Patents

Literature

48results about How to "Waste of time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

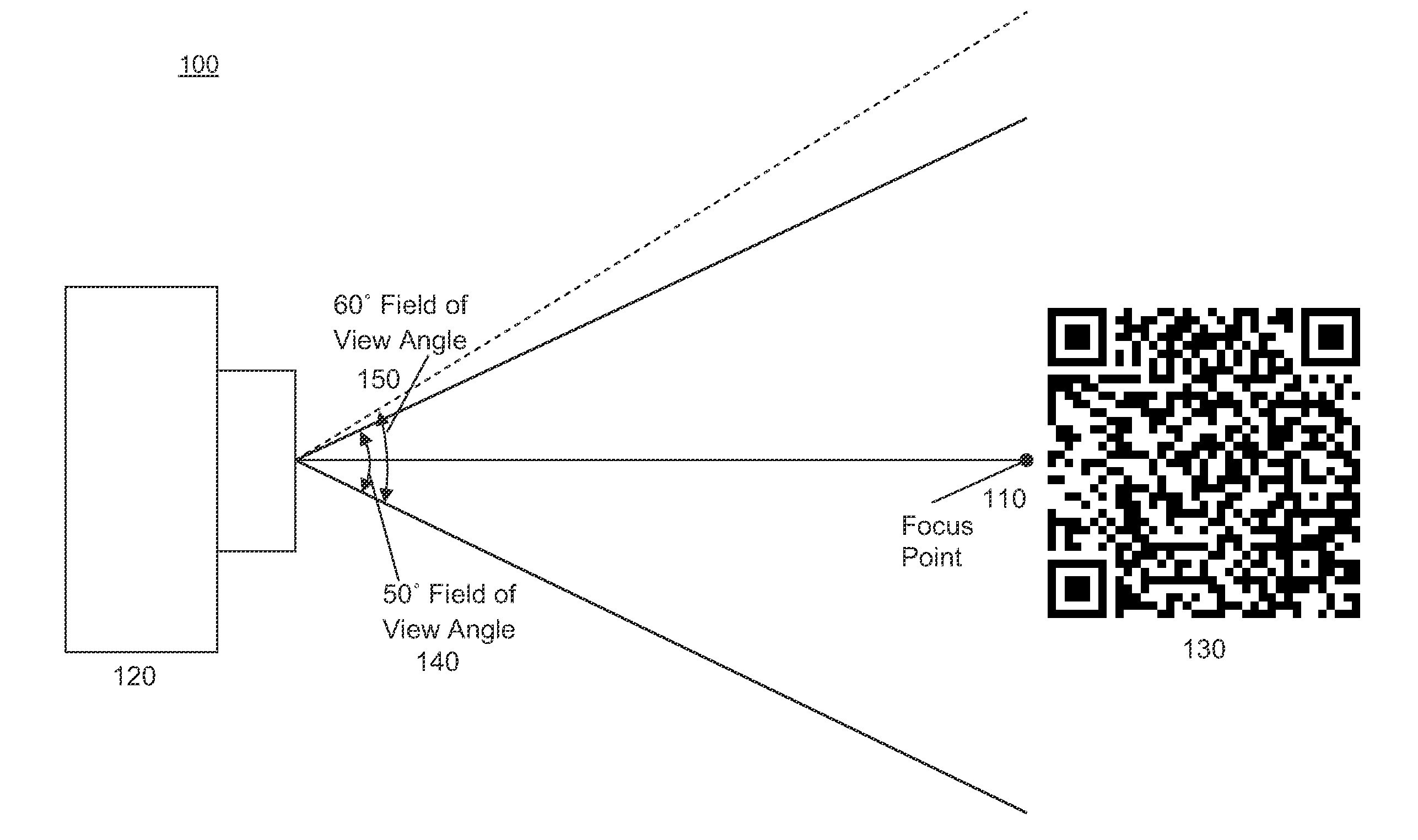

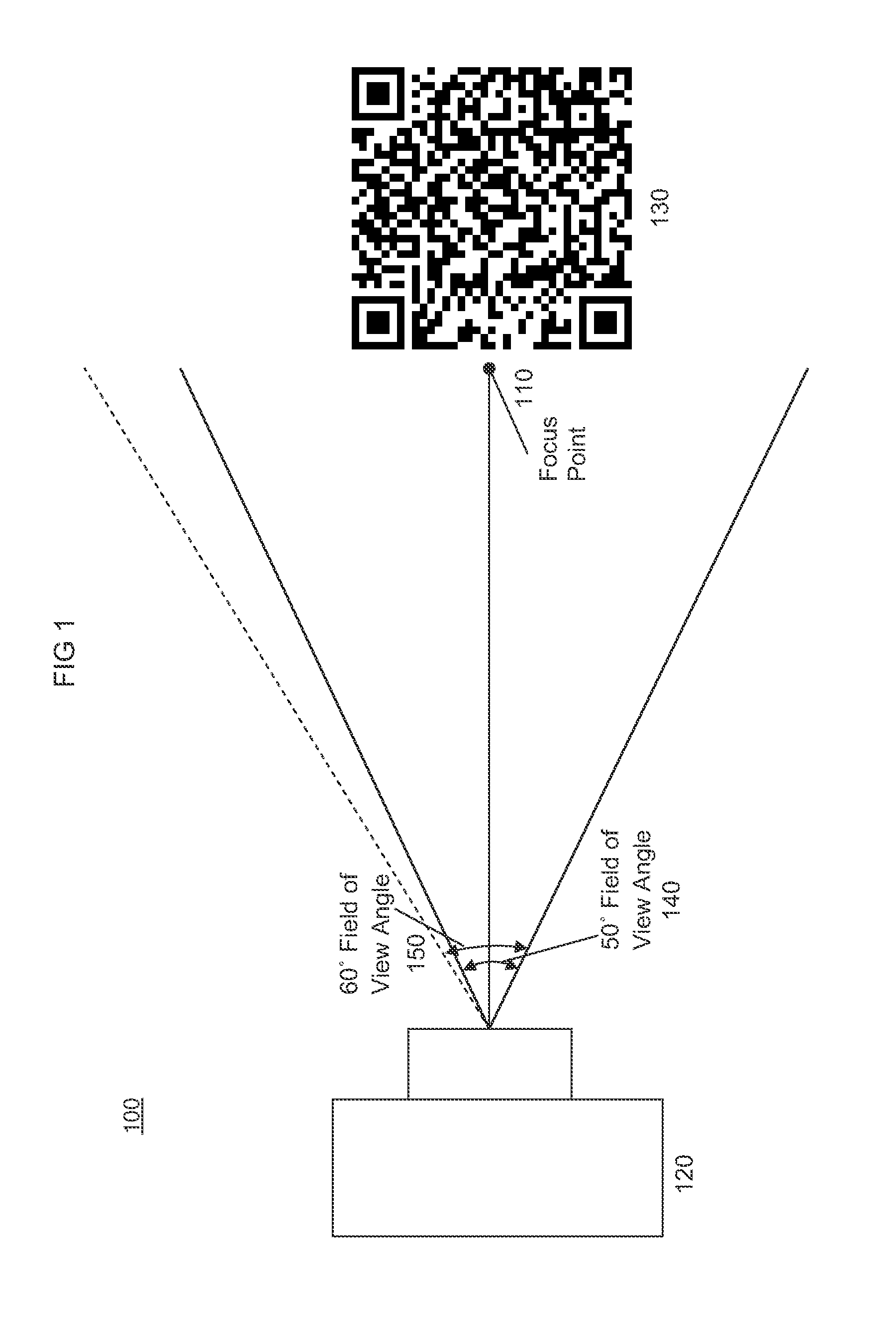

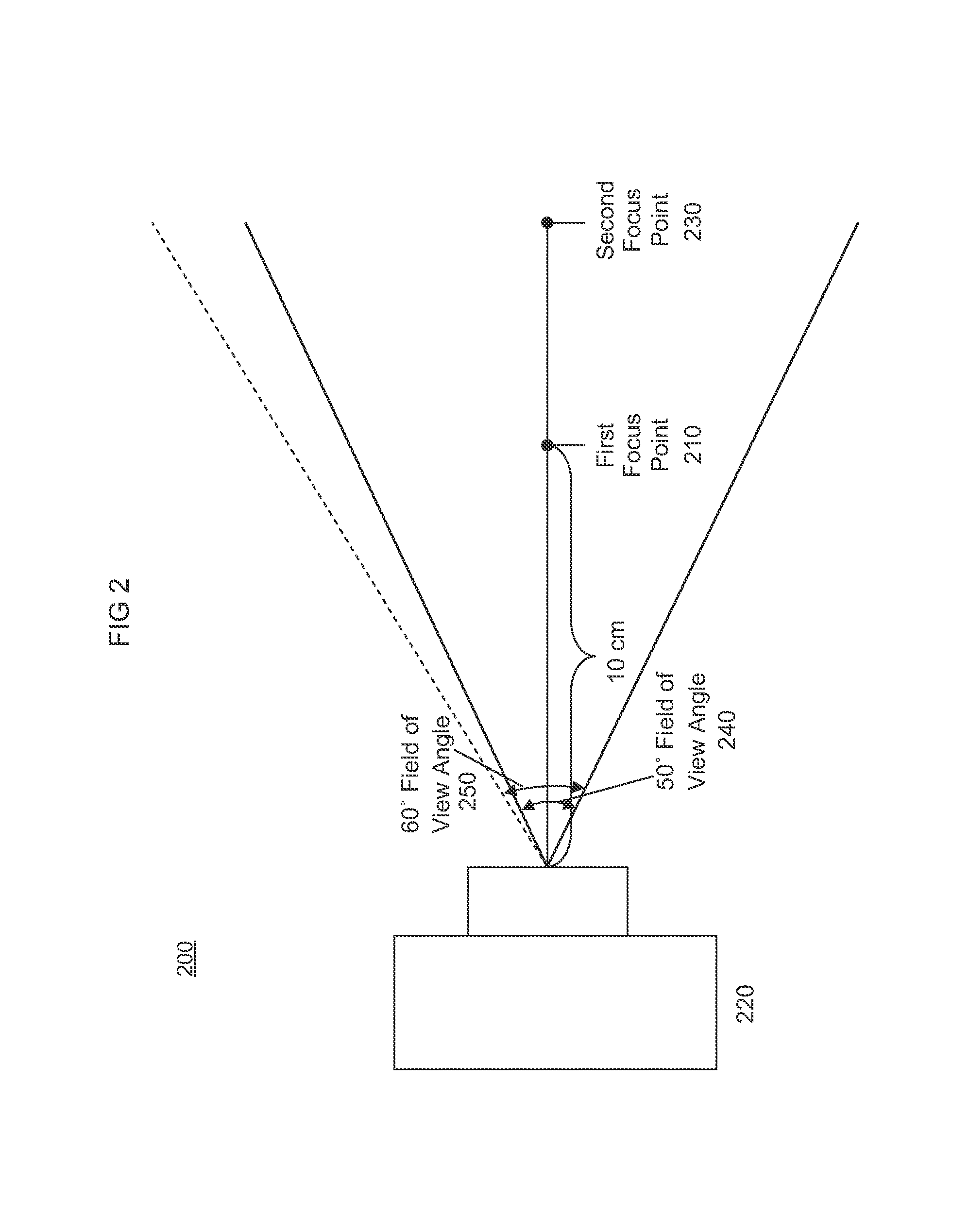

Method of improving decoding speed based on off-the-shelf camera phone

InactiveUS20150062366A1Improve camera speedImprove processing speedTelevision system detailsCharacter and pattern recognitionCamera lensCamera phone

A system and method for decoding an image of decodable indicia, the computer system that includes receiving a request to decode an image, disabling the automatic focus on a camera in a client, setting the focus to a predetermined focus point that is close to the camera lens, capturing the image, locating the decodable indicia in the image and decoding the image of decodable indicia.

Owner:HONEYWELL INT INC

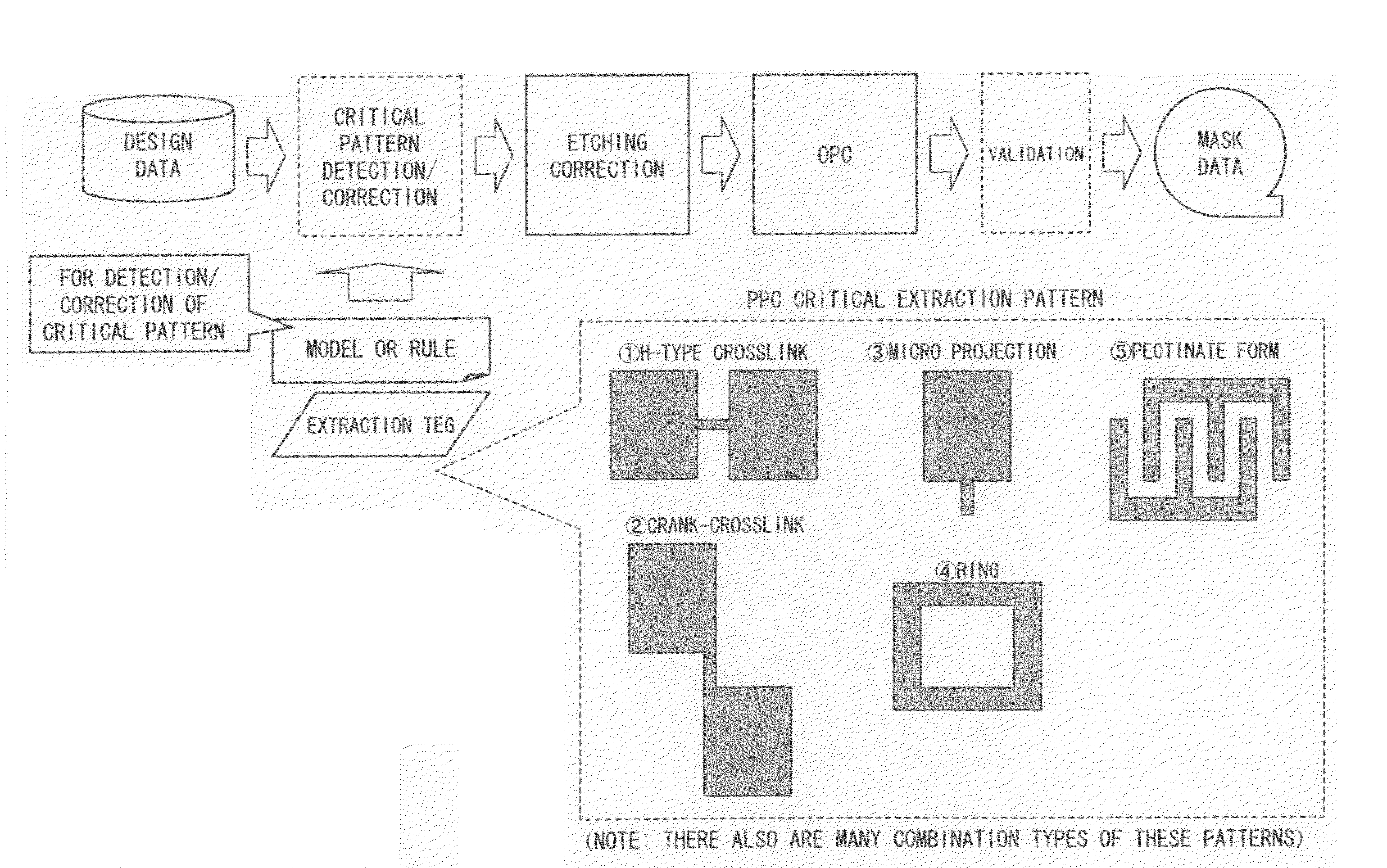

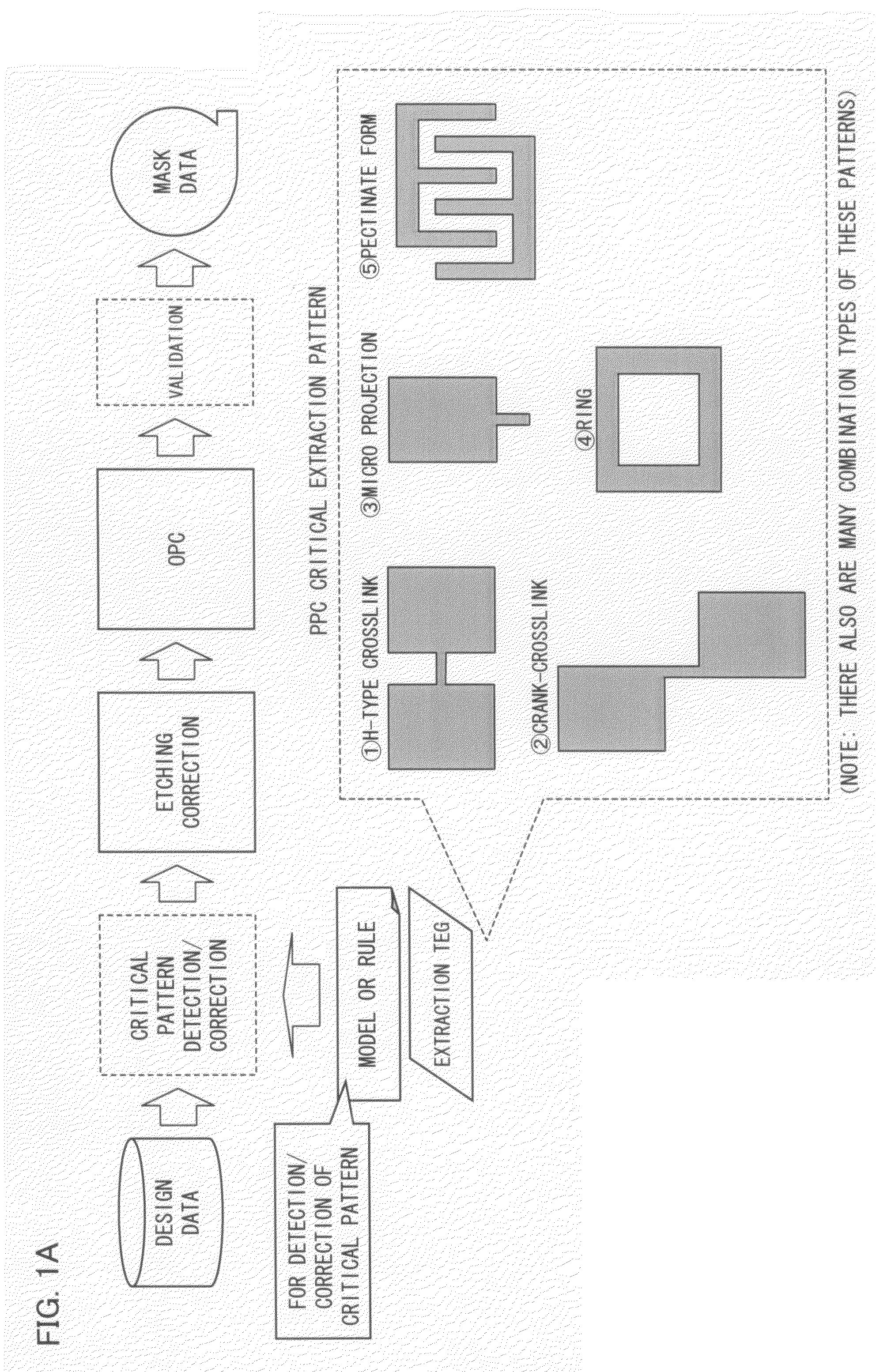

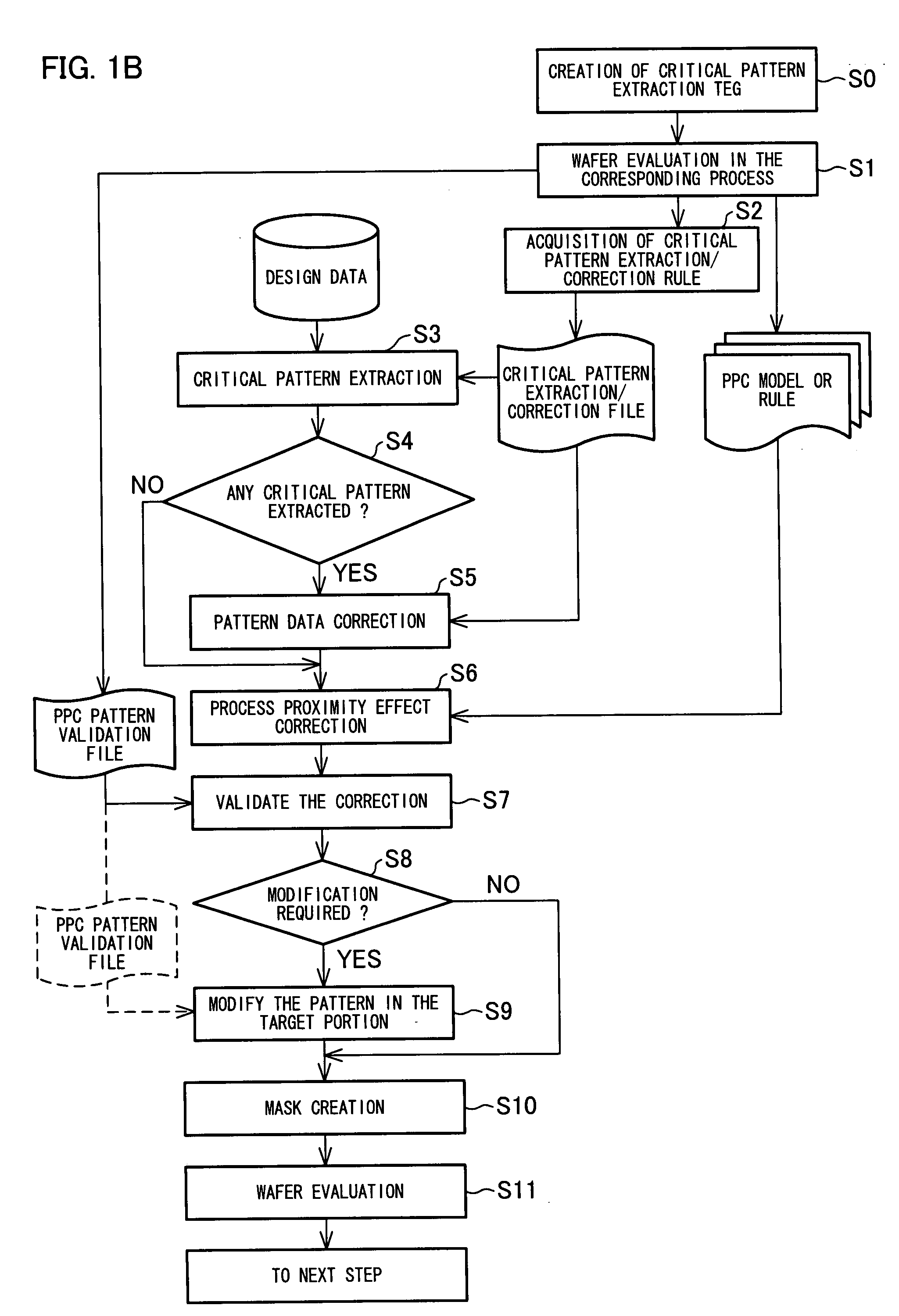

Correction method and correction system for design data or mask data, validation method and validation system for design data or mask data, yield estimation method for semiconductor integrated circuit, method for imporving design rule, mask production method, and semiconductor integrated circuit production method

InactiveUS20080003510A1Wastes in costWastes in development periodPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistValidation methods

The subject invention provides a correction method for design data or mask data comprising the steps of:(i) carrying out PPC of design data or mask data;(ii) exposing and developing a resist with an evaluation mask including a critical pattern which becomes critical in a process, etching a circuit material using the resist having been developed, and measuring pattern sizes of the developed resist and the etched circuit material; (iii) extracting parameter numerical condition for preventing the design data or the mask data from being critical after OPC or PPC, as a rule or as a model based on the pattern sizes of the resist and the circuit material; (iv) extracting a critical pattern with a parameter not satisfying the foregoing rule or the model from the design data or the mask data; and (v) correcting the critical pattern.With this method, the present invention provides such as a validation / correction method for design data or mask data by which a pattern which becomes critical in a process is extracted in advance so that the pattern can be corrected. Consequently, the process spec is achieved in a short period of time after OPC or process proximity effect correction (PPC).

Owner:SHARP KK

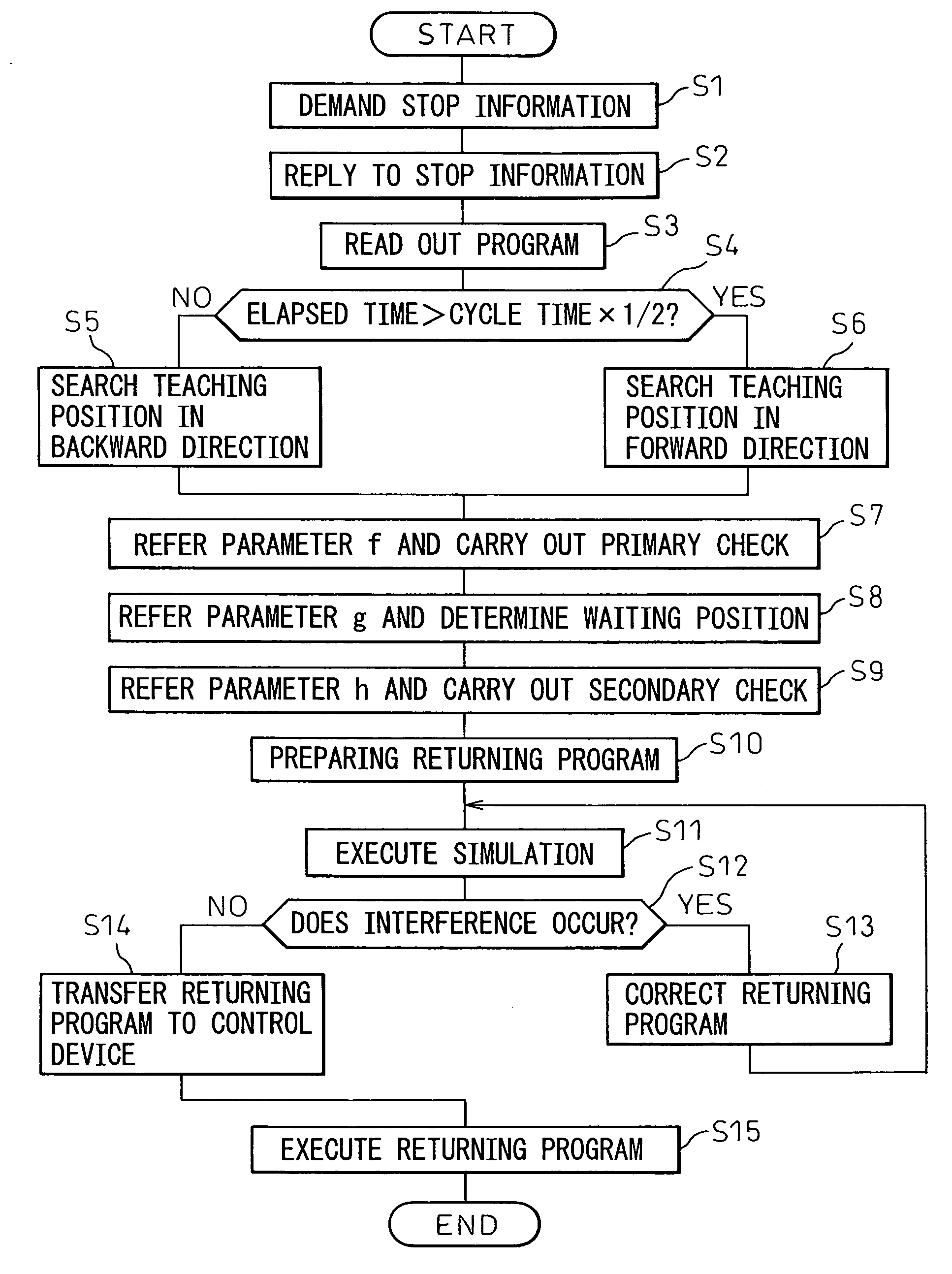

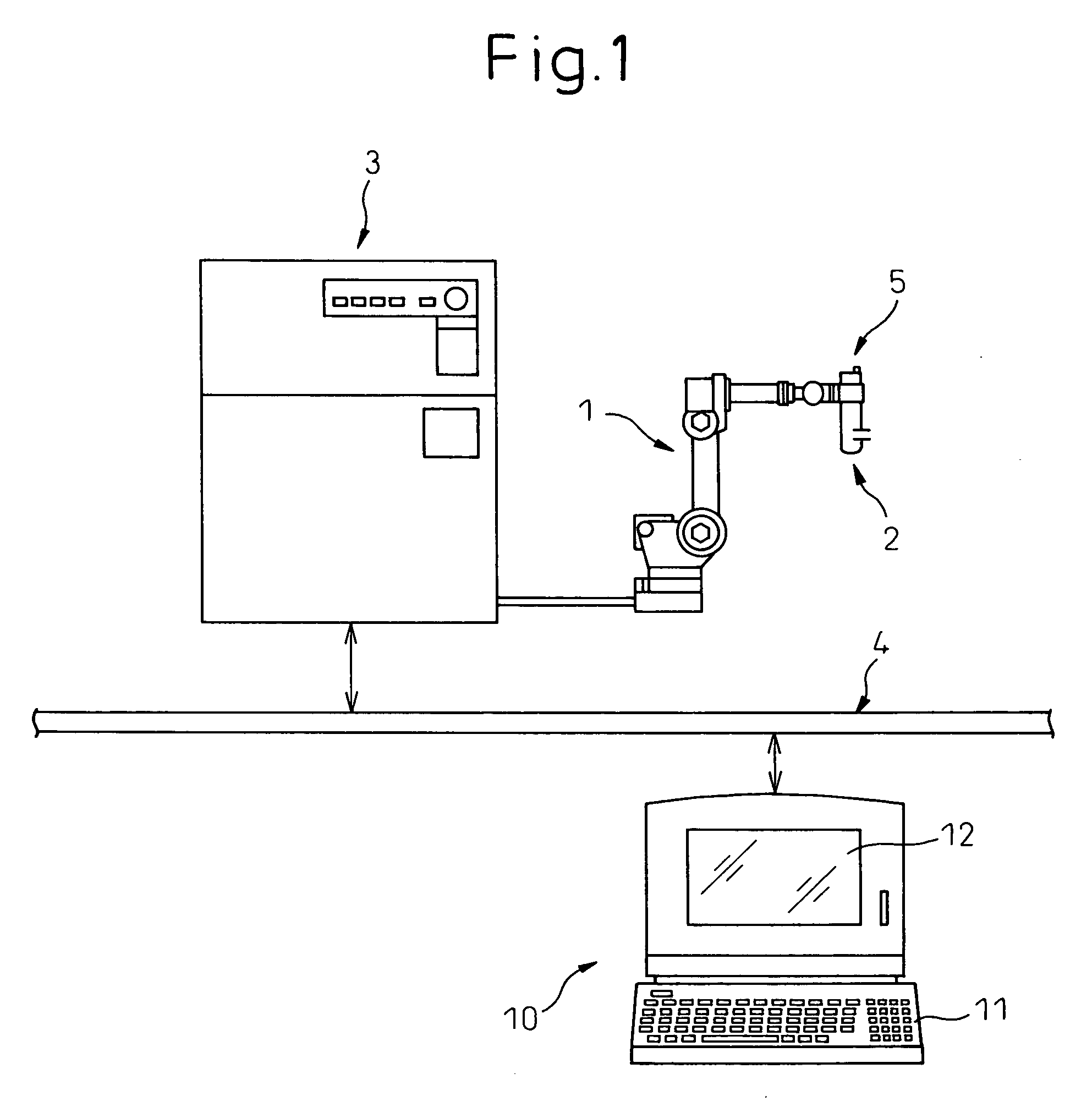

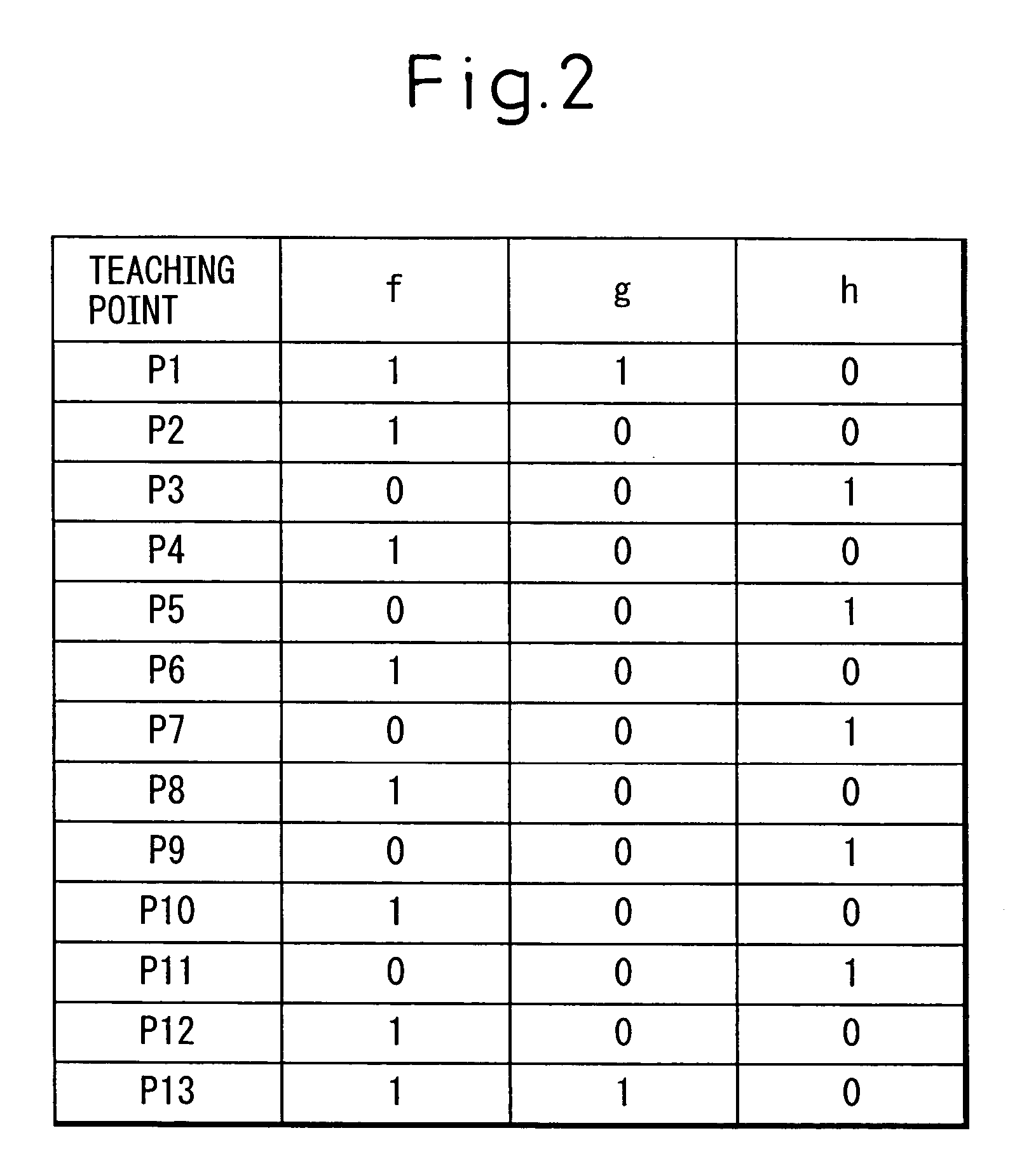

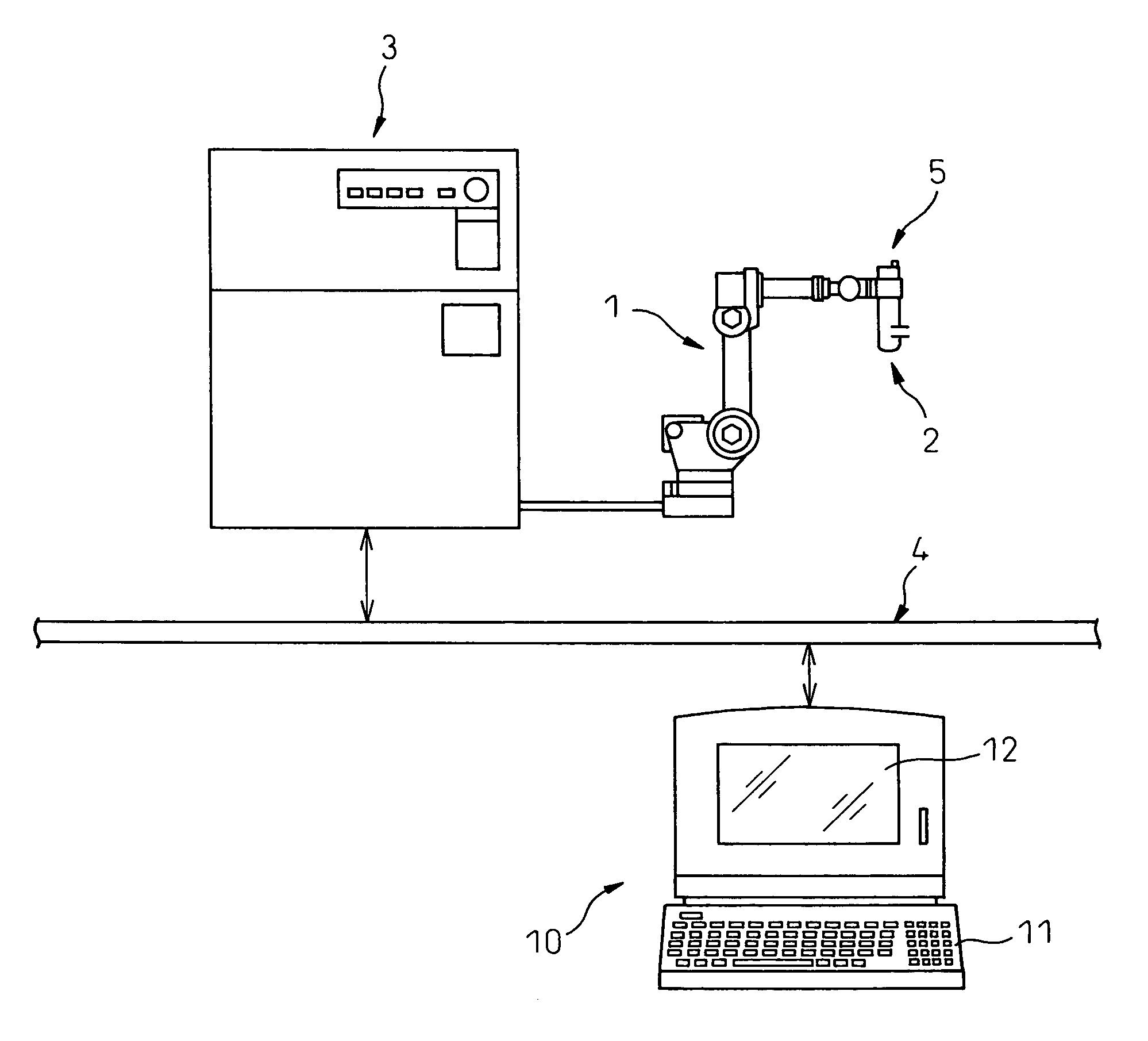

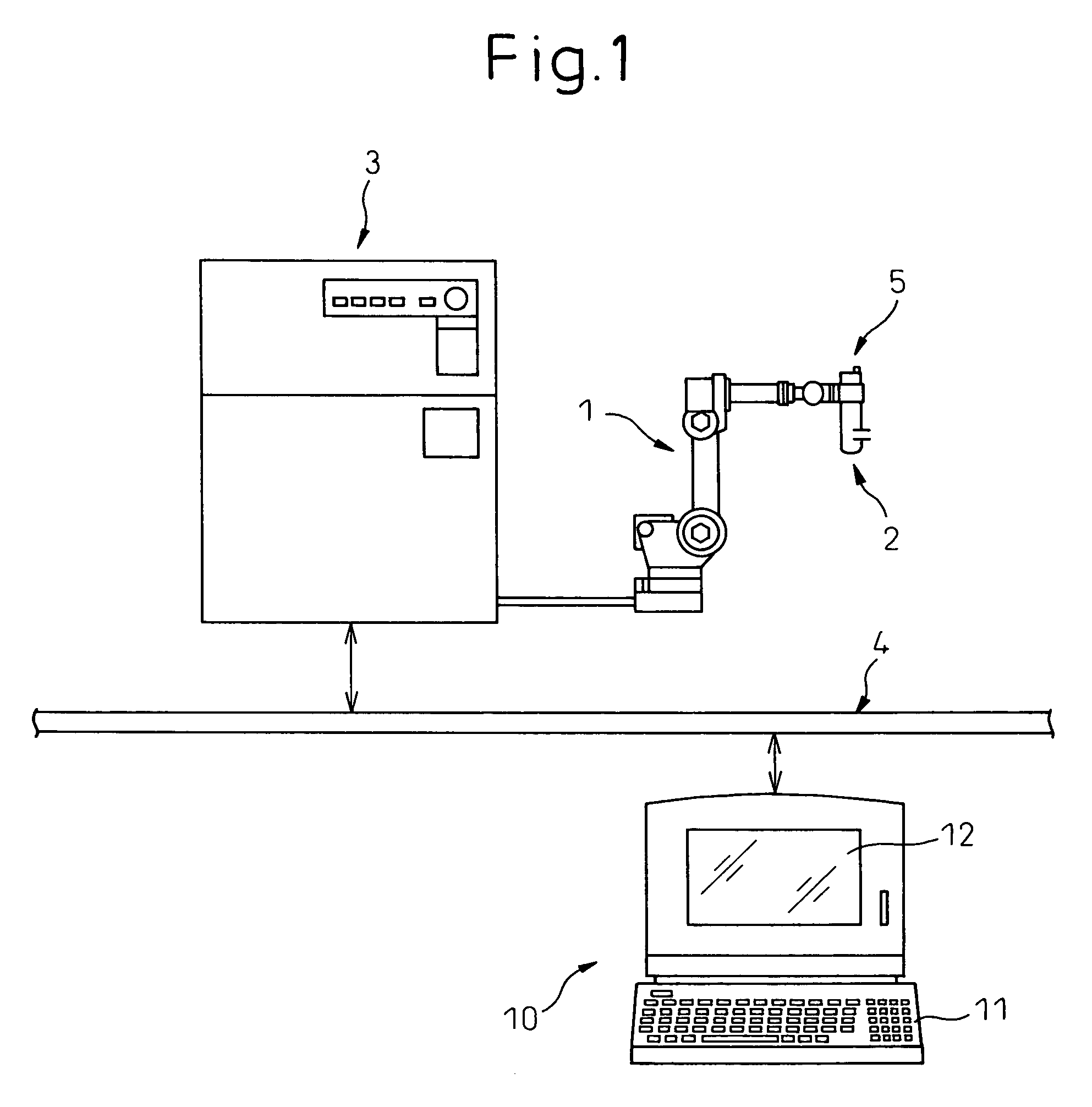

Programming device for returning robot to waiting position

ActiveUS20060009878A1Waste of timeShort timeProgramme-controlled manipulatorComputer controlRobot controlEmbedded system

A programming device for making a program for returning a robot to its waiting position when the robot is stopped by an error. A robot control device is connected to the programming device via a network line. When the robot during operation is stopped by the error, information including data of a position where the robot is stopped is transferred to the programming device. The programming device makes the returning program, based on layout data, the received information and data including teaching positions and attribute data of the positions, by which the robot may be returned from the stop position to the waiting position without interfering with peripheral devices. The returning program is executed by using an offline simulation function of the programming device. The program is transferred to the robot control device after it is judged that interference will not occur. The robot may be safely returned to the waiting position by executing the returning program.

