Shaft force and torque combined testing machine for fastening piece

A technology for fasteners and testing machines, which is used to measure torque/torsion force, measuring devices, instruments, etc. during tightening, which can solve problems such as increasing the complexity of the operation process, achieve good positioning, stable and reliable data, and maintain coaxiality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

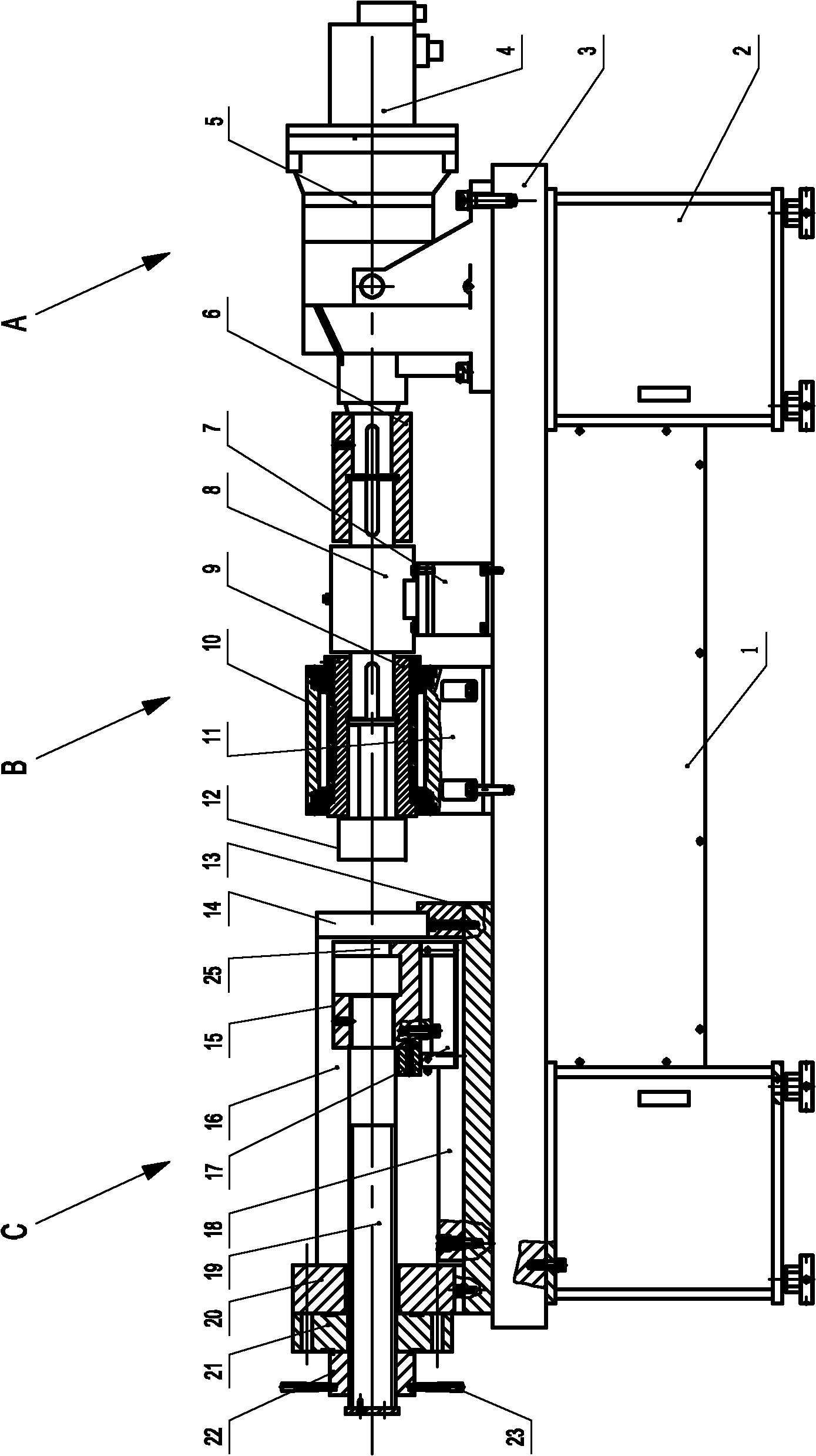

[0029] The fastener axial force-torque combined testing machine of the present invention includes a host computer and a microcomputer measurement and control system.

