Aluminum and aluminum alloy anti-rust cleaning agent and preparation method thereof

A technology of aluminum alloy and cleaning agent, which is applied in the field of chemicals, can solve the problems of material surface blackening and corrosion, and achieve good oil cleaning ability and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

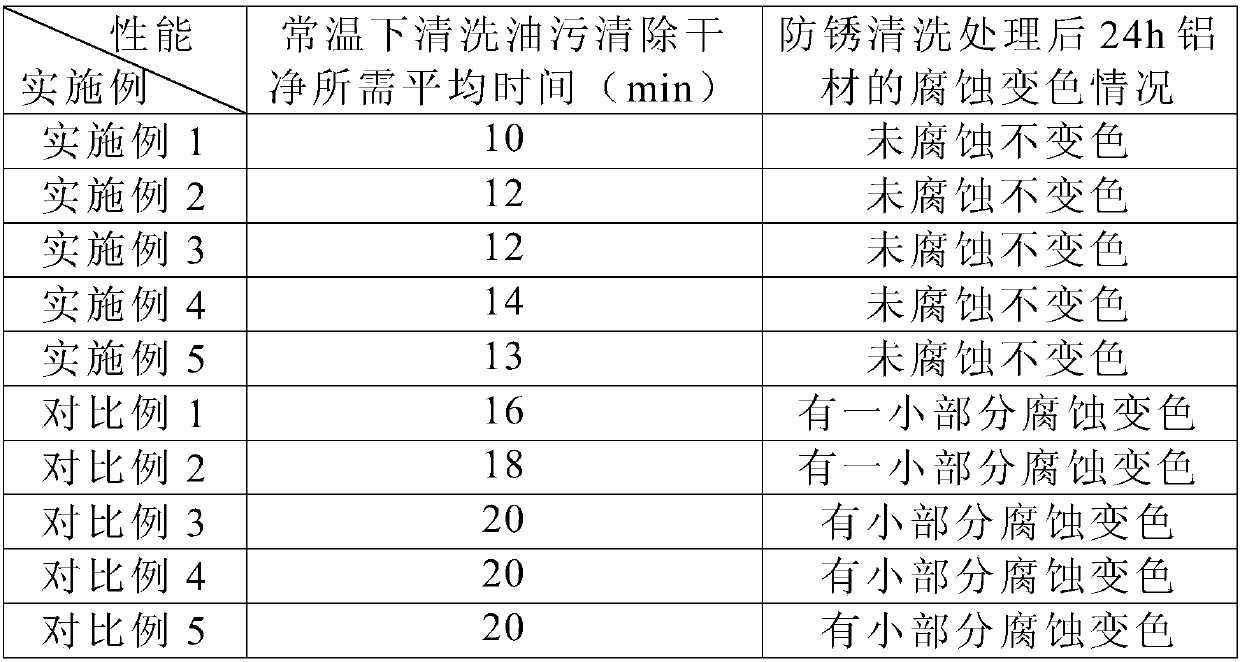

Examples

Embodiment 1

[0028] 1) Weigh the components of the anti-rust cleaning agent in parts by weight: 2 parts of potassium carbonate, 2 parts of sodium metasilicate pentahydrate, 1 part of isooctanoic acid, ternary polycarboxylate after triethanolamine treatment 0.5 parts of salt, 0.5 parts of octenyl succinic anhydride sodium salt, 0.5 parts of isotridecyl atactic polyether, 1 part of sodium citrate, 2 parts of sodium tungstate, and 88 parts of water;

[0029] 2) First dissolve potassium carbonate and sodium metasilicate pentahydrate in 65 parts of water, and stir evenly;

[0030] 3) Add isooctanoic acid and ternary polycarboxylate, heat to 50°C, and continue stirring for 20 minutes to obtain a clear and transparent liquid;

[0031] 4) After the solution is slightly cooled, add octenyl succinic anhydride sodium salt, isotridecyl atactic polyether, sodium citrate, sodium tungstate and the remaining water, and stir evenly;

[0032] 5) Test the pH value of the solution, and adjust the pH to 9.2 w...

Embodiment 2

[0034] 1) Weigh the components of the antirust cleaning agent by weight: 2 parts of sodium tripolyphosphate, 2 parts of sodium carbonate, 0.8 part of n-octanoic acid, 0.4 part of n-decanoic acid, ternary polycarboxylic acid treated with diethanolamine 0.6 parts of ternary polycarboxylate, 0.7 parts of potassium octenyl succinic anhydride, 0.8 parts of isooctyl alcohol polyoxyethylene ether, 0.8 parts of potassium tartrate, 0.8 parts of ethylenediaminetetraacetic acid, 0.7 parts of trisodium phosphate, diethanolamine 0.8 parts, 87 parts of water;

[0035] 2) First dissolve sodium tripolyphosphate and sodium carbonate in 67 parts of water, and stir evenly;

[0036] 3) Then add n-octanoic acid, n-decanoic acid, and tribasic polycarboxylate, and heat to 45°C, and keep stirring for 25 minutes to obtain a clear and transparent liquid;

[0037] 4) After the solution is slightly cooled, add octenyl succinic anhydride potassium salt, isooctyl alcohol polyoxyethylene ether, potassium tar...

Embodiment 3

[0040] 1) Weigh the components of the anti-rust cleaning agent by weight: 2 parts of sodium pyrophosphate, 1 part of sodium orthophosphate, 0.7 parts of isononanoic acid, 0.8 parts of 3,5,5-trimethylhexanoic acid, ternary 0.8 parts of polycarboxylates treated with monoethanolamine, 0.4 parts of dodecenyl succinic anhydride sodium salt, 0.4 parts of isomeric decanol polyoxyethylene ether (E-1006), 0.3 parts of sodium tartrate, 0.4 parts of glycolic acid, 1.2 parts of sodium hexametaphosphate, 1.2 parts of hydrazine hydrate, 89 parts of water;

[0041] 2) Dissolve sodium pyrophosphate and sodium orthophosphate in part of 70 parts of water, and stir evenly;

[0042] 3) Add isononanoic acid, 3,5,5-trimethylhexanoic acid, and tribasic polycarboxylate, and heat to 55°C, and continue stirring for 15 minutes to obtain a clear transparent liquid;

[0043] 4) After the solution is slightly cooled, add sodium dodecenyl succinic anhydride, isomeric decanol polyoxyethylene ether (E-1006),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com