Owner:FANUC LTD

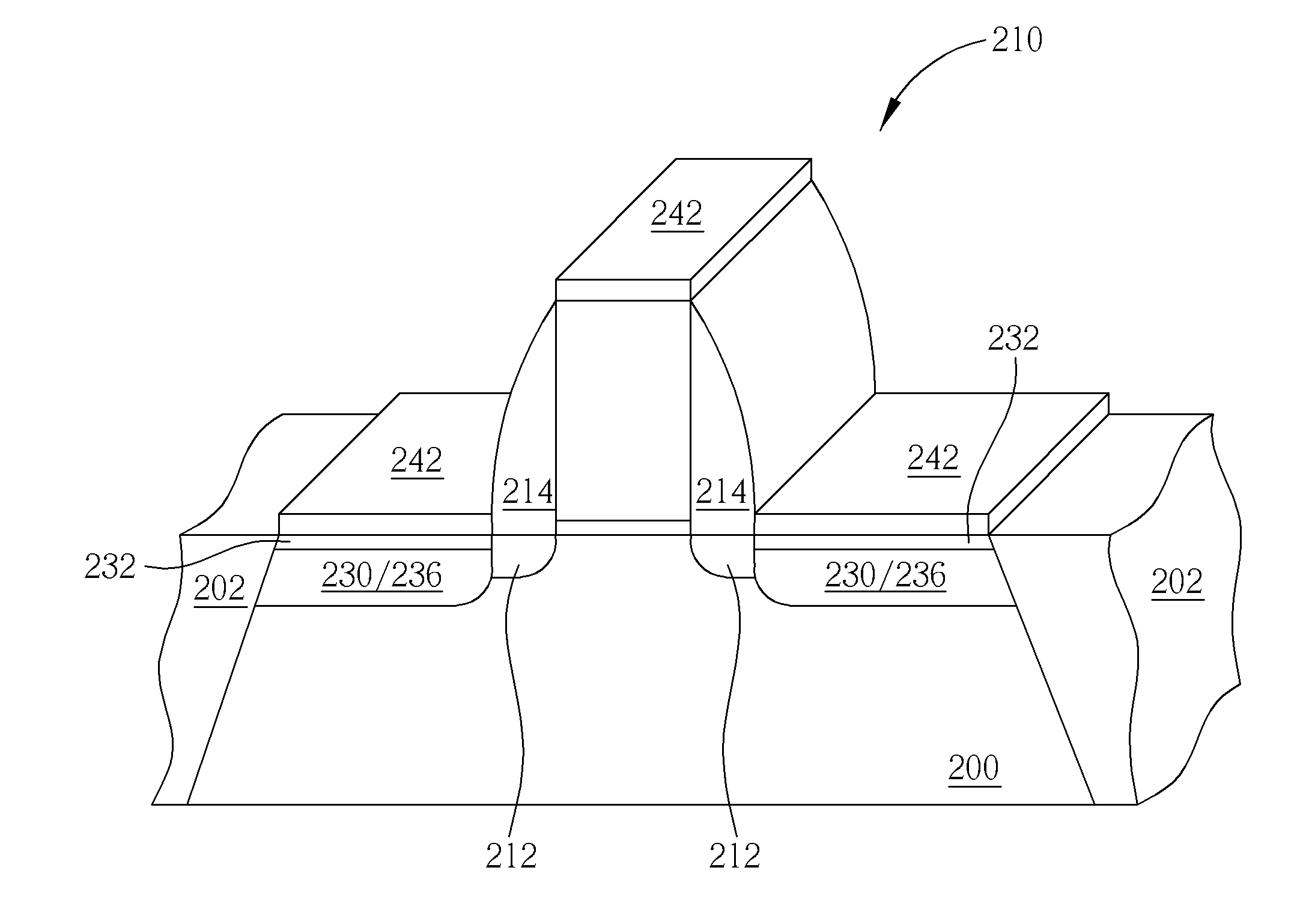

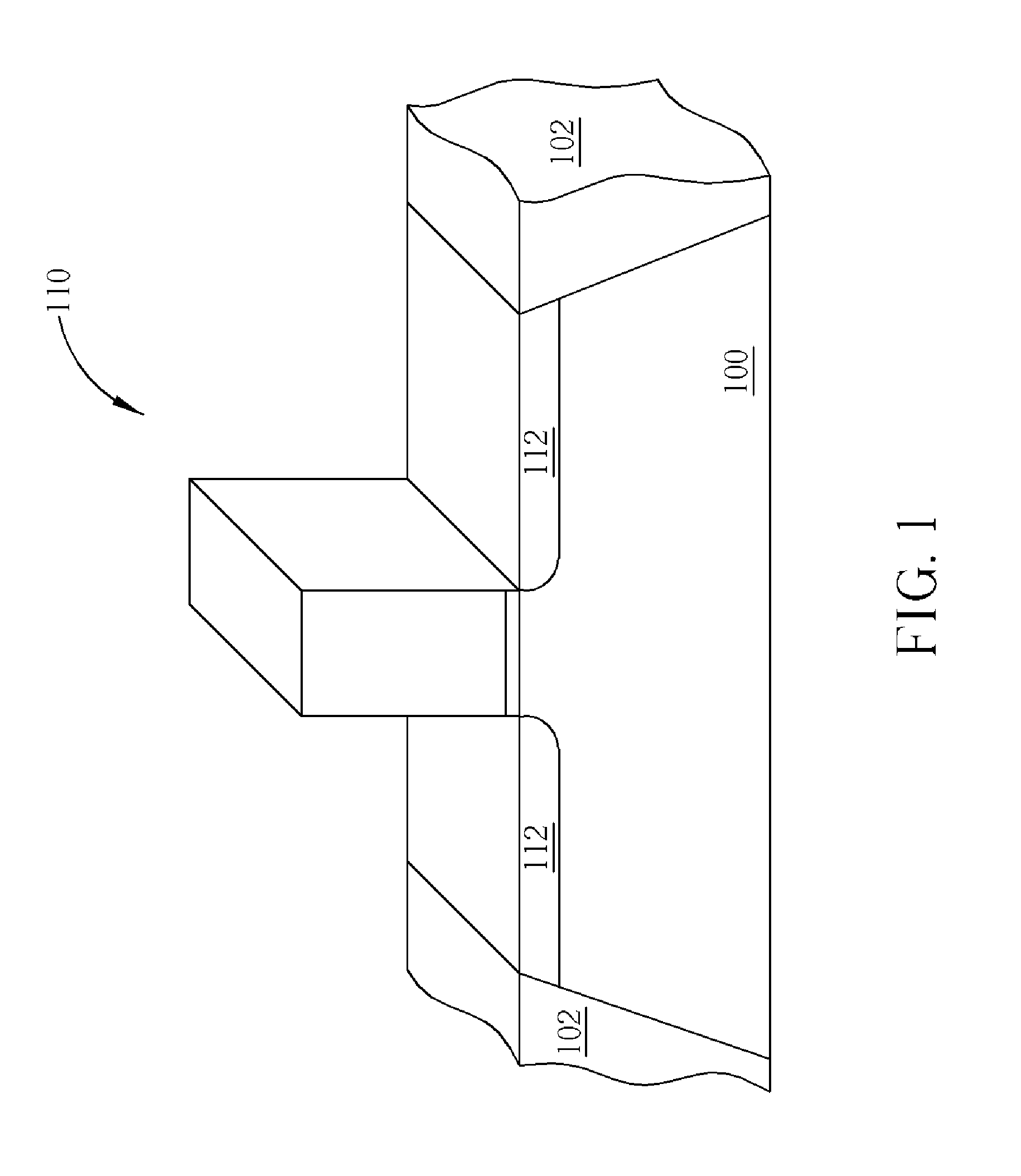

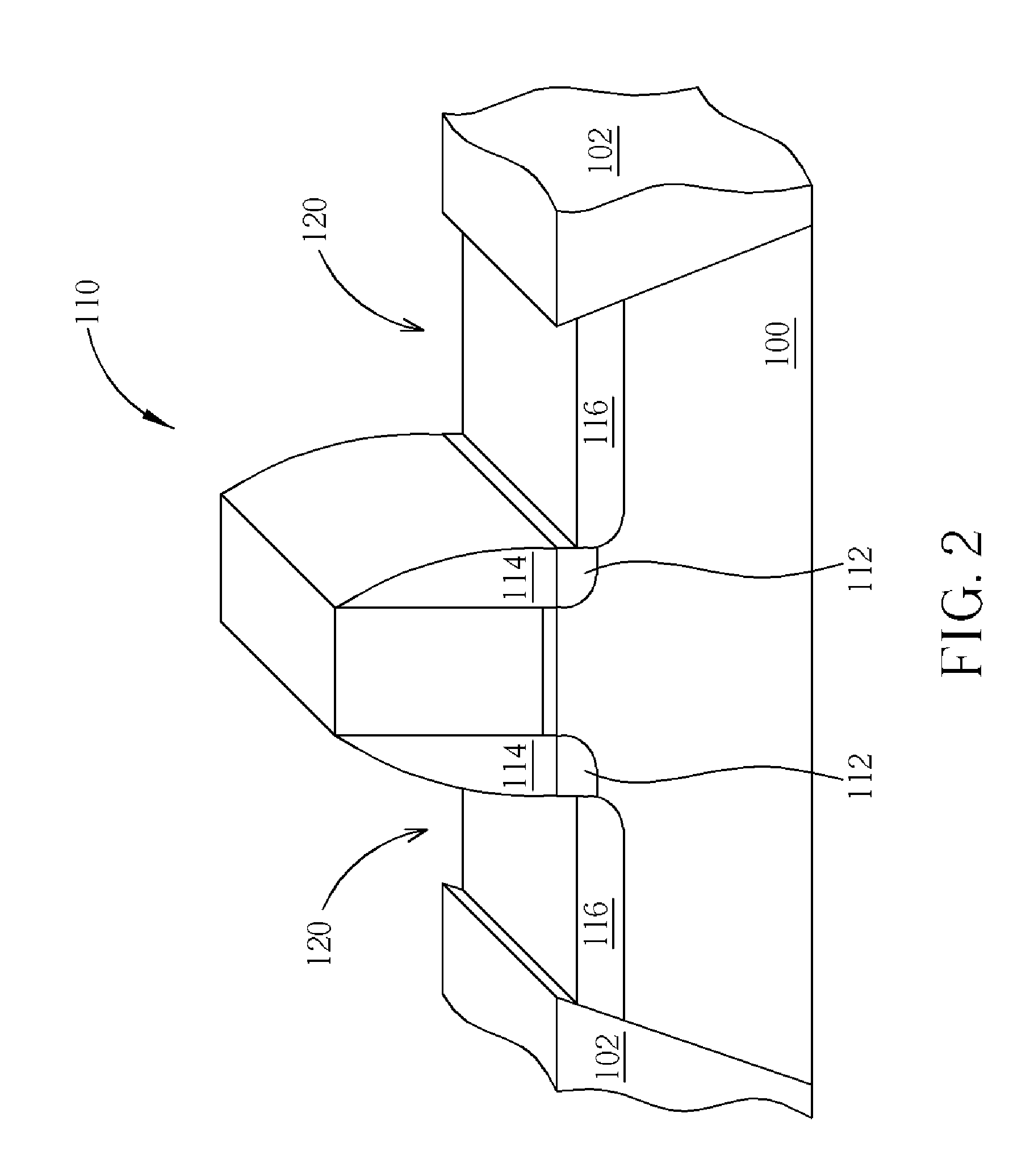

Semiconductor device and manufacturing method thereof

InactiveUS20090278170A1Reduce impactWaste of costSemiconductor/solid-state device manufacturingSemiconductor devicesSalicideSemiconductor

A method for manufacturing a semiconductor device includes providing a substrate having at least a gate structure formed thereon, forming LDDs in the substrate respectively at two side of the gate structure and a spacer at sidewalls of the gate structure, forming a source / drain in the substrate at two side of the gate structure, performing ant etching process to form recesses respectively in the source / drain, forming a barrier layer in the recesses; and performing a salicide process.

Owner:UNITED MICROELECTRONICS CORP

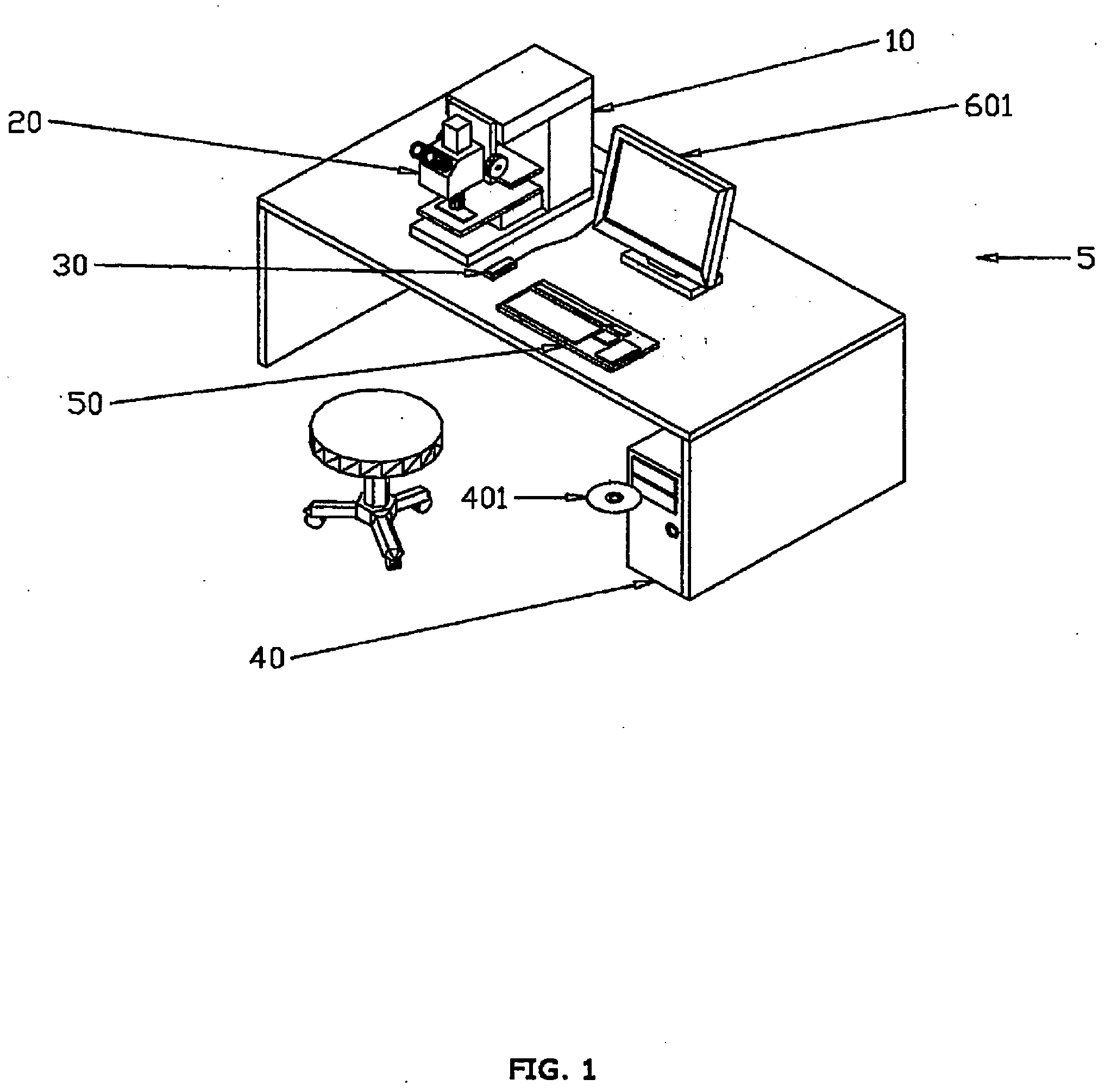

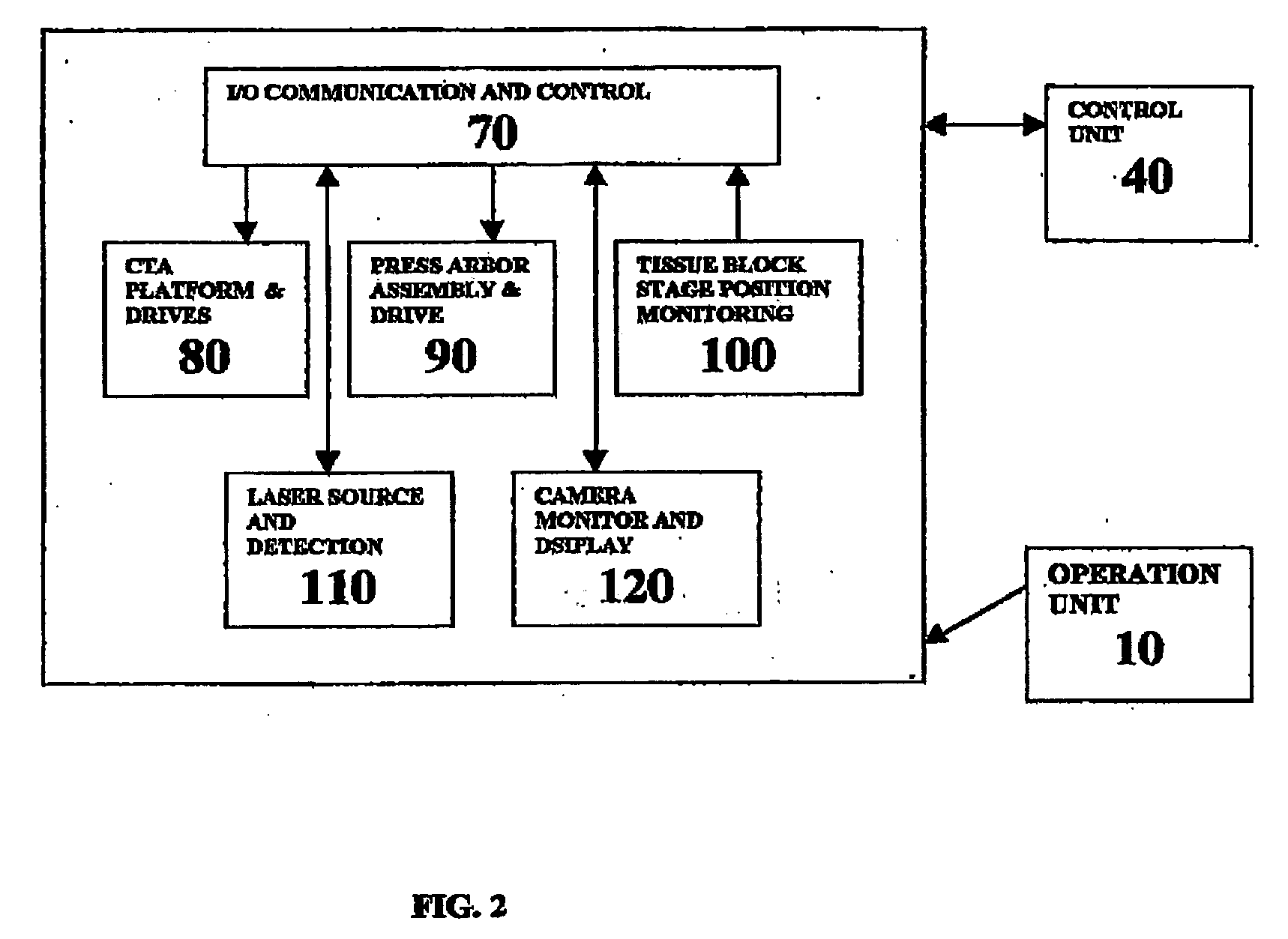

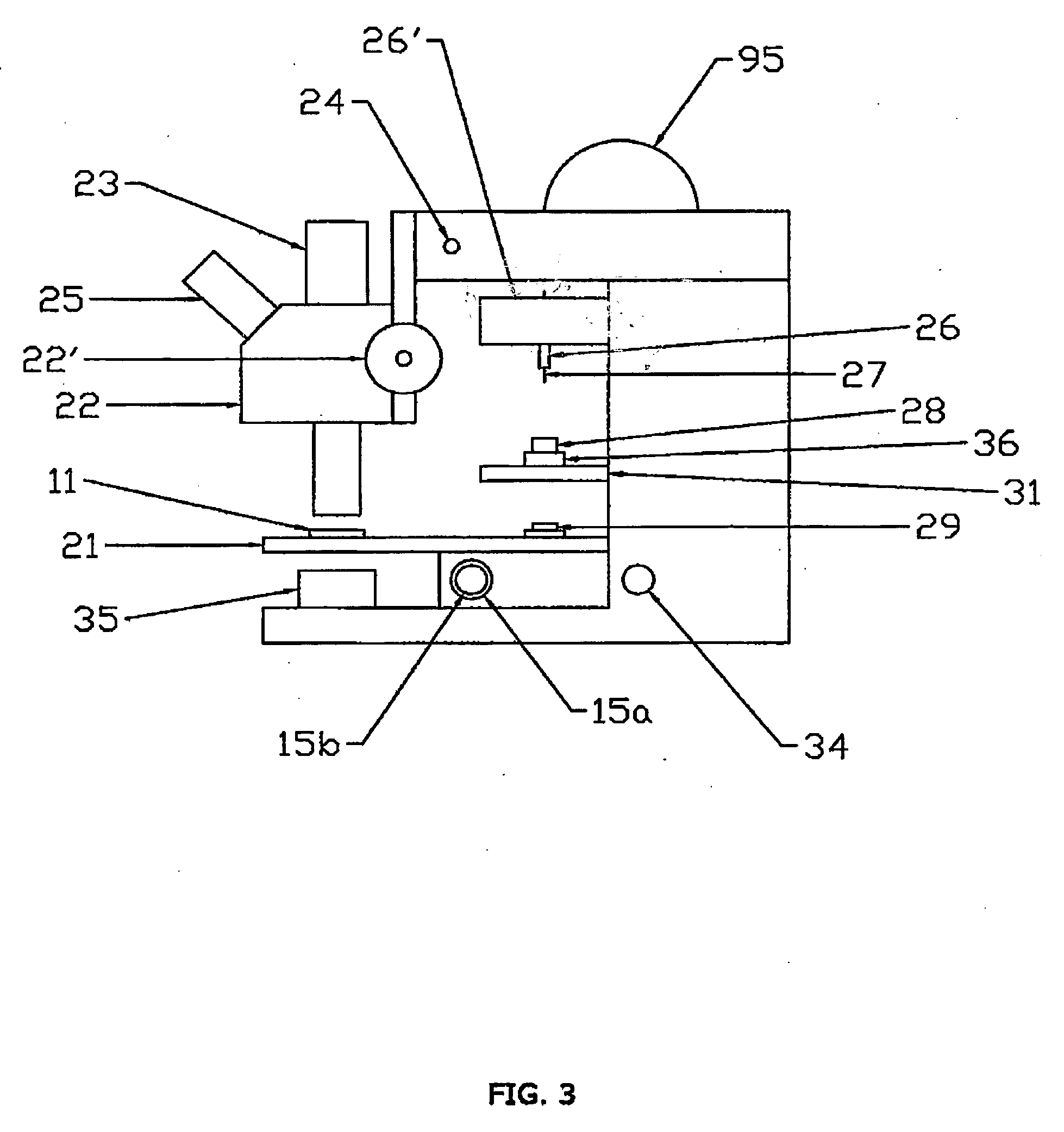

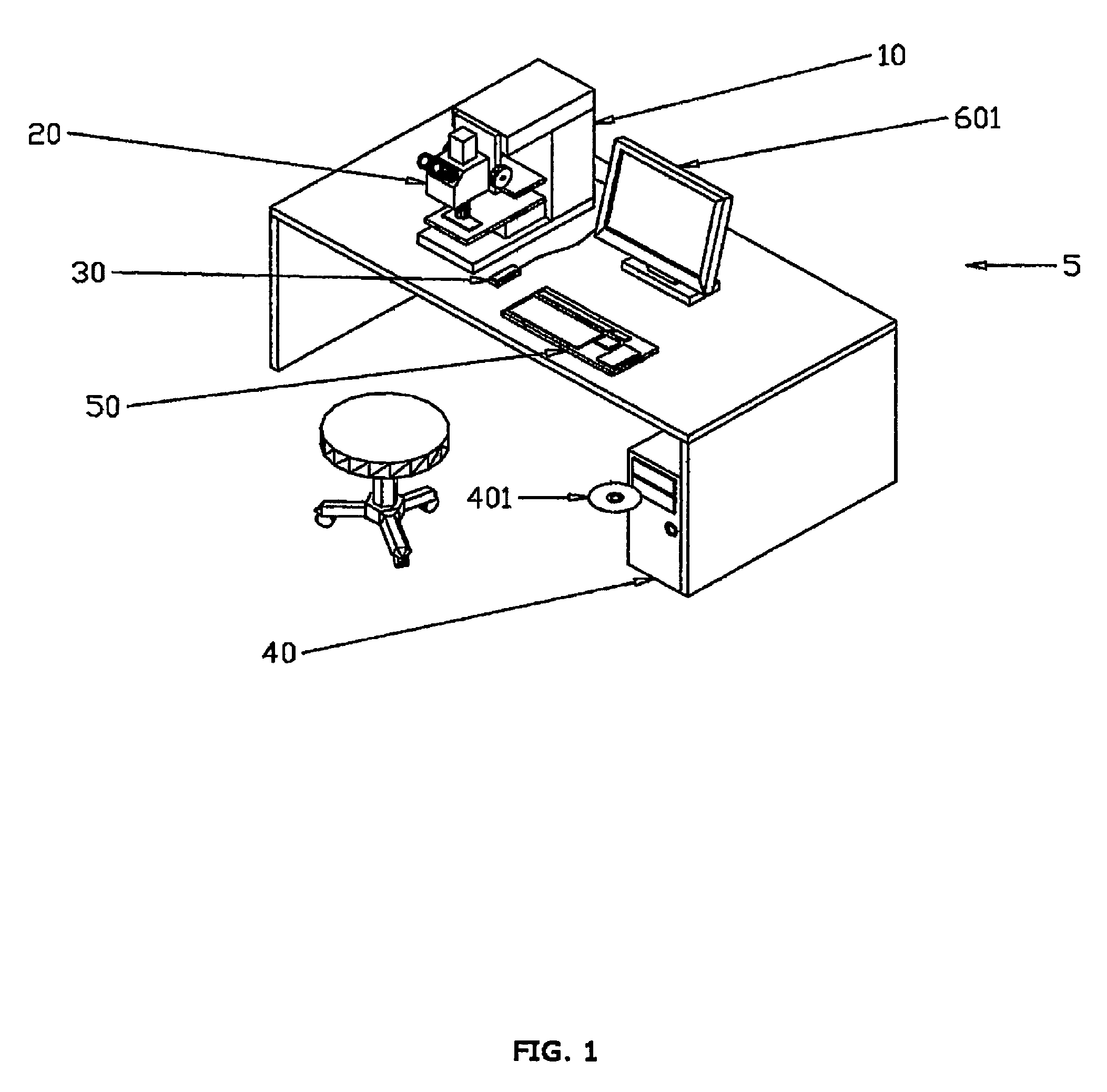

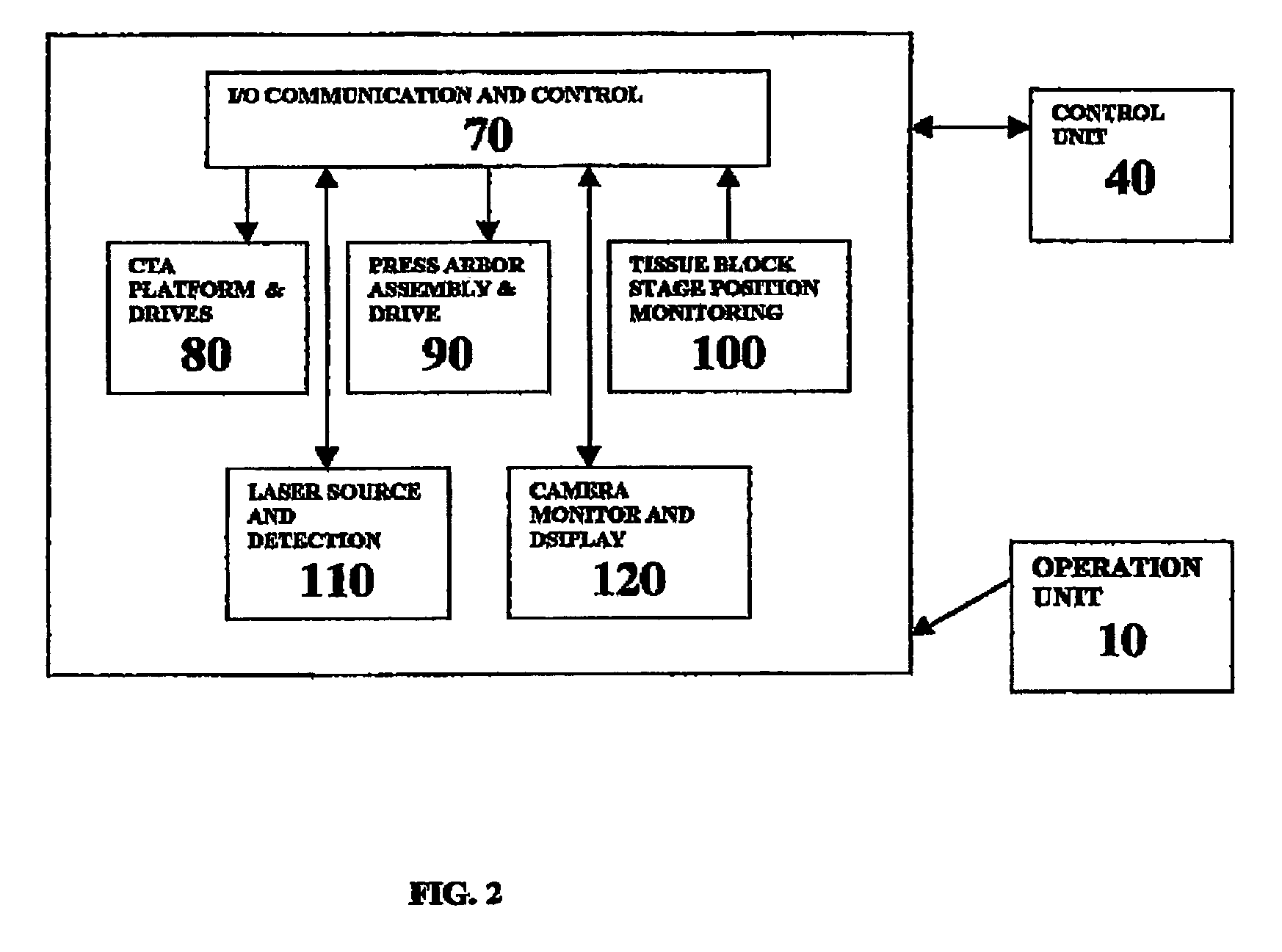

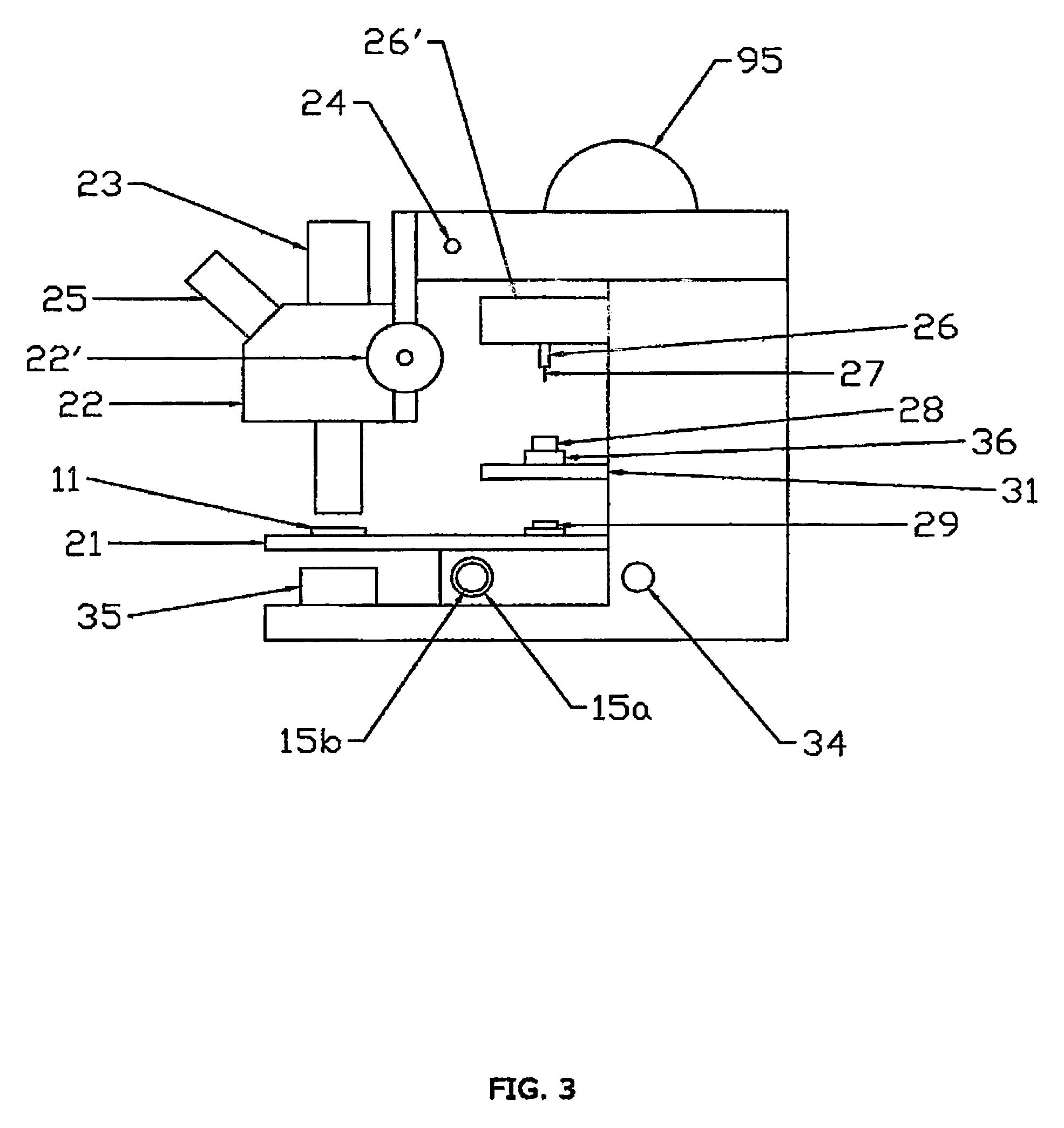

Tissue punch and tissue sample labeling methods and devices for microarray preparation, archiving and documentation

InactiveUS20060199169A1Avoid mistakesWaste of tissueBioreactor/fermenter combinationsBiological substance pretreatmentsVertical tubeTissue Arrays

A workstation that provides an efficient method to collect biological tissues in a column tissue array format from blocks of embedded, frozen tissues, or fresh tissues. The workstation has a control unit for directing operations of the workstation and the operation unit for performing the production of the tissue column array. The operation unit comprises an array of vertical tubes in a platform, an arbor which engages and presses down the designated tube in the array, the embedded tissue block which is mounted directly below the designated tube, assemblies of motors responsive to the control unit for driving the platform and the tissue block, a light source block for generating an alignment signal, and a light detector block which measures the signal from the light source to determine the degree of alignment between the arbor, punch tubes, and the specimen block.

