High power lithium ion battery and method for preparing amorphous carbon coated anode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of low internal resistance and achieve good conductivity, high-rate discharge capacity, and ion diffusion The effect of distance shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1, see Figure 1-3 : Make A1, A2, A3, B1, B2 according to following specific scheme, 5 kinds of batteries are compared, and the preparation process of A1, A2, A3, B1 is:

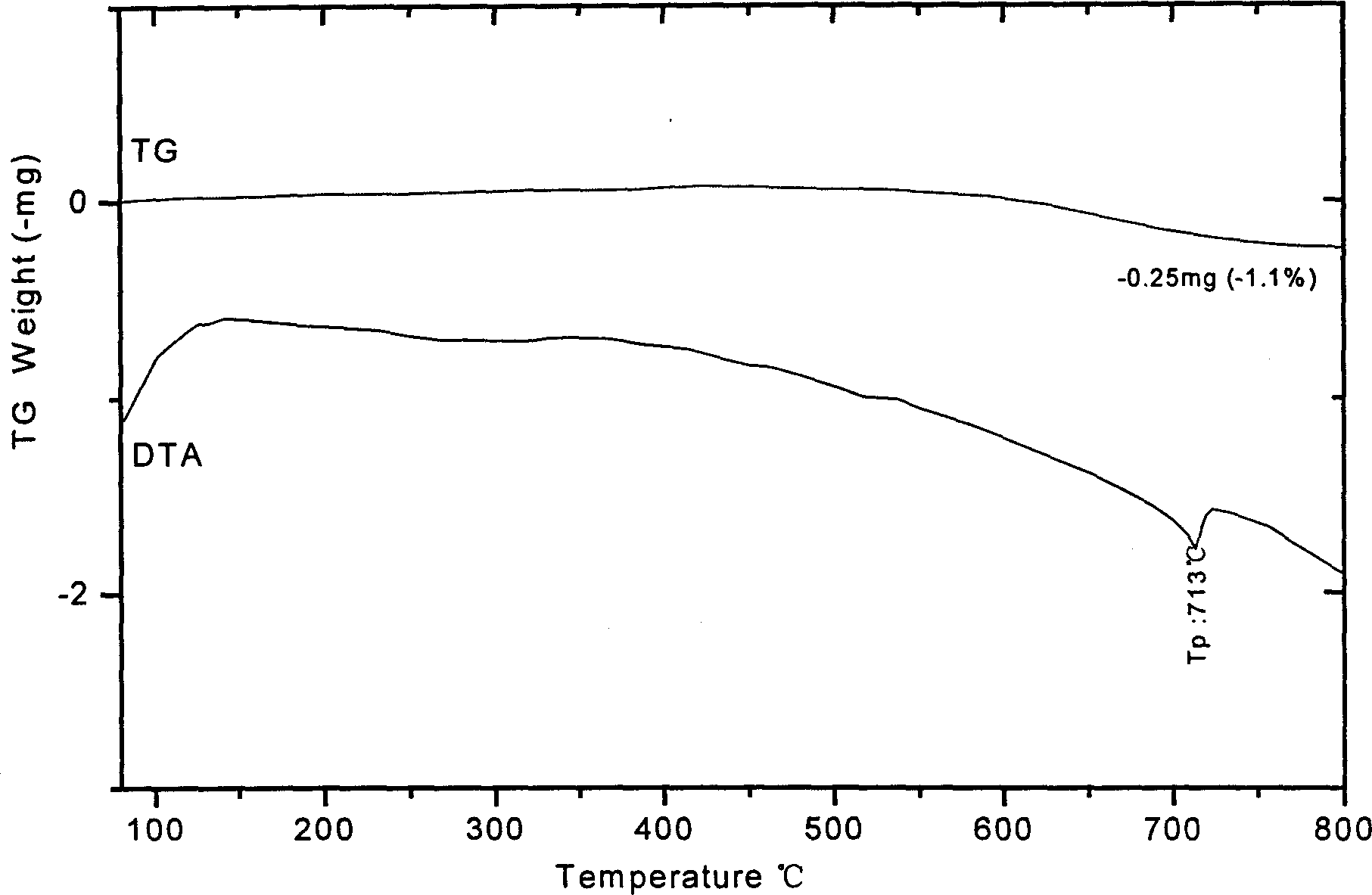

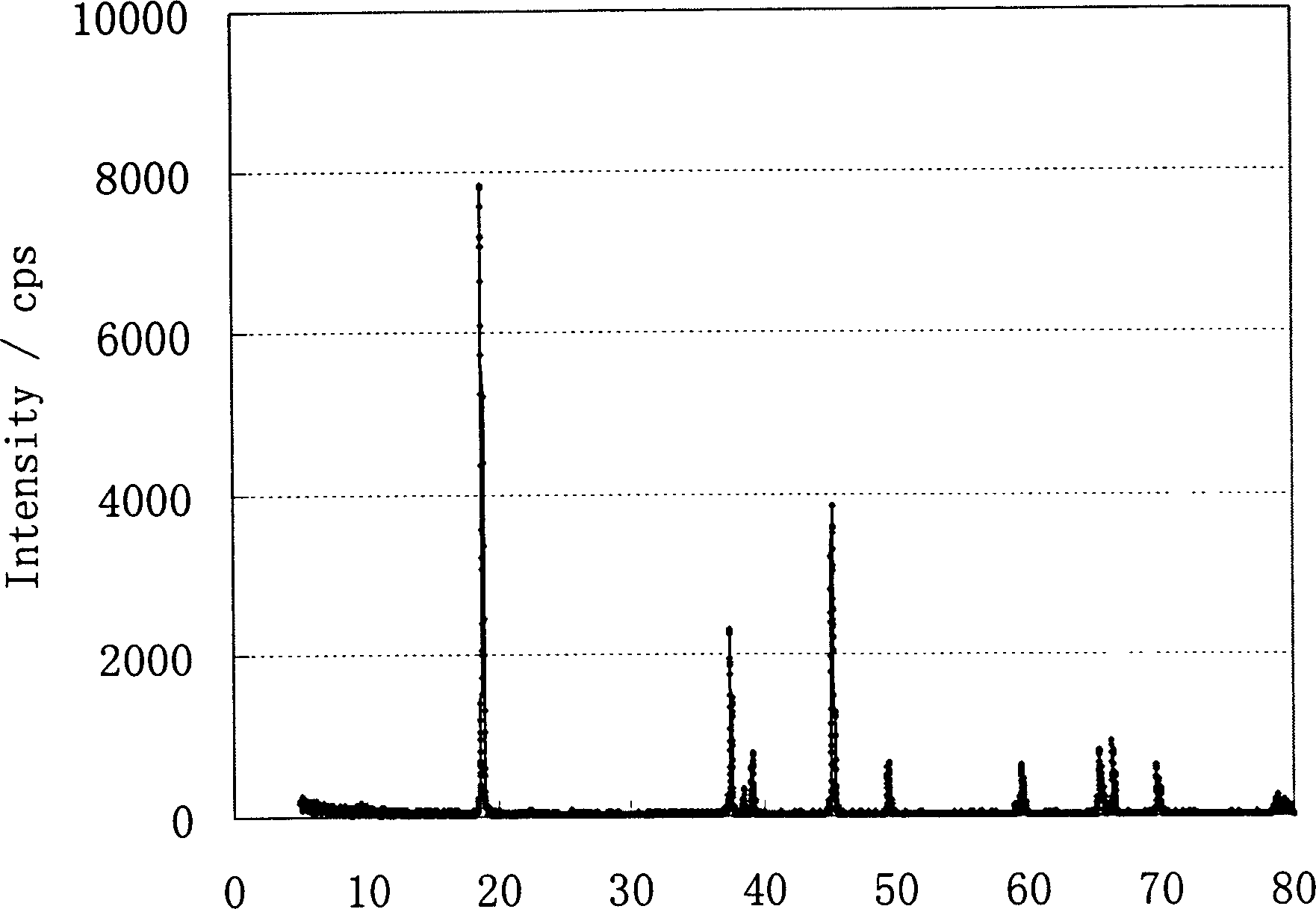

[0026] Preparation of lithium cobalt oxide with core-shell structure: firstly, an aqueous solution of white sugar was prepared. That is, 200g of edible pure white sugar is dissolved in 300ml of deionized water to make a transparent white sugar aqueous solution. The second is hanging sugar, that is, 200g of primary balls with an average D50 particle size of 2, 5, 10, 15 microns LiCoO 2 The powder was added to the above-mentioned white sugar aqueous solution, stirred with a high-speed mixer with a rotation speed of 300 rpm for 30 minutes, then the excess white sugar aqueous solution was filtered off by suction, and dried in air at 60°C for 3 hours. The next step is carbonization into a shell, that is, drying the dried hanging sugar LiCoO 2 Put it in a tunnel furnace, blow Ar gas for 1 hour to...

Embodiment 2

[0051] Example 2, A1, A4, A5, B3, B4 were produced according to the following specific scheme, and five kinds of batteries were compared. The preparation process of A1, A4, A5, and B3 was as follows:

