Steam-valve assembly and electric rice cooker thereof

A steam valve and component technology, which is applied to the field of steam valve components and electric rice cookers, can solve the problems of low steam flow speed, large starting inertia of fan blade component size, and inability to drive fan blades, etc., so as to improve the foam breaking effect and improve the cooking effect. and user experience, the effect of eliminating bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

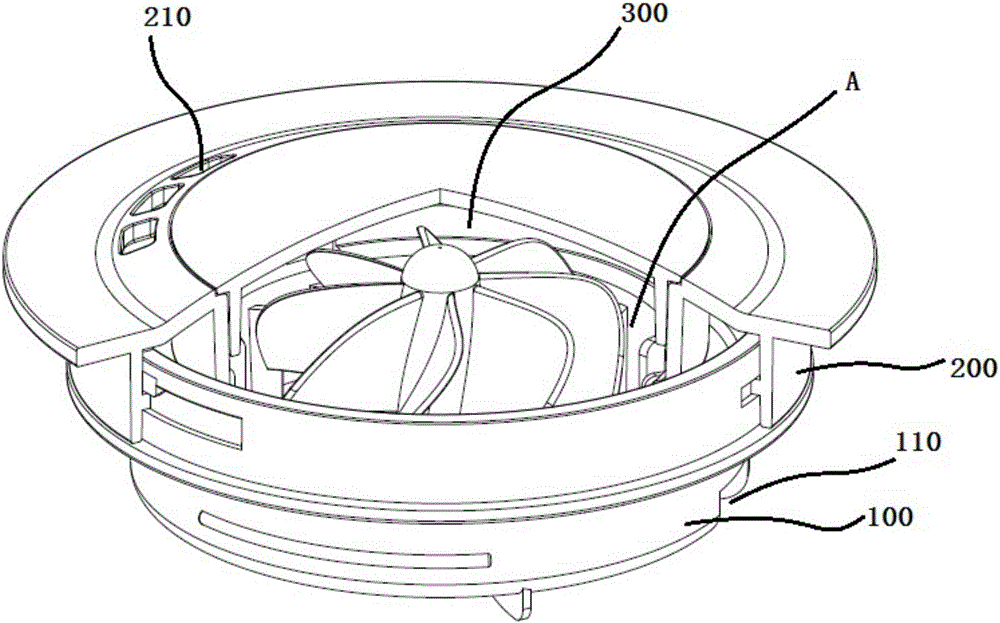

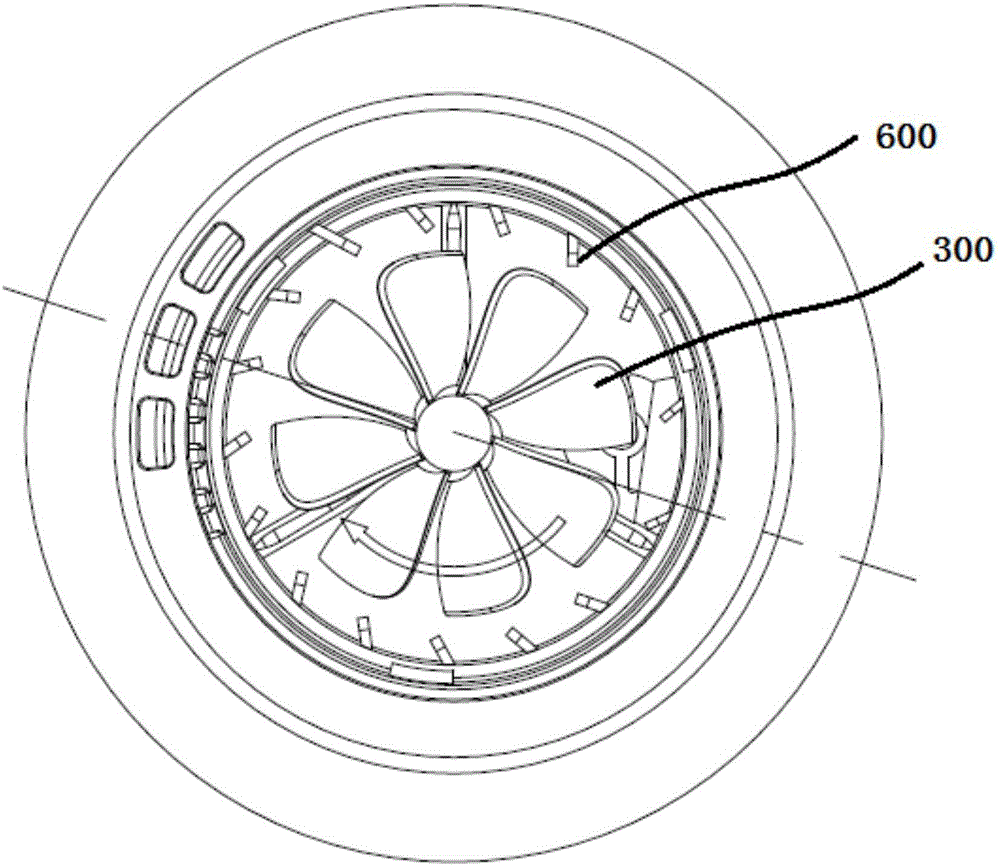

[0038] refer to figure 2 as well as image 3 As shown, a steam valve assembly includes: a valve seat 100 and a valve cover 200, the valve cover 200 is detachably assembled on the valve seat 100, and also includes a fan blade assembly 300 and a support column, wherein the fan blade assembly 300 can be Rotatably installed on the support column; the steam valve assembly also includes a first air inlet 110 and a first air outlet 210, the steam entering from the first air inlet is discharged from the first air outlet, and Drive the fan blade assembly to rotate.

[0039] Specifically, it also includes a number of bubble breaking and spoiling ribs 600 arranged on one of the valve seat or the valve cover, the fan blade assembly rotates to break the bubbles, and the bubble breaking and spoiling ribs squeeze and break the bubbles.

[0040] The fan blade assembly rotates and breaks the bubbles as the main bubble breaking device; the bubble breaking spoiler is the auxiliary bubble brea...

Embodiment 2

[0057] The difference between Embodiment 2 and Embodiment 1 is that a steam guiding component is added.