Owner:EXB TECH

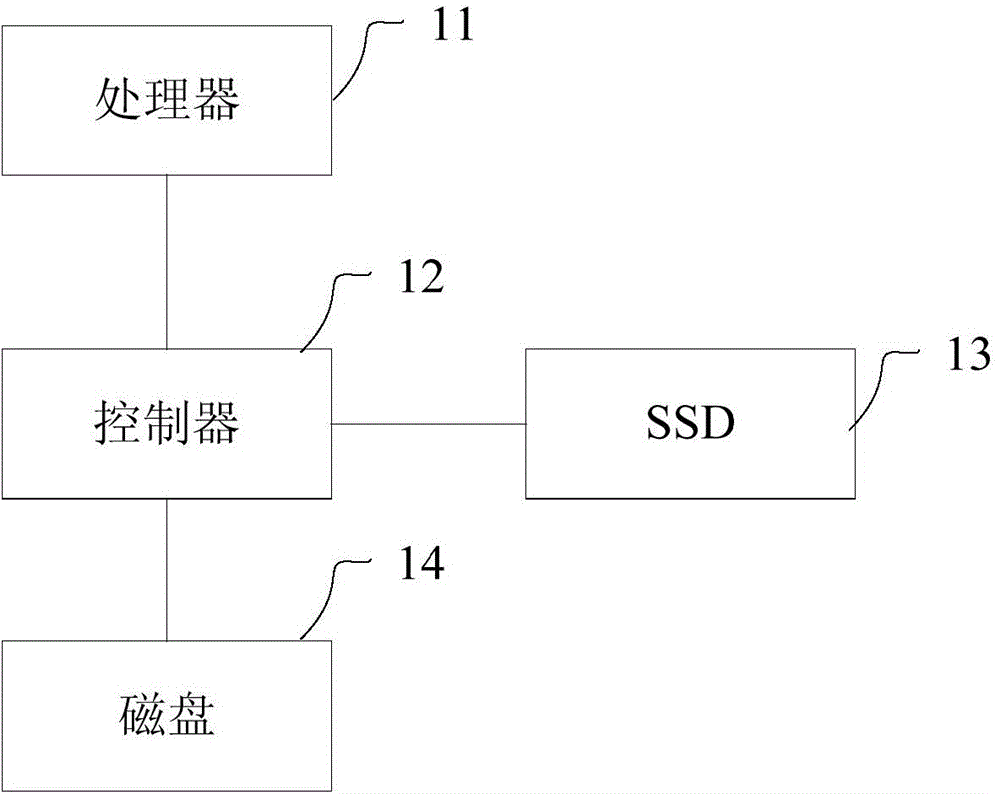

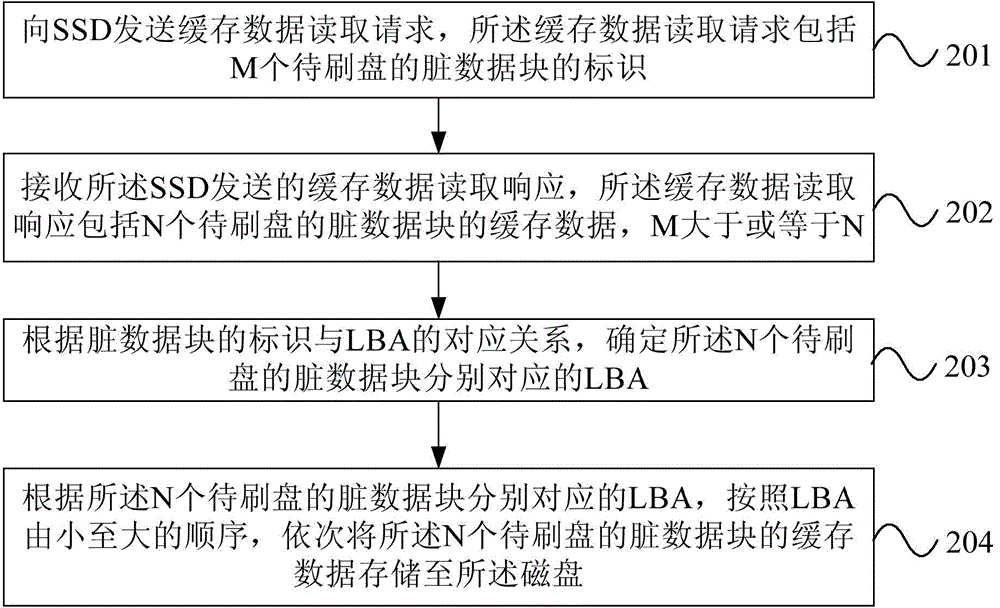

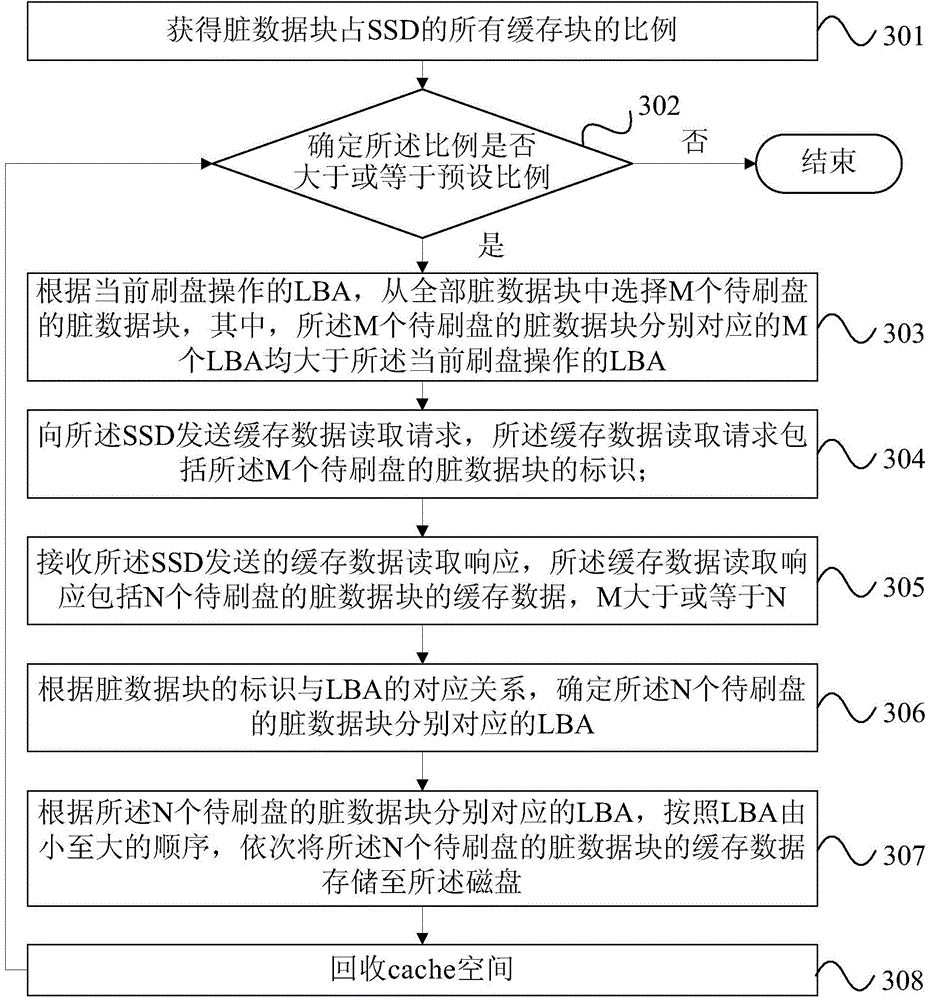

Cached data disk brushing method and device

ActiveCN104461936AImprove brushing efficiencyAvoid brushing timeInput/output to record carriersMemory adressing/allocation/relocationDirty dataRequest–response

The invention provides a cached data disk brushing method and device. The cached data disk brushing method is applied to a storage system. The storage system comprises a controller, a disk and an SSD, wherein the SSD serves as a cache of the disk. The cached data disk brushing method is executed by the controller and comprises the steps of sending a cached data reading request to the SSD, wherein the cached data reading request includes identifications of dirty data blocks of M disks to be brushed; receiving cached data reading request response sent by the SSD, wherein the cached data reading request response includes cached data of dirty data blocks of N disks to be brushed, and the M is greater than or equal to the N; determining LBA respectively corresponding to the dirty data blocks of the N disks according to the corresponding relation of the identifications of the dirty data blocks and the LBA; sequentially storing the cached data of the dirty data blocks of the N disks in the disk according to the LBA respectively corresponding to the dirty data blocks of the N disks and in an LBA sequence from small to large.

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

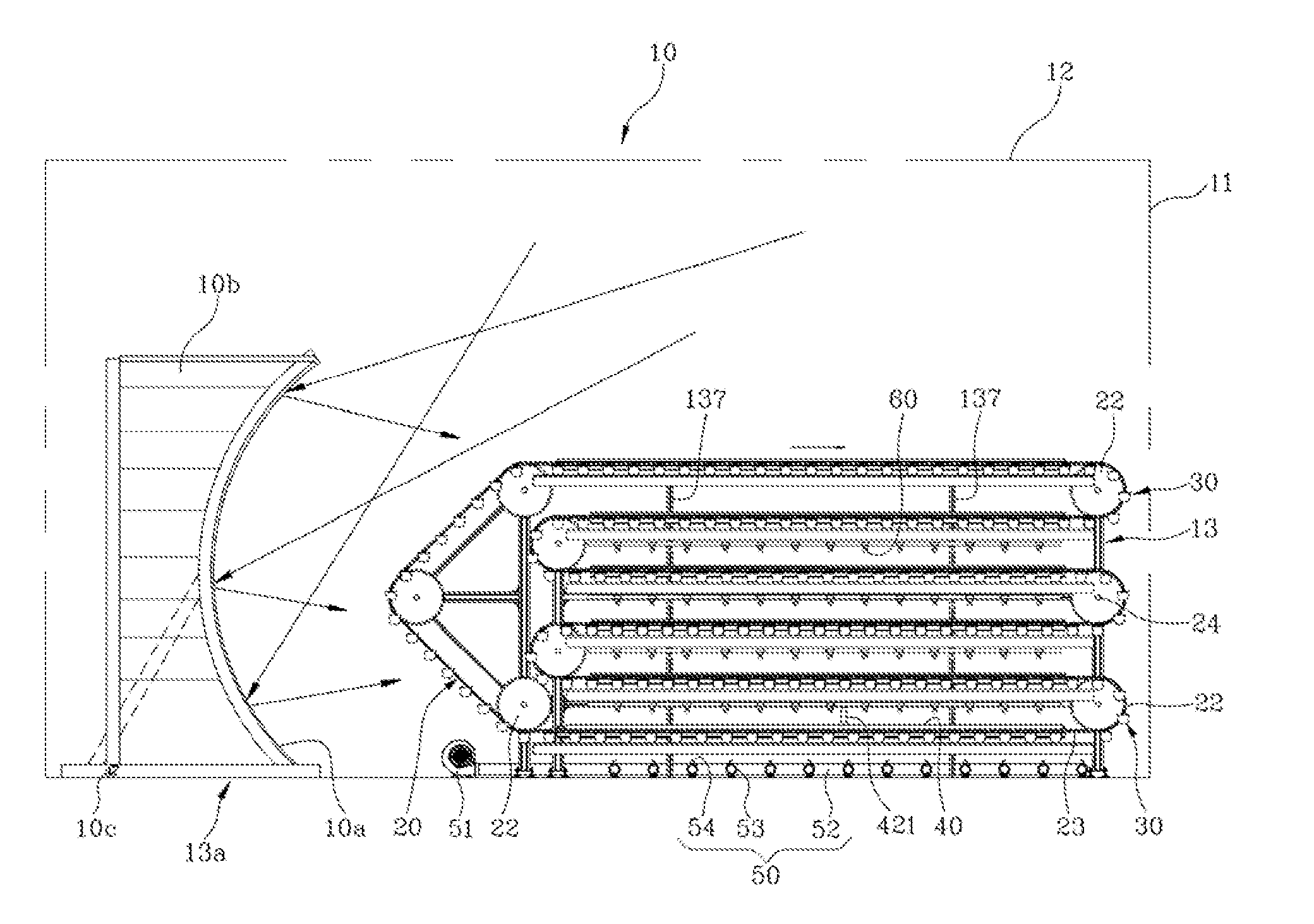

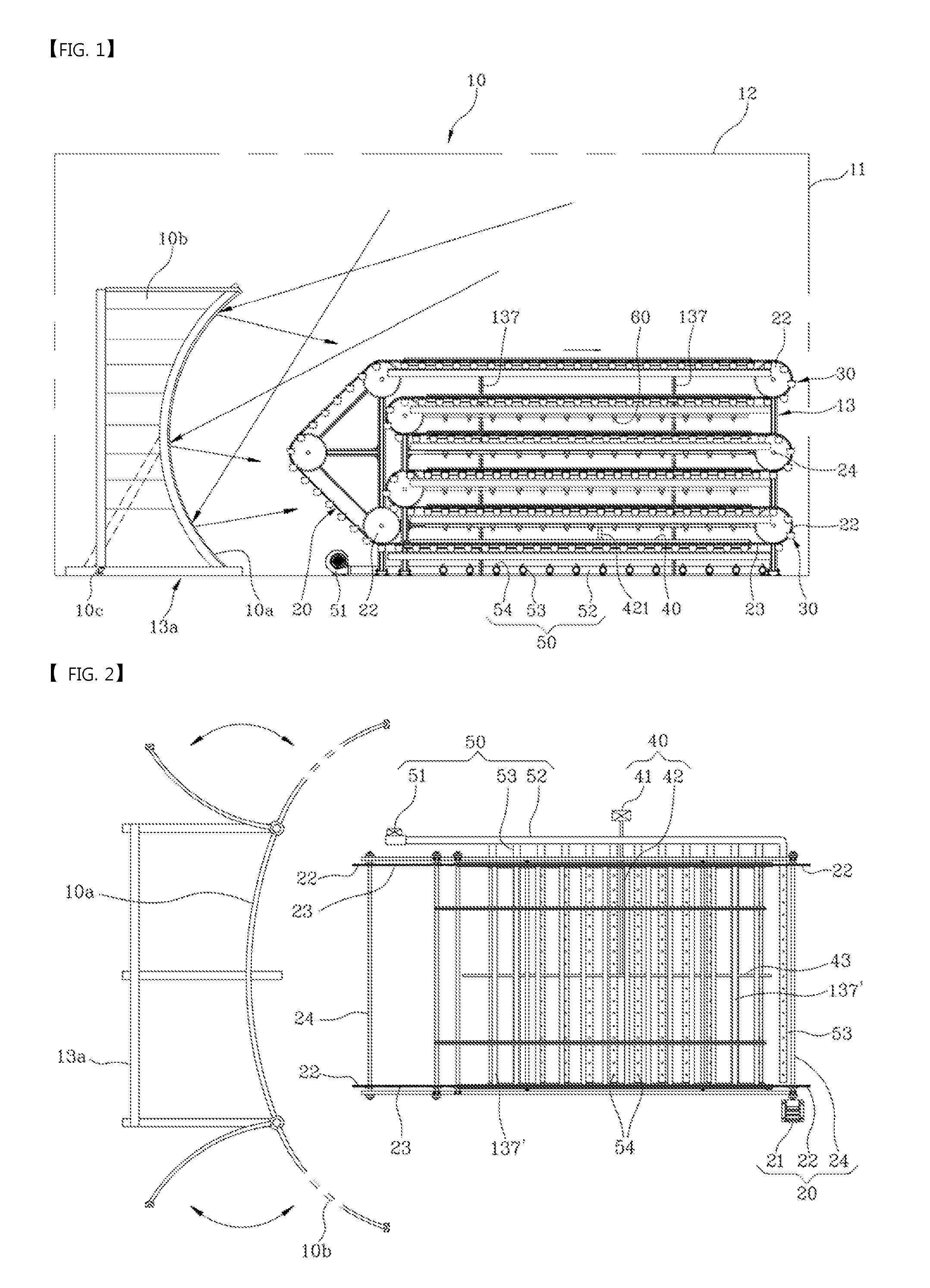

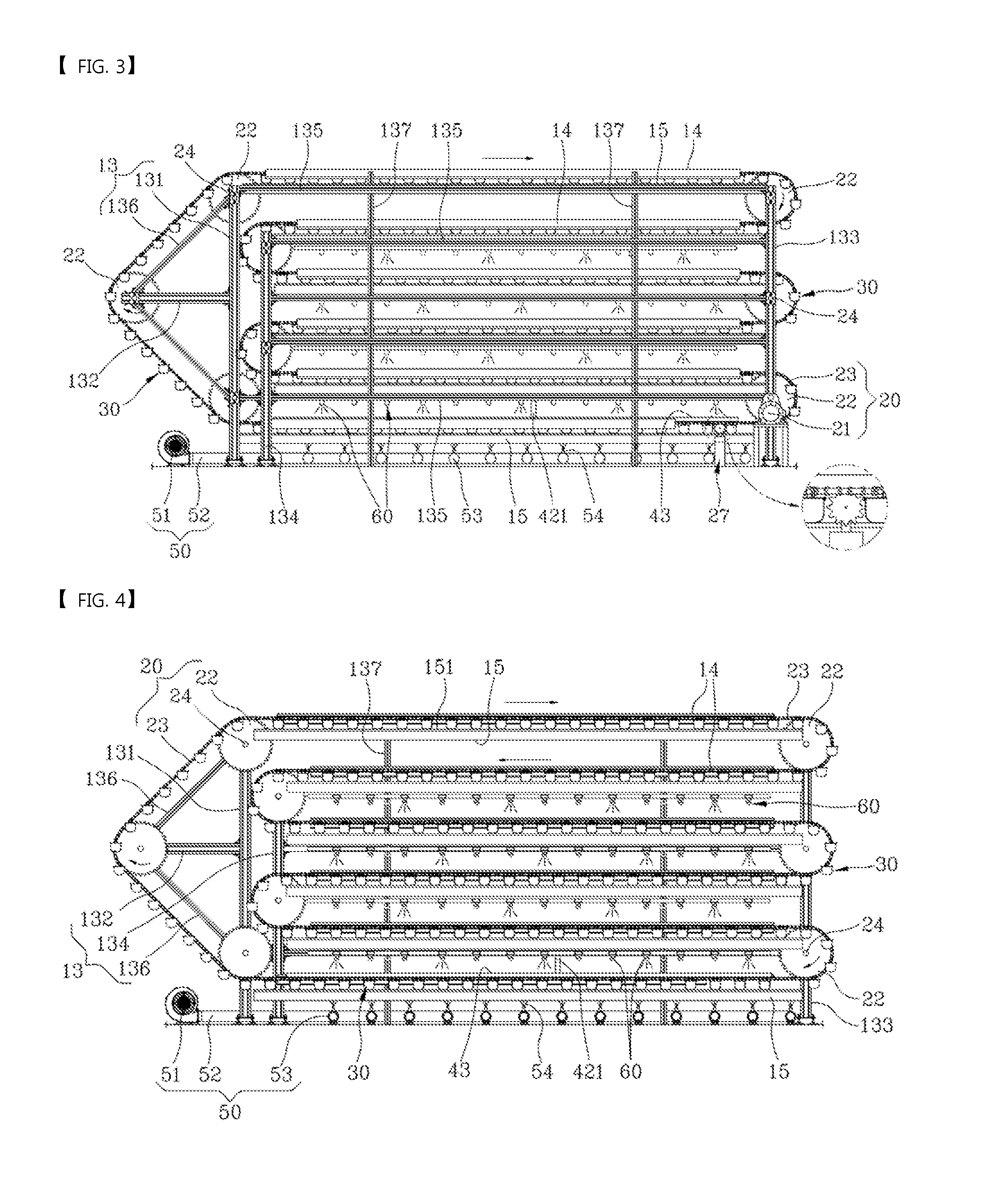

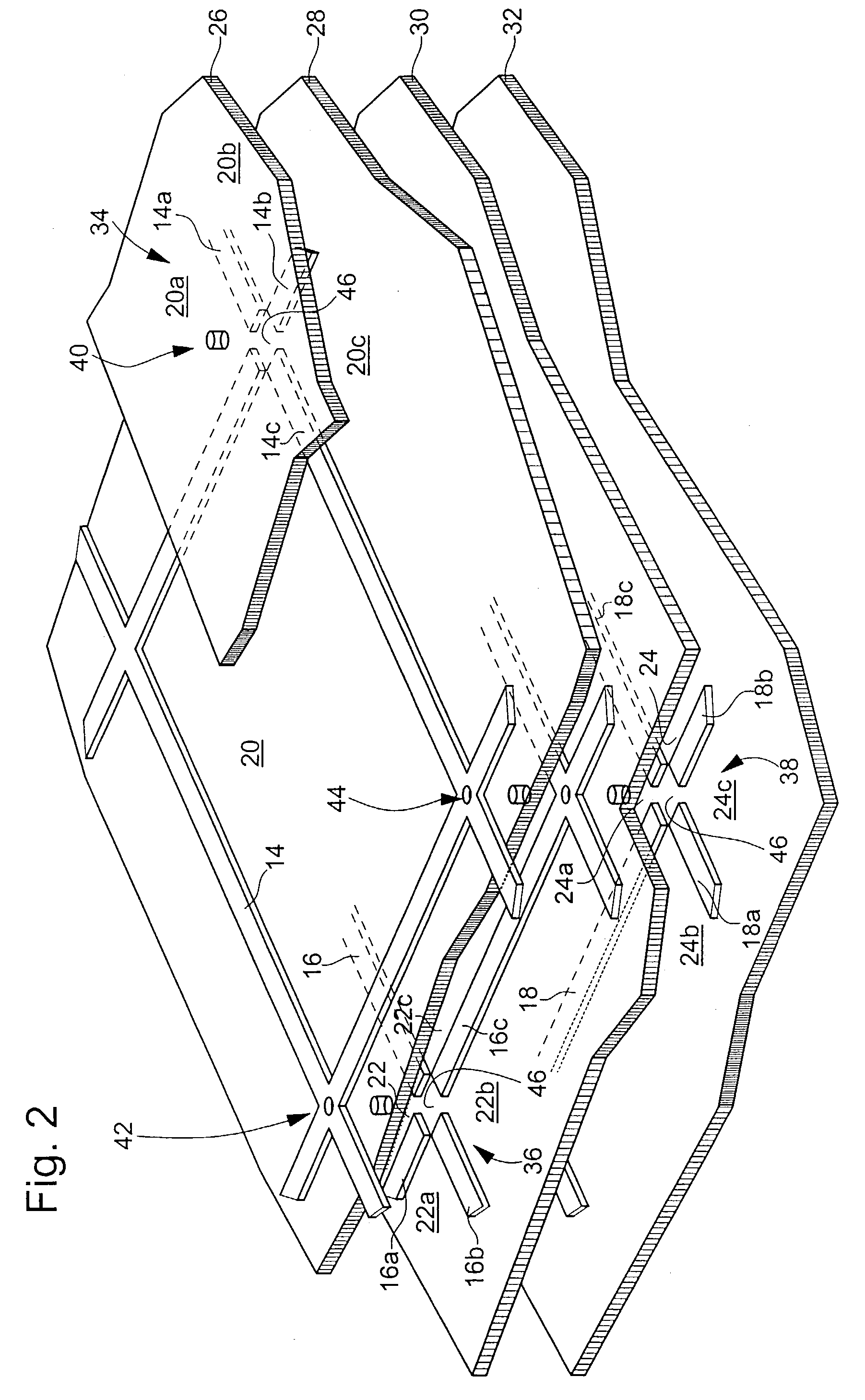

Plant cultivation system

InactiveUS20130305601A1Maximize productivityWorkability maximizedAgriculture gas emission reductionGreenhouse cultivationPlant cultivationEngineering

The plant cultivation system includes: a circulatory system including axises installed in a corresponding portion of a frame installed in a cultivation room; chain gear axis-installed in the axises respectively; a left and a right chains; and a deduction motor connected and installed onto any axis of the axises; cultivating pot members including a can body, and a hook plate, fixed to left and right ends of the upper surface of the can body; and for moving and circulating in the inner space of the cultivation room by rotatably installing as hanging between the left and a right chains by the left and right hook axises and the hook plate; a medicinal fluid supplier; and an air blower, installed in the cultivation room.

Owner:GREEN PLUS CO LTD +1

Tissue punch and tissue sample labeling methods and devices for microarray preparation, archiving and documentation

InactiveUS7405056B2Waste of tissueWaste of timeBioreactor/fermenter combinationsBiological substance pretreatmentsVertical tubeTissue Arrays

A workstation that provides an efficient method to collect biological tissues in a column tissue array format from blocks of embedded, frozen tissues, or fresh tissues. The workstation has a control unit for directing operations of the workstation and the operation unit for performing the production of the tissue column array. The operation unit comprises an array of vertical tubes in a platform, an arbor which engages and presses down the designated tube in the array, the embedded tissue block which is mounted directly below the designated tube, assemblies of motors responsive to the control unit for driving the platform and the tissue block, a light source block for generating an alignment signal, and a light detector block which measures the signal from the light source to determine the degree of alignment between the arbor, punch tubes, and the specimen block.

Owner:EXB TECH

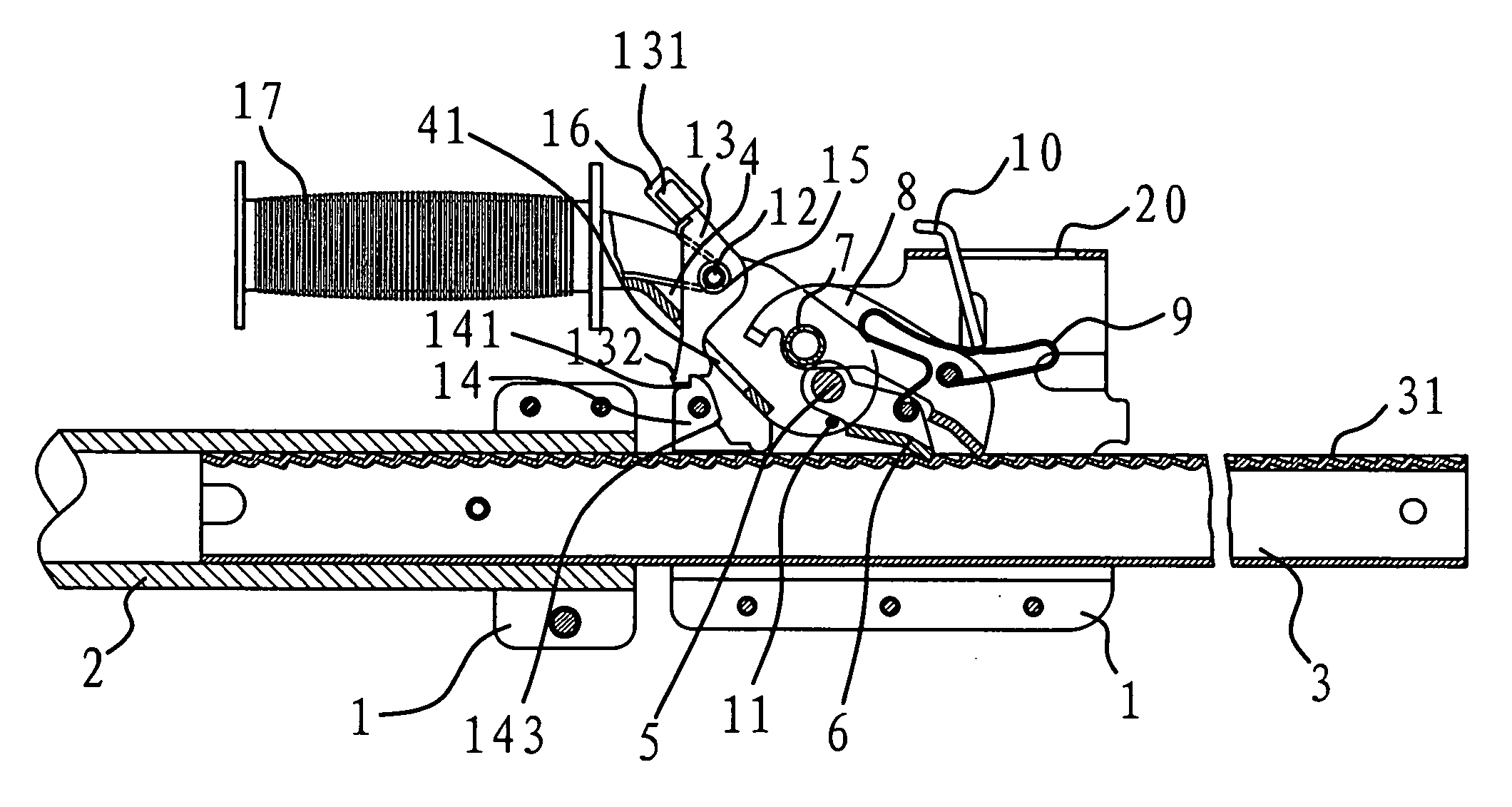

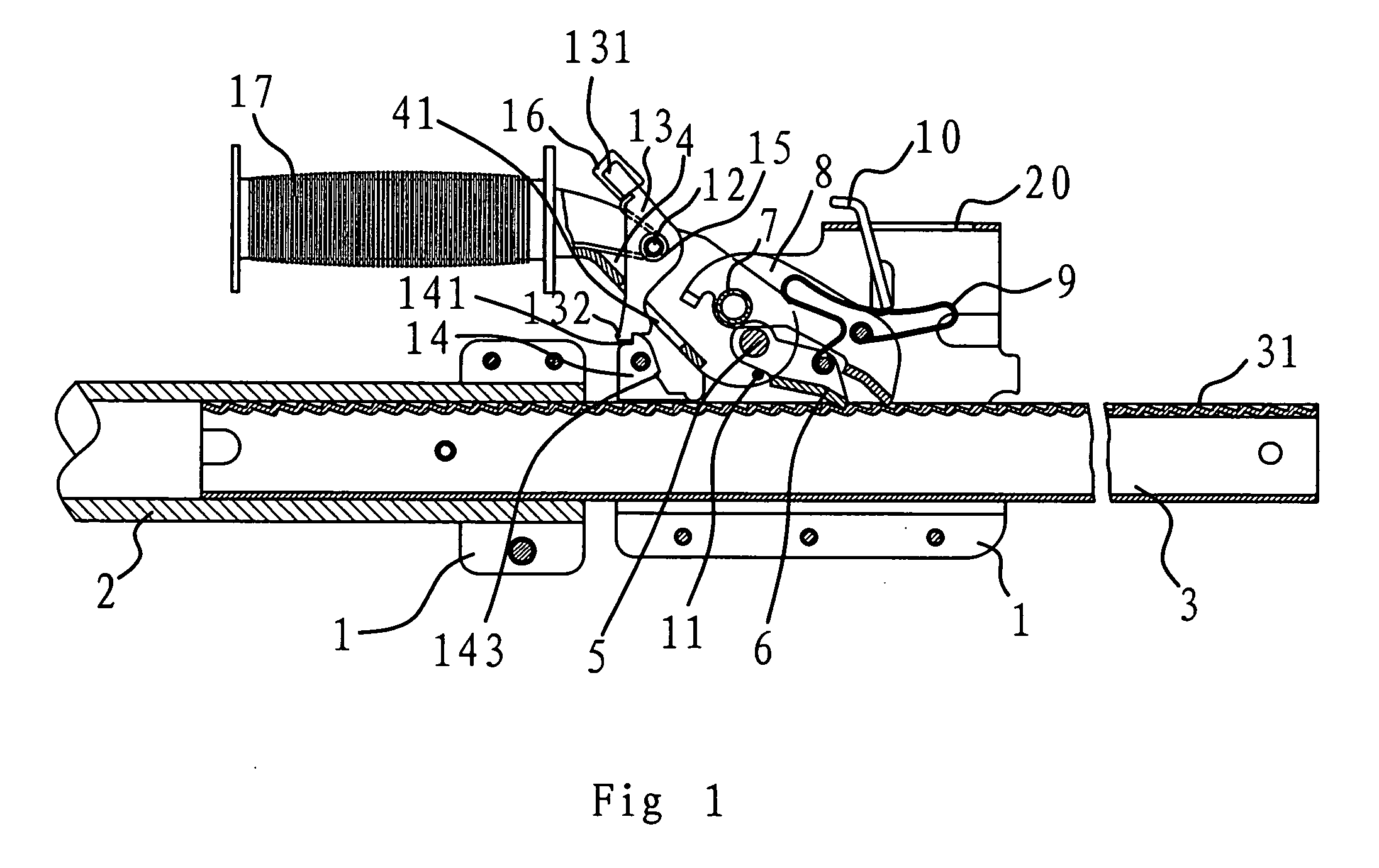

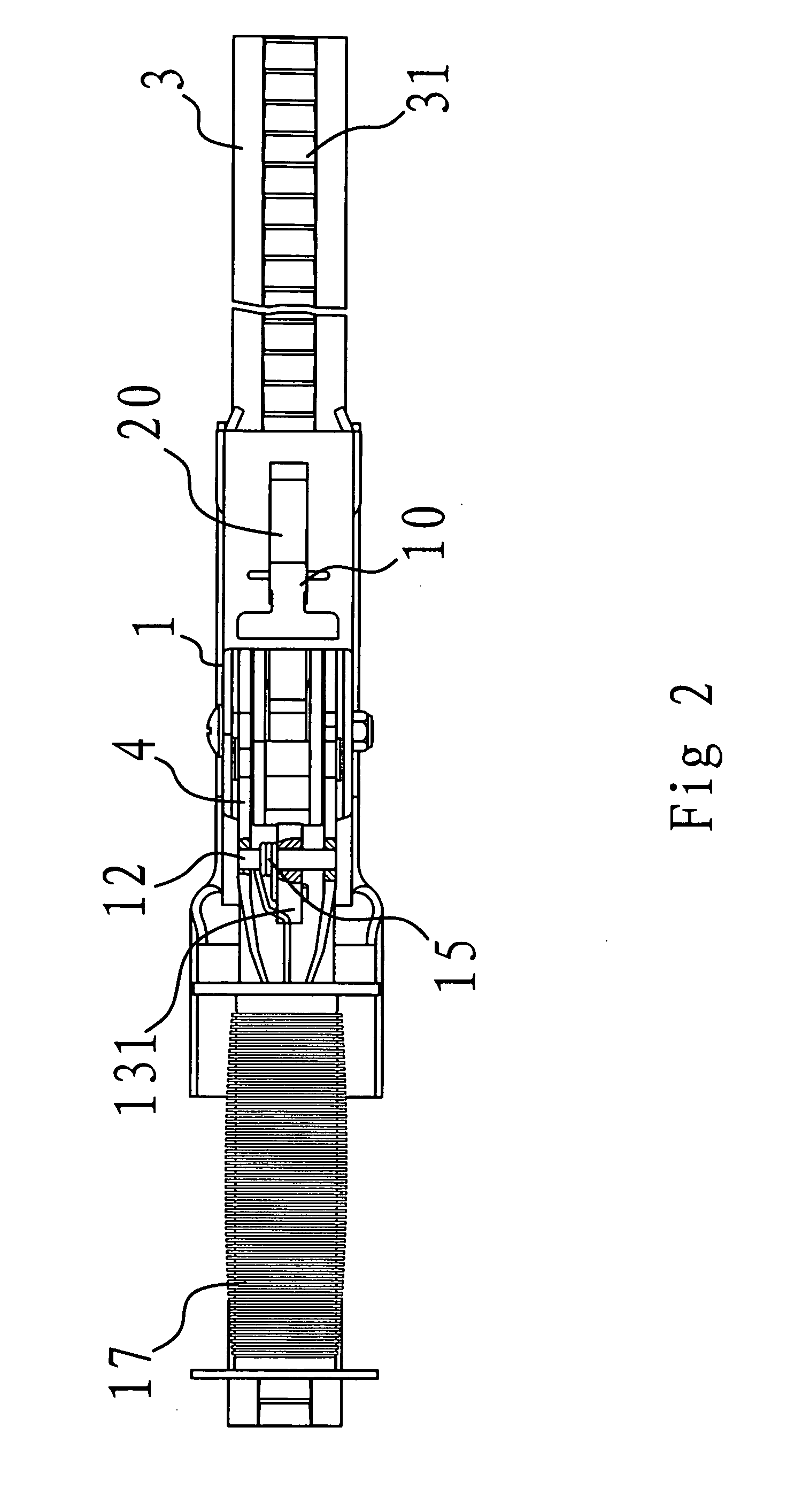

Programming device for returning robot to waiting position

ActiveUS7774099B2Waste of timeShort timeProgramme-controlled manipulatorComputer controlRobot controlEmbedded system

A programming device for making a program for returning a robot to its waiting position when the robot is stopped by an error. A robot control device is connected to the programming device via a network line. When the robot during operation is stopped by the error, information including data of a position where the robot is stopped is transferred to the programming device. The programming device makes the returning program, based on layout data, the received information and data including teaching positions and attribute data of the positions, by which the robot may be returned from the stop position to the waiting position without interfering with peripheral devices. The returning program is executed by using an offline simulation function of the programming device. The program is transferred to the robot control device after it is judged that interference will not occur. The robot may be safely returned to the waiting position by executing the returning program.

