Method for mounting large-scale gangplank of ro-ro vessel

A technology of ro-ro ships and springboards, which is applied to ship components, ship construction, transportation and packaging, etc. It can solve the problems that the installation and welding process cannot meet the requirements, achieve reliable technical process guarantee, improve service life, and ensure coaxiality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0012] 1. Technical requirements for hinge processing and installation

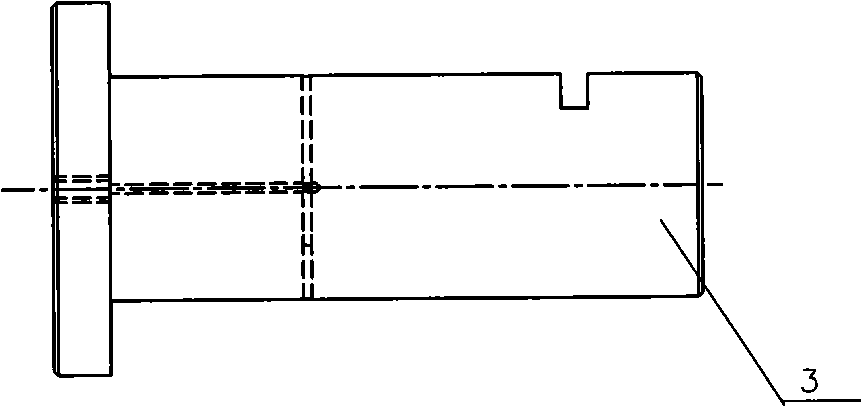

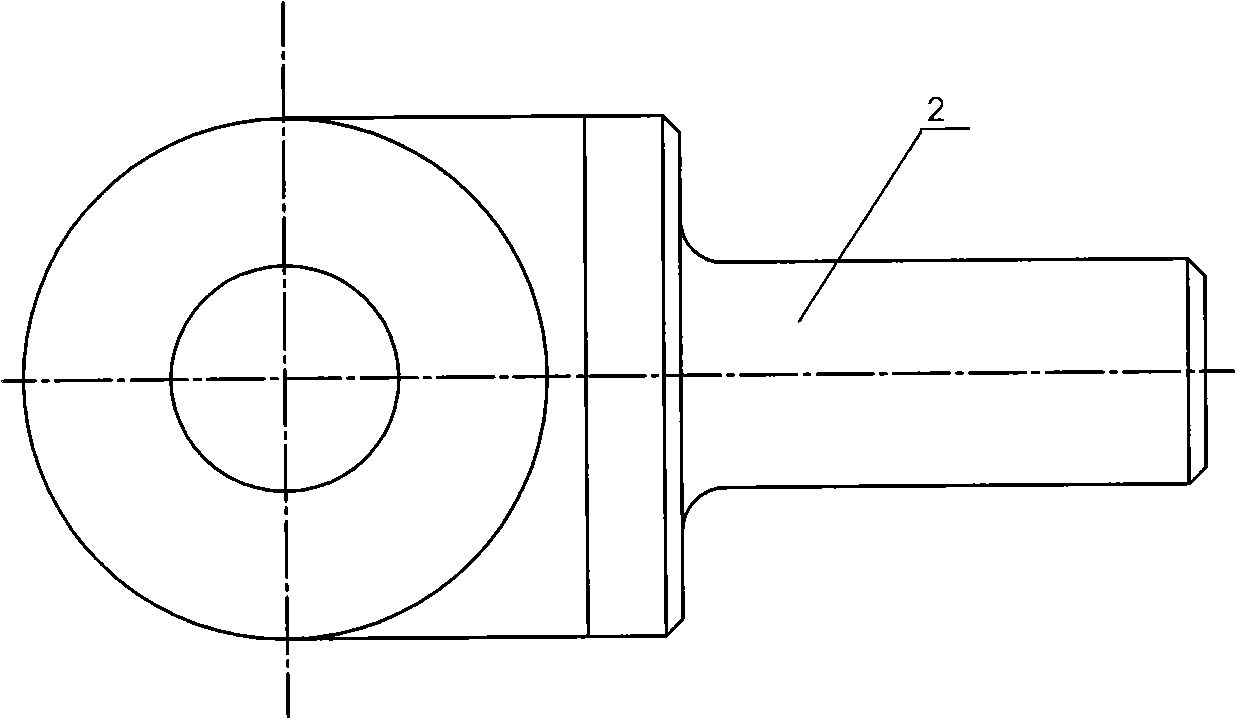

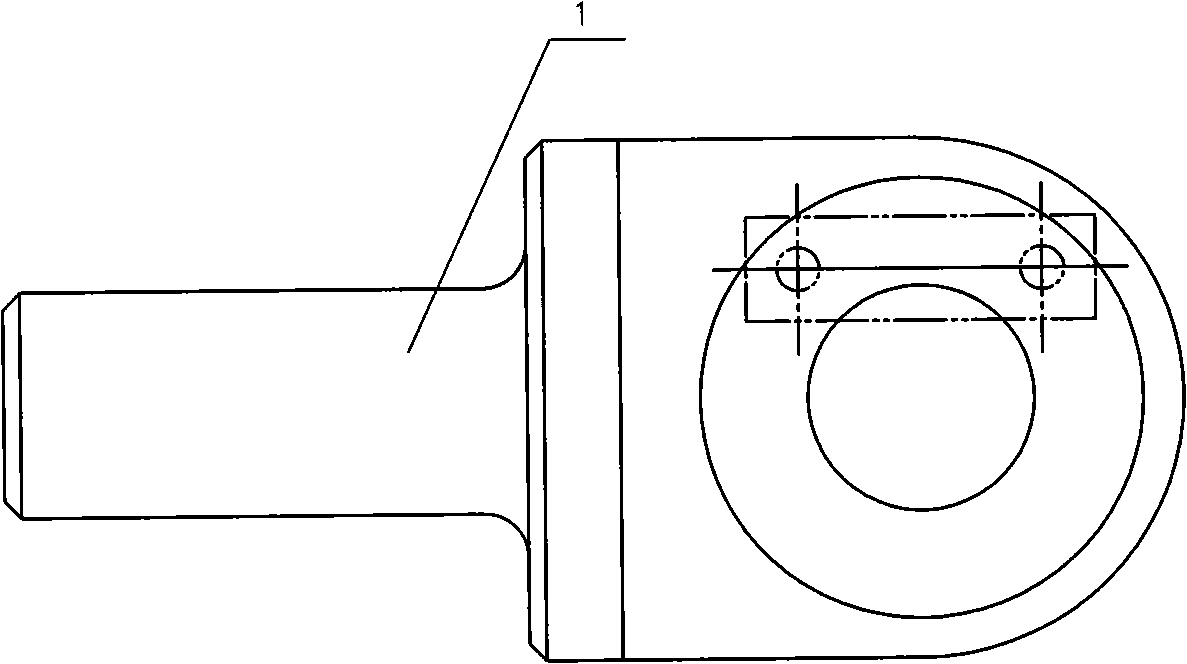

[0013] The technical requirements for springboard hinge support 1, springboard hinge support 2 and springboard hinge shaft 3 are as follows:

[0014] 1) The width of the opening of support 1 is 272mm, and the width of the insertion end of support 2 is 270mm. Considering the free tolerance, the opening width of support 1 is 272mm +3 mm, the width of the insertion end of support 2 is 270 -0.5 mm processing.

[0015] 2) The size of the hinge holes of support 1 and support 2 is φ260 +0.2 mm, hinge shaft size according to φ258 -0.2 mm processing.

[0016] 3) The perpendicularity between the axis of the hinge hole of support 1 and the processing surface of the opening, and the axis of the hinge hole of support 2 and the processing surface of the insertion end is not greater than 0.2mm.

[0017] 4) The coaxiality of the 7 hinge installations is not greater than φ2.4mm.

[0018] 5) The installation spacing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com