Food processor with good noise reduction effect

A food processing machine and noise reduction technology, applied in household appliances, applications, kitchen utensils, etc., can solve the problems of difficult control of pressure relief conditions, many dead spots in cleaning, affecting neighbors, etc. The effect of less dead space and easy rinsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

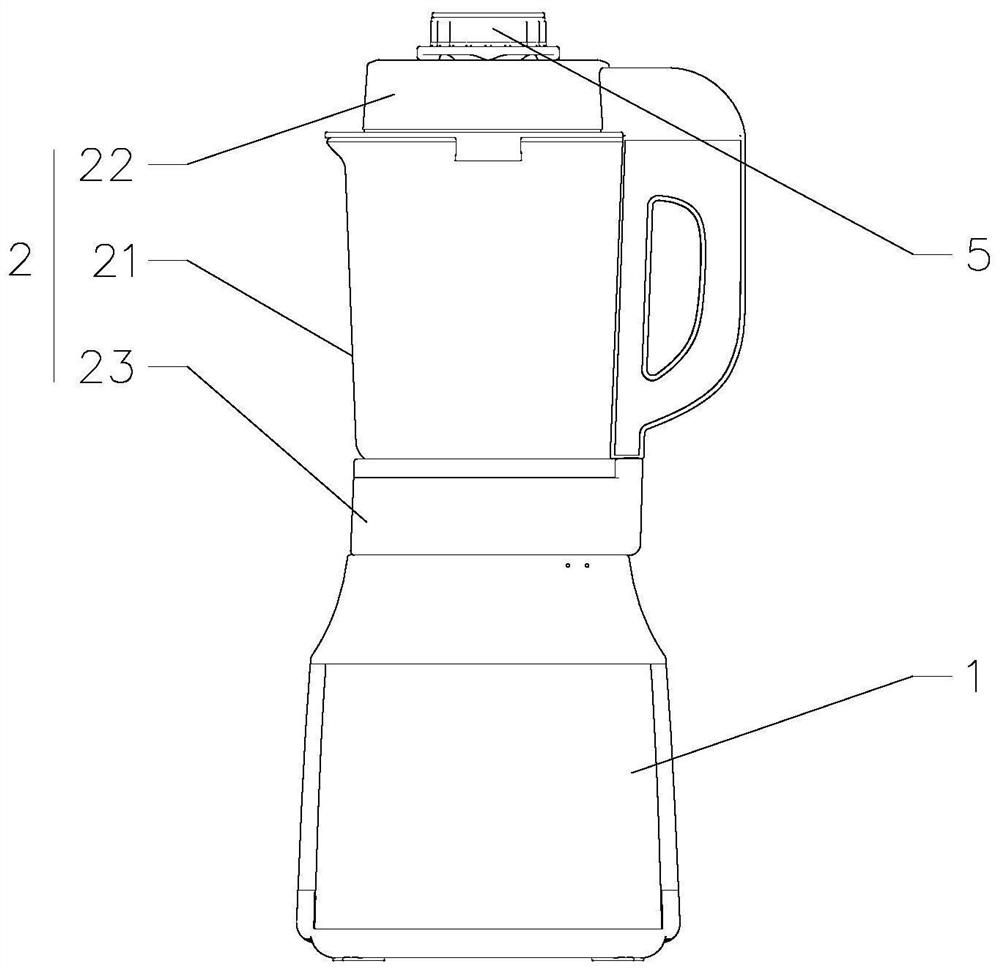

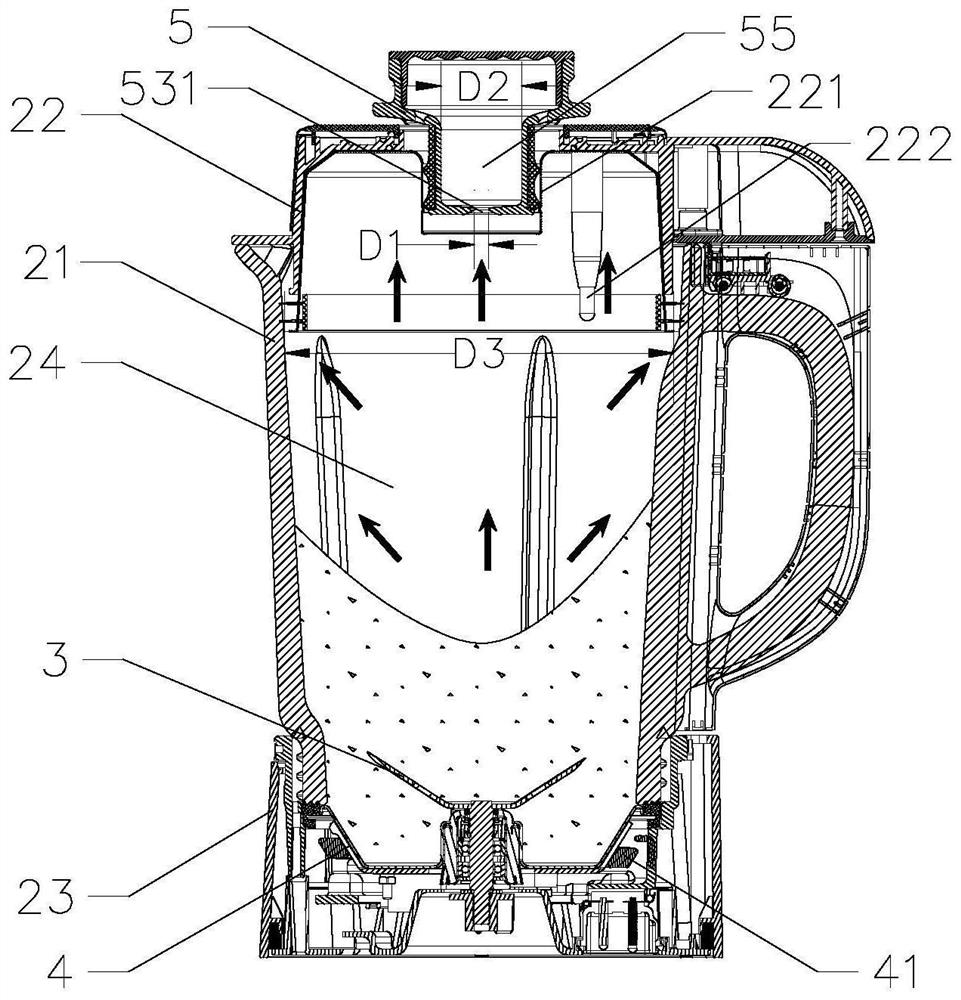

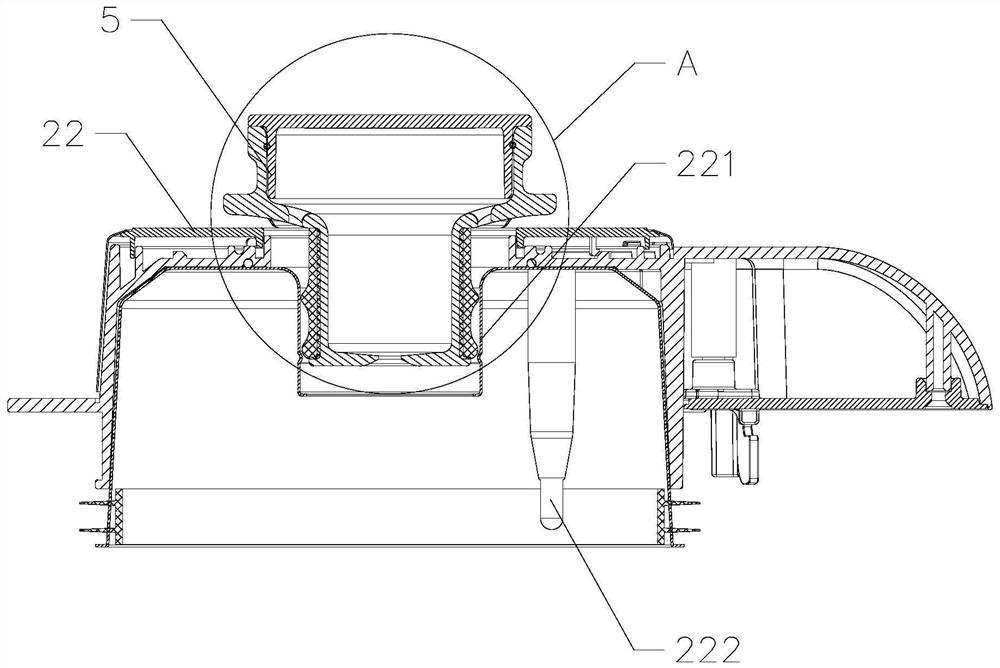

[0043] like Figures 1 to 5 As shown, the present invention provides a food processor with good noise reduction effect, which includes a main machine 1 and a stirring cup 2. The main machine 1 is provided with a motor and a control board, and the stirring cup 2 is provided with a pulverizer 3, and the motor drives the pulverizer 3. Rotate, the stirring cup 2 includes a cup body 21 and a cup cover 22 that covers the top of the cup body 21. The stirring cup 2 also includes a cup holder 23. A cutterhead 4 is arranged between them, and a heat pipe 41 is arranged on the outside of the cutterhead 4. The heat pipe 41 is fixed on the outside of the cutterhead 4 by brazing, and the crushing knife 3 is rotated on the bottom wall of the cutterhead 4. The body 21 and the cutter head 4 encircle to form a crushing chamber 24, the cup cover 22 is provided with an opening, the opening extends downwards to form a feeding channel 221, the feeding channel 221 is provided with a noise reduction c...

Embodiment 2

[0062] The difference between this embodiment and the first embodiment lies in that the positions of the air intake holes are different.

