Kitchen waste crushing and squeezing processor

A kitchen waste and processing machine technology, applied in the direction of presses, grain processing, manufacturing tools, etc., to achieve good crushing effect, improve waste processing efficiency, and speed up.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

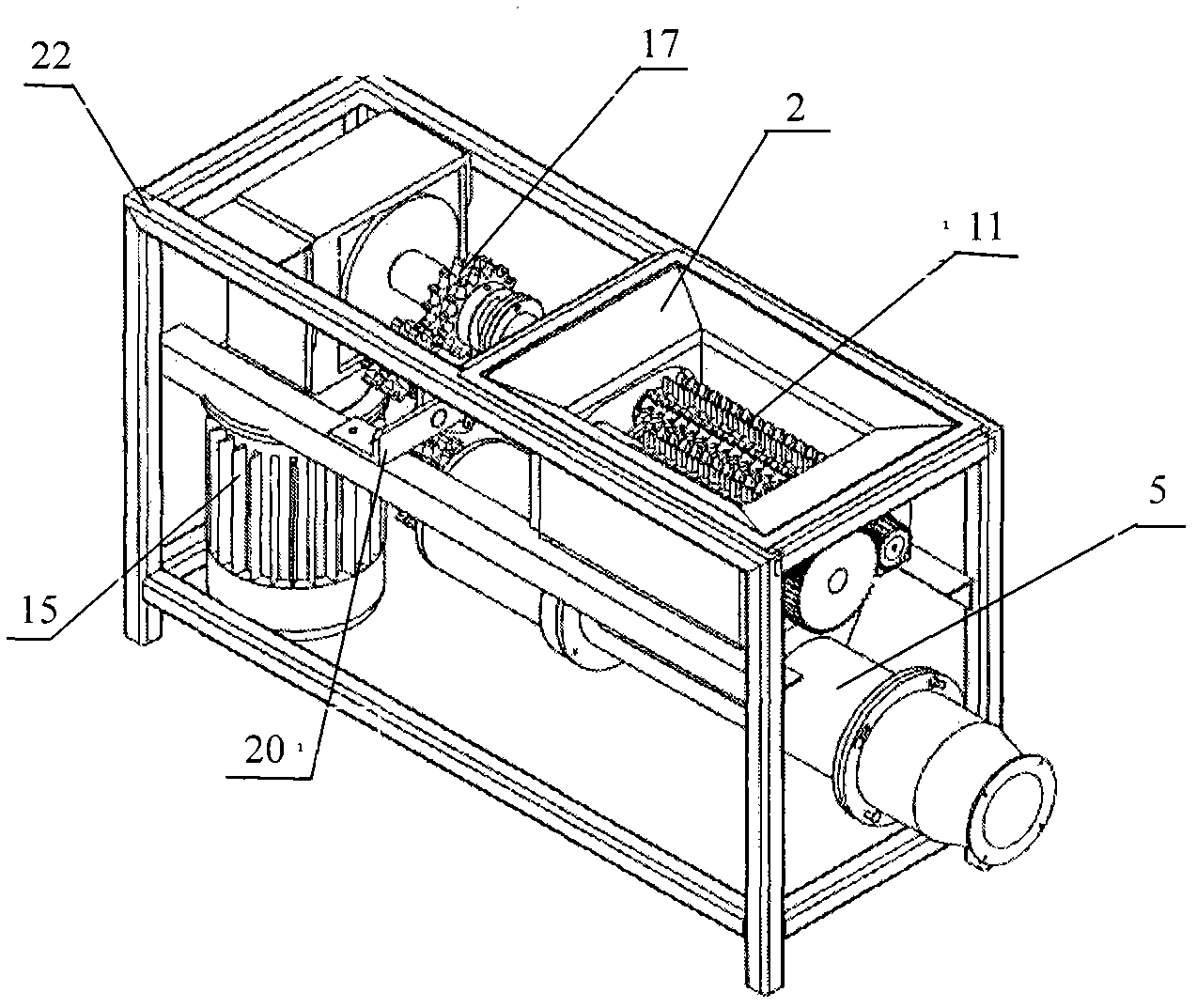

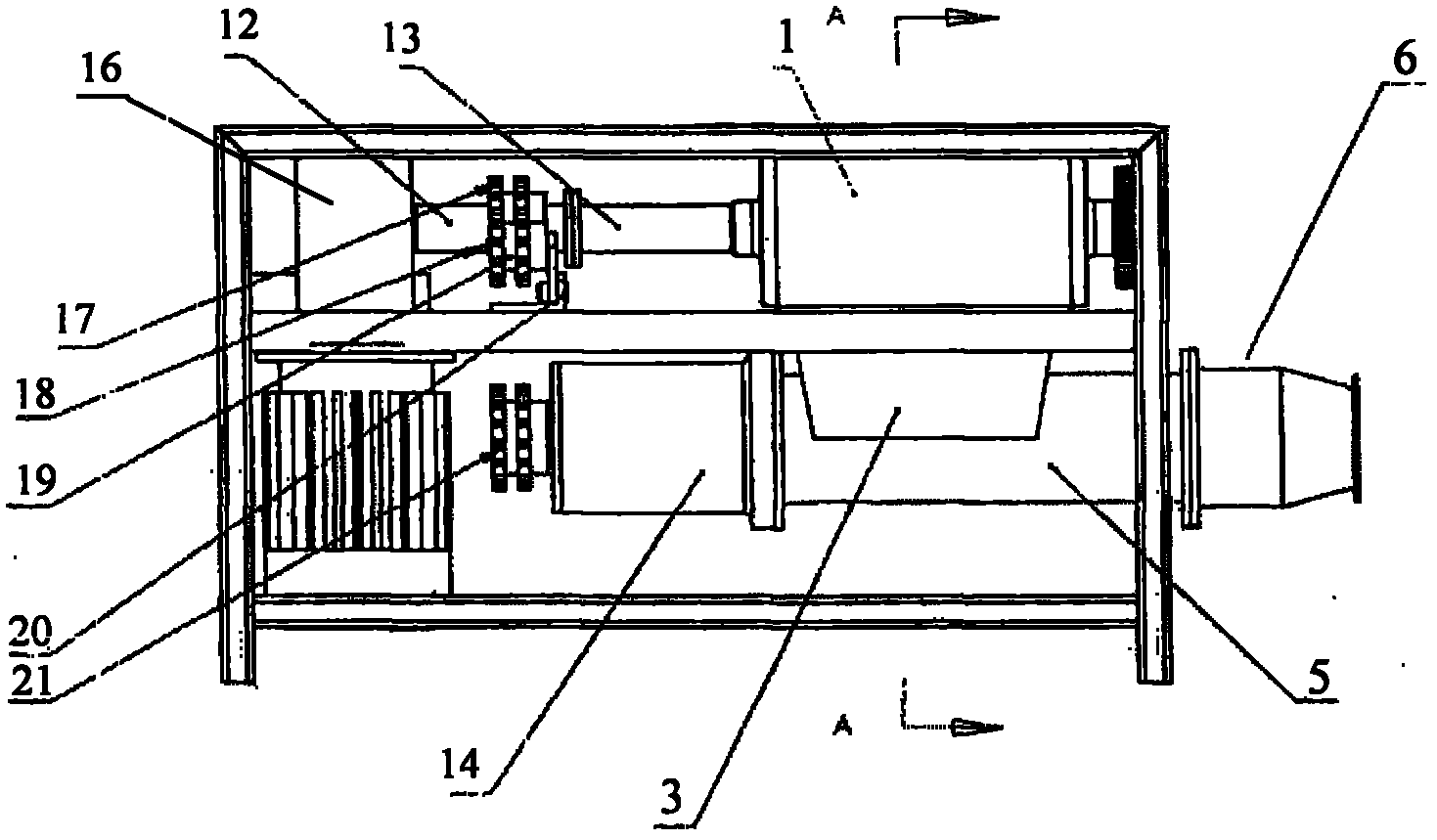

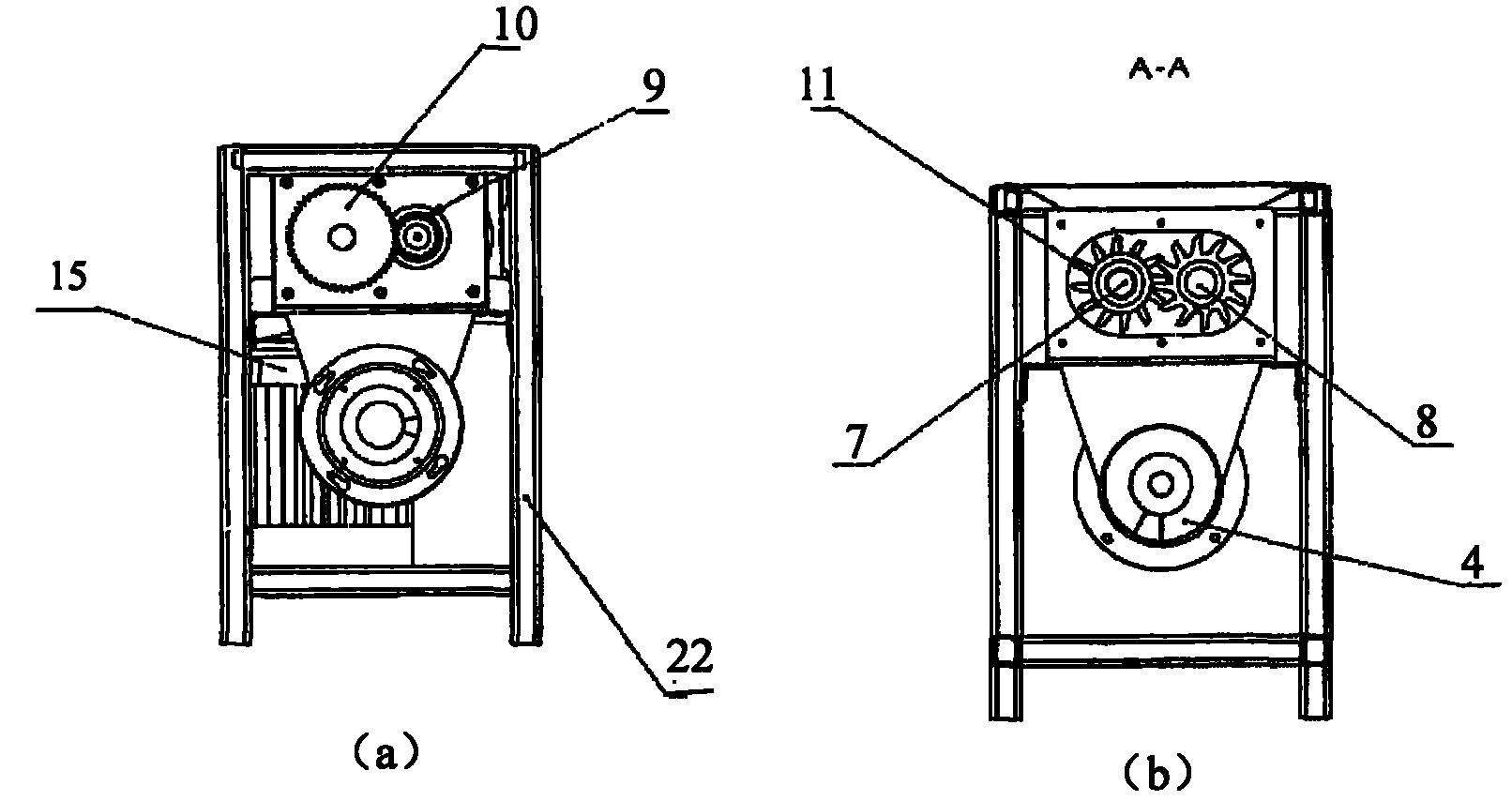

[0064] Such as Figure 1 to Figure 16 As shown, the kitchen waste crushing and pressing machine provided by the present invention includes a power part, a supporting part, a power transmission part, a crushing part, and a pressing and dehydrating part; the power part includes a motor 15, and the supporting part includes a support plate 20 and a frame 22. The power transmission part includes a reducer 16, a connector 12 and a connector 13, a shaft body 14, a sprocket 17, a sprocket 19, a sprocket 21 and a chain, and the crushing part includes a crushing box 1, and the upper end of the crushing box 1 is provided with a feed Port 2, the crushing