[0058] refer to figure 2 , Figure 9 as well as Figure 10 , in order to better guide the steam into the cavity, an upper windshield 120 is also provided on the inner wall of the valve seat 100, the upper windshield is located above the first air inlet 110, and the upper windshield will be formed by the first air inlet 110. The steam entering the first air inlet 110 is guided into the second air inlet 2204; in addition, a side windshield 130 is also arranged on the inner wall of the valve seat, and the upper windshield 120 and the side windshield 130 constitute a steam Guide chamber B.

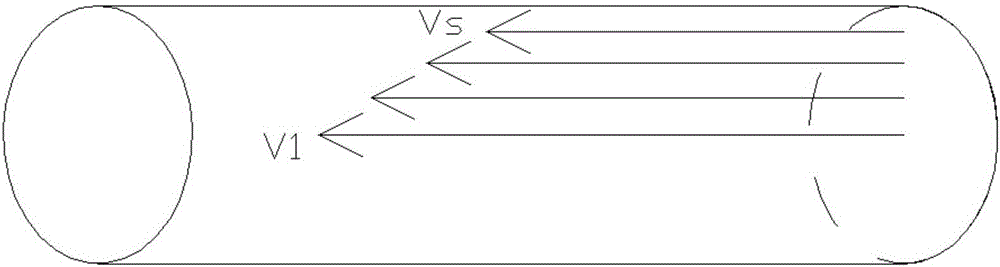

[0059] When the rice cooker heats the liquid, the volume rapidly expands and generates steam. The steam valve acts as a communication device between the inner pot of the rice cooker and the external atmosphere, and the internal gas passes through the inner cover and enters the first ai...

Embodiment 3

[0067] Different from the schemes of Embodiment 1 and Embodiment 2, this scheme provides specific assembly structures of the fan blade assembly and the valve cover.

[0068] refer to Figure 9 , Figure 11 as well as Figure 14 , wherein the fan blade assembly 300 is rotatably installed on the support column 400, the support column is only used as a supporting component, and the support column is fixed, and does not block and guide the steam flowing into the steam valve assembly; After being blown by the steam, the fan blade assembly overcomes the frictional force between the fan blade assembly and the support column to realize self-rotation.

[0069] It also includes a fixing assembly 500 for fixing the support column 400, one end of the fixing assembly 500 is connected to the inner wall of one of the valve seat or the valve cover, and the other end is connected to the lower part of the support column 400, this solution gives The assembly scheme of the support column is sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com