Device for automatic material adding and taking in midway of electric pressure cooker as well as control method

The technology of an electric pressure cooker and a material reclaiming device, which is applied in the field of pressure vessels, can solve the problems of adding materials or checking the cooking of ingredients in the middle, wasting a lot of time, etc., so as to achieve the effect of improving the cooking effect and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention is described in detail below with reference to accompanying drawing and embodiment:

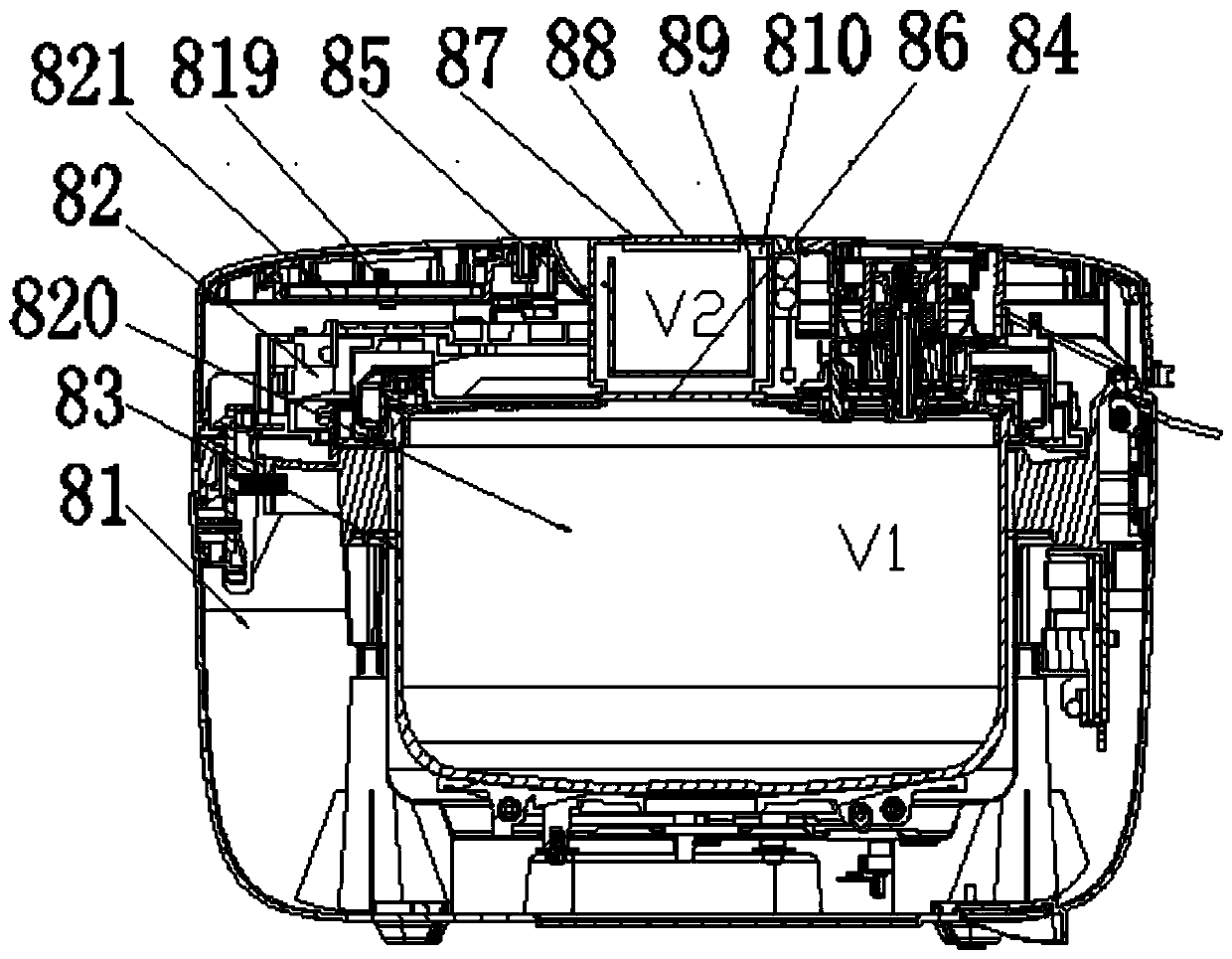

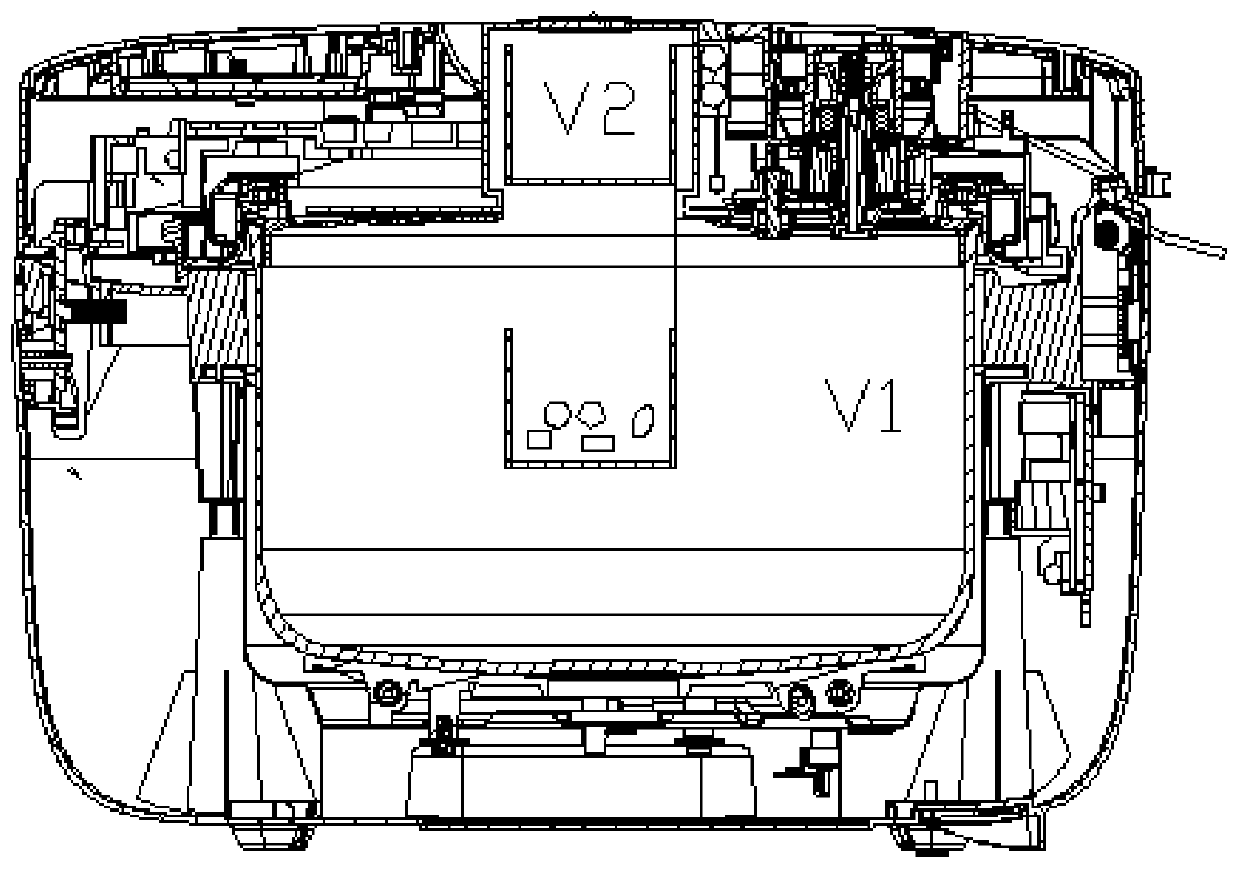

[0087] attached Figure 1-12 It can be seen that an automatic feeding and retrieving device for an electric pressure cooker,

[0088] It includes a pot body 81 and a cover body 82; the pot body 81 is provided with an inner 83 for containing food materials, and the cover body 82 covers the upper part of the pot body to seal the inner pot 83; the pot body is provided with a micro-controller for controlling the operation of the electric pressure cooker Unit MCU819, the cover body 82 is provided with a pressure valve 84 for generating and controlling the pressure value,

[0089] The cover body 82 is provided with a feeding device for feeding materials into the inner pot of the electric pressure cooker during cooking and a feeding device for taking out materials.

