Method for improving tap density of ternary nickel-cobalt-manganese cathode material for lithium-ion battery

A technology for lithium ion batteries and positive electrode materials, which is applied to battery electrodes, positive electrodes, electrical components, etc., can solve problems such as being unsuitable for large-scale industrial production, complex synthesis processes, etc. The effect of volume to capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

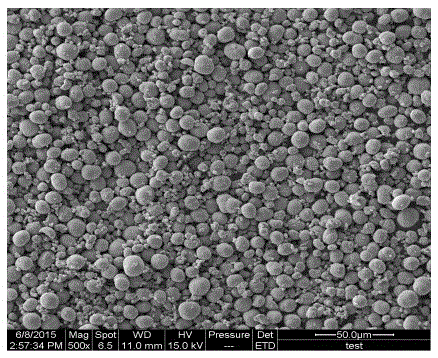

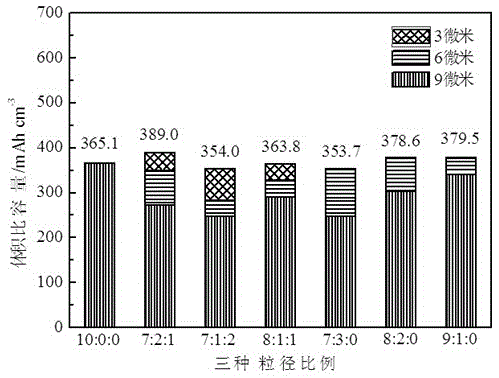

[0017] Specific implementation mode 1: This implementation mode provides a method for increasing the tap density of the ternary nickel-cobalt-manganese positive electrode material for lithium-ion batteries. First, sieve commercialized ternary material precursors with different particle sizes, and then add lithium salt and mix evenly Post-baking to obtain ternary positive electrode materials with different particle sizes, and then mix ternary positive electrode materials with different particle sizes in a certain proportion and then perform secondary low-temperature roasting to obtain high tap density ternary nickel-cobalt-manganese positive electrode materials. The specific steps are as follows:

[0018] 1) The commercial ternary material precursor Ni 0.5 co 0.2 mn 0.3 (OH) 2 Sieve out particles with a particle size of 9 microns, 6 microns and 3 microns, respectively, add lithium carbonate with a molar excess of 7%, use ethanol as a dispersant, stir at high speed to form a s...

specific Embodiment approach 2

[0020] Specific embodiment 2: In this embodiment, a high tap density ternary nickel-cobalt-manganese positive electrode material is prepared according to the following steps:

[0021] 1) The commercial ternary material precursor Ni 0.6 co 0.2 mn 0.2 (OH) 2 Sieve out particles with a particle size of 11 microns, 7 microns and 2 microns, add lithium carbonate with a molar excess of 9% respectively, use ethanol as a dispersant, stir at high speed to form a suspension until evaporated to dryness, and then put it into a constant temperature box for 80 After drying the mixed powder at ℃ for 4 hours, the first high-temperature roasting is carried out, and the temperature is raised from room temperature to 600 ℃ at a rate of 5 ℃ / min, and the temperature is kept at a constant temperature for 6 hours. After cooling down for 2 hours, oxygen flow was started, and then it was naturally cooled to room temperature to prepare ternary nickel-cobalt-manganese cathode materials with particle ...

specific Embodiment approach 3

[0023] Specific embodiment three: In this embodiment, a high tap density ternary nickel-cobalt-manganese positive electrode material is prepared according to the following steps:

[0024] 1) The commercial ternary material precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 Sieve out particles with a particle size of 13 microns, 7 microns and 3 microns, add lithium carbonate with a molar excess of 10% respectively, use ethanol as a dispersant, stir at high speed to form a suspension until evaporated to dryness, and then put it into a constant temperature box for 80 After drying the mixed powder at ℃ for 4 hours, the first high-temperature roasting is carried out, and the temperature is raised from room temperature to 600 ℃ at a rate of 5 ℃ / min, and the temperature is kept at a constant temperature for 6 hours. After cooling down for 2 hours, oxygen flow was started, and then naturally cooled to room temperature to prepare ternary nickel-cobalt-manganese cathode materials with particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com