LiFePO4 cathode material based on P site doped and preparation method thereof

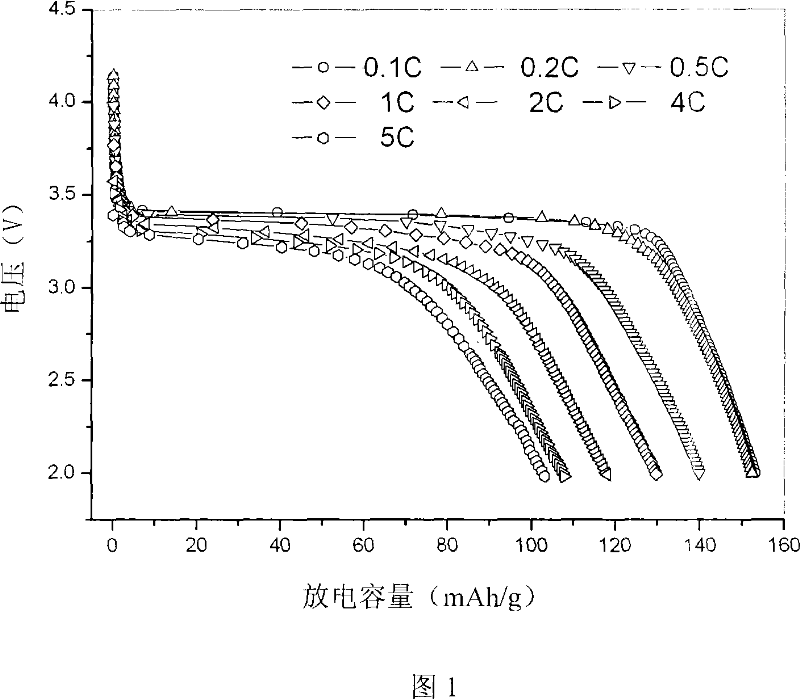

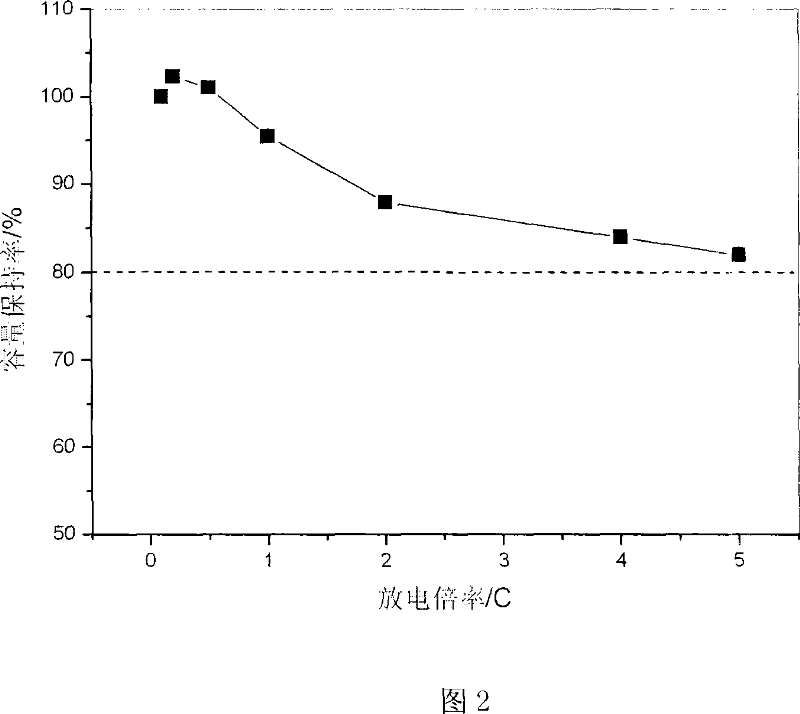

A lithium iron phosphate and cathode material technology, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problems of low volume energy density, poor conductivity, and low bulk density of batteries, and achieve good rate discharge performance, crystallization The effect of good performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: Add 8.34g of ferrous sulfate FeSO 4 ·7H 2 O, 3.45g ammonium dihydrogen phosphate NH 4 H 2 PO 4 Mix, add to the agate ball mill tank, add 5ml of absolute ethanol as the ball mill solvent, seal and mix on a planetary ball mill at 500rpm for 8h, dissolve and filter with deionized water after discharging, and wash with deionized water for 3~4 The concentration of 1mol / L barium nitrate Ba(NO 3 ) 2 Sulfate ion SO cannot be detected in the solution 4 2- . The filtered product was vacuum dried at 60°C for 8 hours to obtain an intermediate product. Put 3.06g lithium acetate CH 3 COOLi·2H 2 O and the intermediate product were added to the ball milling tank, 5ml of absolute ethanol was added as the ball milling solvent, and after sealing, it was mixed on a planetary ball mill at 500rpm for 10h. After the material was discharged, it was vacuum dried at 80℃ for 2h, and then heated at 10ml / s. In a nitrogen-hydrogen mixed gas atmosphere, the temperature is increased to 600°C a...

Embodiment 2

[0021] Example 2: The 16.80g ferrous acetate Fe(CH 3 COO) 2 ·2H 2 O, 11.93g ammonium phosphate (NH 4 ) 3 PO 4 Mix, add to the agate ball mill tank, add 5ml of absolute ethanol as the ball mill solvent, seal and mix on a planetary ball mill at 500rpm for 8h, dissolve and filter with deionized water after discharging, and wash with deionized water for 3~4 all over. The filtered product was vacuum dried at 80°C for 6 hours to obtain an intermediate product. 2.96g lithium carbonate Li 2 CO3 Add 5ml of absolute ethanol as the ball milling solvent with the intermediate product into the ball milling tank. After sealing, continue to mix on the planetary ball mill at 500rpm for 10h. After the material is discharged, vacuum dry at 80℃ for 2h, and then in 15ml / s of nitrogen. In the atmosphere, the temperature rises to 700°C at a heating rate of 5°C / min, the temperature is kept for 5 hours, and the furnace is lowered to room temperature to obtain lithium iron phosphate LiFePO 4 Powder, denote...

Embodiment 3

[0022] Example 3: Add 16.80 g of ferrous acetate Fe(CH 3 COO) 2 ·2H 2 O, 11.33g ammonium phosphate (NH 4 ) 3 PO 4 And 0.60g tin dioxide SnO 2 Mix, add 5ml of acetone as the ball milling solvent to the agate ball milling tank, seal and mix on a planetary ball mill at a speed of 500 rpm for 8 hours, dissolve and filter with deionized water after discharging, and wash with deionized water for 3 to 4 times. The filtered product was vacuum dried at 100°C for 6 hours to obtain an intermediate product. 3.10g lithium carbonate Li 2 CO 3 Add 5ml of acetone as the ball milling solvent with the intermediate product into the ball milling tank. After sealing, continue mixing on the planetary ball mill at 500 rpm for 10 hours. After the material is discharged, it is vacuum dried at 80°C for 2 hours, and then mixed with 10ml / s of nitrogen and hydrogen. In a gas atmosphere, the temperature is increased to 700°C at a heating rate of 5°C / min, and kept at this temperature for 5 hours, and then dropp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com