box 1 is equipped with a roller-type crushing mechanism, and the lower end of the crushing box 1 is provided with a material channel 3; Figure 13 to Figure 16 As shown, the press dehydration part includes a screw 4, a storage sleeve 5, a screen 23 and a press sleeve 6, the screw 4 is installed in the storage sleeve 5, and the upper wall ...

Embodiment 2

[0078] The apex angle of the shaft section at one end of the conical shape of the screw rod 4 is 80°, as Figure 6 and Figure 8 As shown, the top of the gear tooth 26 of the gear 11 is a sharp edge-shaped tooth tip 27 formed by a slope and a vertical surface perpendicular to the base circle of the tooth root, and the angle between the slope and the vertical surface is 30°. Such as Figure 9 and Figure 10 As shown, the gap L between the gear teeth 26 and the washer 11 is 0.2mm, as Figure 12 As shown, the gap S between the gear teeth 261 on the driving shaft 7 and the adjacent gear teeth 262 on the driven shaft 8 is 0.2mm, as Figure 15 (a) and Figure 15 As shown in (c), the shape of the taper cylinder 602 is a truncated cone, and the angle a between the two generatrices of the axial section of the truncated cone is 20°.

[0079] Other specific implementations are the same as in Example 1.

Embodiment 3

[0081] The apex angle of the axial section of the conical one end of the screw rod 4 is 110°, as Figure 6 and Figure 8 As shown, the top of the gear tooth 26 of the gear 11 is a sharp edge-shaped tooth tip 27 formed by a slope and a vertical surface perpendicular to the base circle of the tooth root, and the angle between the slope and the vertical surface is 70°. Such as Figure 9 and Figure 10 As shown, the gap L between the gear teeth 26 and the washer 11 is 1mm, as Figure 12 As shown, the gap S between the gear teeth 261 on the driving shaft 7 and the adjacent gear teeth 262 on the driven shaft 8 is 1mm, as Figure 15 (a) and Figure 15 As shown in (c), the shape of the tapered cylinder 602 is a truncated cone, and the angle a between the two generatrices of the axial section of the truncated cone is 40°.

[0082] Other specific implementations are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com