Owner:FANUC LTD

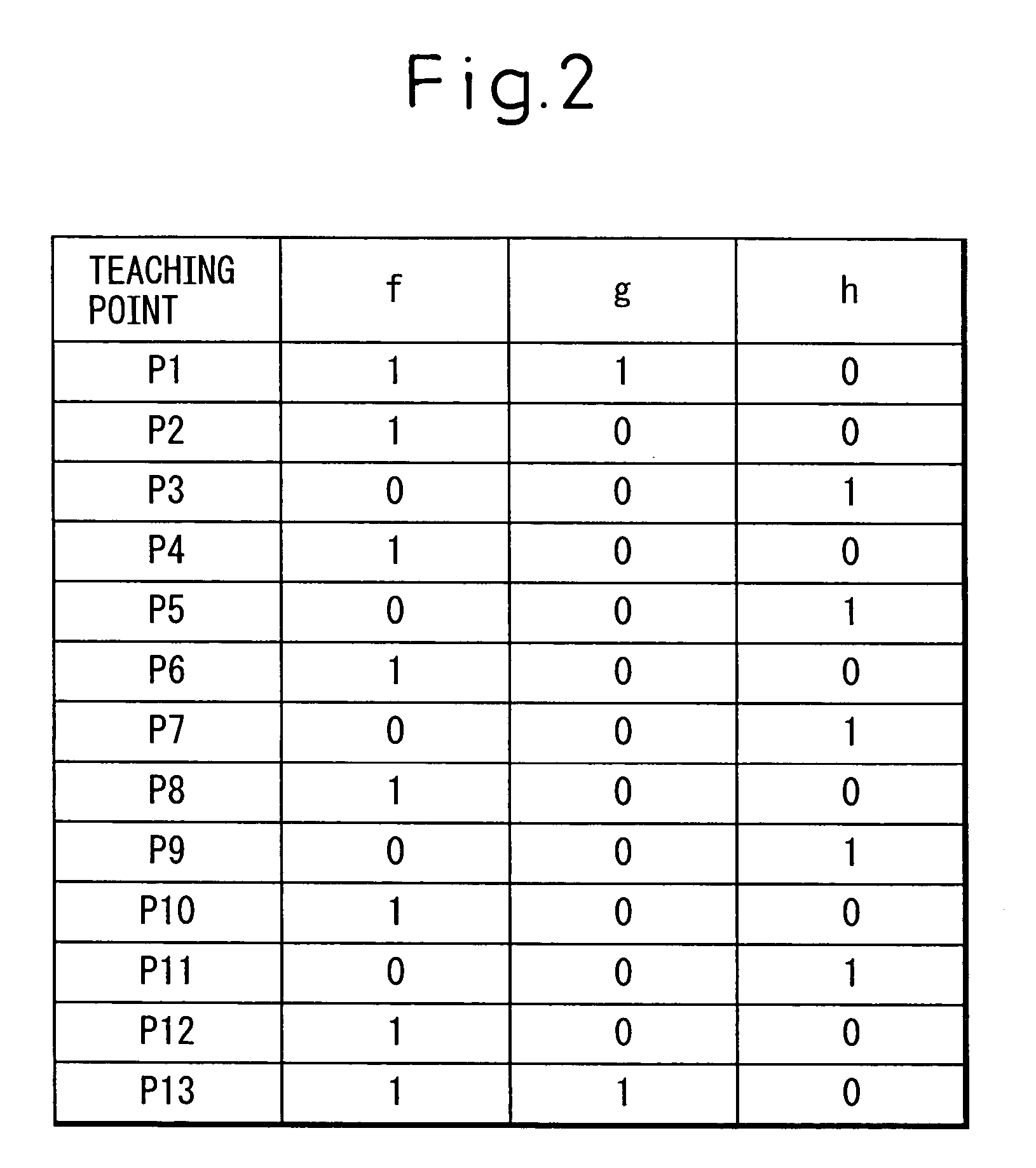

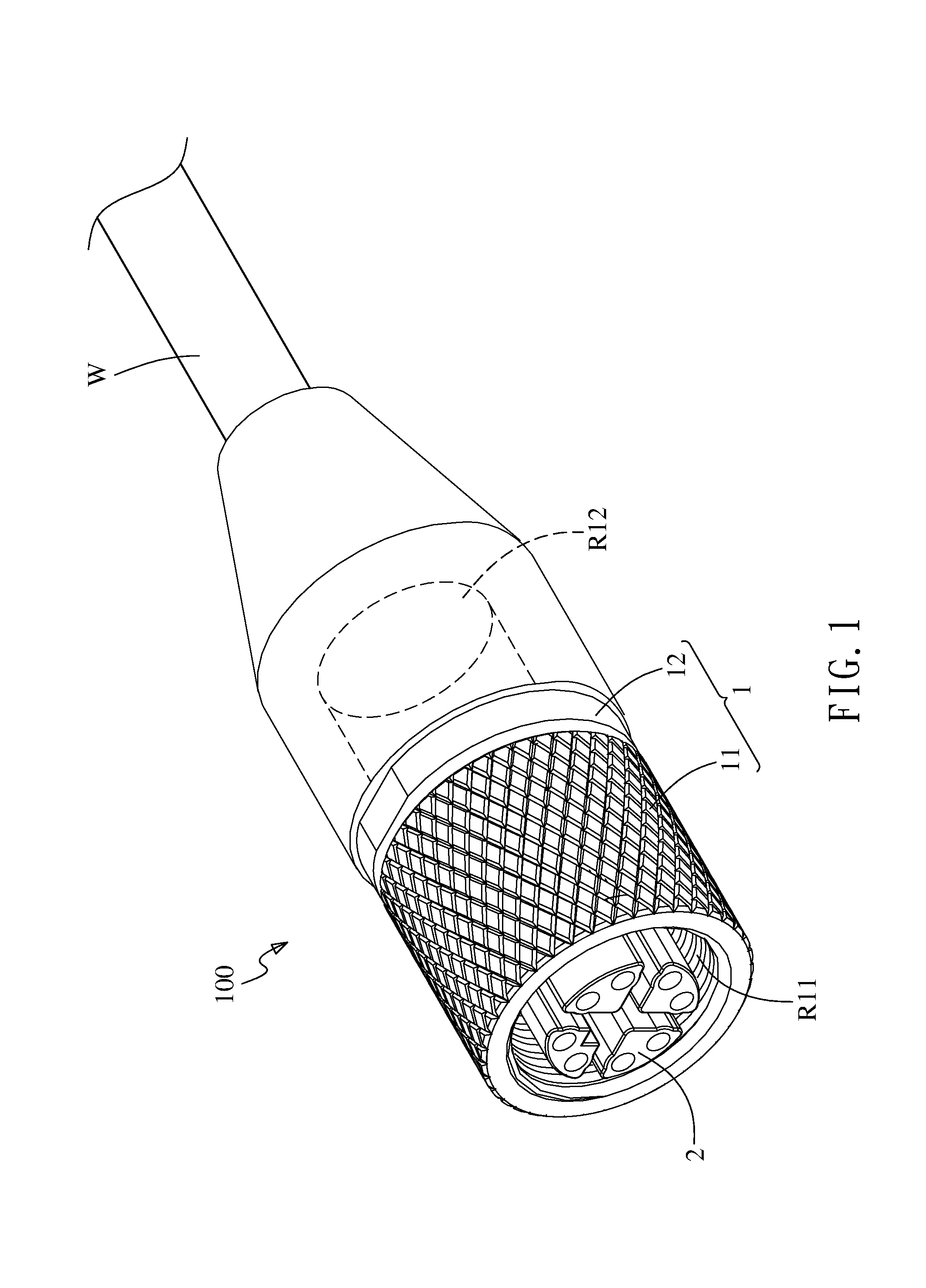

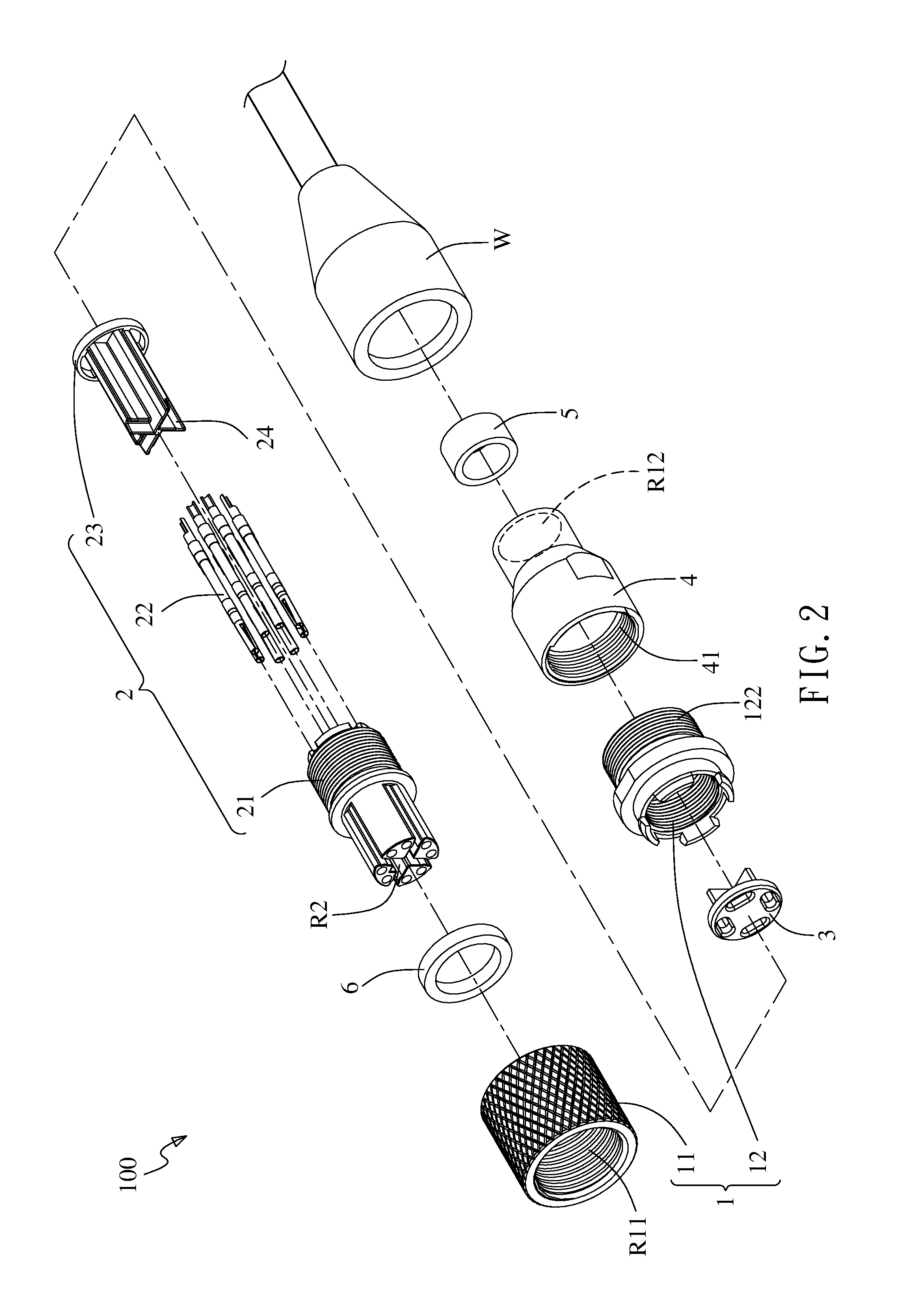

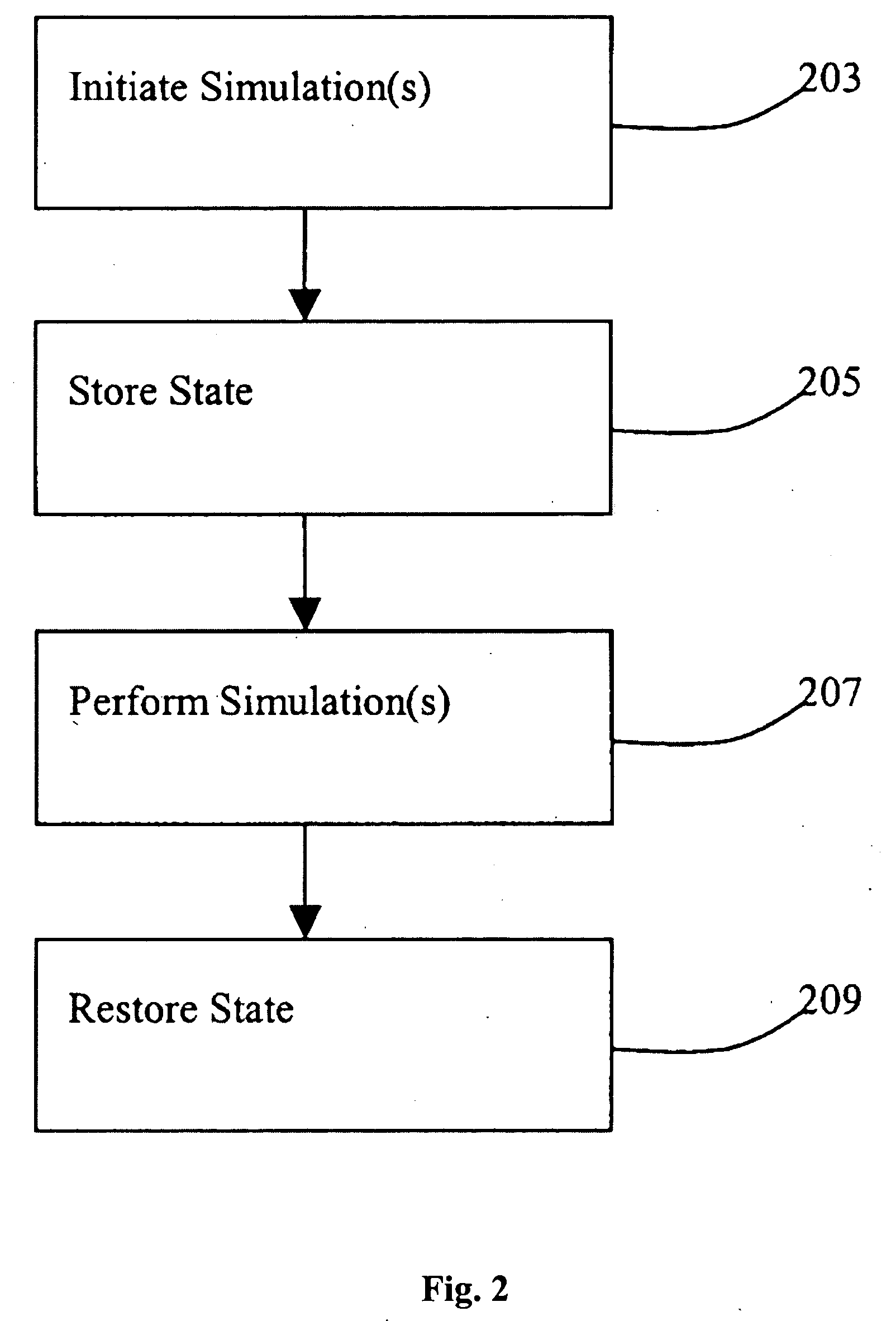

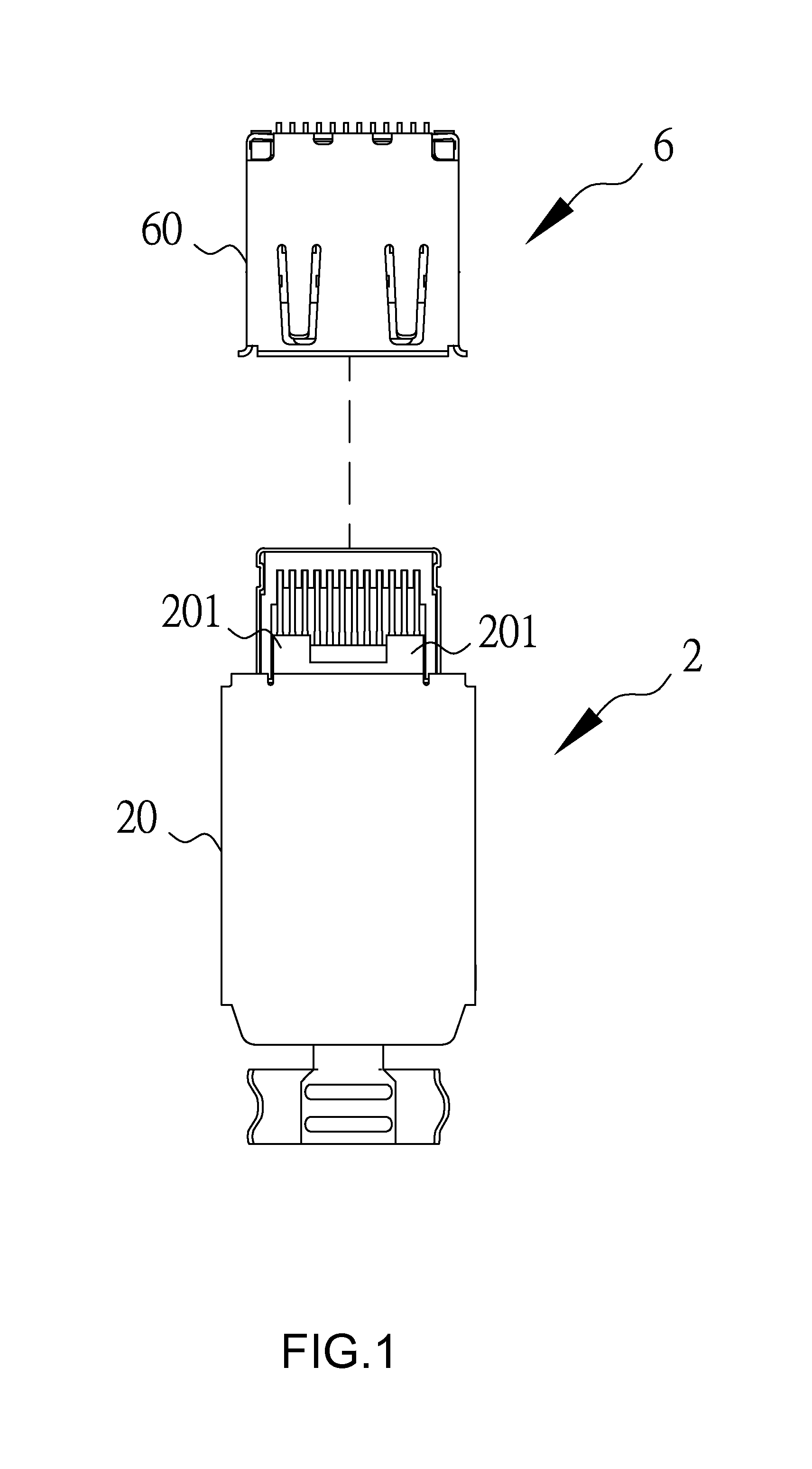

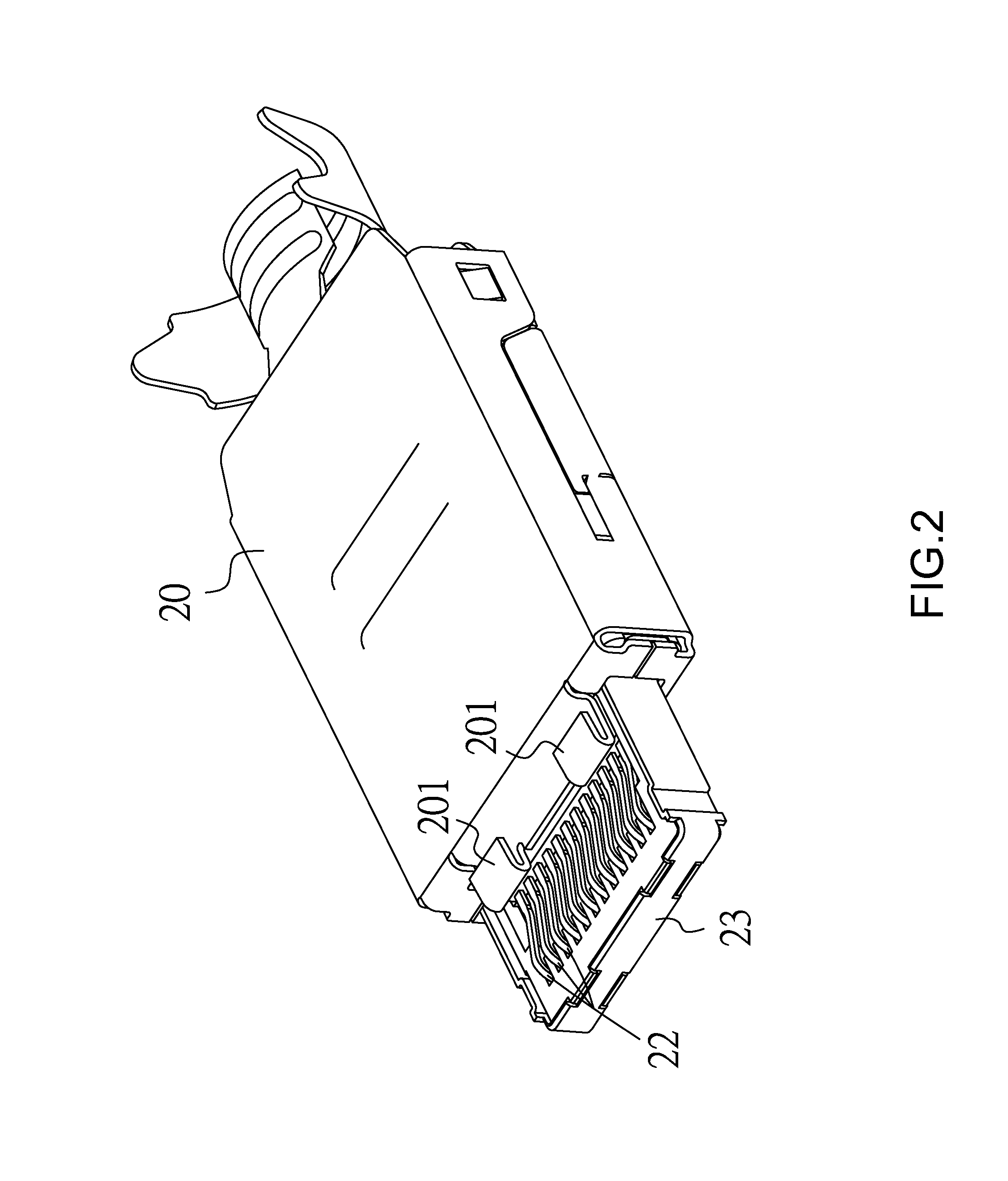

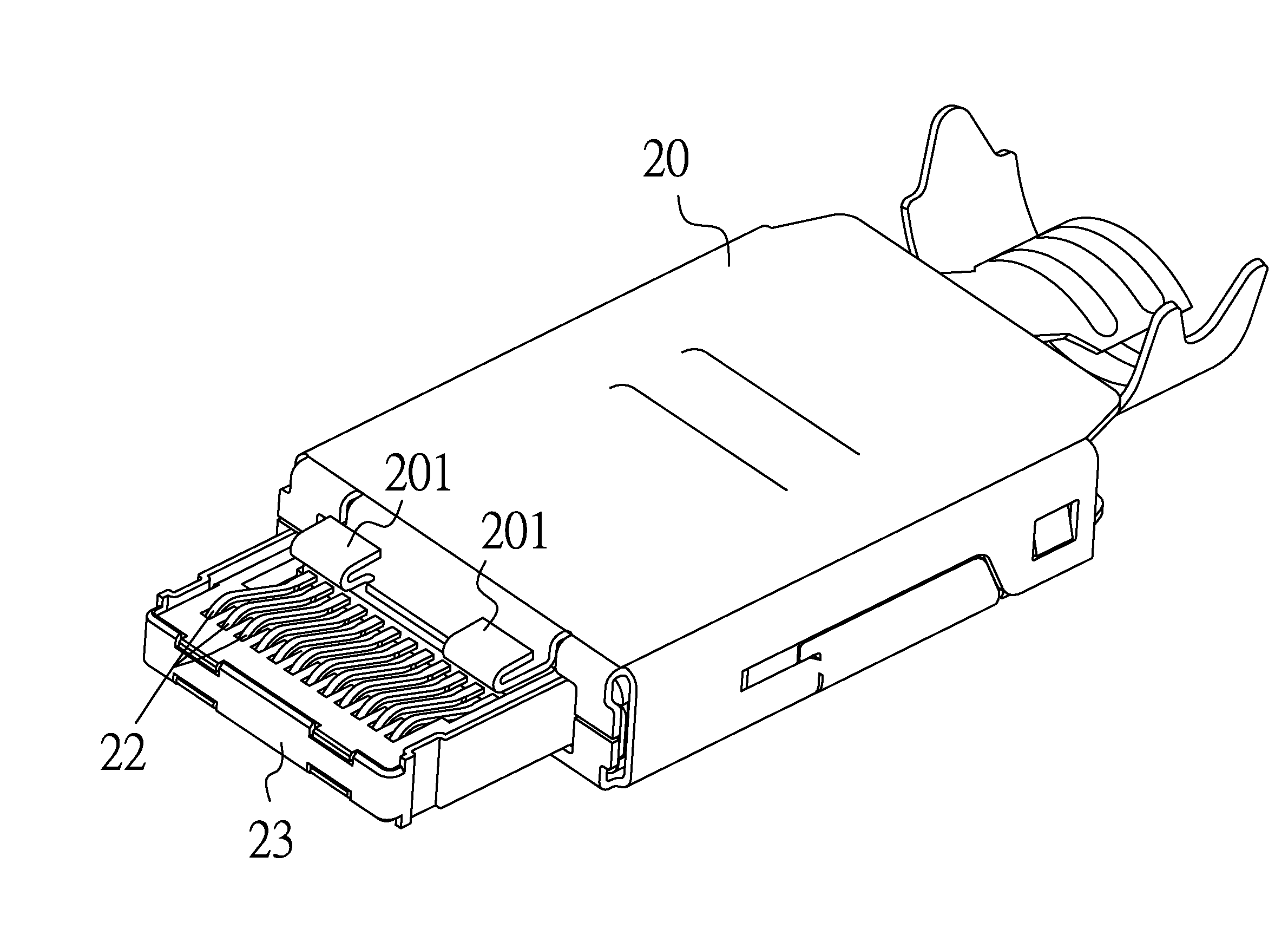

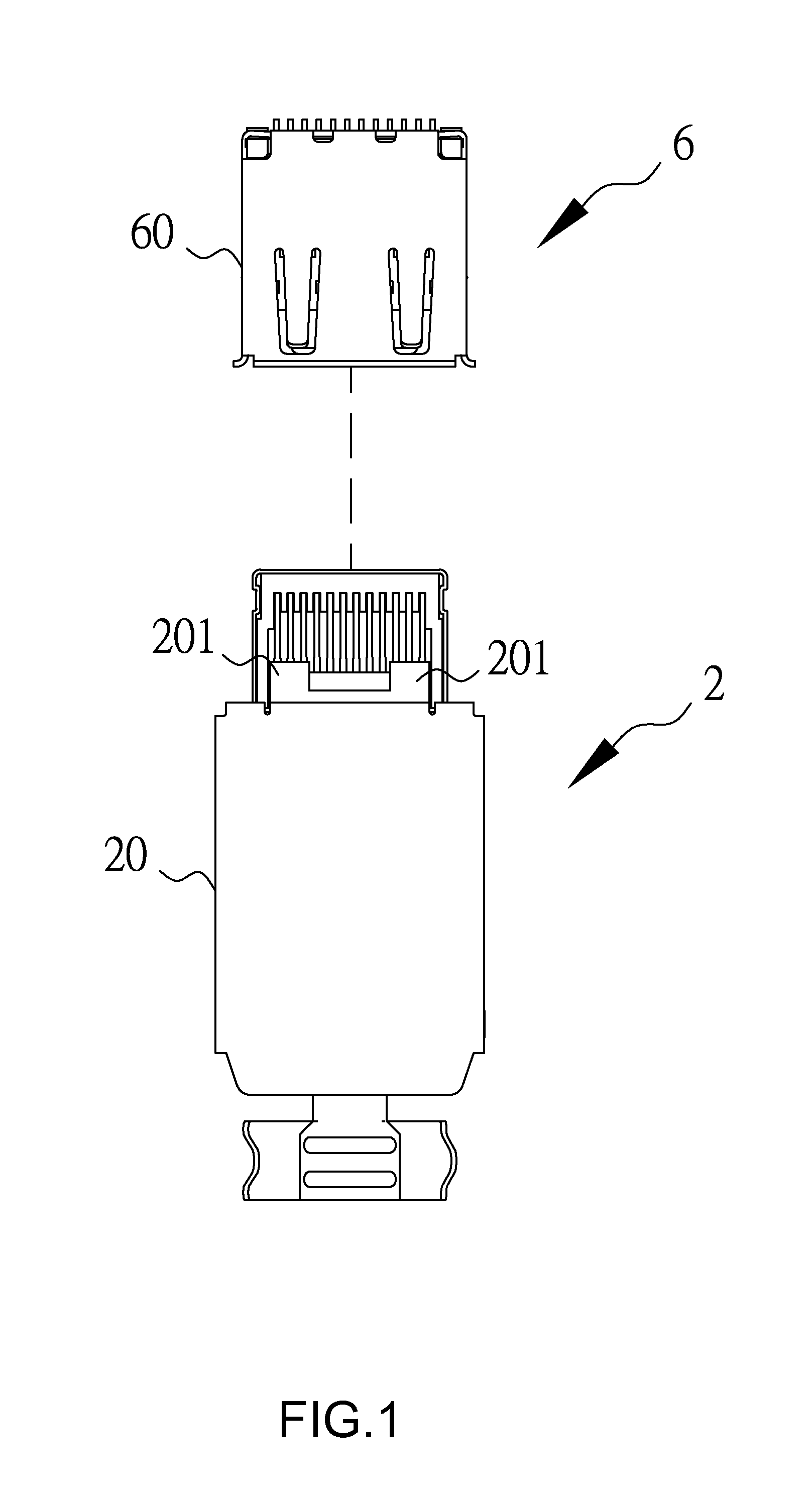

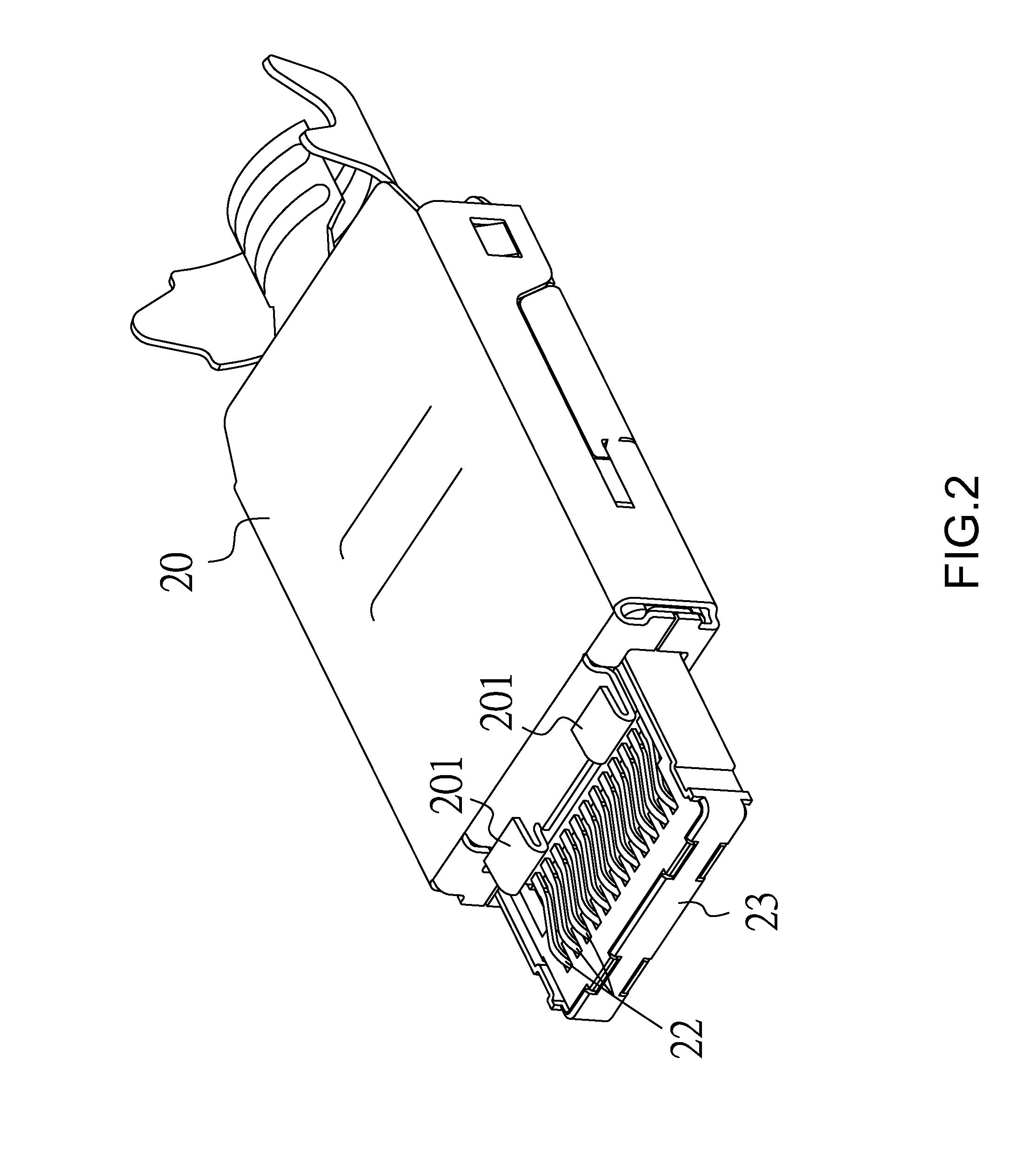

Electrical connector

InactiveUS20160204556A1Waste of timeOne pole connectionsElectrically conductive connectionsEngineeringElectrical connector

An electrical connector includes a connecting casing, a terminal assembly and a receiving member, in favor to attaching on a cable. Each rear end of a plurality of terminals of the terminal assembly protrude to a terminal carrier of the terminal assembly in furtherance to penetrate through the receiving member up till the terminals being exposed out of a rear-side socket of the connecting casing.

Owner:CHANT SINCERE

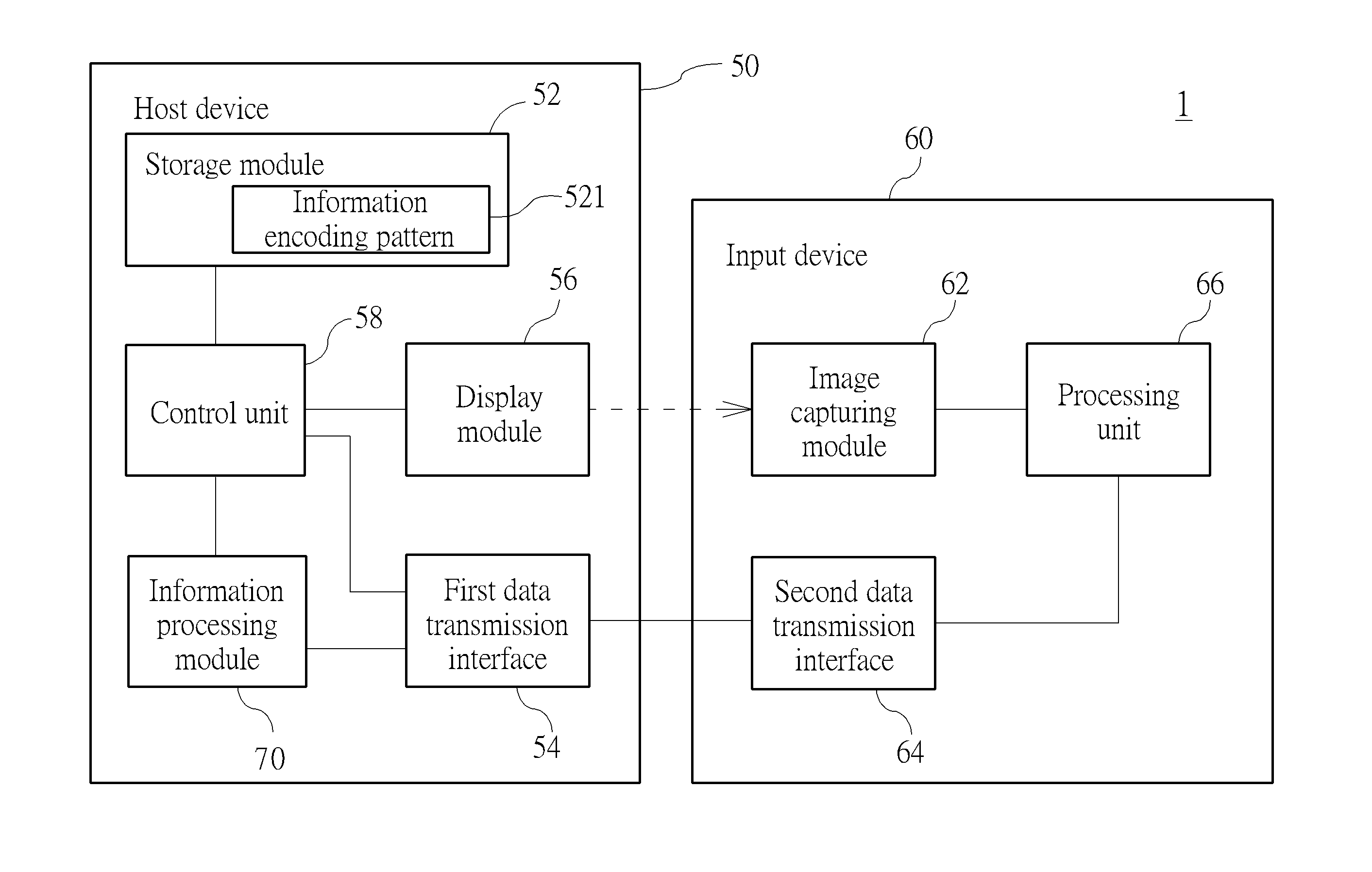

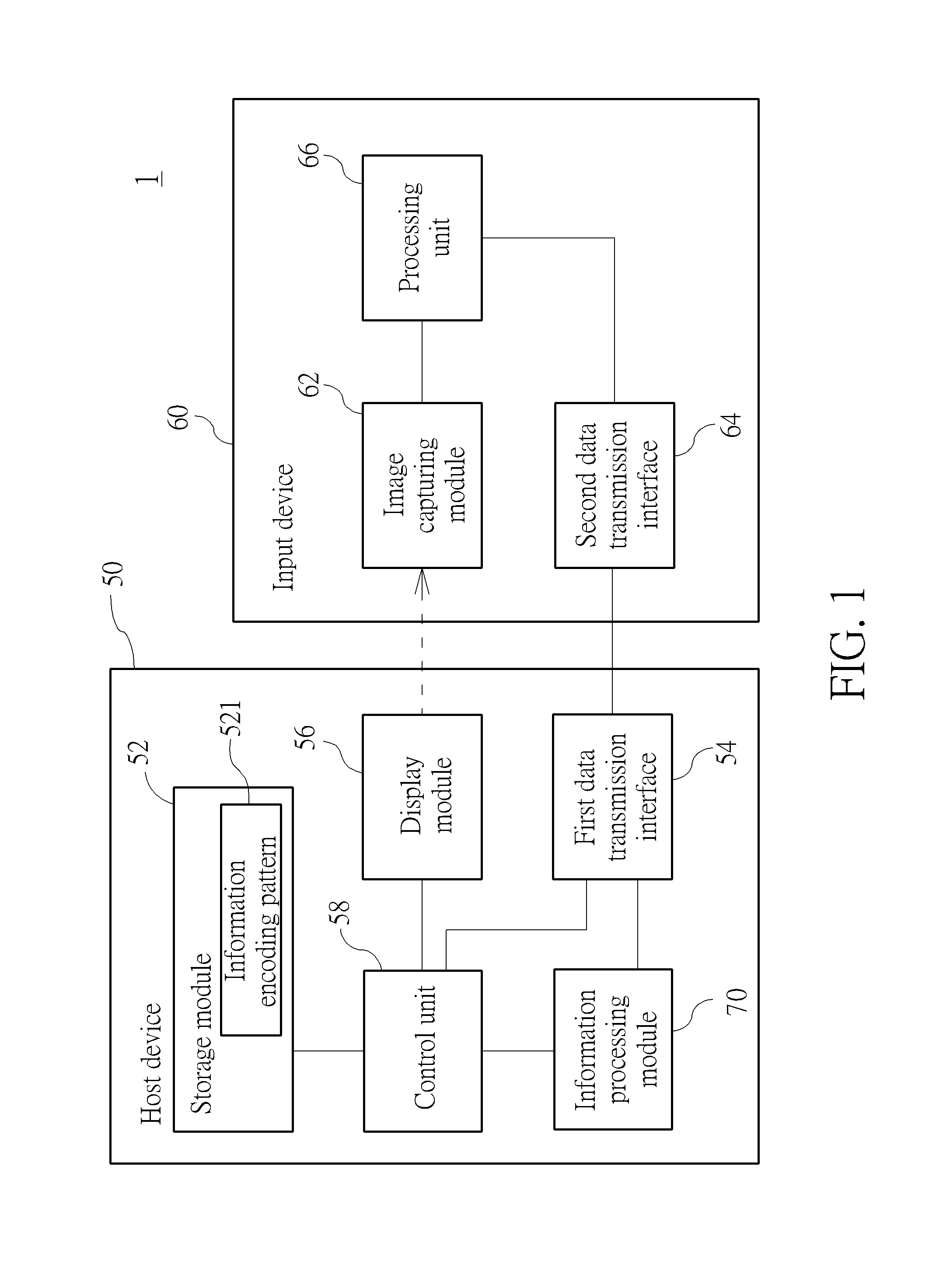

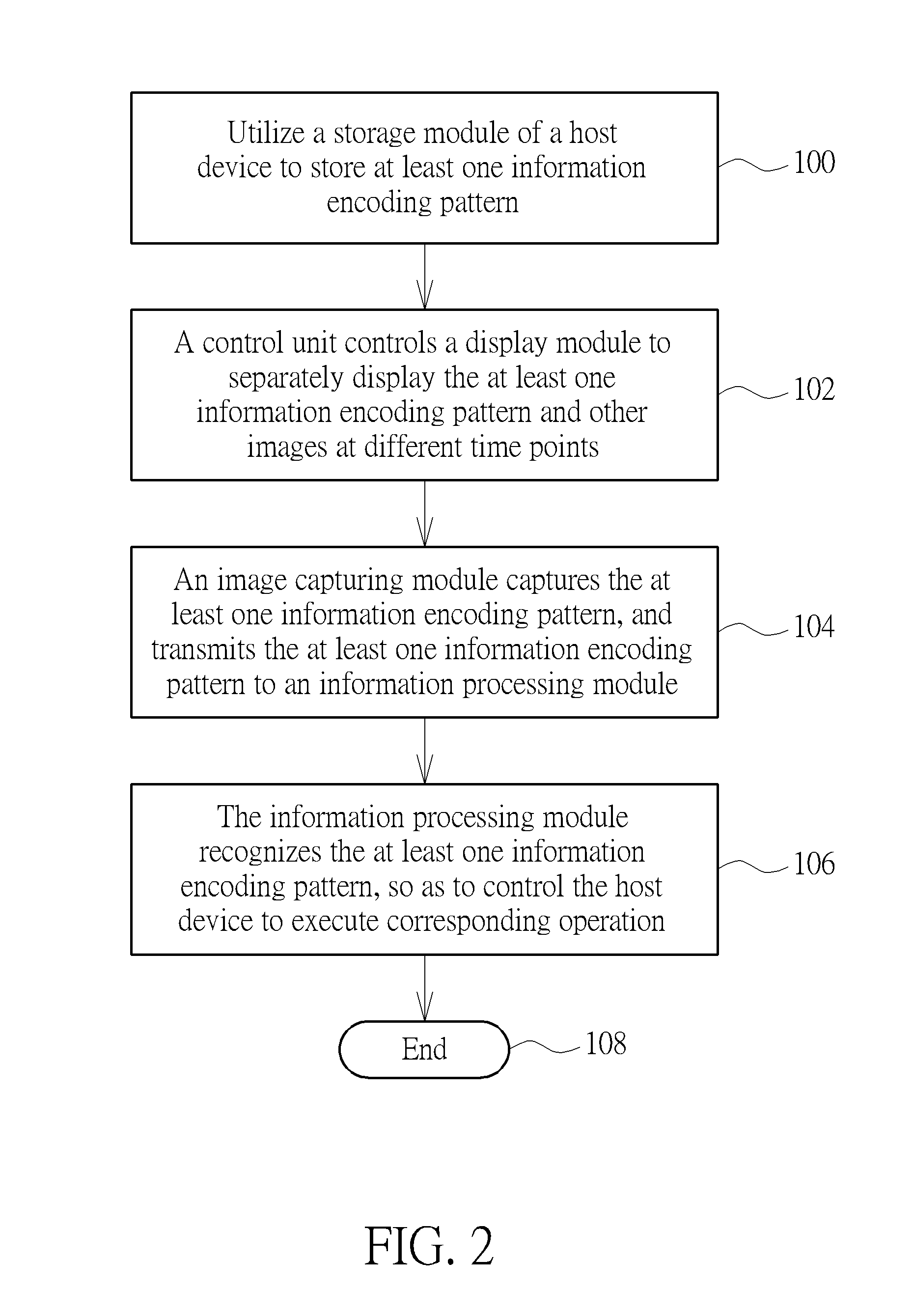

Image processing system for generating information by image recognition and related method

ActiveUS20150278624A1High costLow costInput/output for user-computer interactionImage enhancementData transmissionImage capture

An image processing system includes a host device, an input device and an information processing module. The host device includes a storage module, a first data transmission interface, a display module and a control unit. The control unit controls the display module to separately display at least one information encoding pattern at different time points. The input device includes an image capturing module, a second data transmission interface and a processing unit. The image capturing module captures a part of the at least one information encoding pattern displayed on the display module. The processing unit controls the second data transmission interface to transmit data to the first data transmission interface. The information processing module recognizes the part of the at least one information encoding pattern captured by the image capturing module, so as to control the host device or the input device to execute corresponding operation.

