Bonnet support processing method and clamp and processing equipment for bonnet support

A processing method and technology of processing equipment, applied in metal processing equipment, mechanical equipment, manufacturing tools, etc., can solve the problem of uneven force on the sealing surface of valve opening and closing torque, position tolerance not meeting requirements, unstable product quality, etc. problems, to achieve the effect of improving labor efficiency, ensuring accuracy, and simplifying the workpiece processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

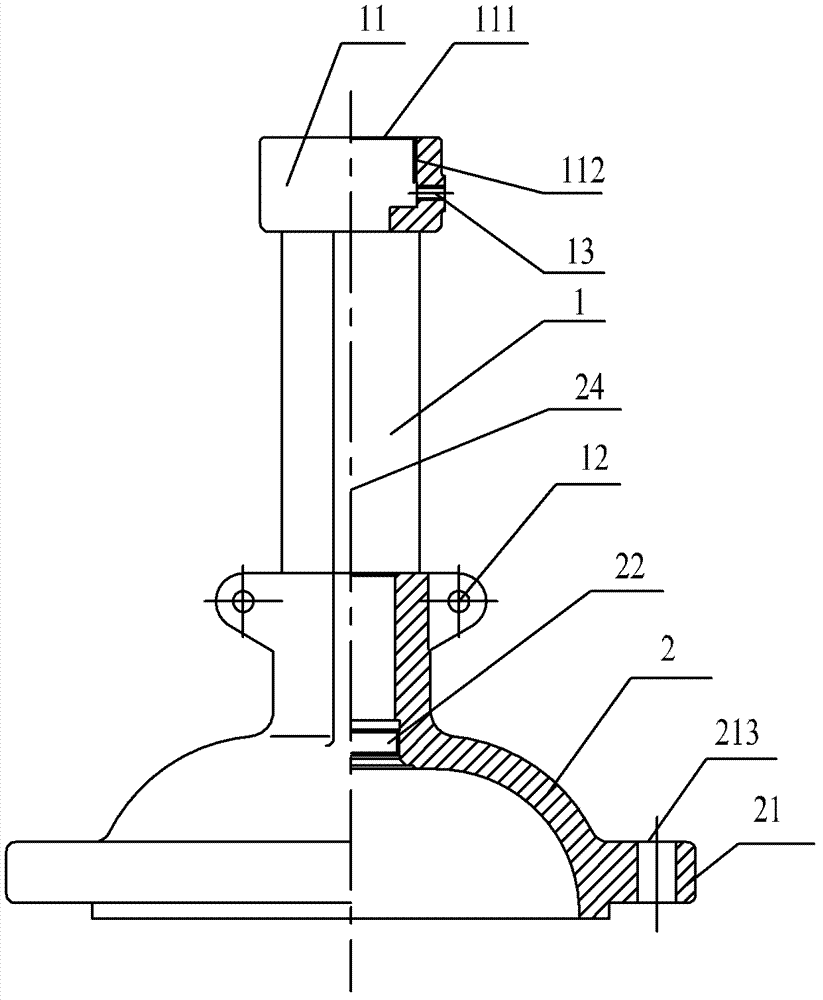

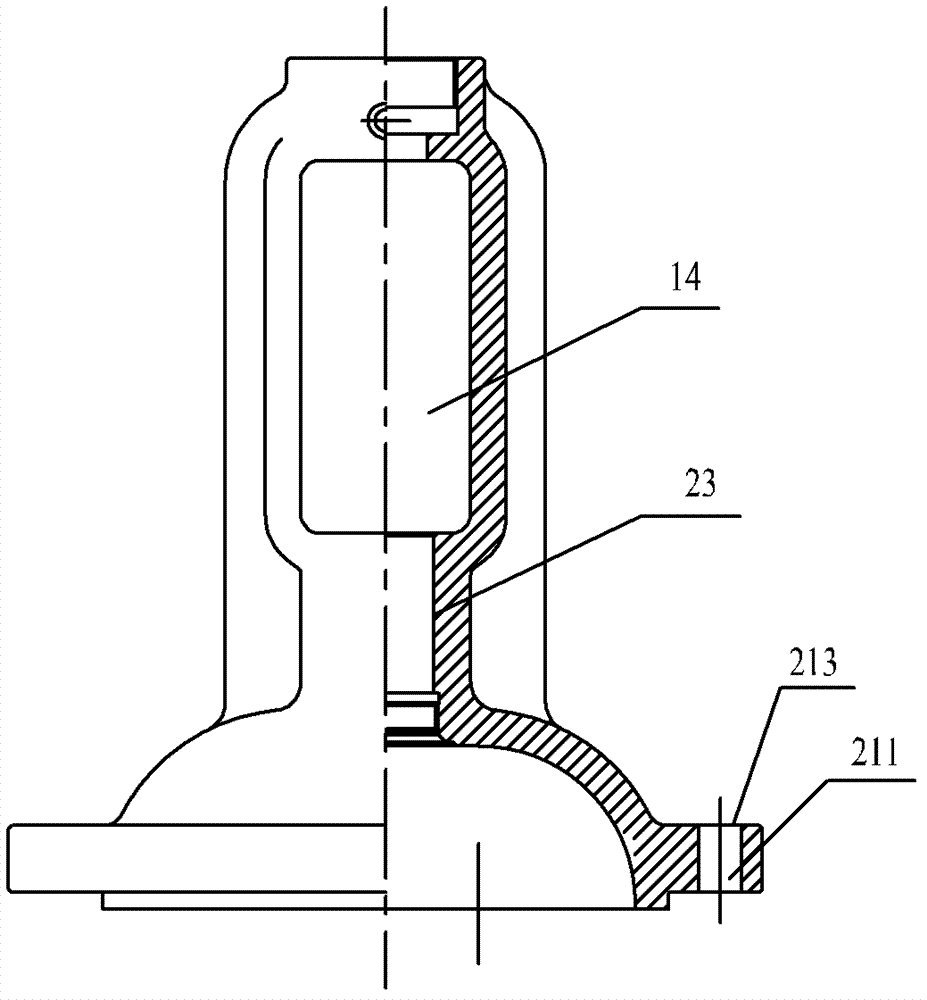

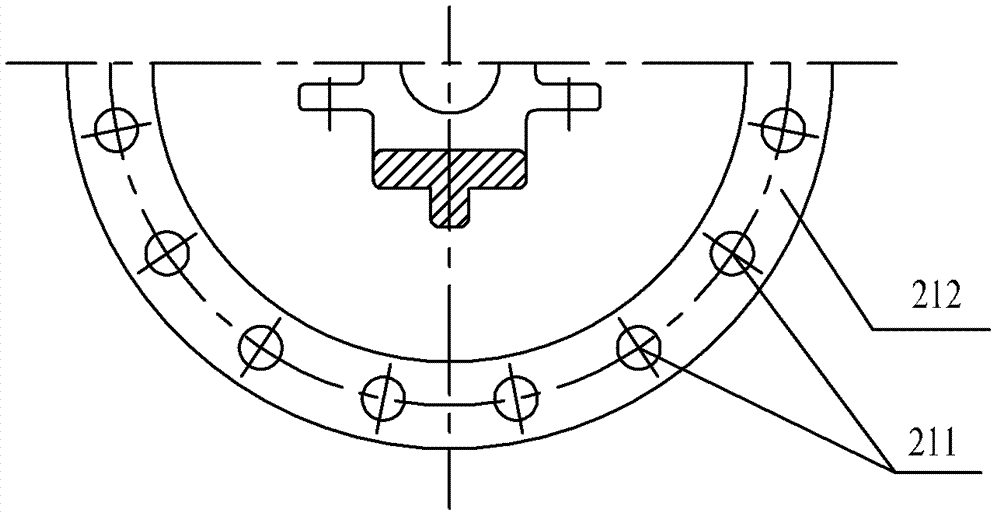

[0038] The present invention relates to a kind of processing method of bonnet bracket, see figure 1 , figure 2 and image 3 , the bonnet bracket includes a bracket 1 and a bonnet 2, the bracket 1 is provided with a valve stem nut hole 11, a joint bolt hole 12 and a valve stem nut lubricating screw hole 13, and the bonnet 2 is provided with a method Flange 21, upper sealing seat 22 and stuffing box 23, the flange 21 is provided with several flange holes 211, the processing equipment 4 for processing the bonnet bracket is provided with a rotary disc 46, and the rotary disc 46 is provided with Special fixture 3, described method comprises the following steps:

[0039] 1) The special fixture 3 fixes the bonnet bracket so that the center line 24 of the bonnet bracket is coaxial with the main shaft of the processing equipment 4;

[0040] 2) The processing equipment 4 cuts the flange plane 212; after the flange plane 212 is cut, the rotary disc 46 is rotated at an angle of 180° t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com