[0052] Preparation of lithium cobalt oxide with core-shell structure: firstly, an aqueous solution of white sugar was prepared. That is, 200g of edible pure white sugar is dissolved in 300ml of deionized water to make a transparent white sugar aqueous solution. The second is hanging sugar, that is, 200g of primary balls with an average D50 particle size of 2 microns LiCoO 2 The powder was added to the above-mentioned white sugar aqueous solution, stirred with a high-speed mixer with a rotation speed of 300 rpm for 30 minutes, then the excess white sugar aqueous solution was filtered off by suction, and dried in air at 60°C for 3 hours. The next step is to carbonize into a shell, that is, put the dried hanging sugar in a tunnel furnace, and replace the air in the chamber with Ar...

Embodiment 3

[0076] Example 3, A1, A6, A7, A8, B5, and B6 were produced according to the following specific schemes, and five kinds of batteries were compared, and the preparation process of A1, A6, A7, and B8 was as follows:

[0077] Preparation of lithium cobalt oxide with core-shell structure: firstly, an aqueous solution of white sugar was prepared. That is, 200g of edible pure white sugar is dissolved in 300ml of deionized water to make a transparent white sugar aqueous solution. The second is hanging sugar, that is, 200g of primary balls with an average D50 particle size of 2 microns LiCoO 2 The powder was added to the above-mentioned white sugar aqueous solution, stirred with a high-speed mixer with a rotation speed of 300 rpm for 30 minutes, then the excess white sugar aqueous solution was filtered off by suction, and dried in air at 60°C for 3 hours. The next step is to carbonize into a shell, that is, put the dried hanging sugar in a tunnel furnace, and replace the air in the ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com