a nitrogen-doped graphene-silicon composite material, the outer shell is a double layer, and from the inside to the outside is a silane coupling agent layer and an organic lithium compound. layer; the silane coupling agent layer is a silane coupling agent, and the silane coupling agent is γ-(2,3-epoxypropoxy)propyltrimethoxysilane; the nitrogen-doped graphene-silicon composite material is composed of Nano-silicon material and nitrogen-doped graphene coated outside the nano-silicon material, the mass ratio of the nano-silicon material and nitrogen-doped graphene is 1:5; the organolithium compound layer is composed of organolithium compound and polylidene fluoride Composed of ethylene, the organolithium compound is sec-butyllithium; the thickness ratio of the nitrogen-doped graphene-silicon composite material, silane coupling agent...

Embodiment 3

[0067] The nitrogen-doped graphene-silicon composite negative electrode material in this embodiment presents a core-shell structure, the inner core is a nitrogen-doped graphene-silicon composite material, the outer shell is a double layer, and from the inside to the outside is a silane coupling agent layer and an organic lithium compound. layer; the silane coupling agent layer is a silane coupling agent, and the silane coupling agent is γ-(methacryloyloxy)propyltrimethoxysilane; the nitrogen-doped graphene-silicon composite material is made of nano-silicon material and nitrogen-doped graphene coated on the nano-silicon material, the mass ratio of the nano-silicon material to nitrogen-doped graphene is 3:10; the organolithium compound layer is composed of organolithium compound and polyvinylidene fluoride, The organic lithium compound is phenyllithium; the thickness ratio of the nitrogen-doped graphene-silicon composite material, the silane coupling agent, and the organic lithiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com