Owner:WISTRON CORP

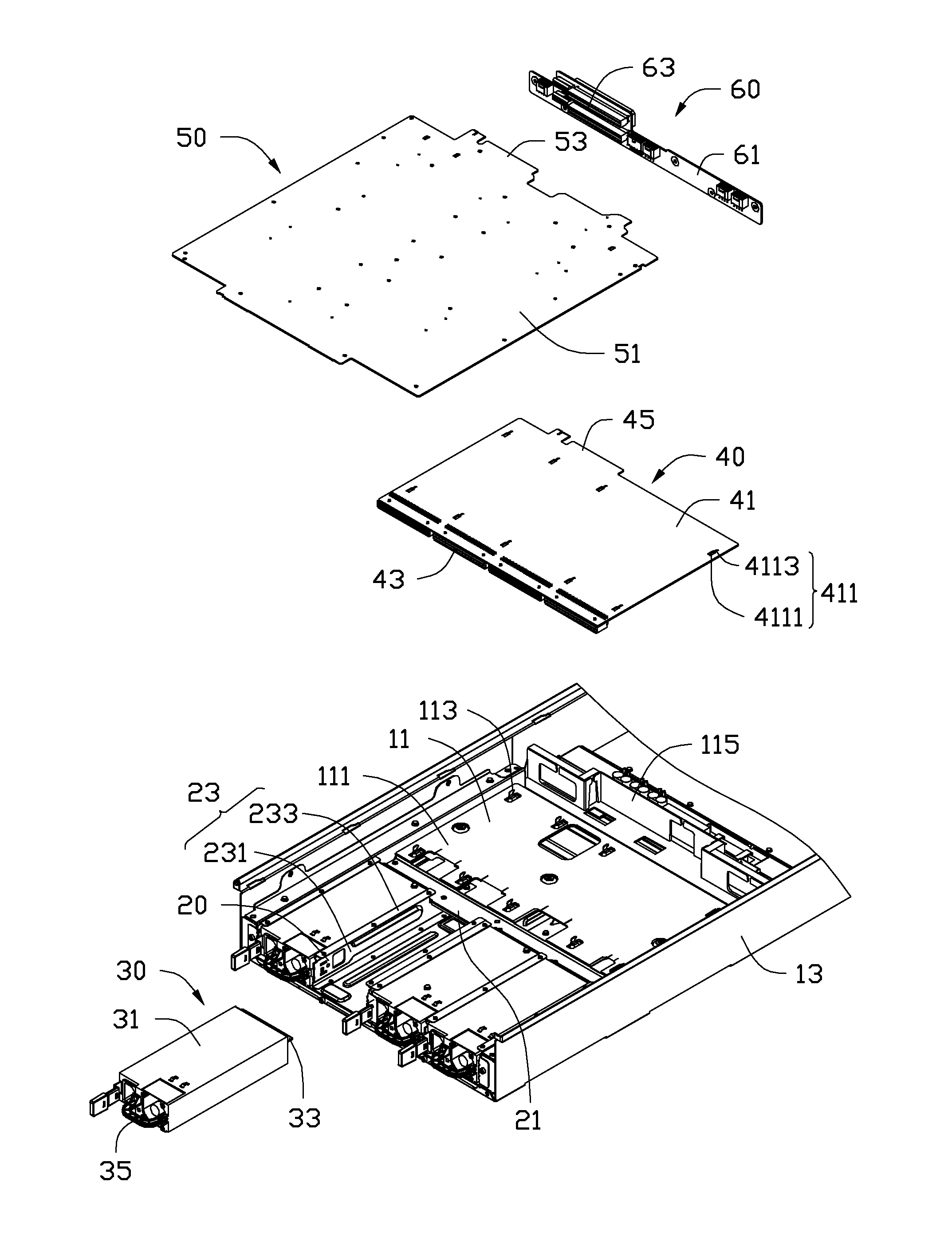

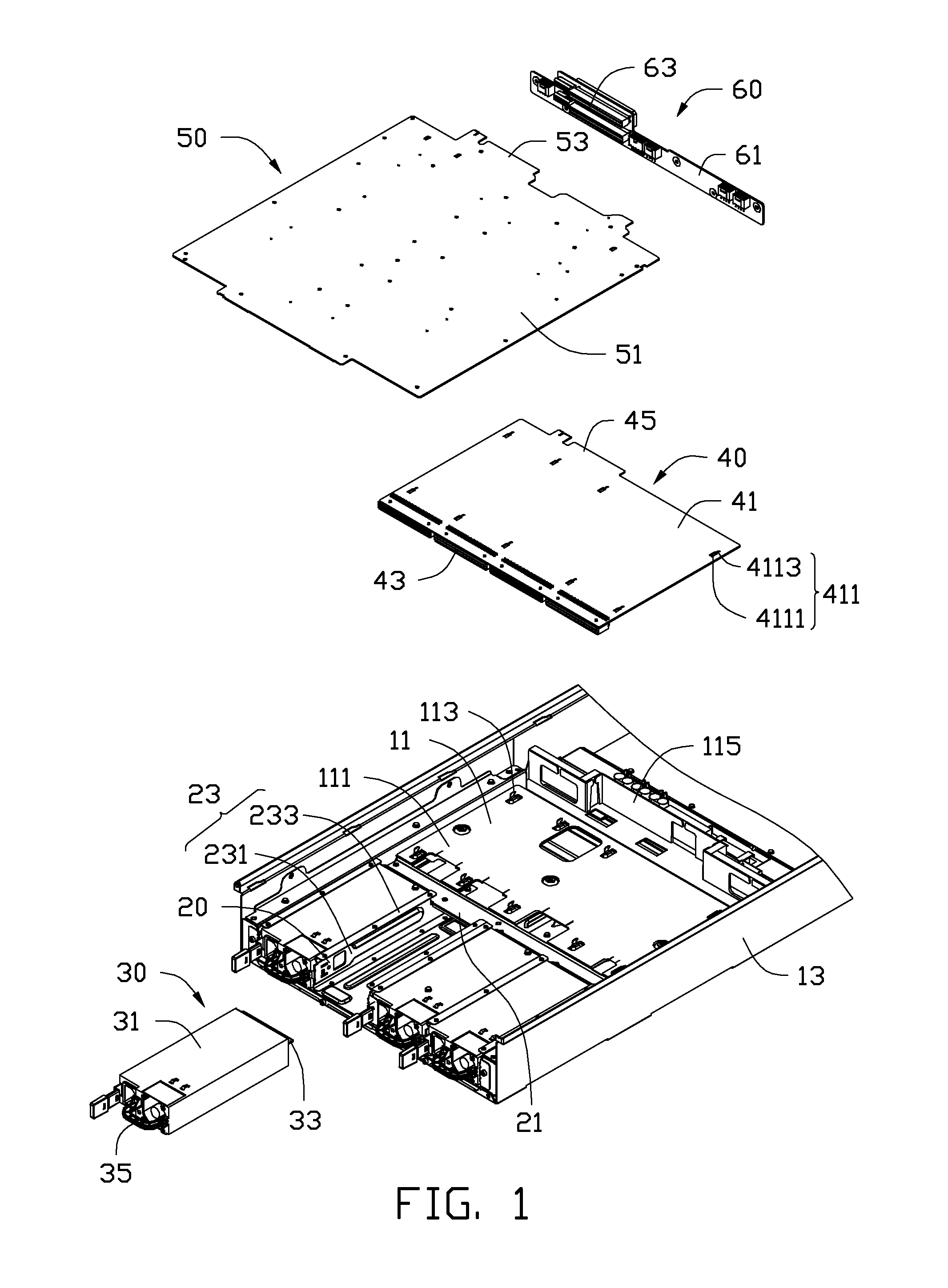

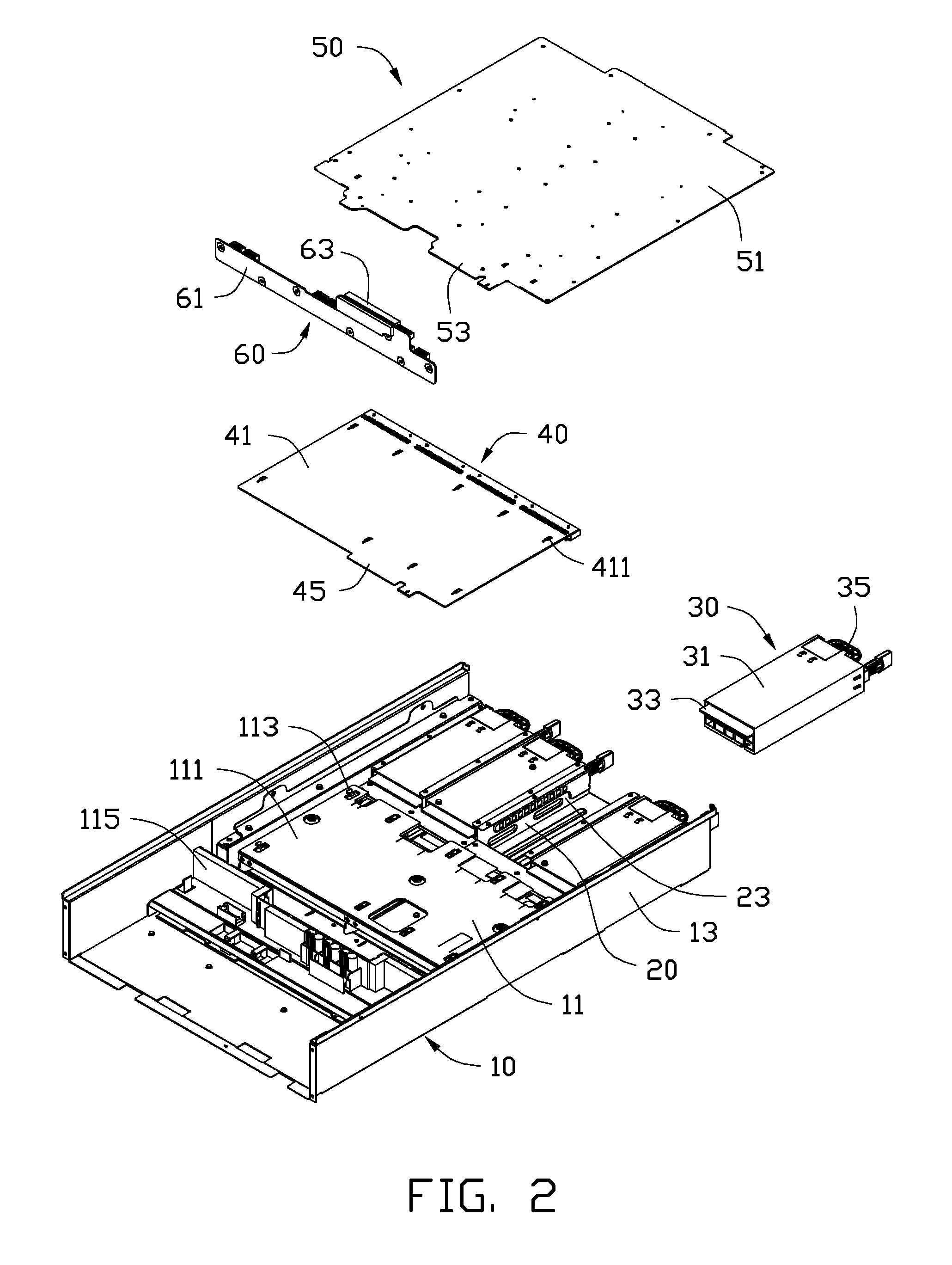

Power supply assembly of server

A power supply assembly includes an enclosure, a power supply, an adapter board, a mother board, and an adapter card. The power supply includes a power supply body and an inserting terminal. The adapter board includes an adapter board body, a connecting terminal, and a first inserting head extending from the adapter board body. The inserting terminal is inserted in the connecting terminal. The mother board includes a mother board body and a second inserting head. The mother board body is substantially parallel to the adapter board body. The adapter card includes an adapter card body and two connectors extending from the adapter card body. The two connectors are electronically connected to the first inserting head and the second inserting head. The adapter card body is substantially perpendicular to the mother board body and the adapter board body.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

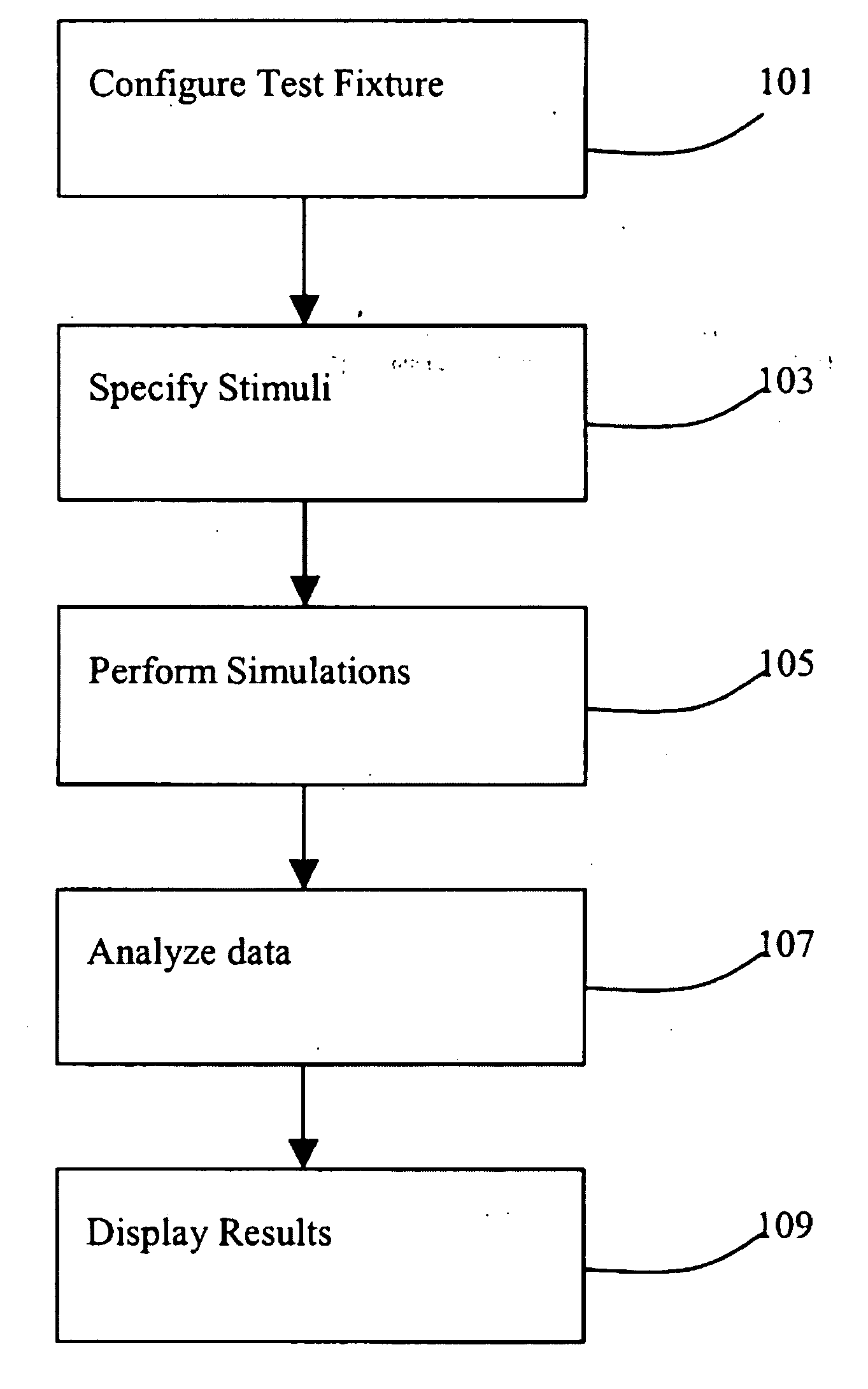

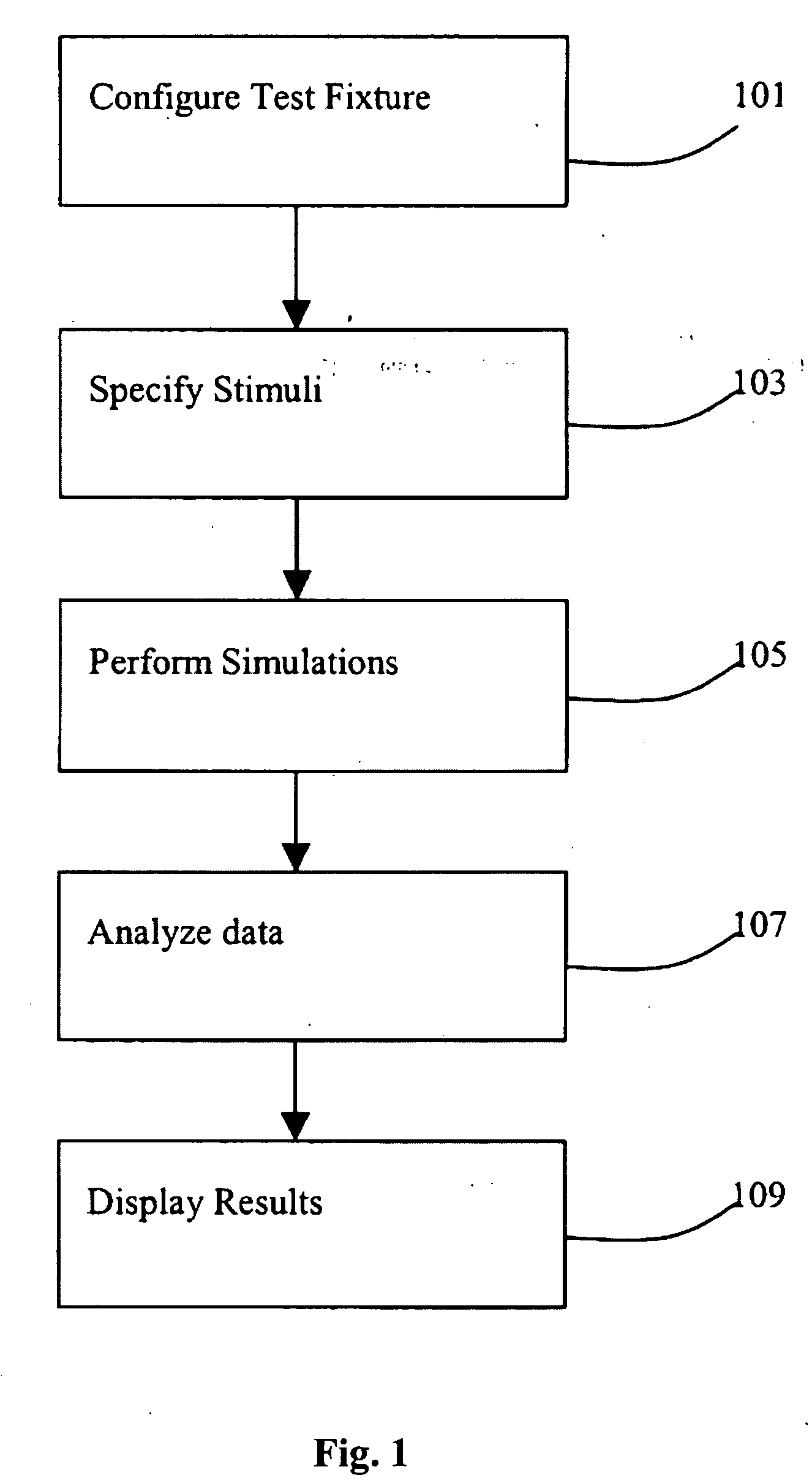

Method and system for implementing circuit simulators

InactiveUS20040243375A1Waste of timeProcessing speedElectronic circuit testingError detection/correctionReusabilityEngineering

A system and method for performing circuit simulation is described. The present approach provides methods and systems that create reusable and independent measurements for use with circuit simulators. Also disclosed are parallelizable measurements having looping constructs that can be run without interference between parallel iterations. Reusability is enhanced by having parameterized measurements. Revisions and history of the operating parameters of circuit designs subject to simulation are tracked. Mechanisms are provided that allow for viewing, measurement or other manipulation of signals at specific locations in a circuit design for simulation, such as parameters that include observation points which are implemented using probes. One approach to executing a measurement is via a controllable and flexible control statement, which in one embodiment is the "run" statement. Improved interfaces for viewing, controlling, and manipulating simulations and simulation results are also provided.

Owner:CADENCE DESIGN SYST INC

Electrical connector plug having a metallic shield surronding a front edge of the plug

InactiveUS9160115B2Low failure rateAvoid structural damageTwo-part coupling devicesCoupling protective earth/shielding arrangementsDielectricElectrical connection

Owner:ADVANCED CONNECTEK INC

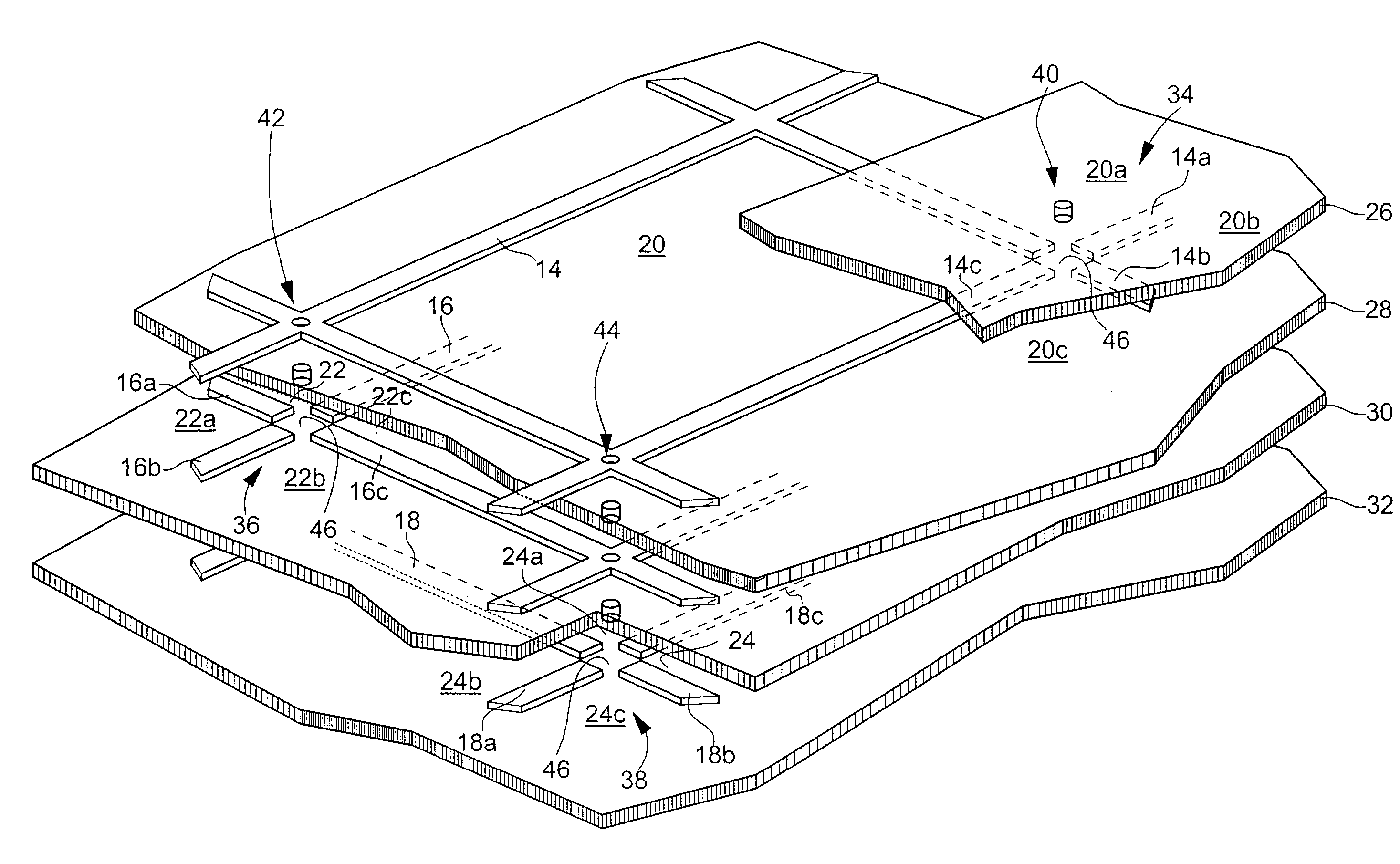

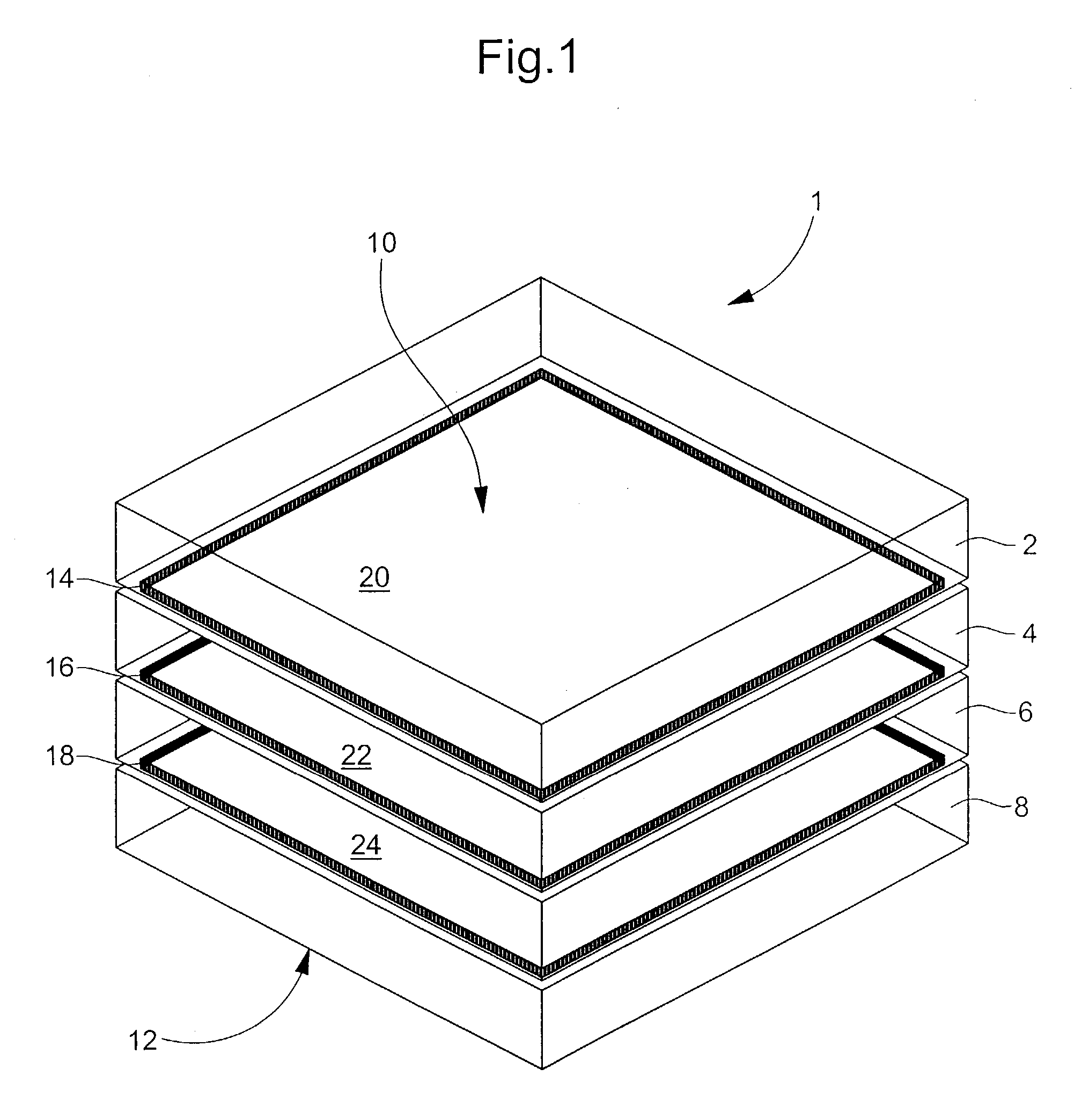

Method for manufacturing a batch of multi-layered cells, such as liquid crystal display cells, or electrochemical photovoltaic cells

InactiveUS6982019B2Simple and quick to fillEasy to prepareHollow inflatable ballsHollow non-inflatable ballsLiquid-crystal displayElectrical battery

The present invention concerns a method for manufacturing a plurality of multi-layered cells, particularly liquid crystal display cells, or electrochemical photovoltaic cells, or a combination of such cells, each cell including at least two superposed sealed cavities each delimited by a sealing frame and filled with a liquid, this method comprising the step of collectively manufacturing a batch of cells including at least three plates common to all the display cells and connected to each other by patterns of sealing material connecting said plates to each other and forming the sealing frames which delimit the cavities of said cells, this method being characterised in that filling holes are pierced through the plates such that each of the cavities of a cell is fed by a different filling hole, each of the filling holes being in communication with at least two cells and feeding the cavities of the same level, i.e. comprised between the same two plates, or different levels of these at least two cells, said filling holes being isolated in a sealed manner from the cavities that they must not feed.

Owner:ASULAB SA

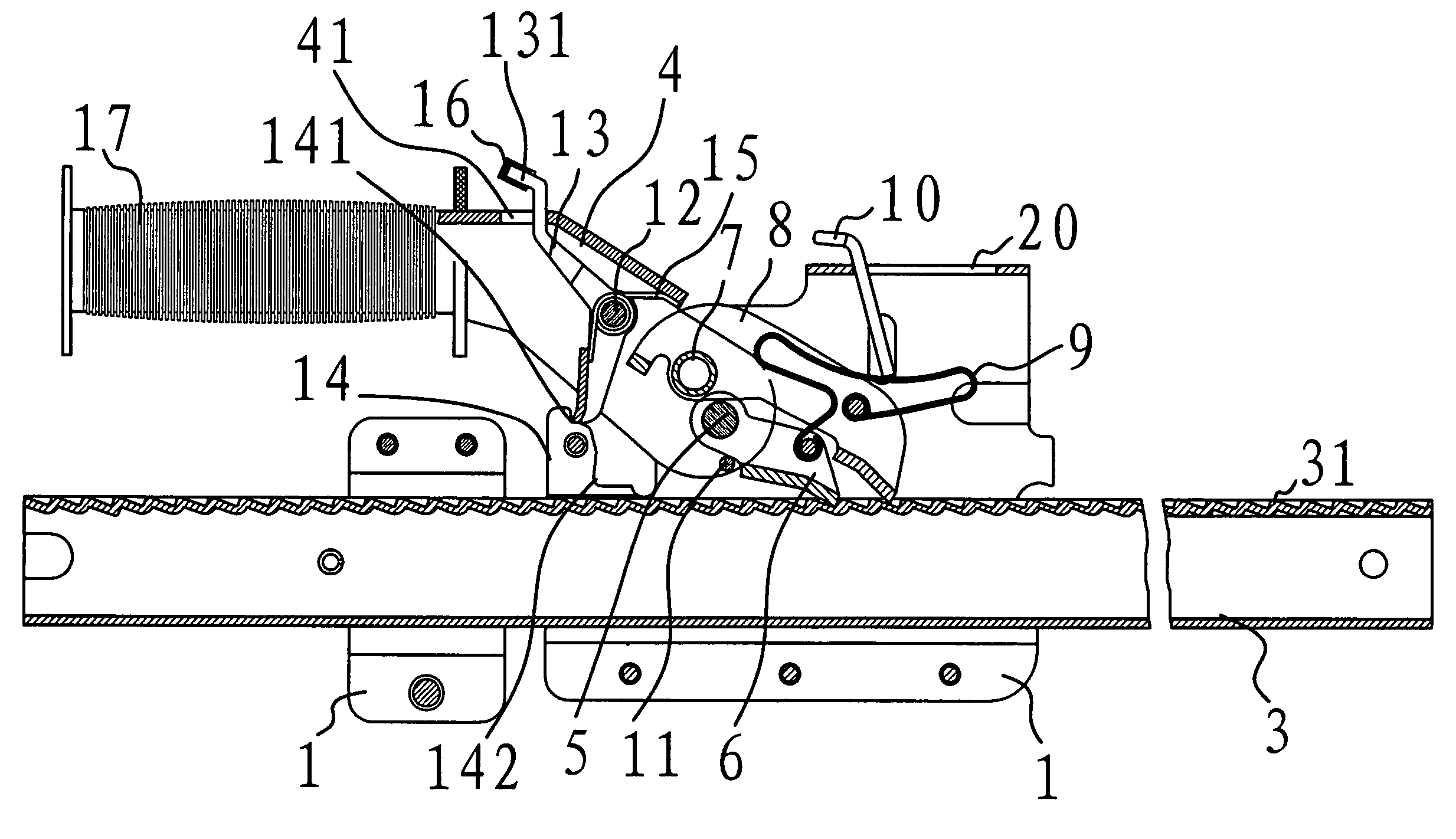

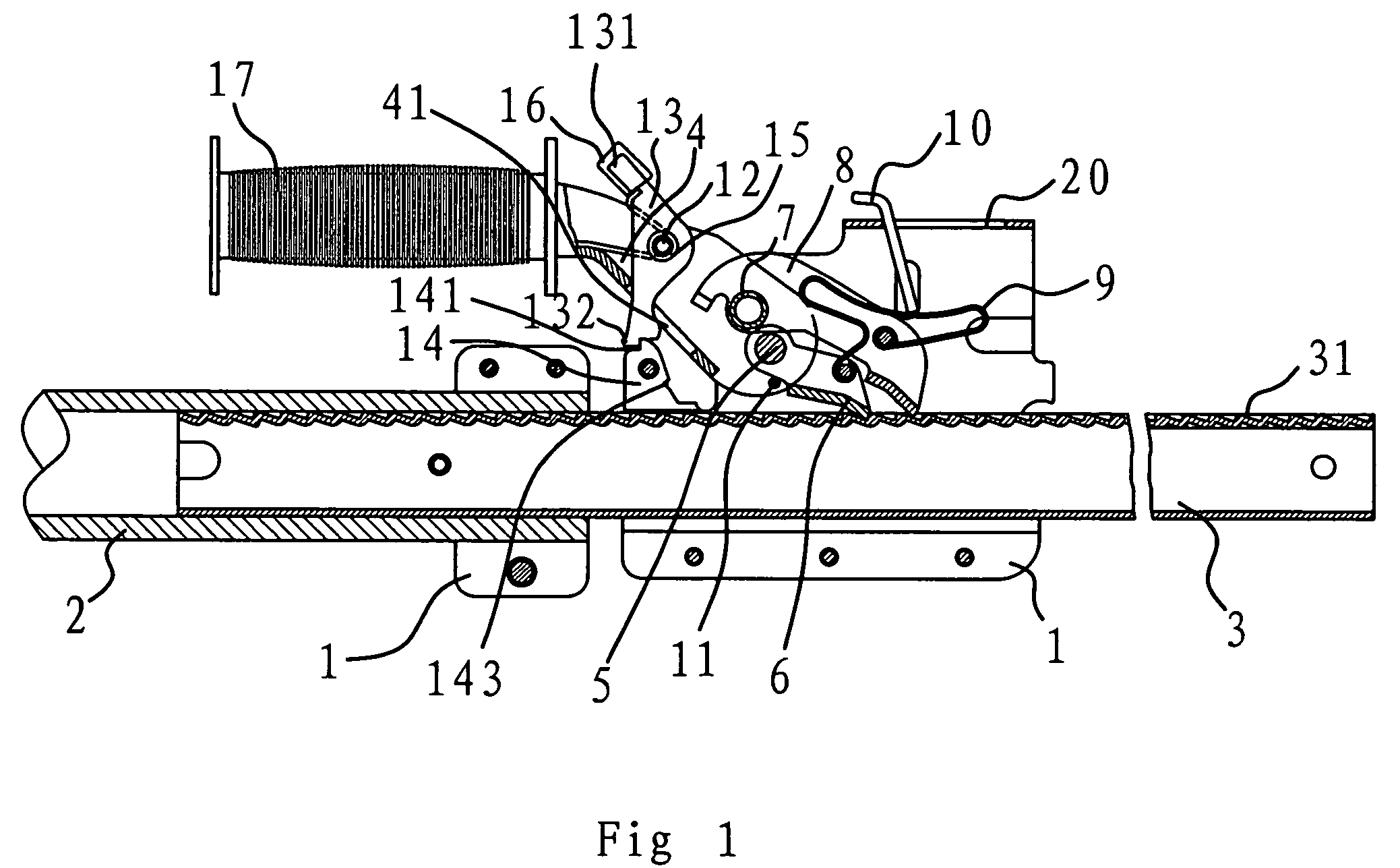

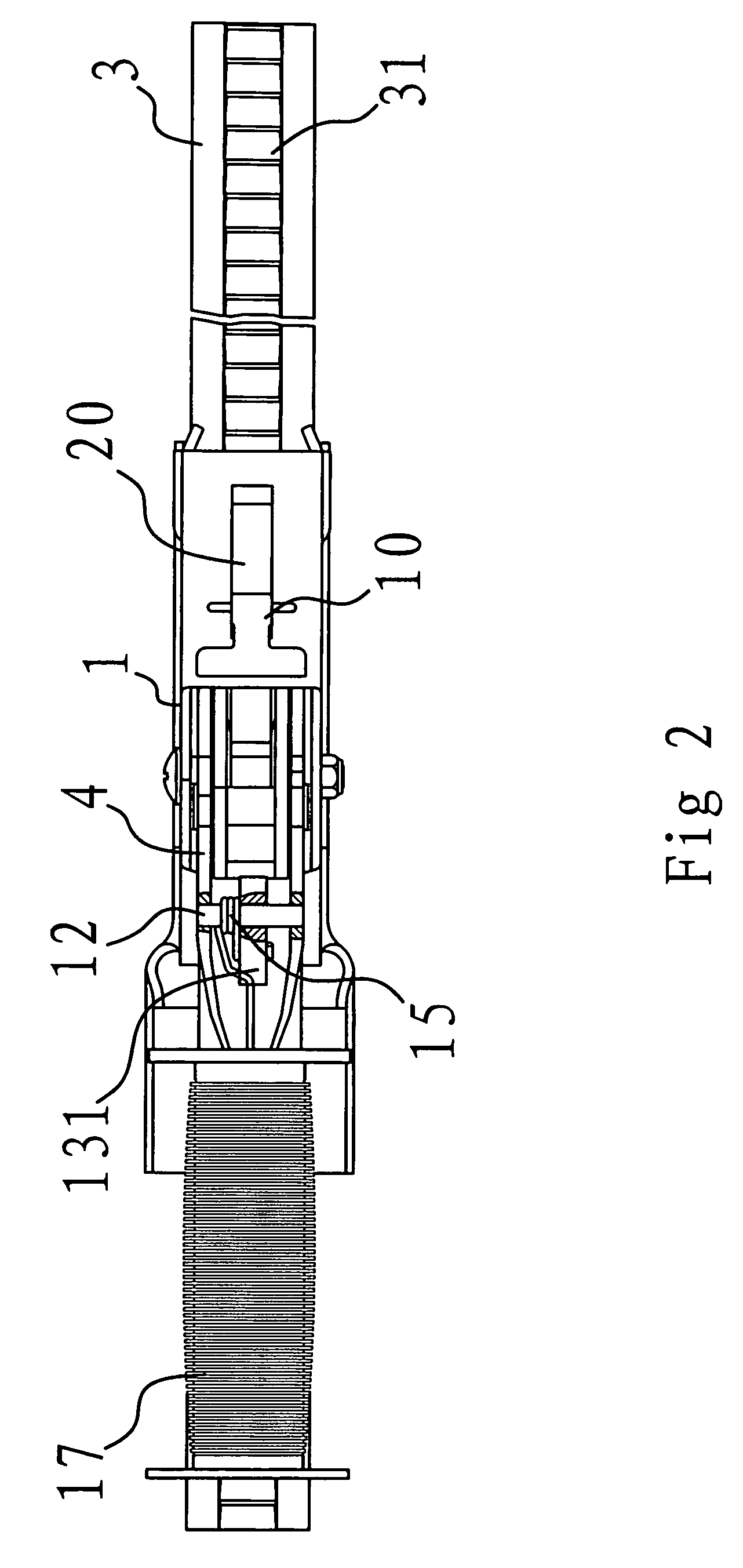

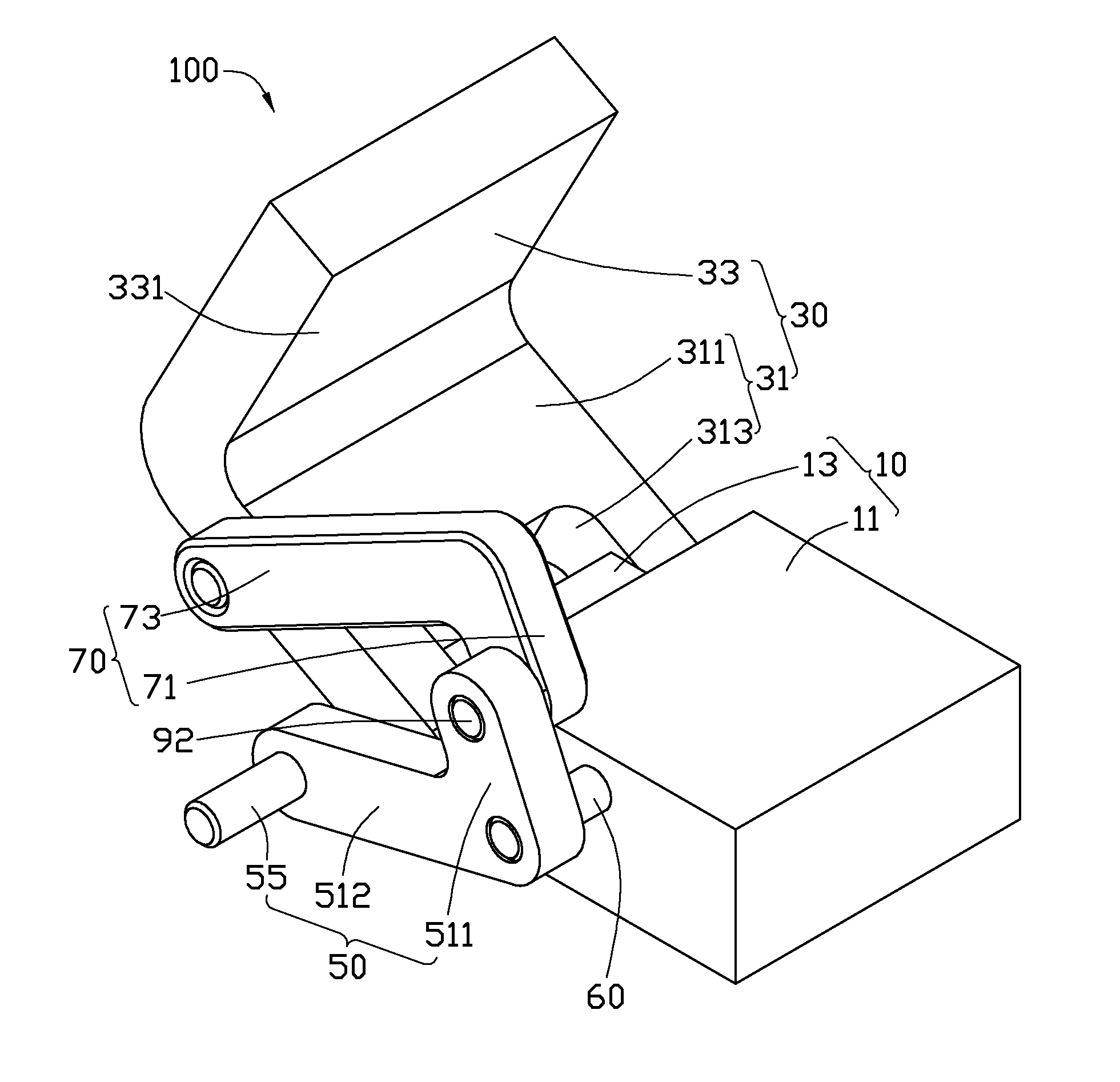

Goods fastening apparatus with improved structures

ActiveUS20070170407A1Improve simplicityImprove compactnessLifting devicesLoad securingEngineeringGear tooth

