Vehicle supporting bridge pipe and end face flange welding machine and welding method thereof

A flange and bridge tube technology, which is applied in the field of welding equipment for supporting bridge tubes and flanges and their welding, can solve the problems of large welding workload, heavy tasks, and difficult to guarantee welding quality, so as to reduce welding deformation and improve coaxiality. The effect of improving the welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

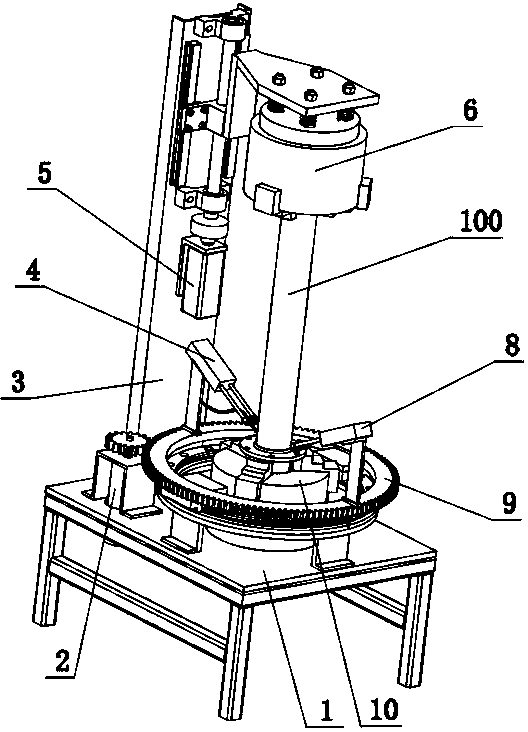

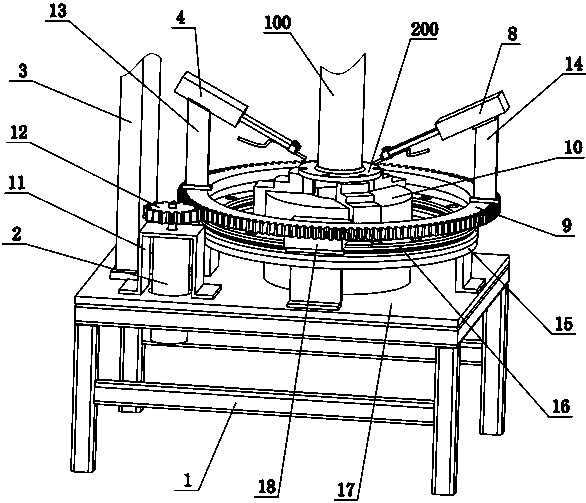

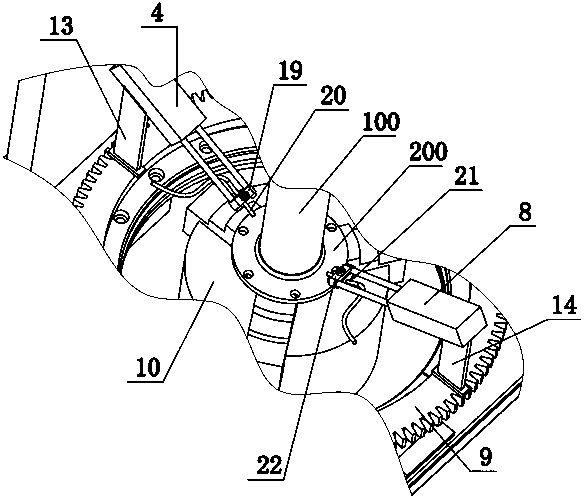

[0031] combine Figure 1~6 , a vehicle support bridge tube and end face flange welding machine of the present invention includes a welding seat 1, a servo motor 2, a vertical beam 3, a double-rod cylinder 4, a servo motor 2 5, a three-jaw chuck 6, a double rod Cylinder two 8, ring gear 9, three-jaw chuck two 10, motor frame one 11, gear 12, cylinder frame one 13, cylinder frame two 14, guide rail frame 15, ring guide rail 16, support plate 17, slider one 18, Welding torch fixing block one 19, welding torch one 20, welding torch two 21, welding torch fixing block two 22, motor frame two 23, shaft coupling 24, bearing housing one 25, lead screw 26, slide block two 27, lead screw nut 28, Linear guide rail one 29, bearing housing two 30, lower pressure plate 31, stud 32, lock nut 33, spring 34, connecting plate 35, linear guide rail two 36, slider two 37, the upper end of the welding seat 1 is fixedly supported Flat plate 17, support flat plate 17 is arranged along horizontal dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com