Grinding method and device for outer diameter of tapered roller based on large crown

A tapered roller and grinding technology, which is applied in the direction of grinding driving device, grinding/polishing equipment, grinding machine tool parts, etc., can solve the problems that cannot meet the precision requirements, etc., and achieve easy realization and promotion, high economic benefits and social benefits, the effect of reducing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

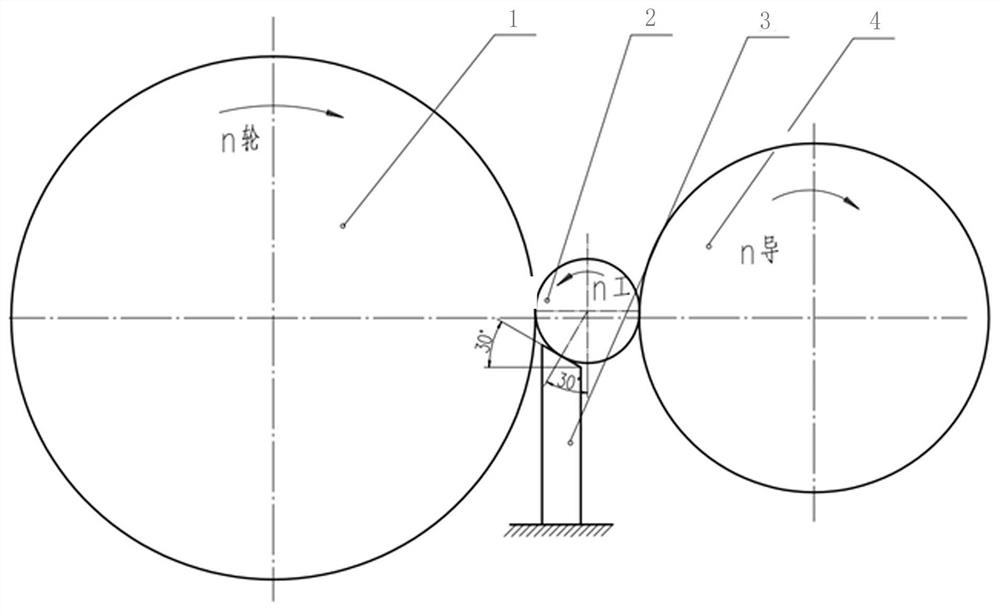

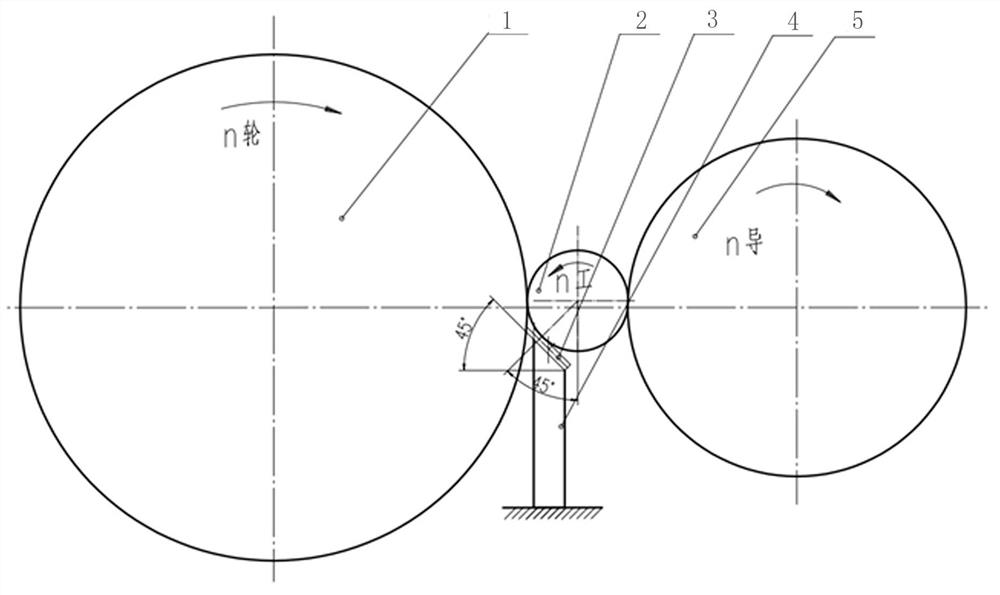

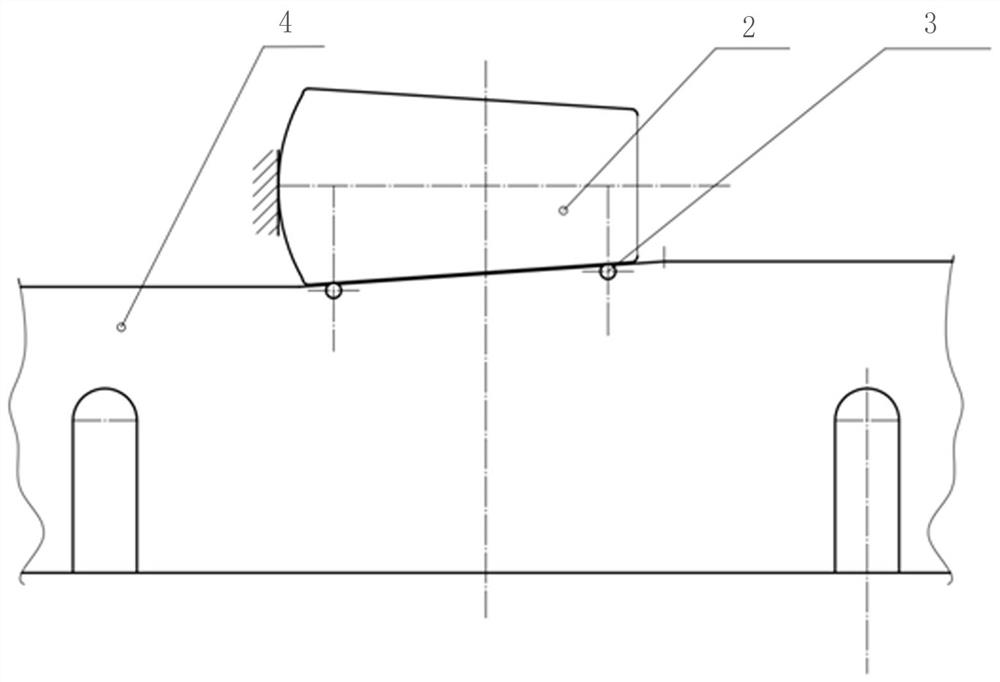

[0022] Example: see figure 1 -- image 3 , in the figure, 1-grinding wheel, 2-tapered roller, 3-alloy rod, 4-guide plate, 5-guide wheel.

[0023] Based on the large-convex tapered roller outer diameter grinding method, the centerless grinding machine is used to grind the positioned grinding wheel 1, the guide wheel 5 and the guide plate 4, and the cutting method is used to complete the outer diameter grinding of the tapered roller 2, wherein the guide wheel 5 is Clockwise rotation, under the action of friction between the guide wheel 5 and the tapered roller 2, and overcome the friction resistance between the tapered roller 2 and the guide plate 4, to drive the tapered roller 2 to rotate counterclockwise, and the grinding wheel 1 to rotate clockwise. Carry out grinding feed motion at the same time, realize grinding processing, the present invention starts from guide plate 4 support method and structure: ① increase the driving force of guide wheel 5 and roller 2, rationally se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com