A goods fastening apparatus with improved structures is disclosed herein, which comprises a body, a pipe fixedly connected to the body and a gear rack passing through the body and partly muff-coupled with the inside of the pipe. A hand grip and a positioning claw are hinged to the body through a primary pivot. A driving claw is hinged to the hand grip through a secondary pivot. A plate spring is positioned between the driving claw and the positioning claw. A mobile stopper sheet pressed against the plate spring is provided at the upper portion of the body. The front ends of the driving claw and the positioning claw can be embedded into the gear teeth of the gear rack with aid of the plate spring. A stopper pin is fixed at the hand grip. The stopper pin is positioned at the edge of one side of the positioning claw facing the gear rack while the front end of the positioning claw is embedded into the gear teeth of the gear rack. Said goods fastening apparatus achieves high working efficiency, and is easy to operate and control.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

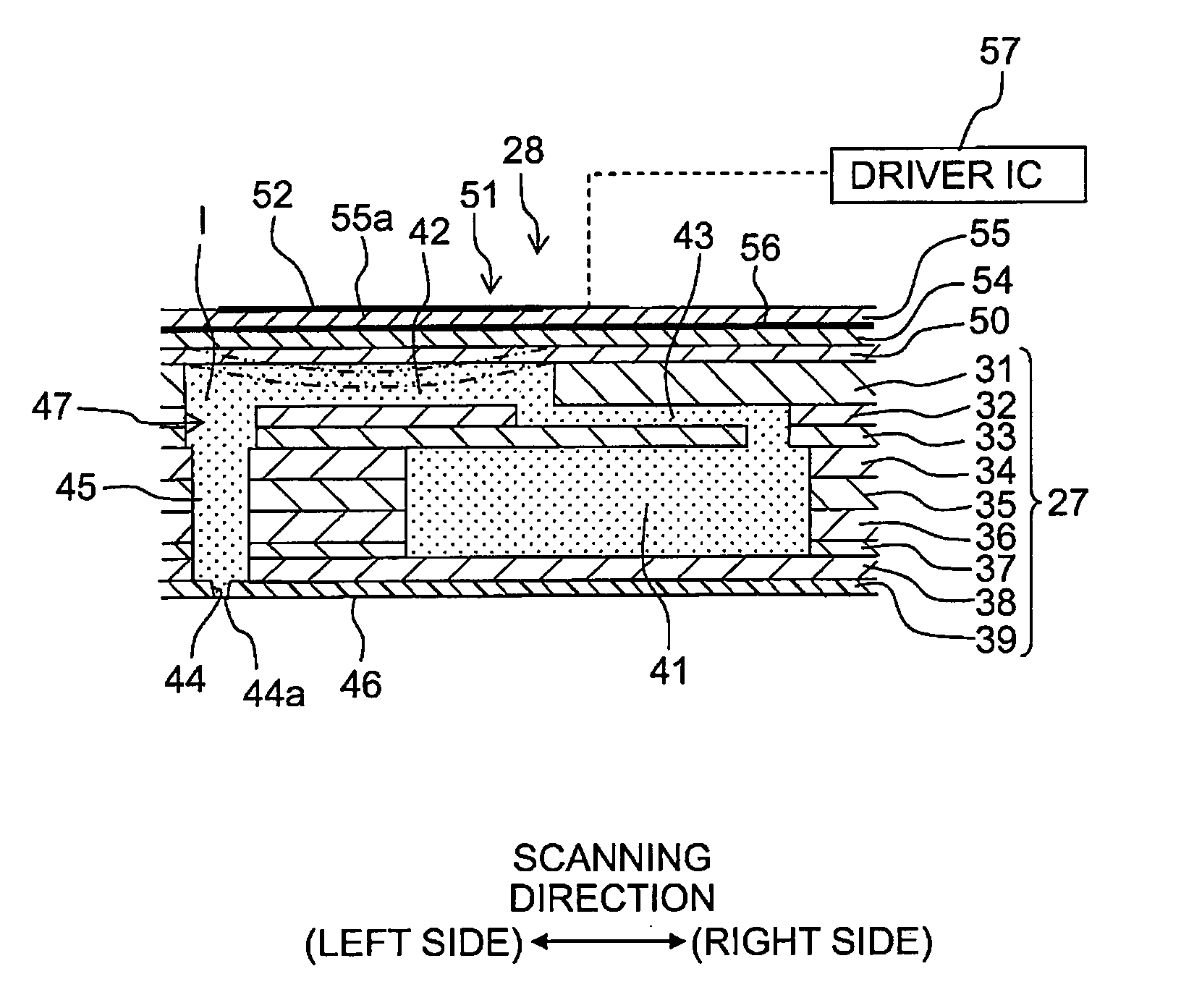

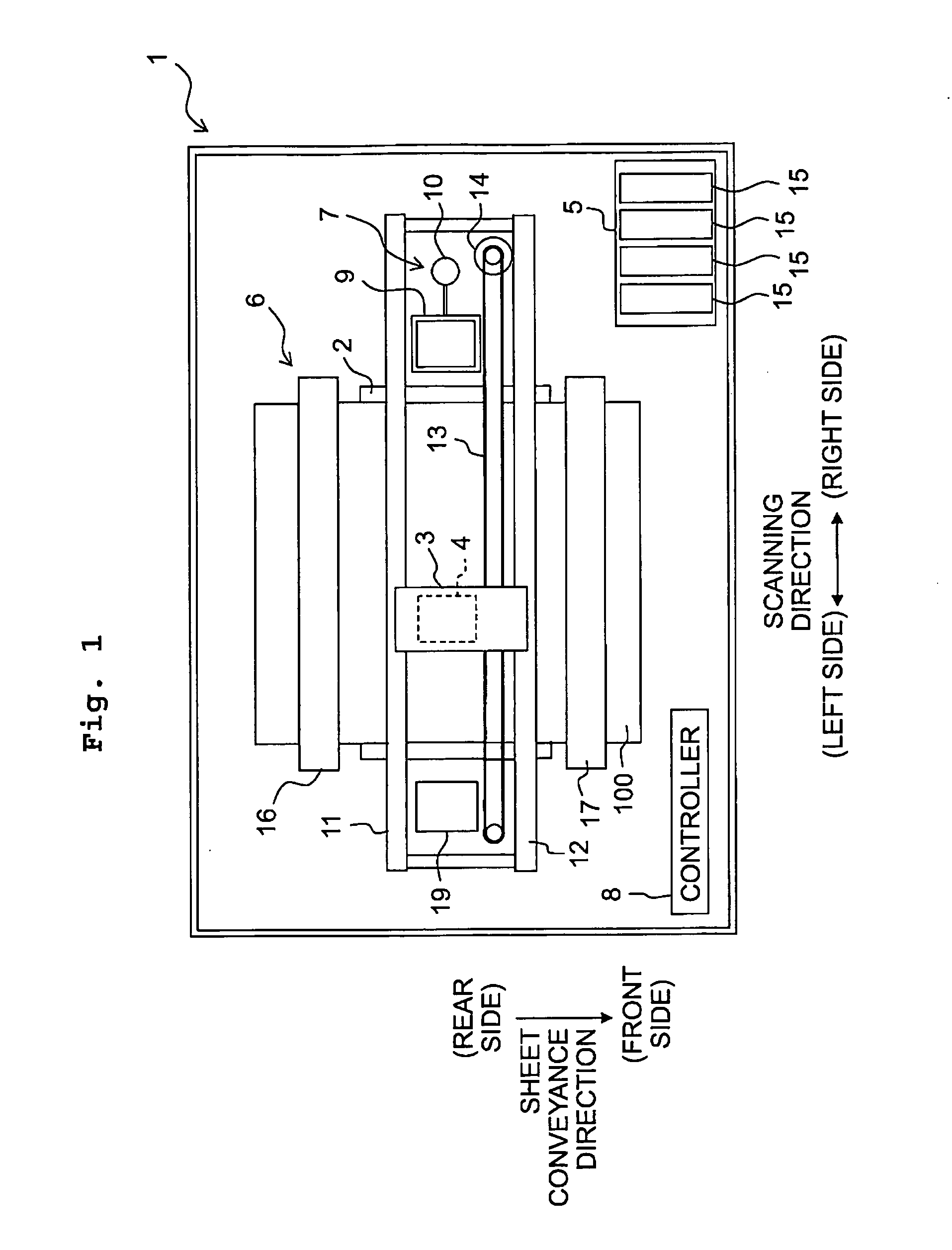

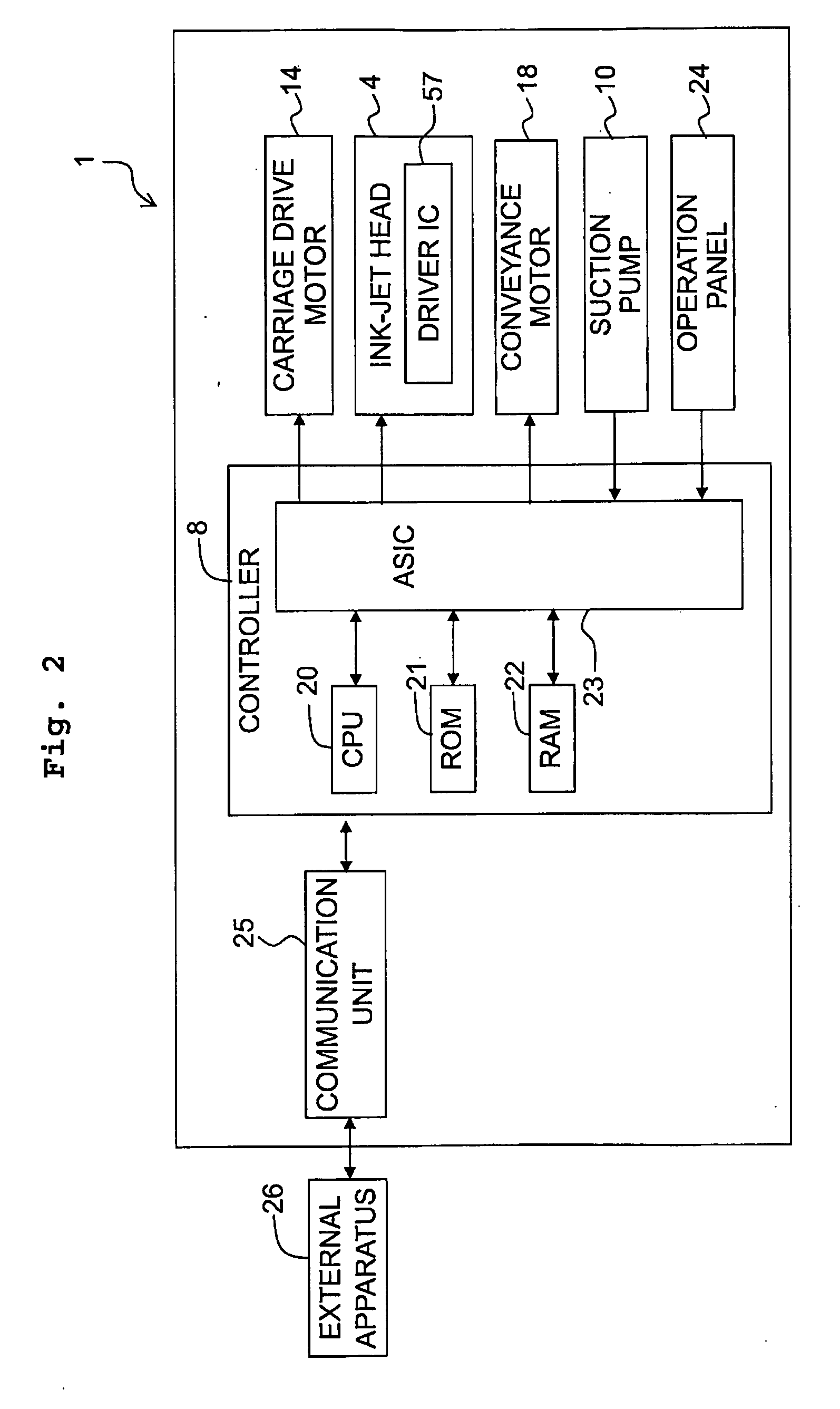

Liquid discharge apparatus

ActiveUS20160185105A1Eliminate thickeningThickening of liquidOther printing apparatusEngineeringDriven element

There is provided a liquid discharge apparatus including: a liquid discharge head which includes a channel structure provided with a nozzle and a liquid channel, a driving element, and a driving unit; a light emitting part; a liquid receiving part receiving light passed through or reflected by the meniscus; and a controller. The controller controls the driving unit to apply at least one of several kinds of meniscus driving signals to the driving element in a state that the light emitting part emits the light to the nozzle, thereby vibrating the meniscus in the nozzle, and is configured to determine a recovery operation from among several kinds of recovery operations which have mutually different liquid discharge amounts to be discharged from the nozzle, on the basis of an amount of light which is received by the light receiving part in the case of vibrating the meniscus of the liquid.

Owner:BROTHER KOGYO KK

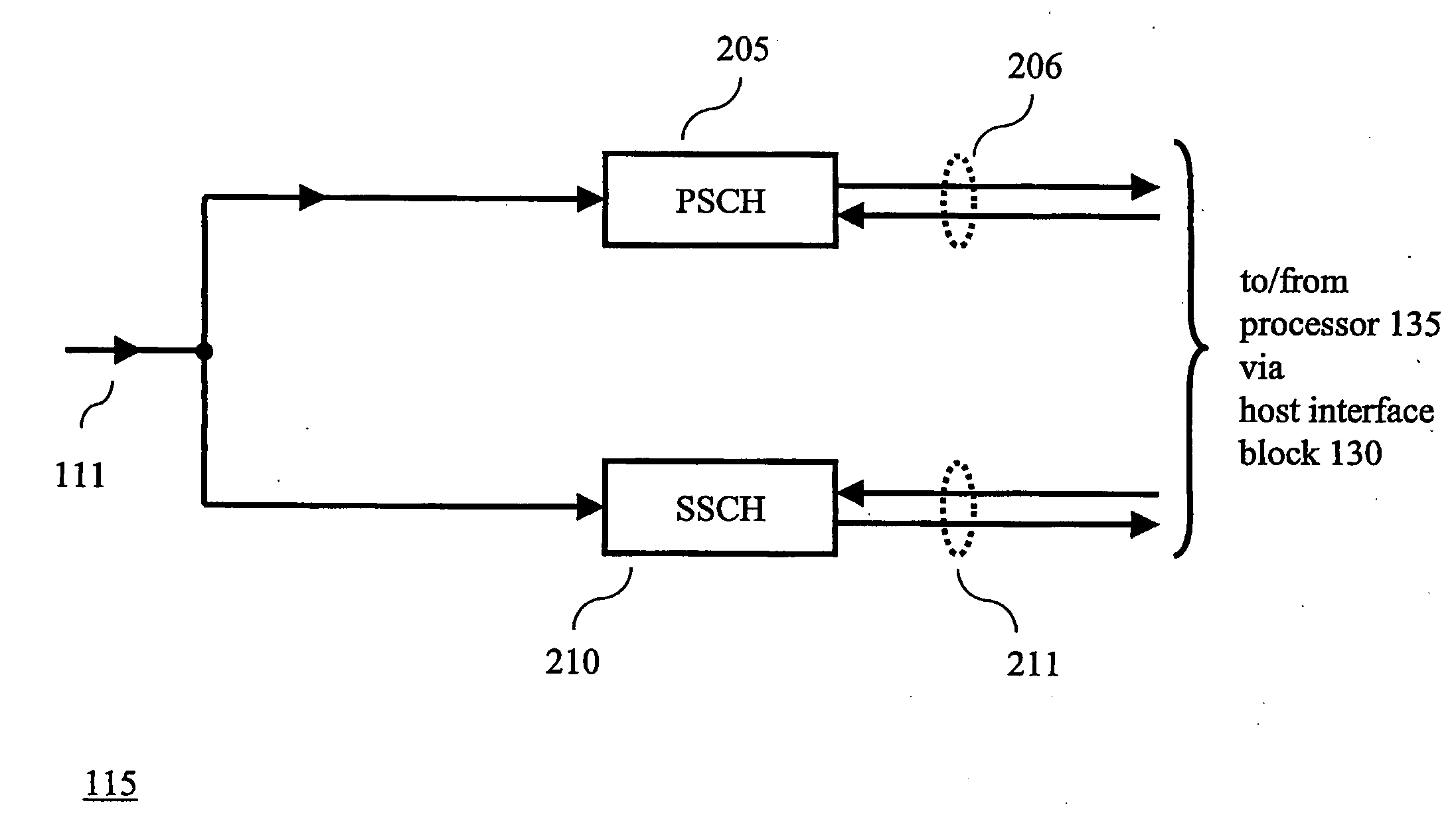

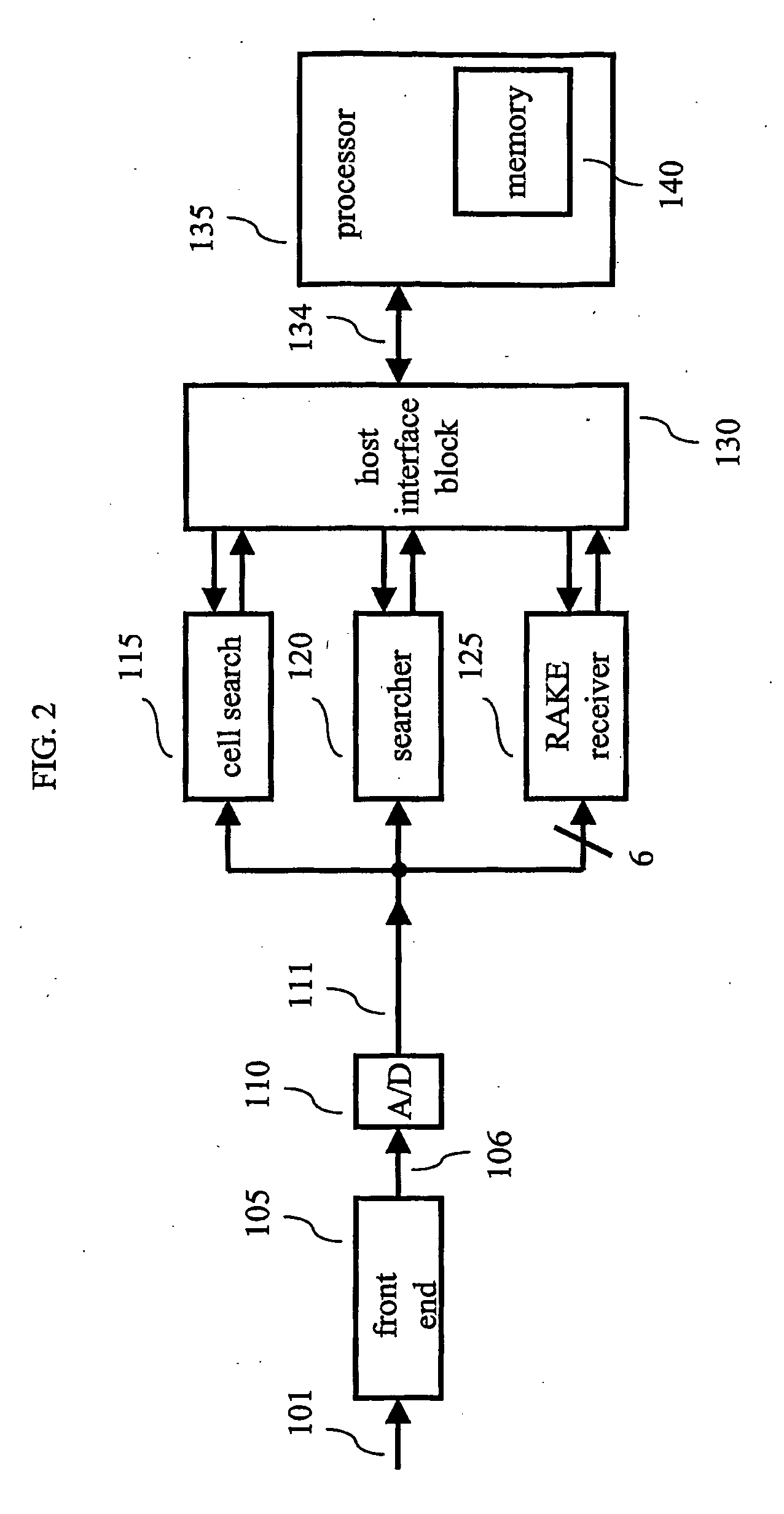

Adaptive Frame Synchronization in a Universal Mobile Telephone System Receiver

InactiveUS20080144583A1Time wastingFailure can not be determinedSynchronisation arrangementTime-division multiplexComputer networkSlot synchronization

A Universal Mobile Telephone System (UMTS) receiver performs slot synchronization using a received primary synchronization channel (PSCH). Subsequent to completion of slot synchronization, the UMTS receiver adaptively controls the duration of processing of the secondary synchronization channel (SSCH) for determining frame synchronization.

Owner:THOMSON LICENSING SA

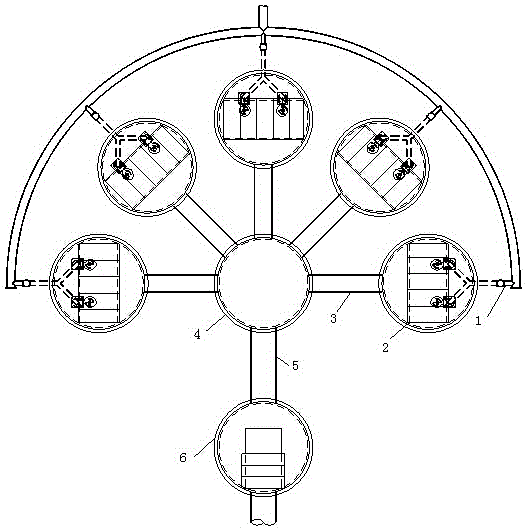

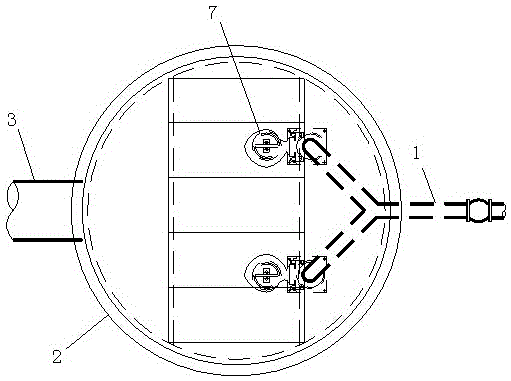

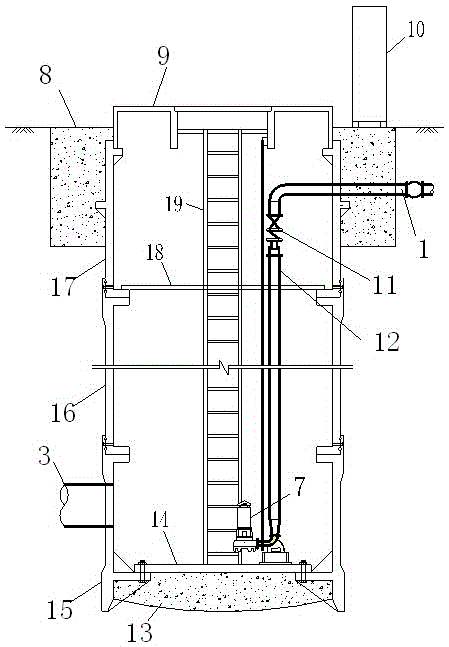

Glass reinforced plastic open caisson modularization pump station capable of being quickly constructed and construction method thereof

InactiveCN105089145AHigh degree of standardizationFast constructionSewerage structuresCaissonsFiberglass reinforced plastic gratingBuilding construction

The invention discloses a glass reinforced plastic open caisson modularization pump station capable of being quickly constructed and a construction method thereof. The glass reinforced plastic open caisson modularization pump station comprises glass reinforced plastic pump room wells which are communicated with a glass reinforced plastic distribution well through distribution pipes, and the glass reinforced plastic pump room wells are communicated with a glass reinforced plastic grille well through a water inlet pipe; the bottoms of the glass reinforced plastic pump room wells are provided with draining pumps, and the draining pumps are connected with water outlet pressure pipes. The construction method of the glass reinforced plastic open caisson modularization pump station comprises the steps that glass reinforced plastic shafts from industrialized production are assembled into a well body at the construction site, the well body is sunk to the design elevation by adopting a drop shaft sinking method, and after bottom sealing by concrete is completed at the bottom of the well body, a lass reinforced plastic bottom plate is installed; after bottom sealing is completed, other equipment, pipelines and a well lid are installed, and therefore construction of a single small glass reinforced plastic pump room well pump station is completed; then the multiple glass reinforced plastic pump room wells are connected to the glass reinforced plastic distribution well through the distribution pipes as needed and connected with the glass reinforced plastic grille well through the water inlet pipe, and then the pump station with the larger scale is formed.

Owner:JIAXING PLANNING & RES INST

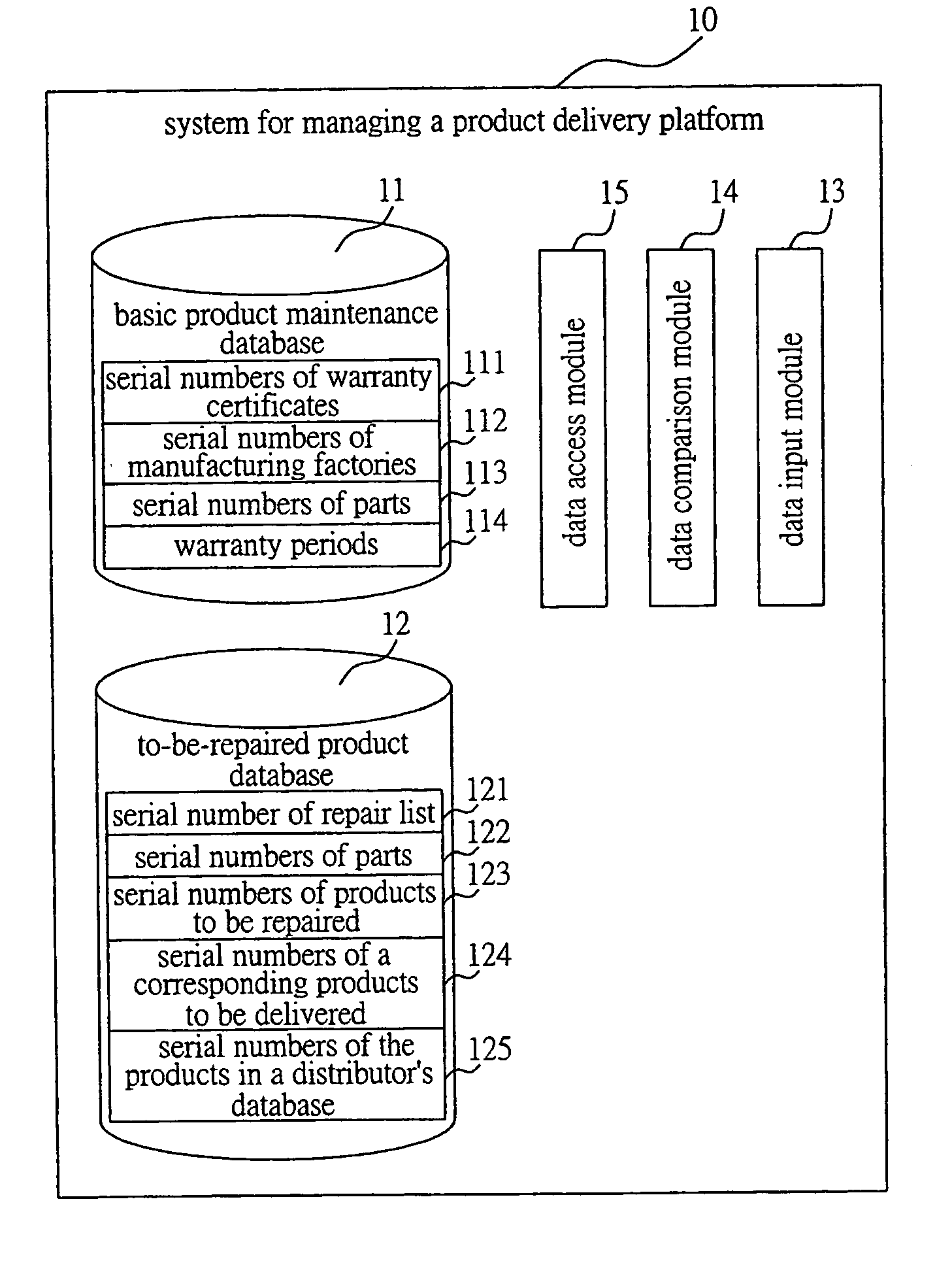

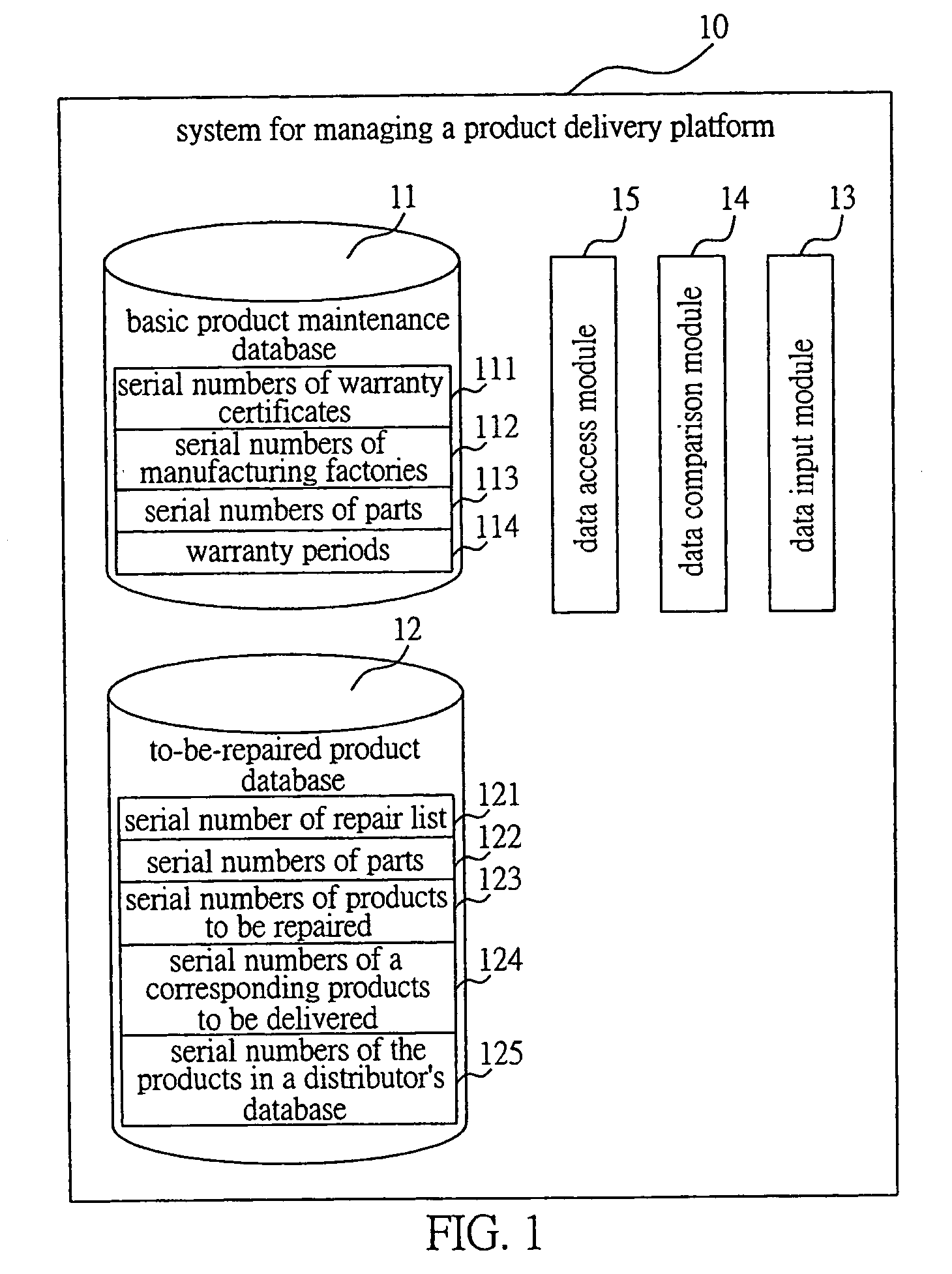

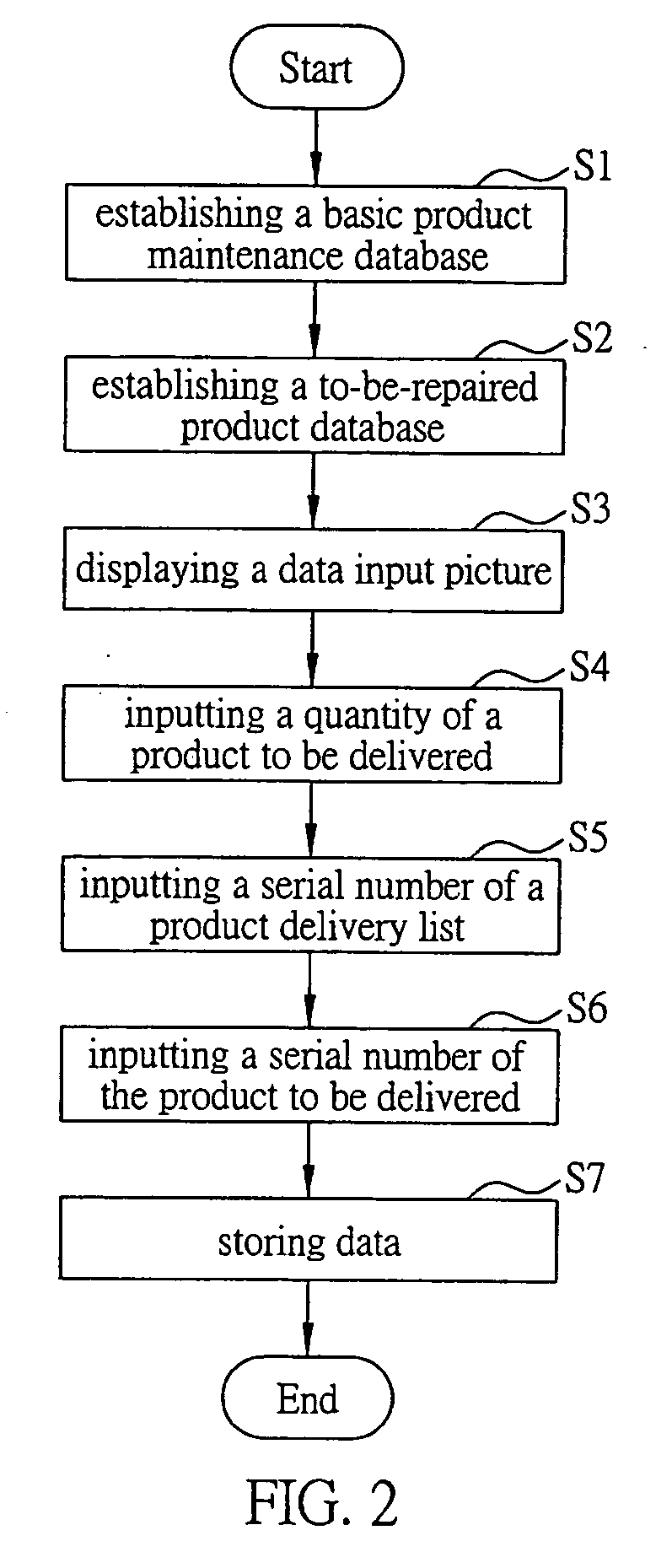

System and method for managing product delivery platform

InactiveUS20060259374A1Improve accuracyDamage to reputationAcutation objectsPayment architectureData accessFile comparison

A system and a method for managing a product delivery platform are proposed. The system includes a to-be-repaired product database for storing data of products to be repaired; a data input module for inputting a quantity and a serial number of a product to be delivered; a data comparison module for automatically comparing the quantity of the product to be delivered with a maximum product delivery quantity stored in the to-be-repaired product database corresponding to the product, and analyzing composition of the serial number of the product to be delivered so as to determine whether the inputted quantity and serial number of the product to be delivered are correct; and a data access module for storing the serial number of the product to be delivered into the to-be-repaired product database so as to generate a product delivery list serving as a basis for delivering the product to be delivered.

