Combined-type diesel engine waste heat energy recycling system

A technology of recovery system and diesel engine, which is applied in the direction of charging system, mechanical equipment, steam engine device, etc., can solve the problems of limited application range, insufficient utilization of exhaust waste heat, easy decomposition, etc., and achieve the effect of reducing irreversible loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The following combined with the attached figures and the system structure of the invention is further explained through the embodiment, it is necessary to emphasize that the examples of this embodiment are narrative, not limited, and do not limit the protection scope of the present invention.

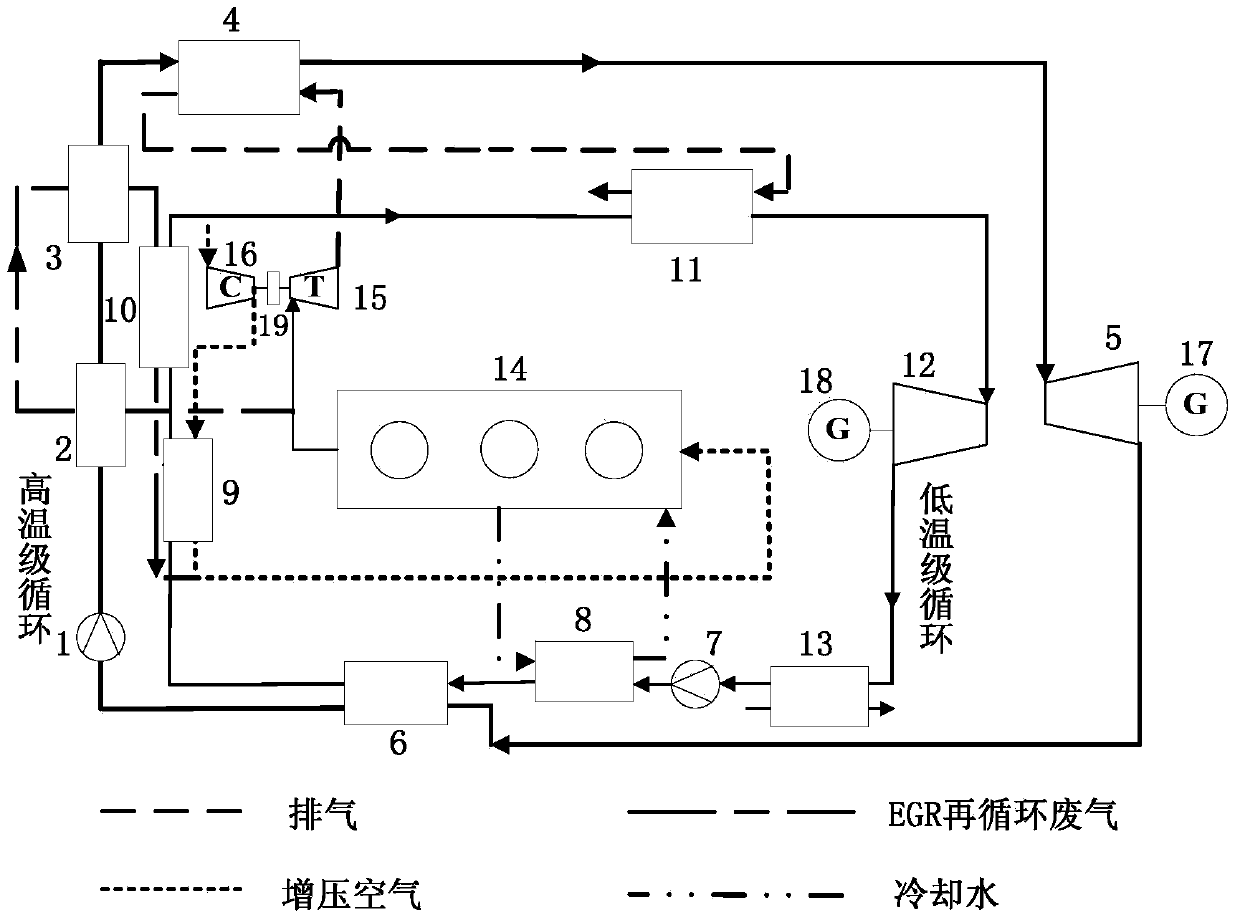

[0010] Composite diesel engine residual heat energy recycling system, including two diesel engines, high and low temperature pumps, temperature difference electricals, high and low temperature two EGR heat exchangers, high and low temperature heat exchangers, high and low temperature turbines, two two steam turbines, two two, two The two condenser, the height temperature, the cooling water exchange of the cylinder, the heating air shifter, the turbine, the supercharger, and the medium -to -center motor. Its specific composition structure is: from the cold end of high temperature -level industrial quality pump, temperature difference electrical 2, high -temperature EGR heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com