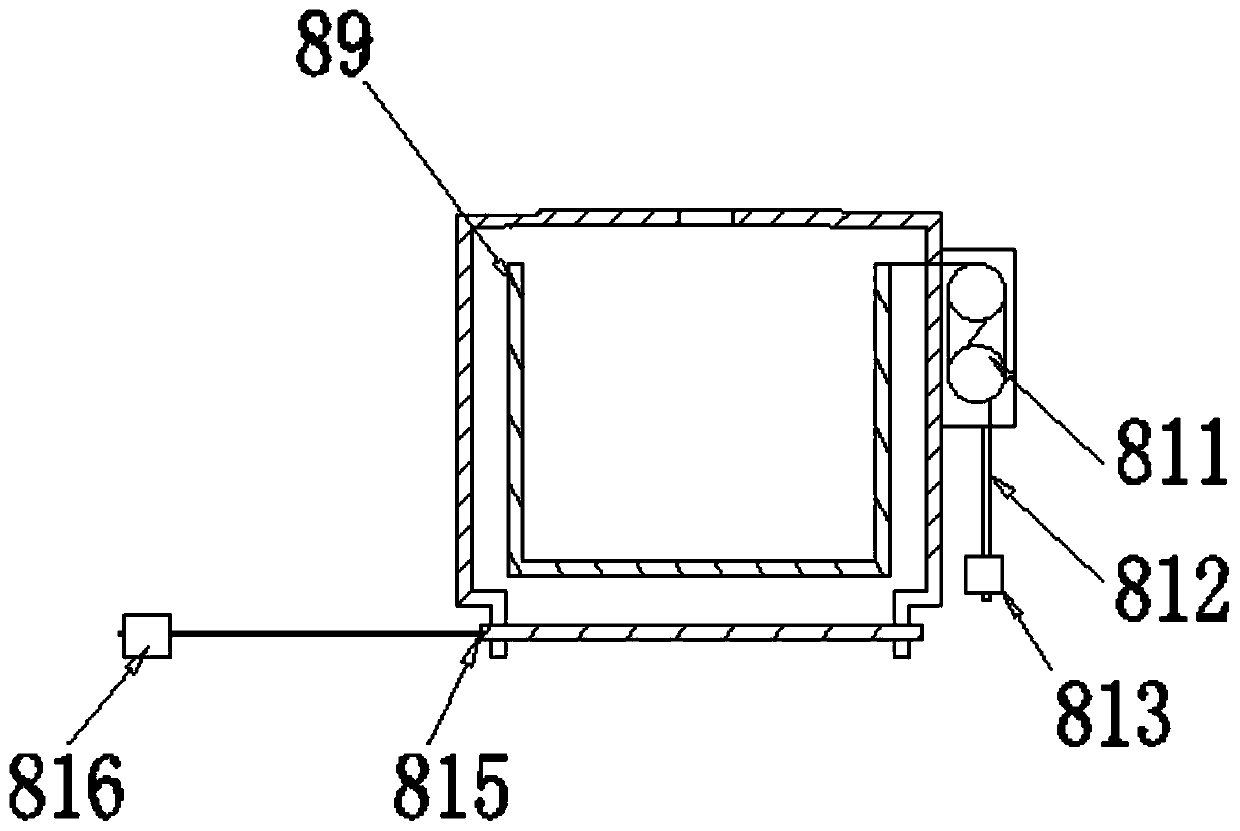

[0090] The cover is provided with a pressure relief transfer bin 85; the pressure relief transfer bin 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com