Owner:INVENTEC CORP

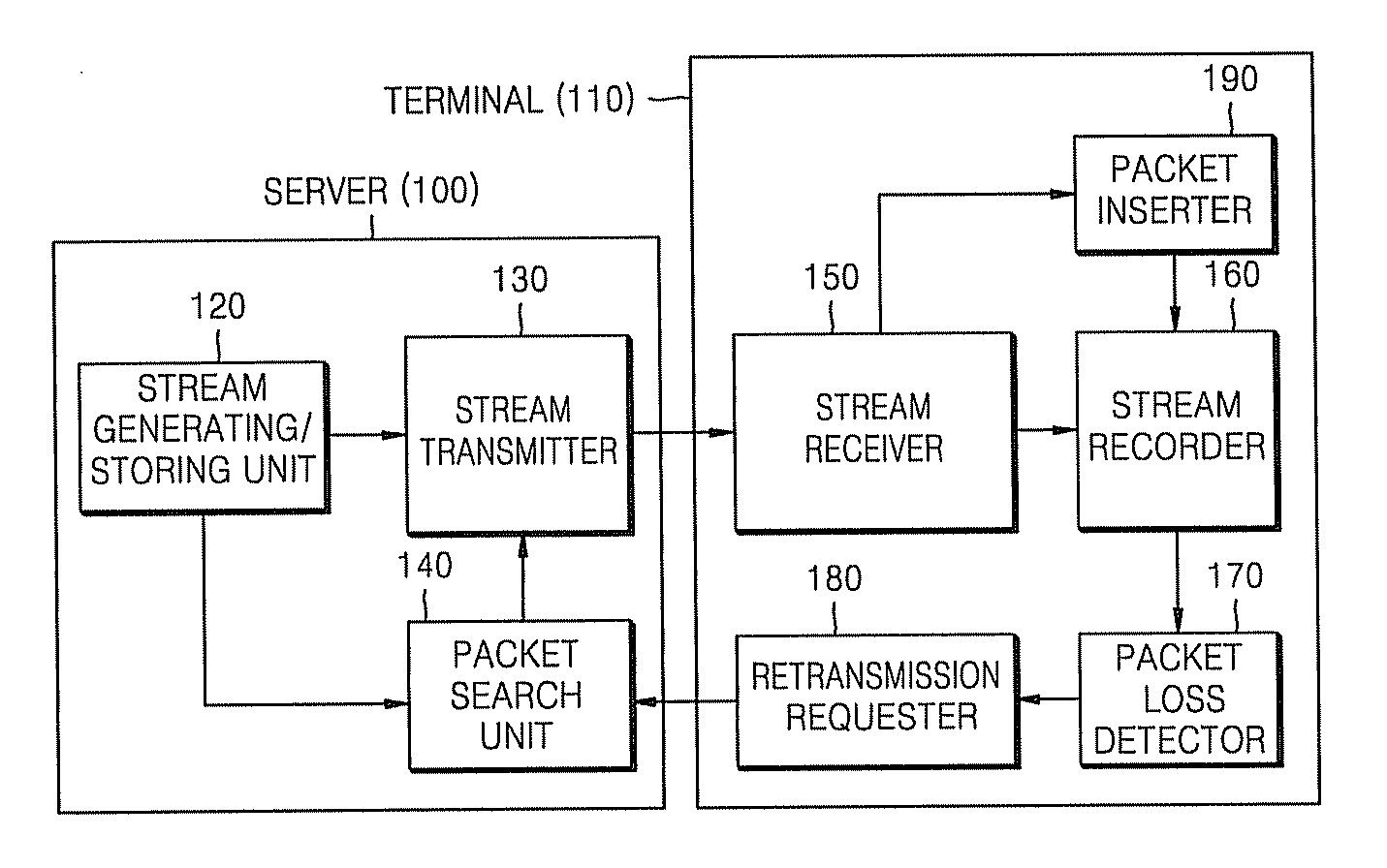

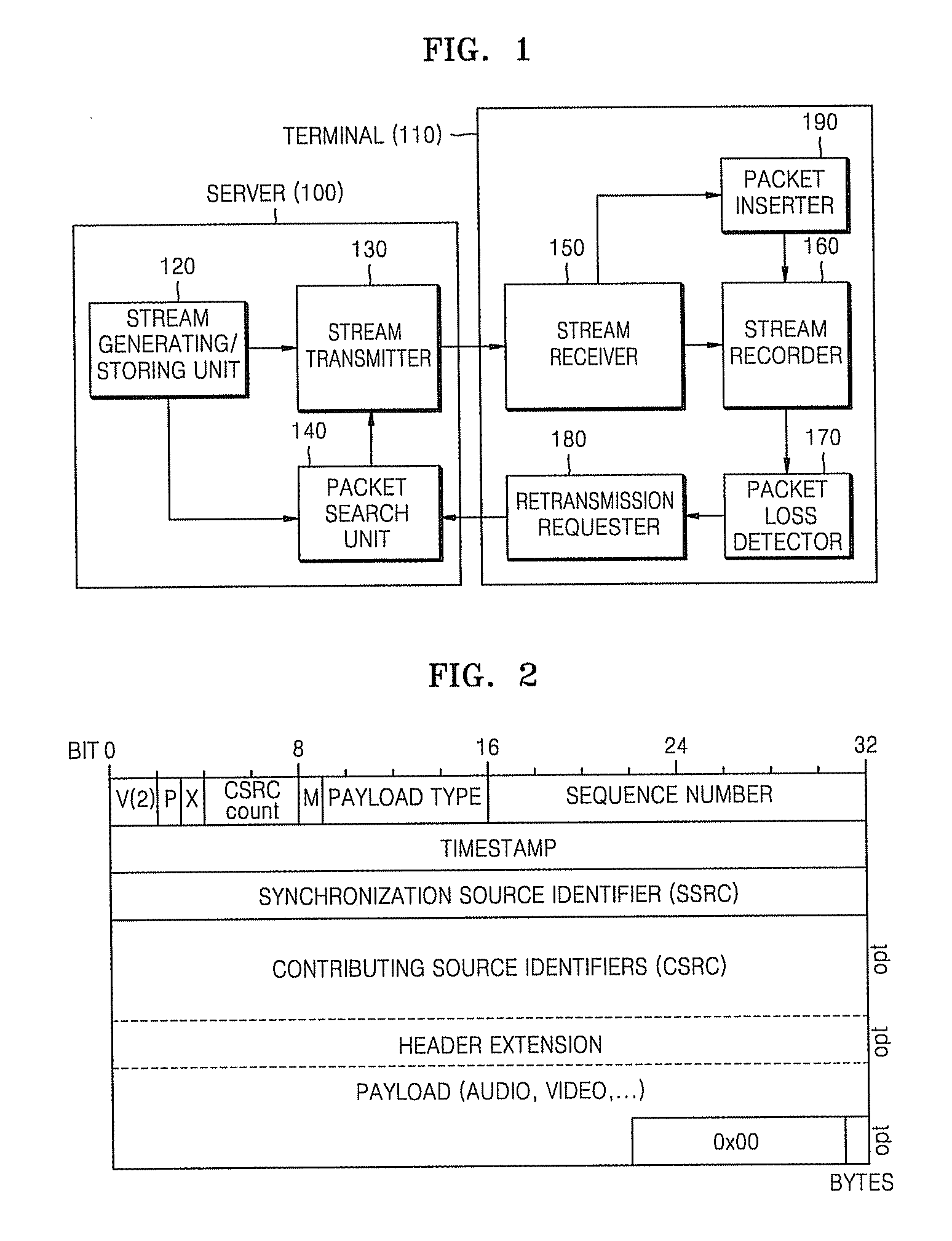

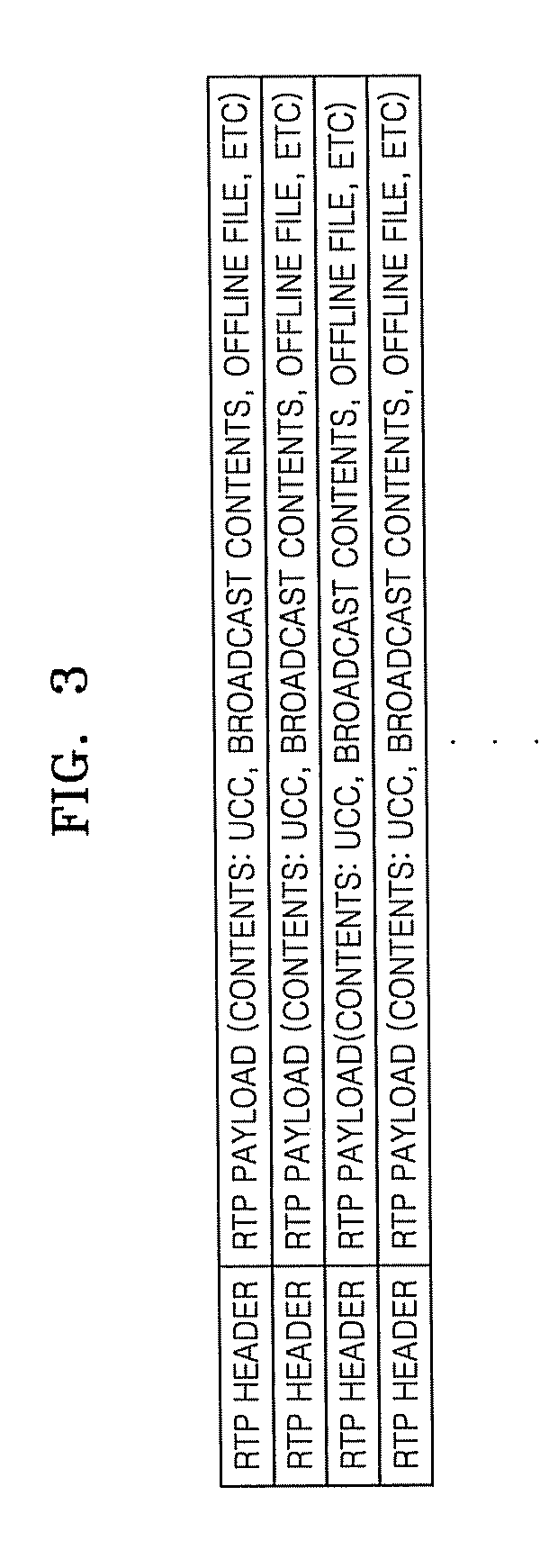

Stream recording method, apparatus, and system

InactiveUS20080159295A1Reduce inconvenienceWaste of timeError prevention/detection by using return channelData switching by path configurationPacket lossReal-time computing

A stream recording method, apparatus, and system. When a packet loss is detected in packets constituting a stream while the stream transmitted from a server is recorded, the lost packet is retransmitted so as to be inserted into a specific portion of the recorded stream. Therefore, it is possible to reduce inconvenience and a waste of time required for downloading the whole stream to be recorded when the packet loss occurs during recording as well as to decrease a network load.

Owner:SAMSUNG ELECTRONICS CO LTD

Electrical connector plug and conductive wire and assembly provided with the same

ActiveUS20150111428A1Increased durabilityEliminate troubleCouplings bases/casesTwo-part coupling devicesDielectricElectrical connection

An electrical connector plug has resilient contact terminals for electrical connection to an electrical connector socket. The electrical connector plug has an electrically conductive housing, and a dielectric shell and resilient contact terminals are mounted in the electrically conductive housing. The dielectric shell has a base portion and a front edge portion extending from the base portion. Two groups of resilient contact terminals are mounted on the dielectric shell and axially symmetrical to each other in the longitudinal direction, with each of the resilient contact terminals having a flat section and an upwardly protruding contact section. A metallic shield frame surrounds the front edge portion and is electrically connected to the electrically conductive housing, with the metallic shield frame having a front section and two lateral protective sections. The lateral protective sections have a height no less than that of the upwardly protruding contact sections.

Owner:ADVANCED CONNECTEK INC

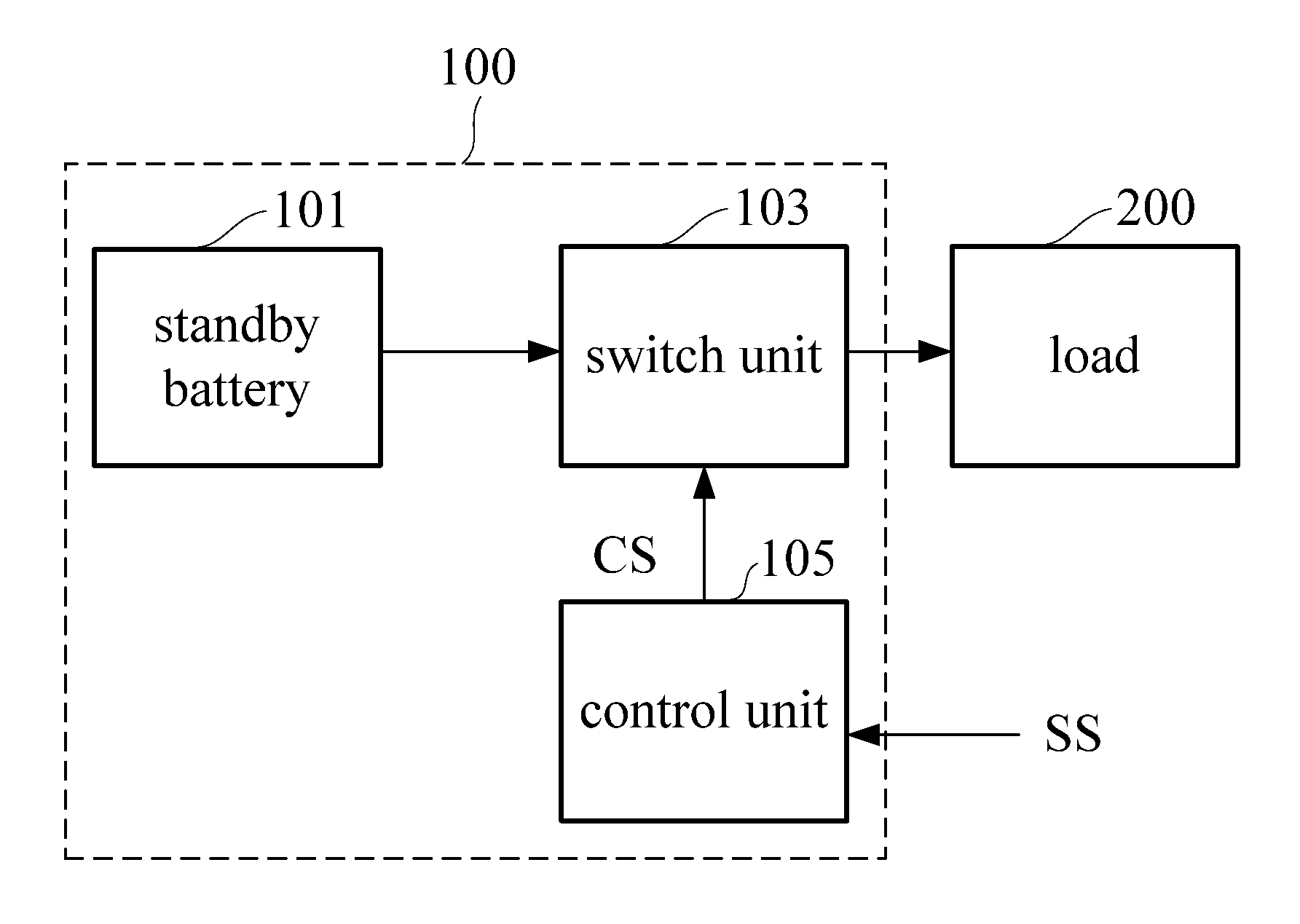

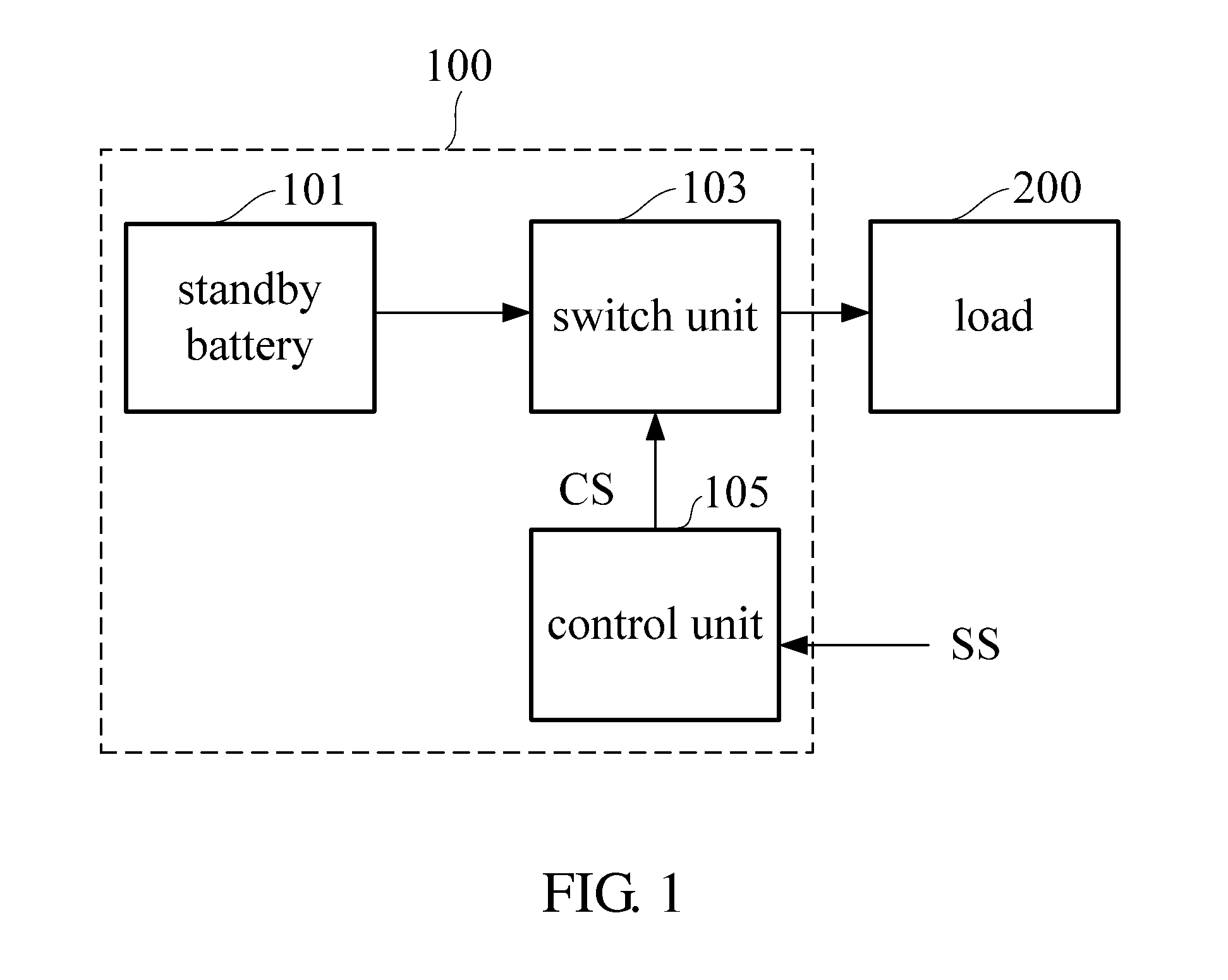

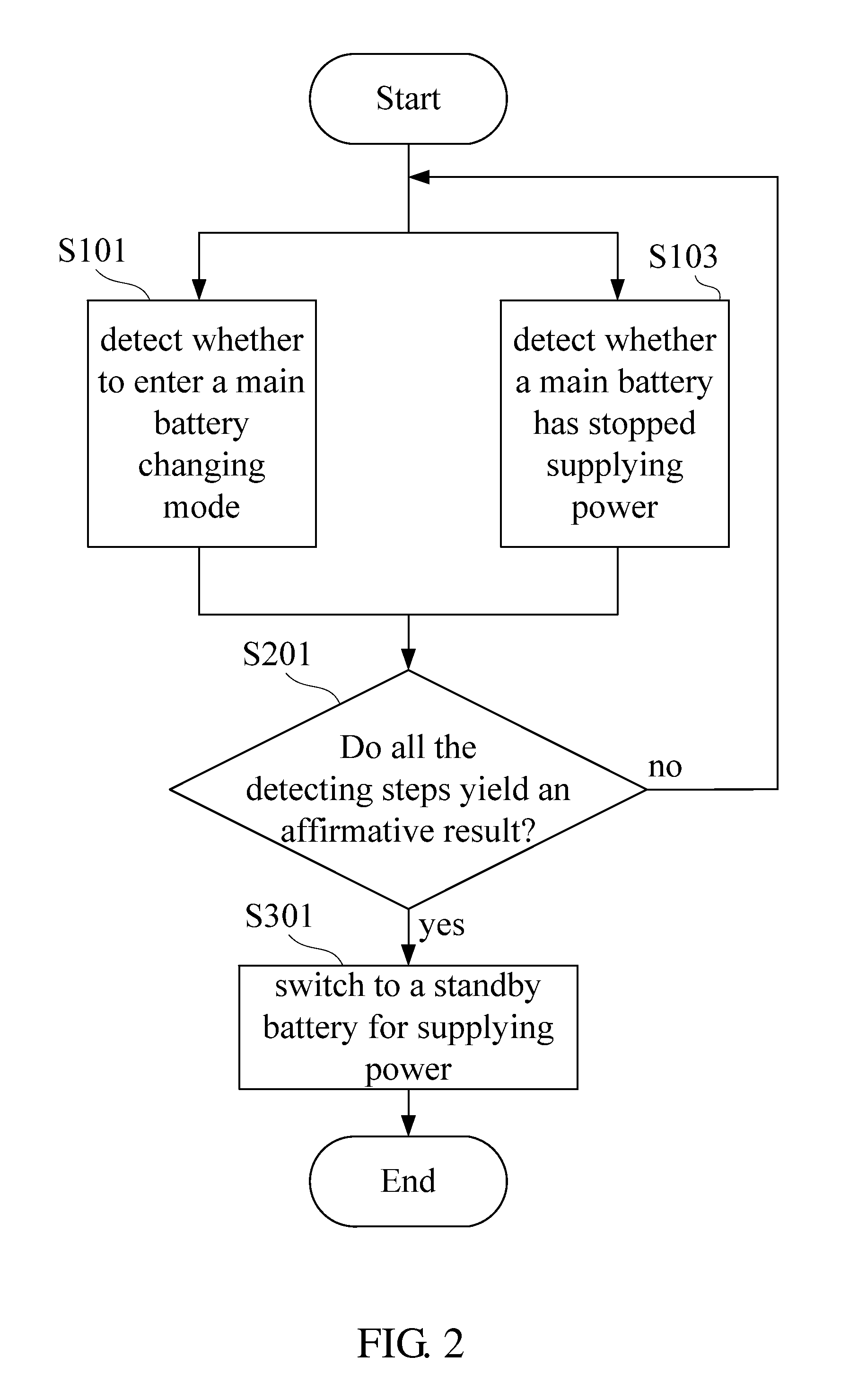

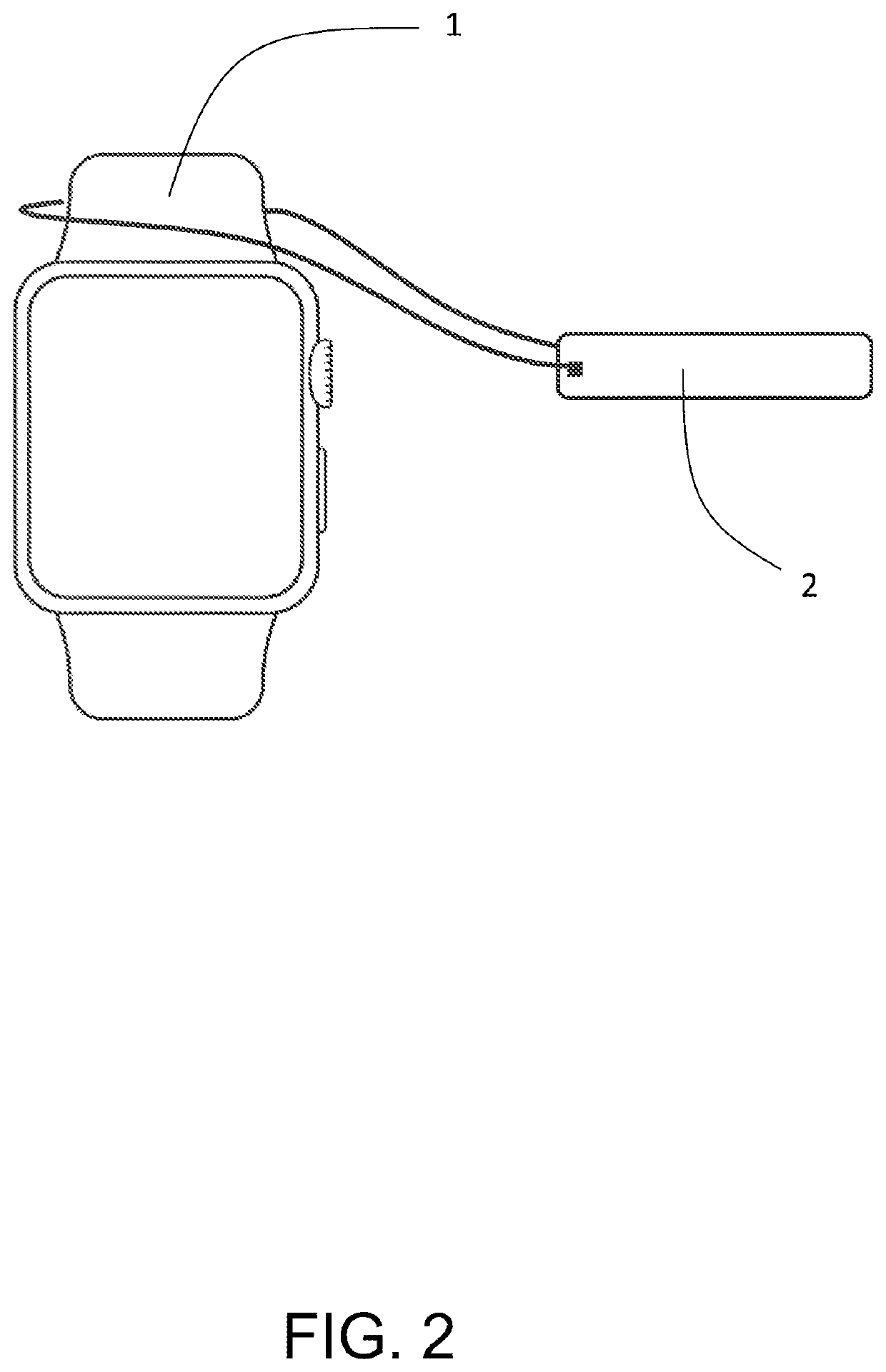

Standby power system for handheld electronic device and method for supplying standby power

InactiveUS20130038126A1Enabling changeWaste of timeBatteries circuit arrangementsPower network operation systems integrationTime efficientElectrical battery

A standby power system for handheld electronic device and a method for supplying standby power are introduced. The system and method enable detection whether a handheld electronic device is set to a predetermined power consumption state whereby the handheld electronic device operates in a power supplying state of a standby battery and whether a main battery of the handheld electronic device is disconnected, allowing a user to change the main battery without shutting down the handheld electronic device and thereby saving time.

Owner:ASKEY TECH JIANGSU +1

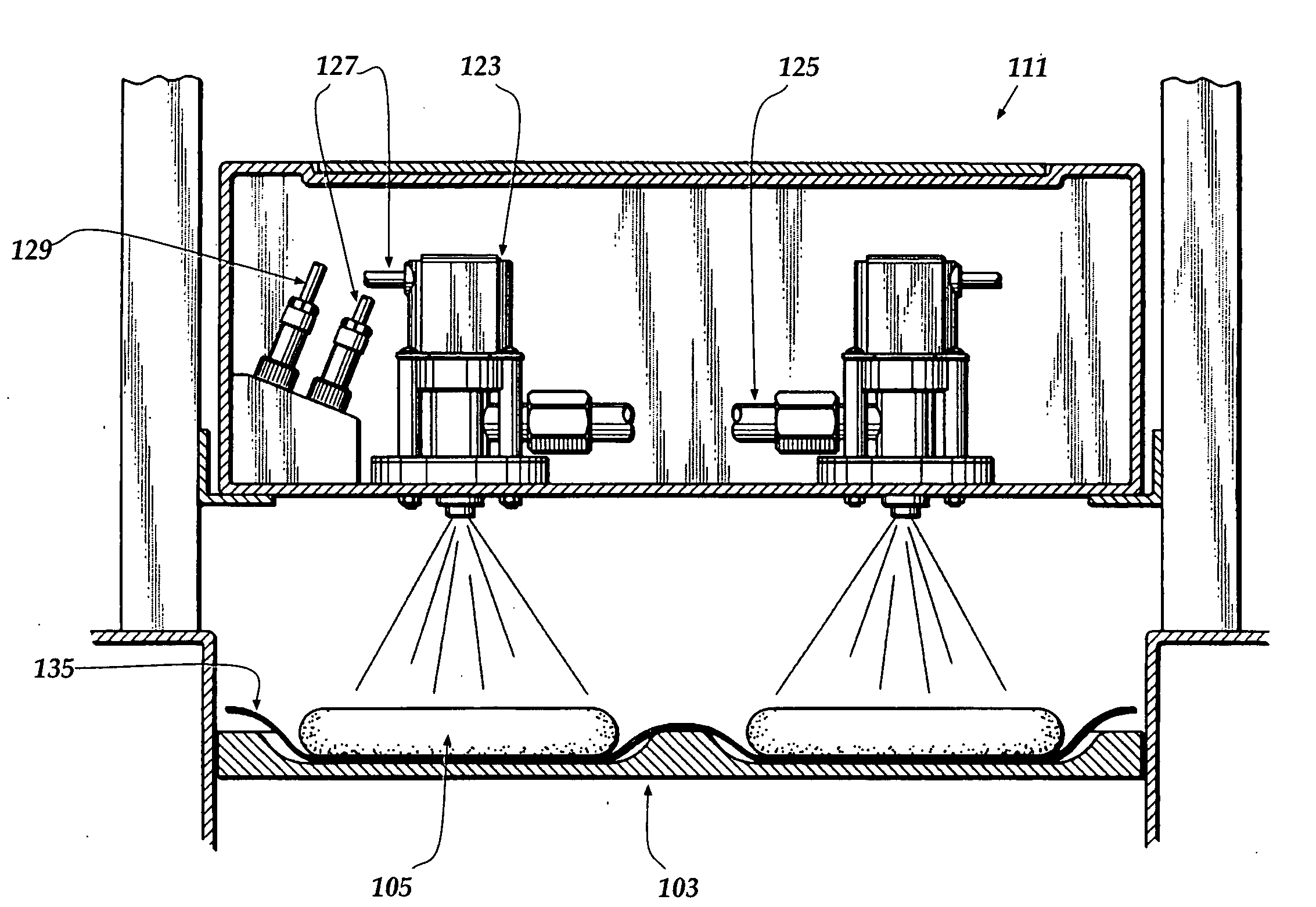

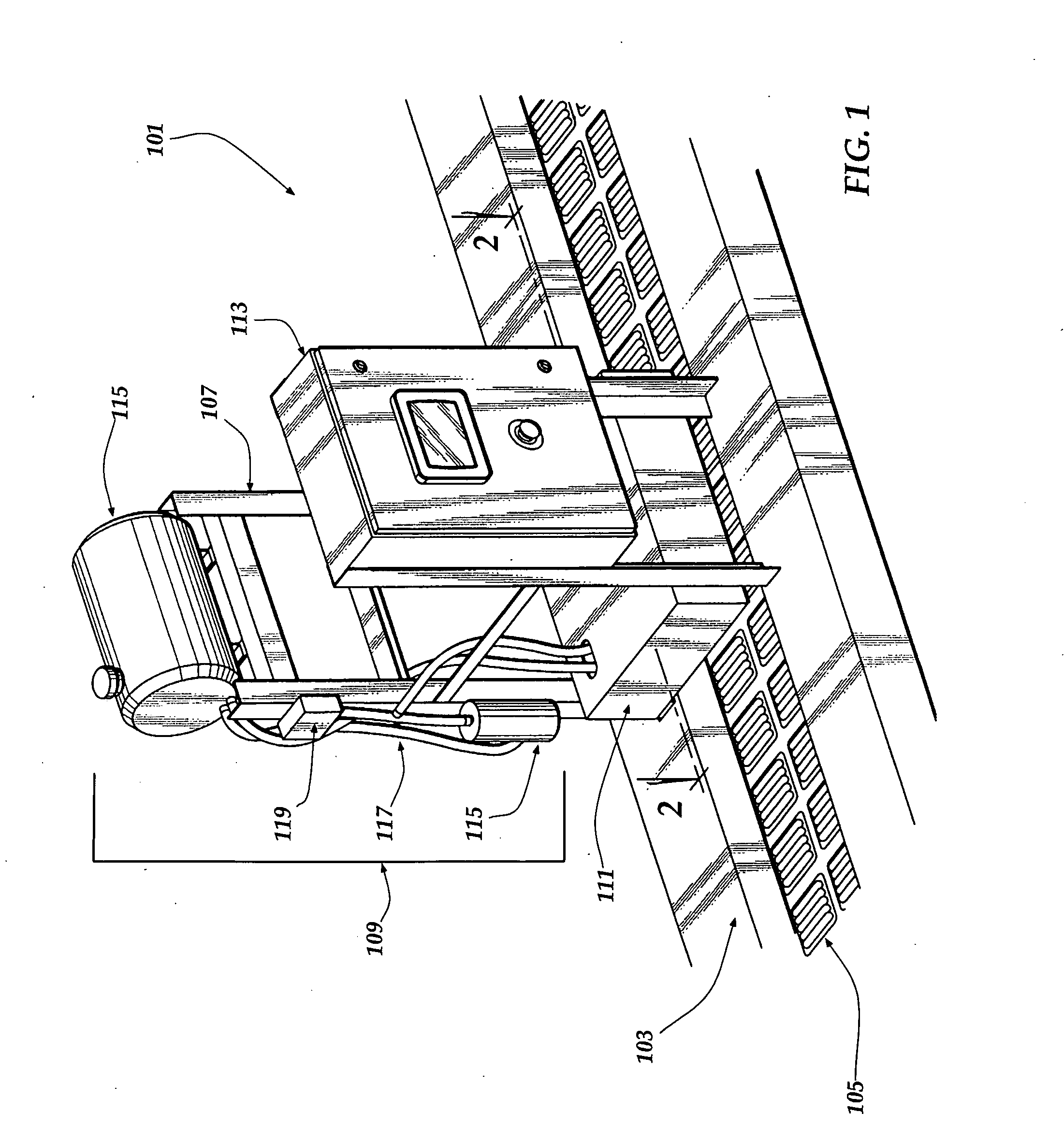

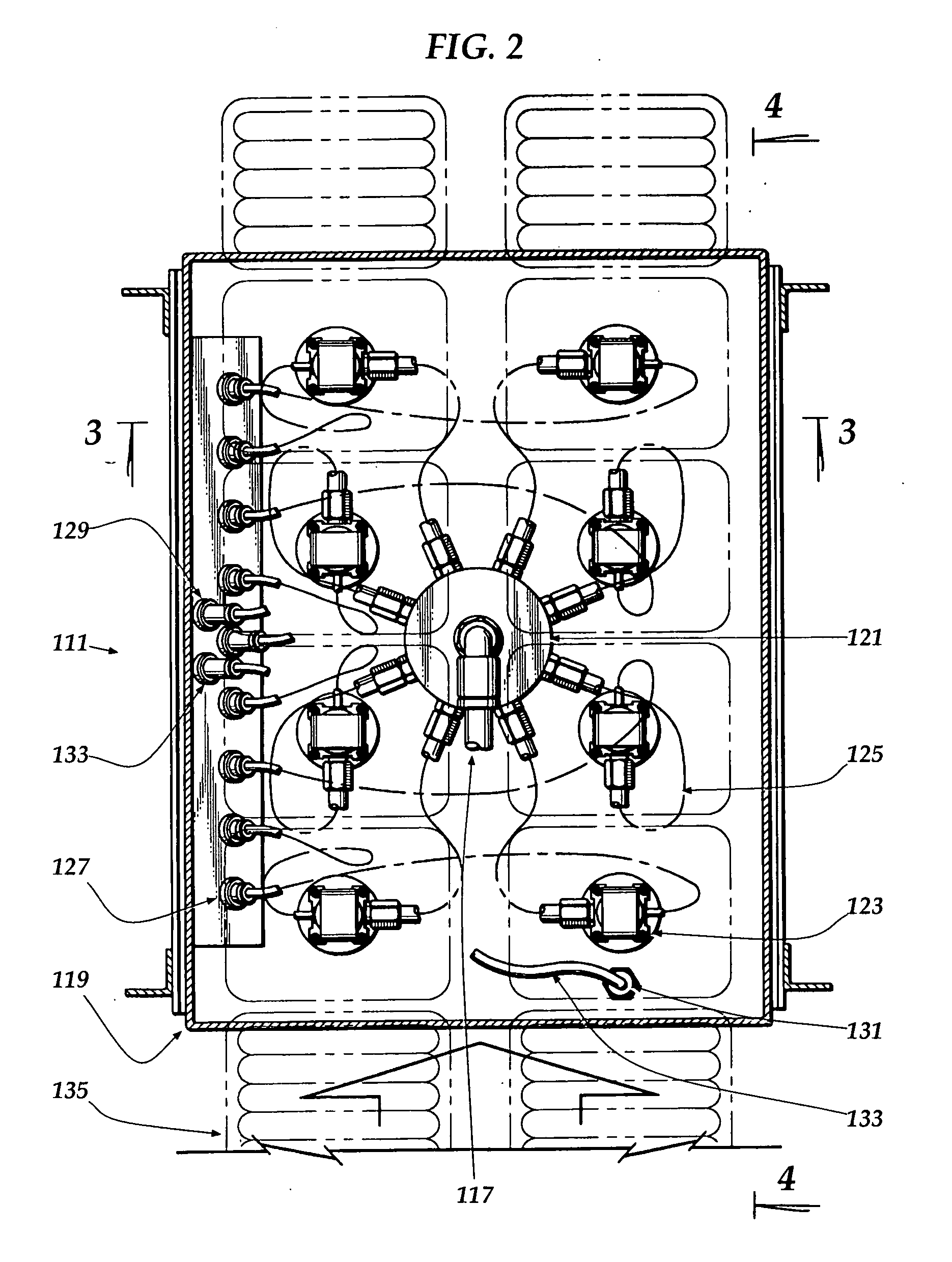

Inline antimicrobial additive treatment method and apparatus

InactiveUS20100206183A1Waste of timeIncrease efficiencyClimate change adaptationMeat/fish preservation using liquidsChemistryFood packaging

An antimicrobial treatment method for treatment of solid and semisolid foods in industrial food transport systems is provided. For solid and semisolid food applications, the method and related apparatus comprises a conveyor-based transport system in which antimicrobial additives are added to food packaging. The additives are metered into the packages using optical sensors to identify the size of packages, the amount of additive to be administered, and when such packages are in position to receive administration of the additives. The method is capable of realizing greater than 3 log reductions in live microbes in foodstuffs. The technology may also be used to apply any liquid or semi-solid additive or ingredient into packaging, including in nonfood applications such as medical equipment manufacturing.

Owner:MURPHY RONG YAN

Goods fastening apparatus with improved structures

ActiveUS7389970B2Improved simple and compact structureEasy to implementLifting devicesLoad securingEngineeringGear tooth

A goods fastening apparatus is disclosed which comprises a pipe fixedly connected to a body and a gear rack passing through the body and partly muff-coupled with the inside of the pipe. A hand grip and a positioning claw are hinged to the body through a primary pivot. A driving claw is hinged to the hand grip through a secondary pivot. A plate spring is positioned between the driving claw and the positioning claw. A mobile stopper sheet pressed against the plate spring is provided at the upper portion of the body. A stopper pin is fixed at the hand grip. The stopper pin is positioned at the edge of one side of the positioning claw facing the gear rack while the front end of the positioning claw is embedded into the gear teeth of the gear rack.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

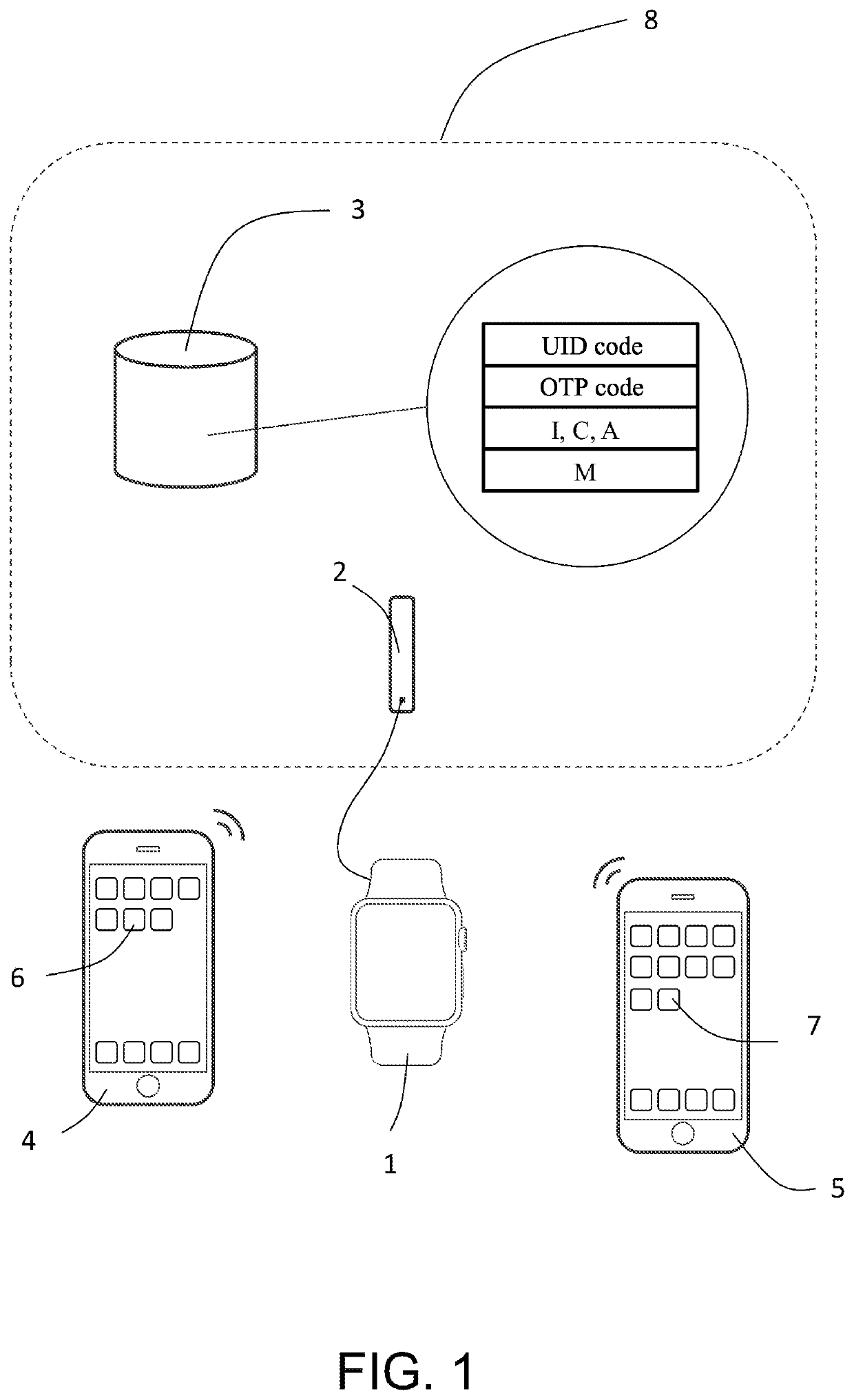

Method and system for the certification of a product to be shipped

PendingUS20210217028A1Waste of timeAvoid receivingLogisticsCommerceIndustrial engineeringManufacturing engineering

The present invention relates to a method and a system for the certification of a product to be shipped wherein the latter is associated with a tag meant to be queried by several devices before and after shipment to determine whether the data contained therein remain unchanged after the shipment of the product.

