Preparation method for nickel-manganese-cobalt compound hydroxide and reaction kettle for preparing nickel-manganese-cobalt compound hydroxide

A composite hydroxide, nickel-manganese-cobalt technology, applied in chemical/physical/physical-chemical stationary reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve the problem of uneven particle size, waste, spherical To solve problems such as poor density, to achieve uniform particle size distribution, increase gram capacity, and be easy to industrialize.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

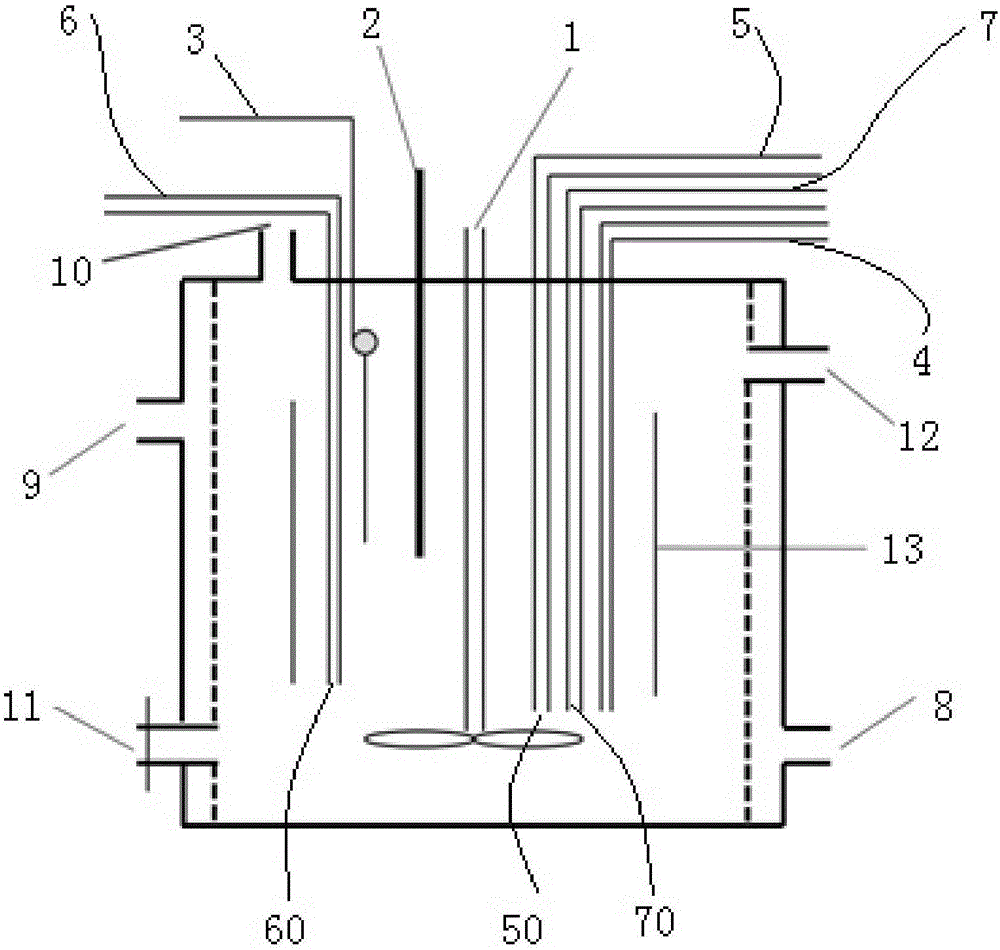

[0031] The reaction kettle used to prepare the nickel-manganese-cobalt composite hydroxide of the present embodiment, the schematic diagram of the structure is as follows figure 1As shown, the reactor body is included, and the reactor body is provided with a stirrer 1, a pH meter 2, a temperature controller 3, and is also connected with a complexing agent pipe 4, a lye pipe 5, a main salt liquid pipe 6 and a distribution pipe. Salt solution pipe 7, one end of the liquid outlet of the complexing agent pipe 4 goes deep into the reactor body, and is used to pass into the complexing agent solution inside the reactor body, and one end of the liquid outlet 50 of the lye pipe 5 goes deep into the reactor Inside the main body, it is used to feed lye into the inside of the reactor body. The main salt solution pipe 6 and the sub-salt solution pipe 7 are both used to feed the multi-element metal salt solution into the inside of the reactor body. The liquid outlet of the main salt solution...

Embodiment 2

[0035] The preparation method of the nickel-manganese-cobalt composite hydroxide of the present embodiment, the device used is as figure 1 shown, including the following steps:

[0036] 1) Press Ni 0.6 mn 0.2 co 0.19 Zn 0.01 (OH) 2 The stoichiometric ratio of nickel sulfate, manganese nitrate, cobalt chloride, and zinc sulfate is dissolved to make a multi-element metal salt solution with a total metal ion molar concentration of 2mol / L; prepare a concentration of 8mol / L with deionized water and sodium hydroxide The sodium hydroxide solution is used as lye; Complexing agent solution is the ammoniacal liquor of mass concentration 20%;

[0037] 2) Through the complexing agent pipe, lye pipe, and main salt solution pipe of the 25L reactor, respectively pass the complexing agent solution, lye solution, and multi-element metal salt solution into the reactor, wherein the multi-element metal salt in the main salt liquid pipe The flow rate of the solution is 25ml / min, the flow rat...

Embodiment 3

[0041] The preparation method of the nickel-manganese-cobalt composite hydroxide of the present embodiment, the device used is as figure 1 shown, including the following steps:

[0042] 1) Press Ni 0.5 mn 0.28 co 0.2 Mg 0.02 (OH) 2 The stoichiometric ratio of nickel acetate, manganese nitrate, cobalt sulfate, and magnesium sulfate is dissolved to make a multi-element metal salt solution with a total metal ion molar concentration of 3mol / L; it is 5mol / L with deionized water and sodium hydroxide. Sodium hydroxide solution is used as lye; Complexing agent solution is the ammonium sulfate solution of mass concentration 22%;

[0043] 2) Through the complexing agent pipe, lye pipe, and main salt solution pipe of the 25L reactor, respectively pass the complexing agent solution, lye solution, and multi-element metal salt solution into the reactor, wherein the multi-element metal salt in the main salt liquid pipe The flow rate of the solution is 15ml / min, the flow rate of the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com