[0063] In this example, if Image 6 As shown, the insertion portion 53 includes a bottom wall and a side wall, and the air inlet 531 is located near the junction of the bottom wall and the side wall of the insertion portion 53, so that the air flow is difficult to form air bubbles at the air inlet, and the contact between the air bubbles and the inner cavity Because of multi-surface contact, the direction of surface tension of the bubbles is different, so it is difficult to form bubbles, that is, it is easier to break the bubbles, and at the same time, the exhaust is smoother, and the air pressure difference between the inner cavity and the crushing cavity is better maintained, which is conducive to breaking the bubbles. Air holes can also be arranged on the bottom wall of the insertion part, especially at the center, so as to maintain the ...

Embodiment 3

[0066] The difference between this embodiment and Embodiments 1 and 2 is that the inner surface of the top cover of the noise reduction cover is provided with a diffuse reflection surface.

[0067] In this example, if Figure 7 As shown, the inner surface of the noise reduction cover top cover 56 is provided with a diffuse reflection surface 561, and the diffuse reflection surface 561 is provided with multiple circles and rings are set in phase, that is, the combination of multiple circles of concentric circles forms a sound diffuse reflection surface, so that the sound propagates to On the diffuse reflection surface, the sound waves reflected by different circles will interfere with each other to eliminate noise, so as to play a good role in noise reduction, thereby greatly reducing the noise of the food processor when it is working.

[0068] The structures and beneficial effects of other parts not described are the same as those of Embodiments 1 and 2, and will not be repeat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com