Method for frame mounting of non-intercepting gridded electron gun of klystron

A gate-controlled electron gun and no interception technology, which is applied in klystrons, electron tubes with velocity/density modulation electron flow, electron/ion guns of time-of-flight electron tubes, etc., can solve problems affecting electron emission characteristics, etc., to achieve Effects of reduced weight and volume, powerful functions, and reduced current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

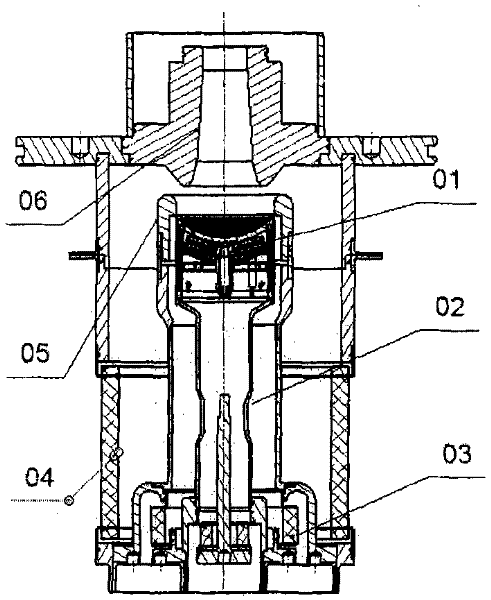

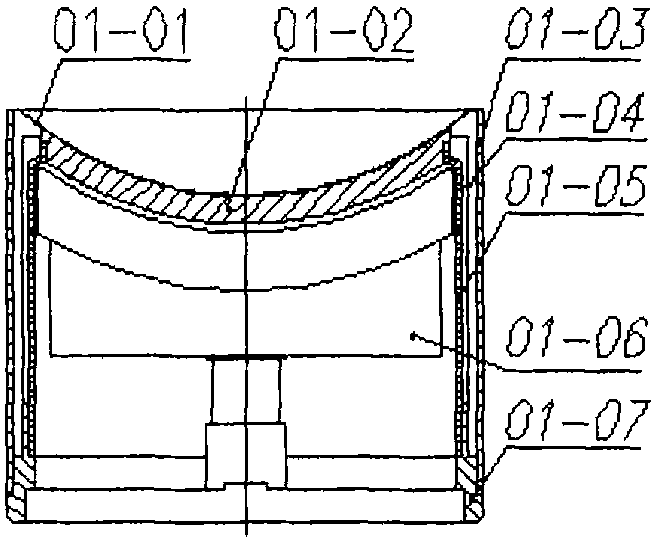

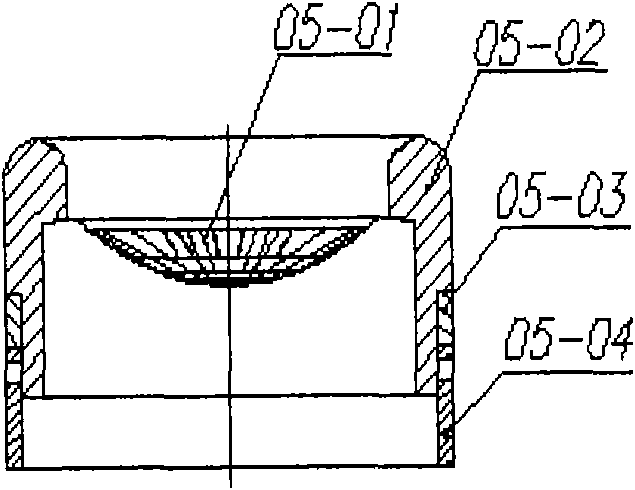

[0041] Such as figure 1 Shown is a schematic diagram of the structure of a non-intercepting gate-controlled electron gun for a klystron. The mechanical structure of the non-intercepted grid-controlled electron gun is mainly composed of six major components, namely, the cathode heater subassembly 01, the cathode heater support assembly 02, the gate control lead wire assembly 03, the insulating section assembly 04, the beam-focusing pole assembly 05, and the anode assembly 06. see Figure 2a , Figure 2b , the main composition of the grid-controlled electron gun without interception is that the shadow grid 01-01 of molybdenum material is attached to the surface of the spherical barium-tungsten cathode 01-02, and the cathode heater subassembly 01 formed with the heater is fixed on the cathode heater support assembly 02 Above, the molybdenum material control grid 05-01 is fixed in the oxygen-free copper material focusing pole 05-02 to form the focusing pole assembly 05, and a po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com