Owner:EBAY INC

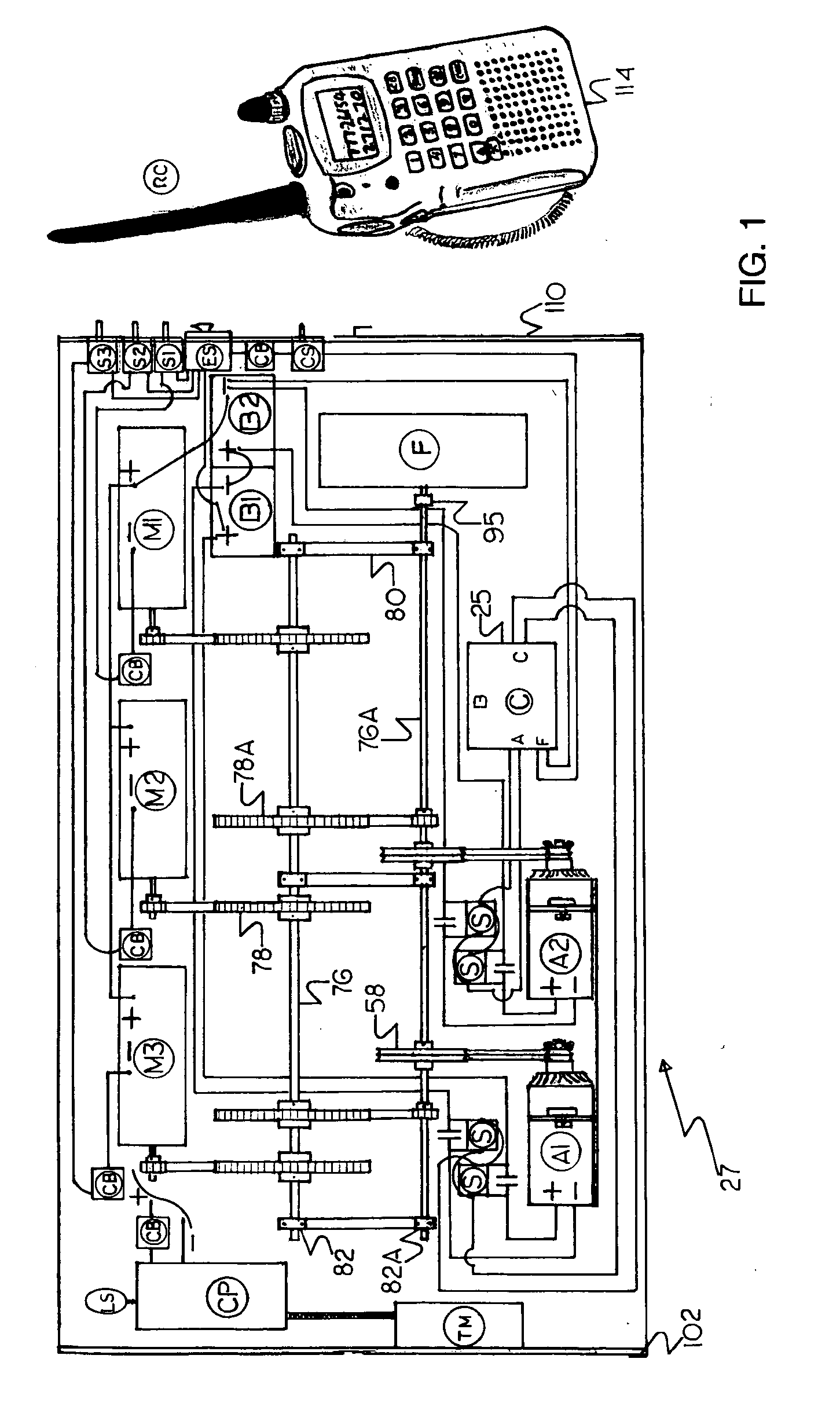

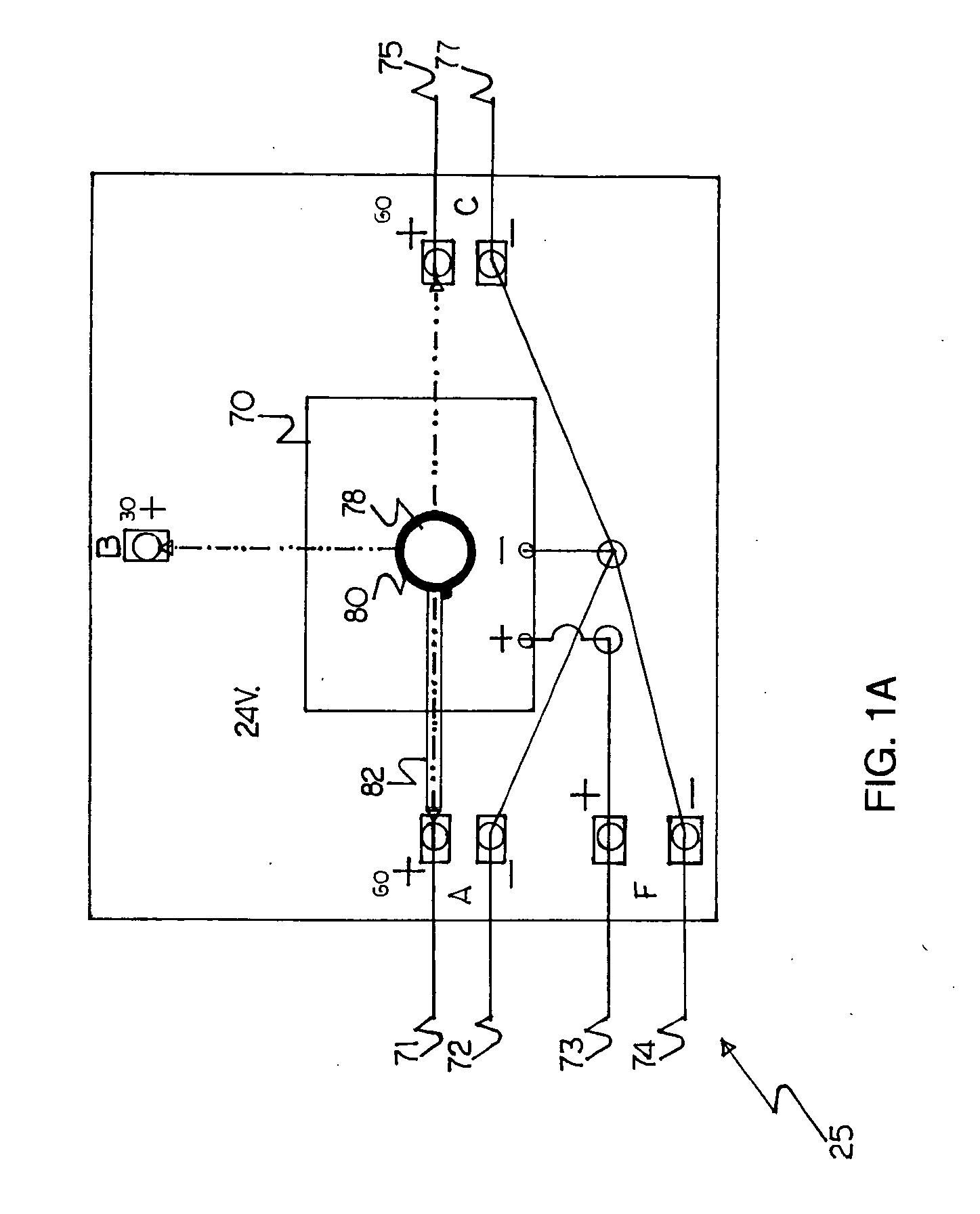

Perpetual motion fan module

InactiveUS20050151510A1No interruption of operationLoss in efficiencyBatteries circuit arrangementsMachines/enginesPerpetual motionVolt

A means for creating perpetual motion of a battery operated device has been disclosed. A battery operated device such as a large commercial fan can be made to operate continuously eliminating the need for a separate re-charging process for the batteries as long as the fan is kept in operation. This can be accomplished having at least two batteries which are connected in series to give the desired volts, and at least two charging components to charge each battery separately, as the fan is used.

Owner:BAILEY RUDOLPH V

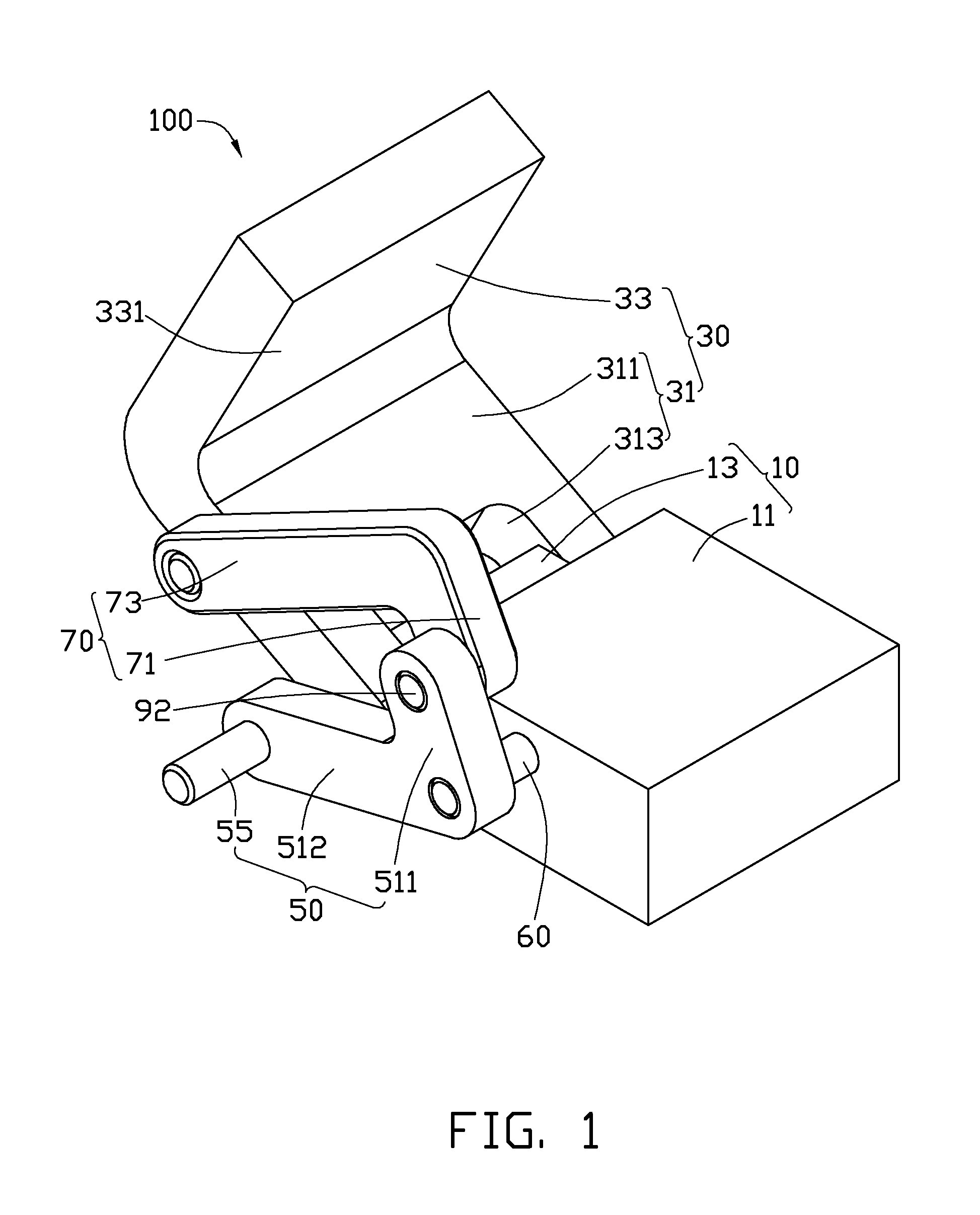

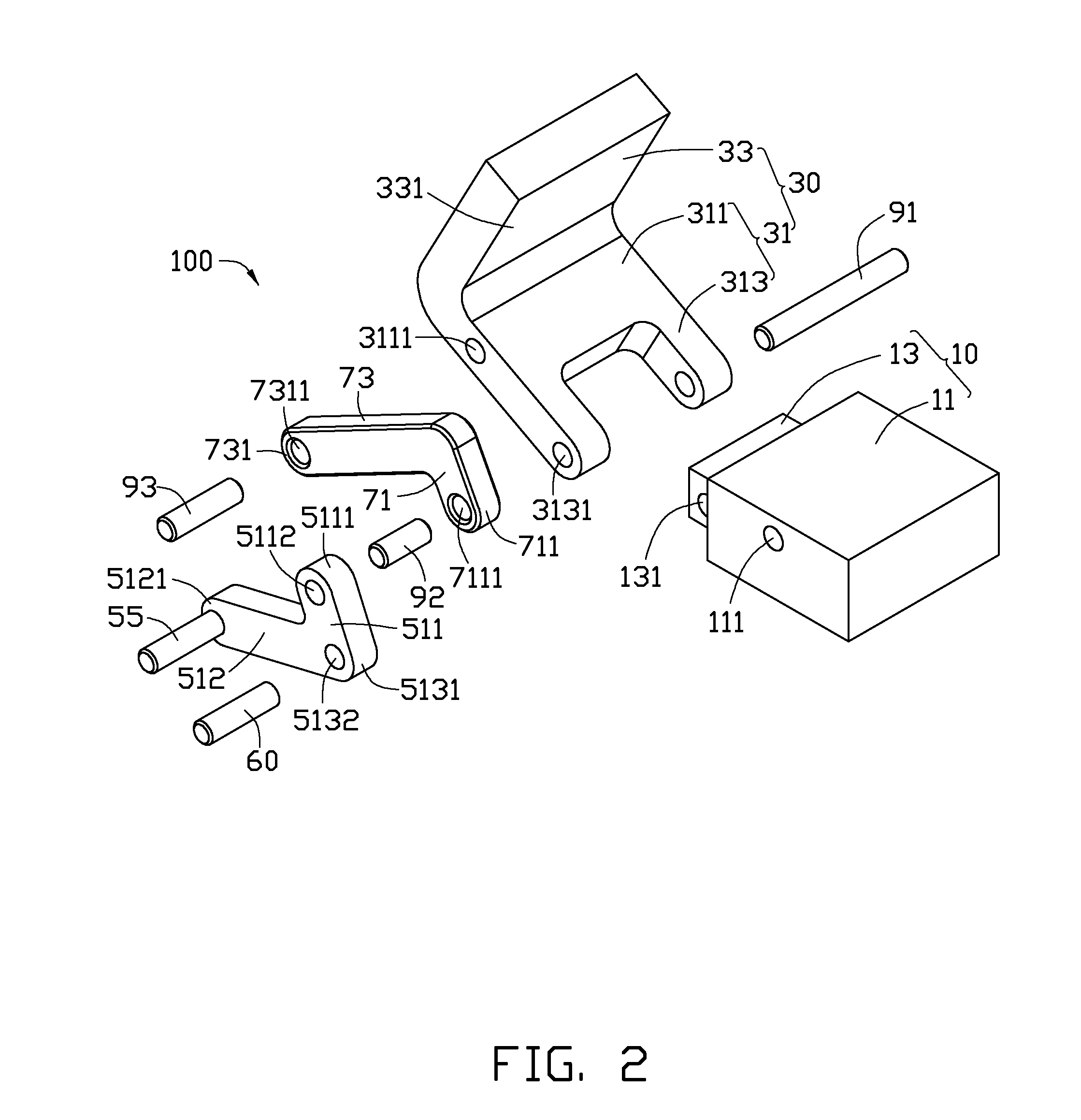

Clamping assembly

InactiveUS20130199002A1Waste of timeLow efficiencySnap fastenersClothes buttonsEngineeringMechanical engineering

A clamping assembly includes a base, a clamping block, a first linkage, and a second linkage. The clamping block includes a rotating portion and a clamping portion. The rotating portion is rotatably connected to the base. The clamping portion extends out from the rotating portion towards the base. The first linkage is rotatably connected to the base, and includes a first rod portion and a second rod portion extending from the first rod portion. The second linkage includes a third rod portion and a fourth rod portion extending from the third rod portion. The third rod portion rotatably connects with the first rod portion. The fourth rod portion rotatably connects with the rotating portion of the clamping block.

Owner:SHENZHENSHI YUZHAN PRECISION TECH CO LTD +1

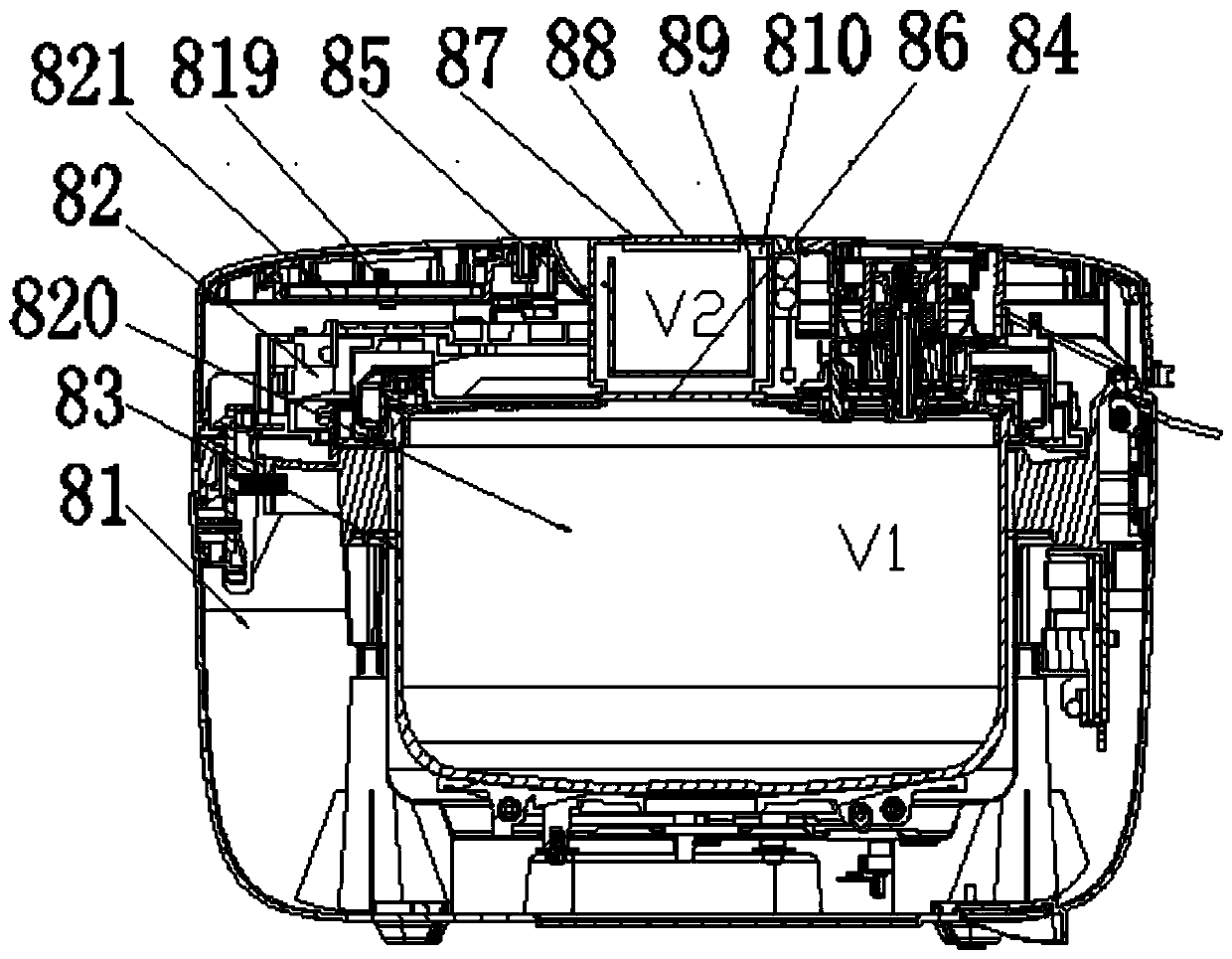

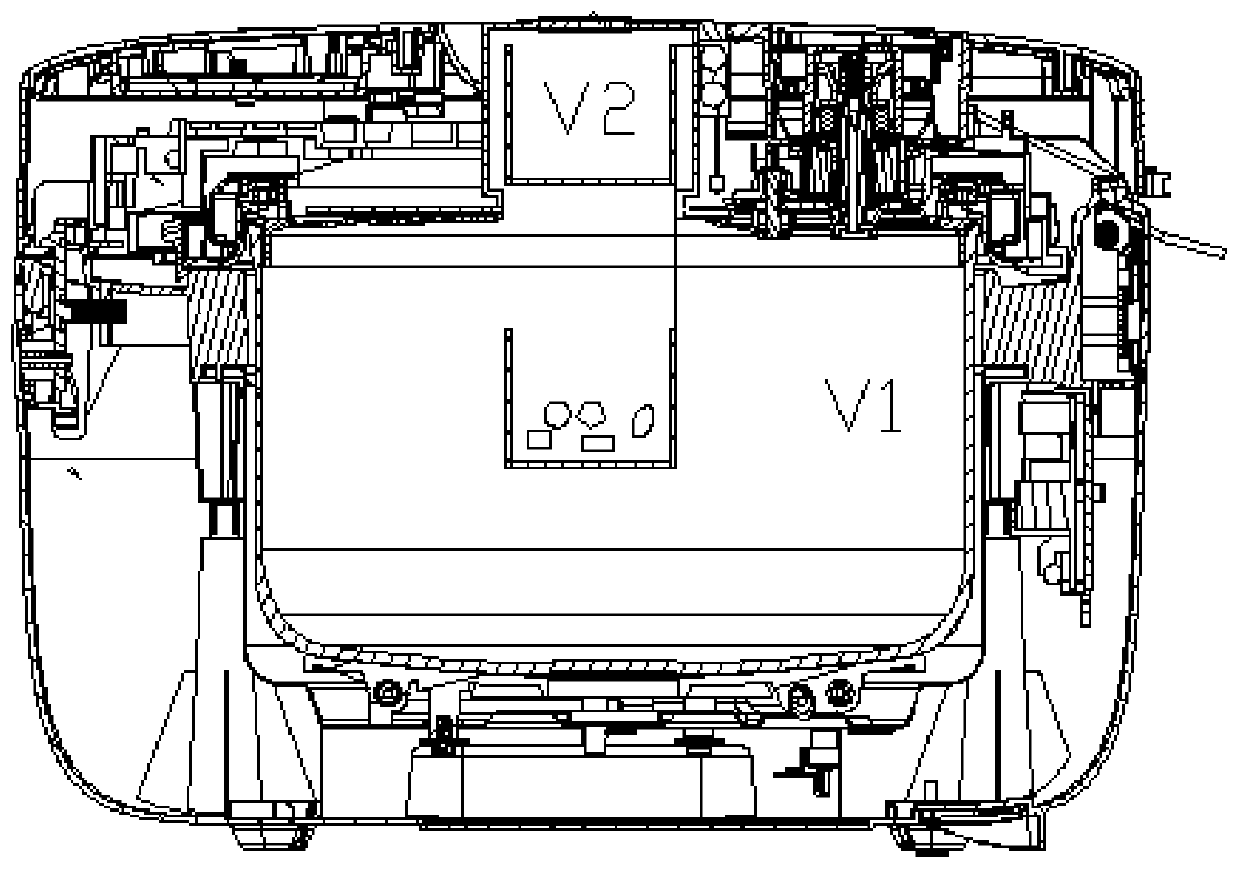

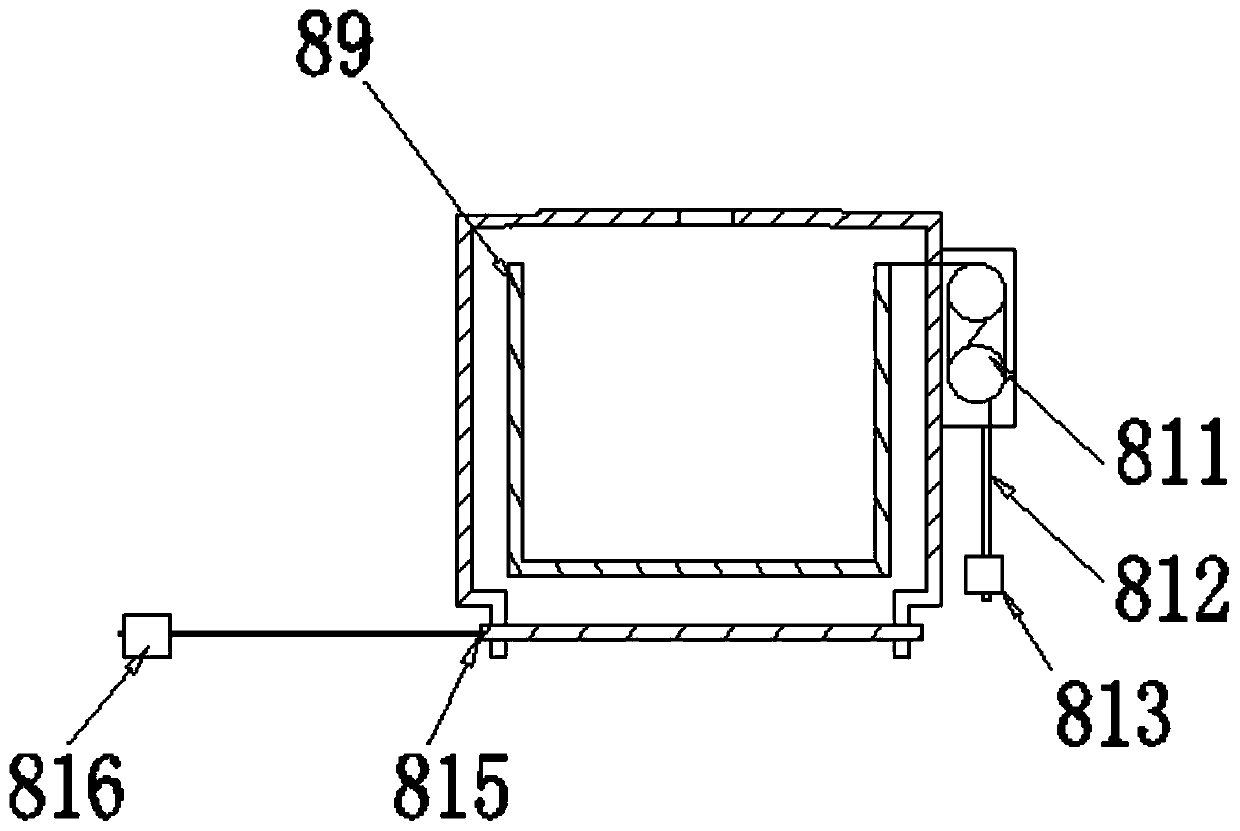

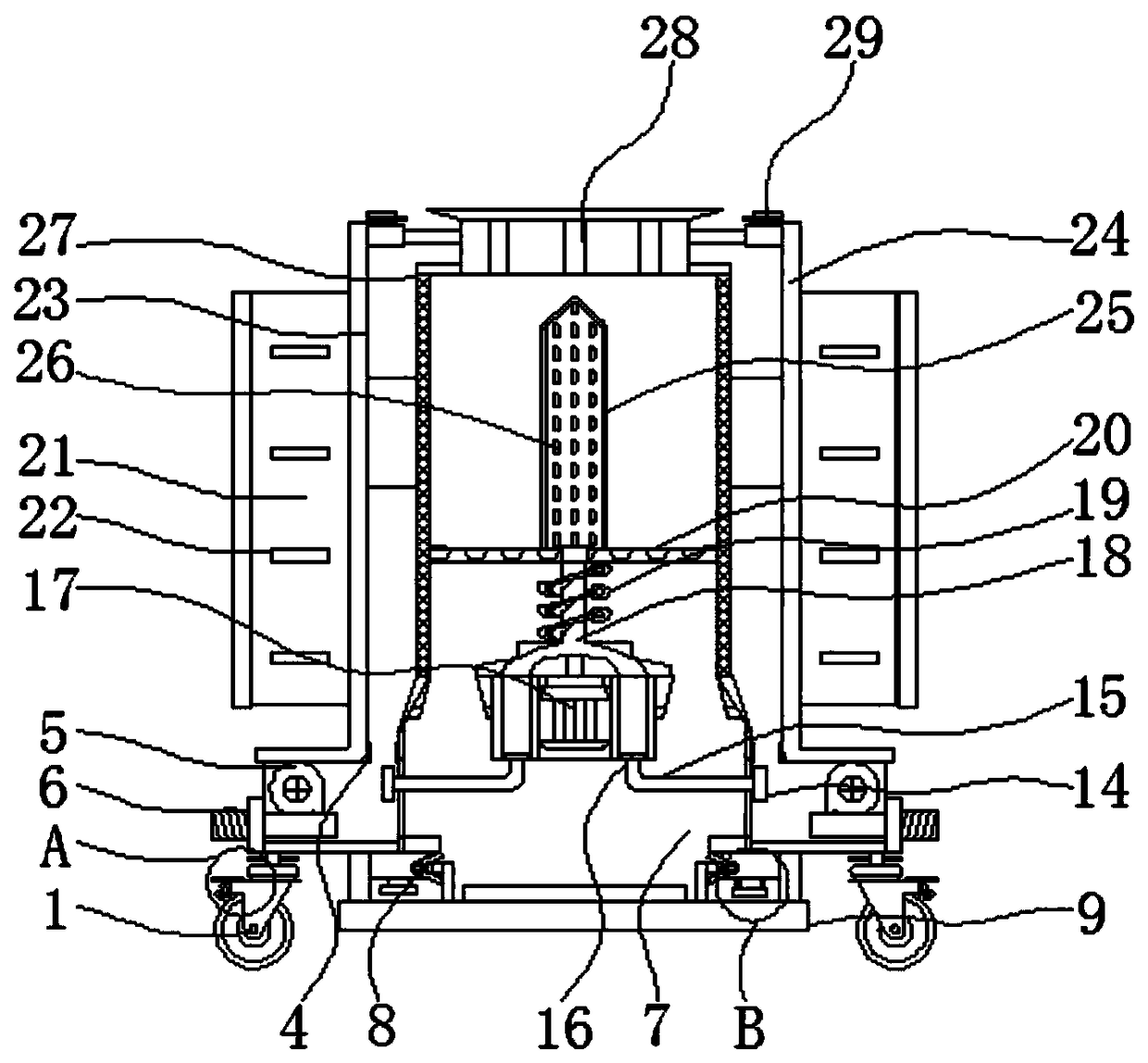

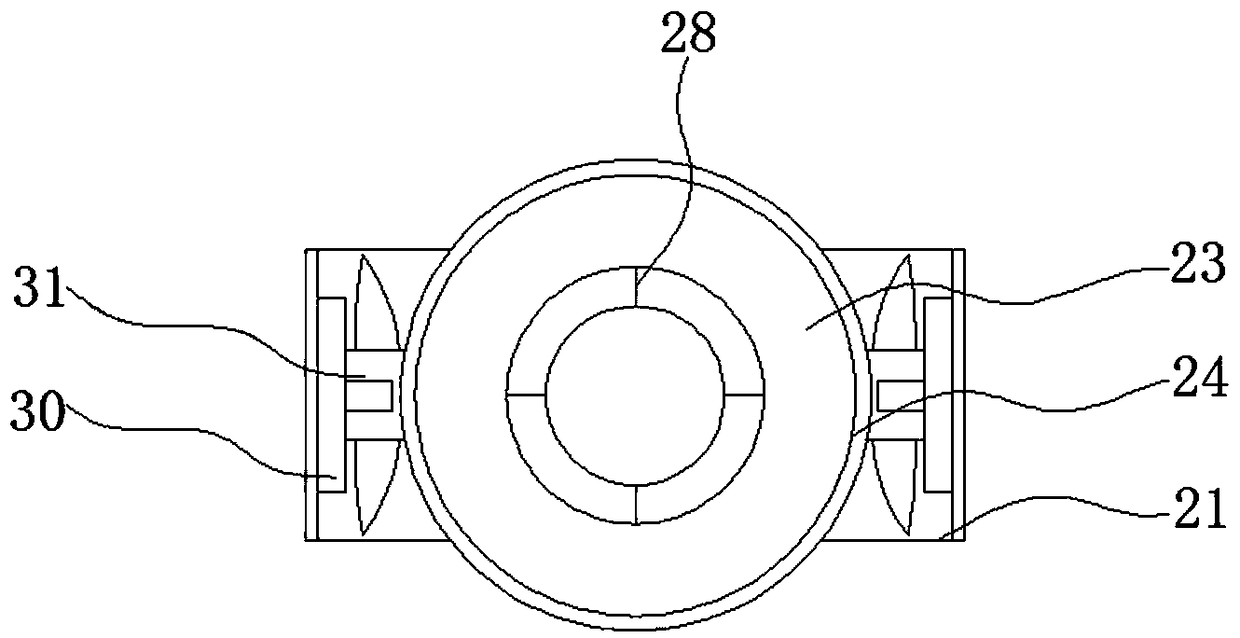

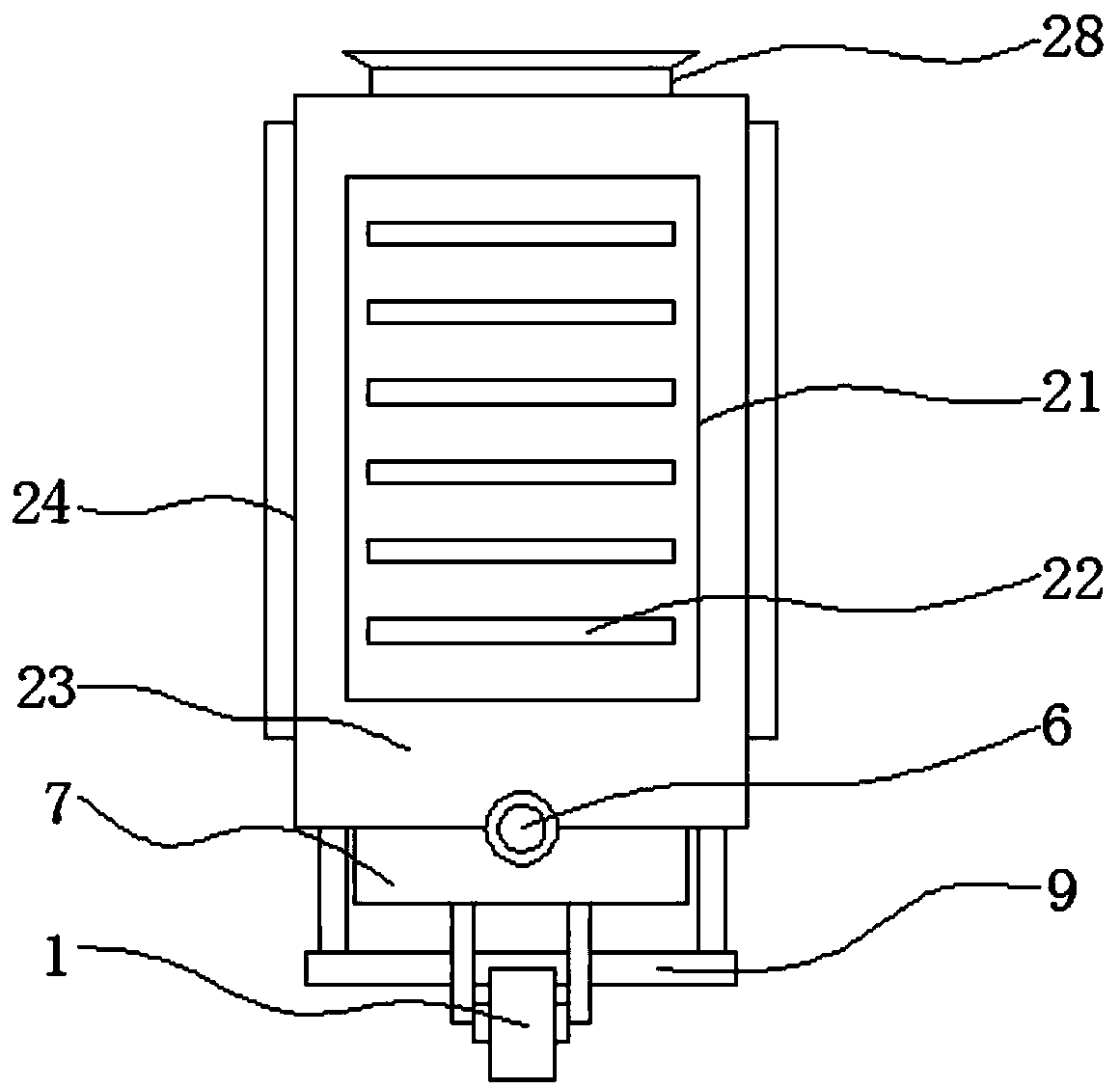

Device for automatic material adding and taking in midway of electric pressure cooker as well as control method

The invention relates to a device for automatic material adding and taking in midway of an electric pressure cooker as well as a control method. The device comprises a pot body and a cover body; an inner pot for storing food materials is arranged in the pot body; the cover body covers the upper part of the pot body and is used for sealing the inner pot; a microcontrol unit (MCU) for controlling the work of the electric pressure cooker is arranged in the pot body; a pressure valve for generating and controlling a pressure value is arranged on the cover body; a material adding device for throwing materials in the pot as well as a material taking device for taking out the materials in the cooking process of the electric pressure cooker are arranged on the cover body. According to the device for automatic adding and taking materials in the midway of the electric pressure cooker, the cooking state of increasing the food materials and checking the food materials can be automatically executedin the cooking process without waiting for pressure relief of the electric pressure cooker, waste of time caused by the fact that a user stays beside the electric pressure cooker for a long time is avoided, energy is saved and the cooking effect of the food materials is improved.

Owner:SHANGHAI CHUNMI ELECTRONICS TECH CO LTD

Anti-blocking environment-friendly oil and residue separating equipment for oil refining

InactiveCN109442882AWaste of timeImprove work efficiencyDrying solid materials without heatDrying machines with non-progressive movementsIdler-wheelBrake pad

The invention relates to anti-blocking environment-friendly oil and residue separating equipment for oil refining. The anti-blocking environment-friendly oil and residue separating equipment comprisesan idler wheel and an oil guiding groove; a brake block is mounted above the idler wheel, and a supporting block is mounted on the right side of the brake block; a water pump is mounted on the innerside of the oil guiding groove which is located above a connecting block; a spiral connector is arranged on the left side of the oil guiding groove, and an oil and residue groove is formed in the right side of the oil guiding groove; a clamping block is mounted on the inner side of the oil and residue groove, and a bottom plate is arranged below the oil and residue groove; and a joining block is mounted below the clamping block, and a positioning block is arranged on the inner side of the joining block. The anti-blocking environment-friendly oil and residue separating equipment has the beneficial effects that through arrangement of a guard plate, a vent hole, a mounting block and a fan, the fan discharges air by facing an oil leakage net, thus the oil leakage net can be effectively prevented from being blocked, practicability of the equipment is improved, the temperature of internal waste oil can be lowered, oil and residue separating is easier to conduct, the guard plate can protect internal parts against being damaged when the equipment is collided, and thus the self-protection capacity of the equipment is enhanced.

Owner:广东博昊实业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com