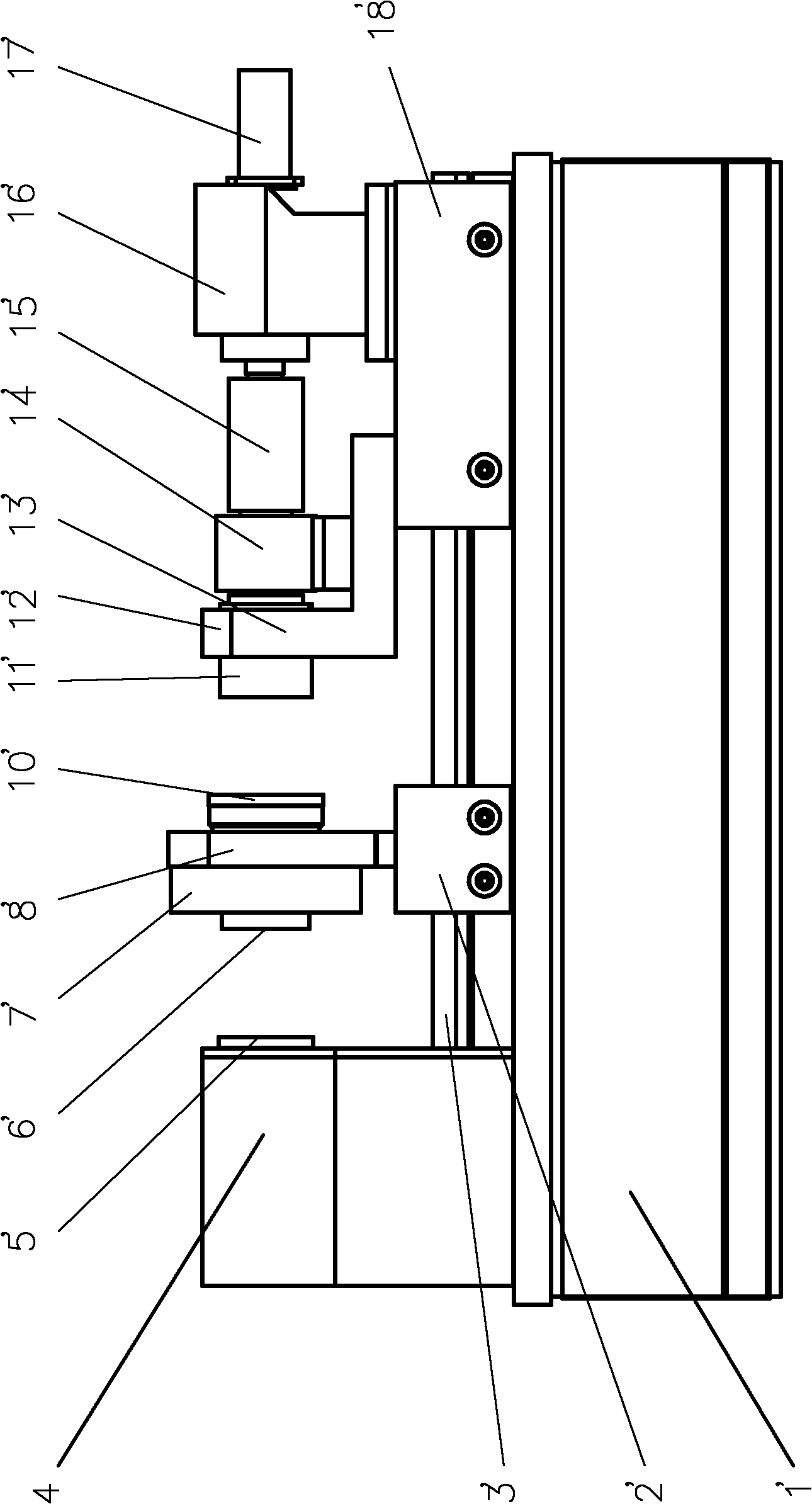

[0030] refer to figure 2 , the host machine includes a cabinet 1, two sliding doors 2 are arranged on the front of the cabinet 1, and a working platform 3 is arranged above the cabinet 1. The working platform 3 is provided with a motor reducer section A, a torque sensor section B and a reaction frame section C in sequence from right to left.

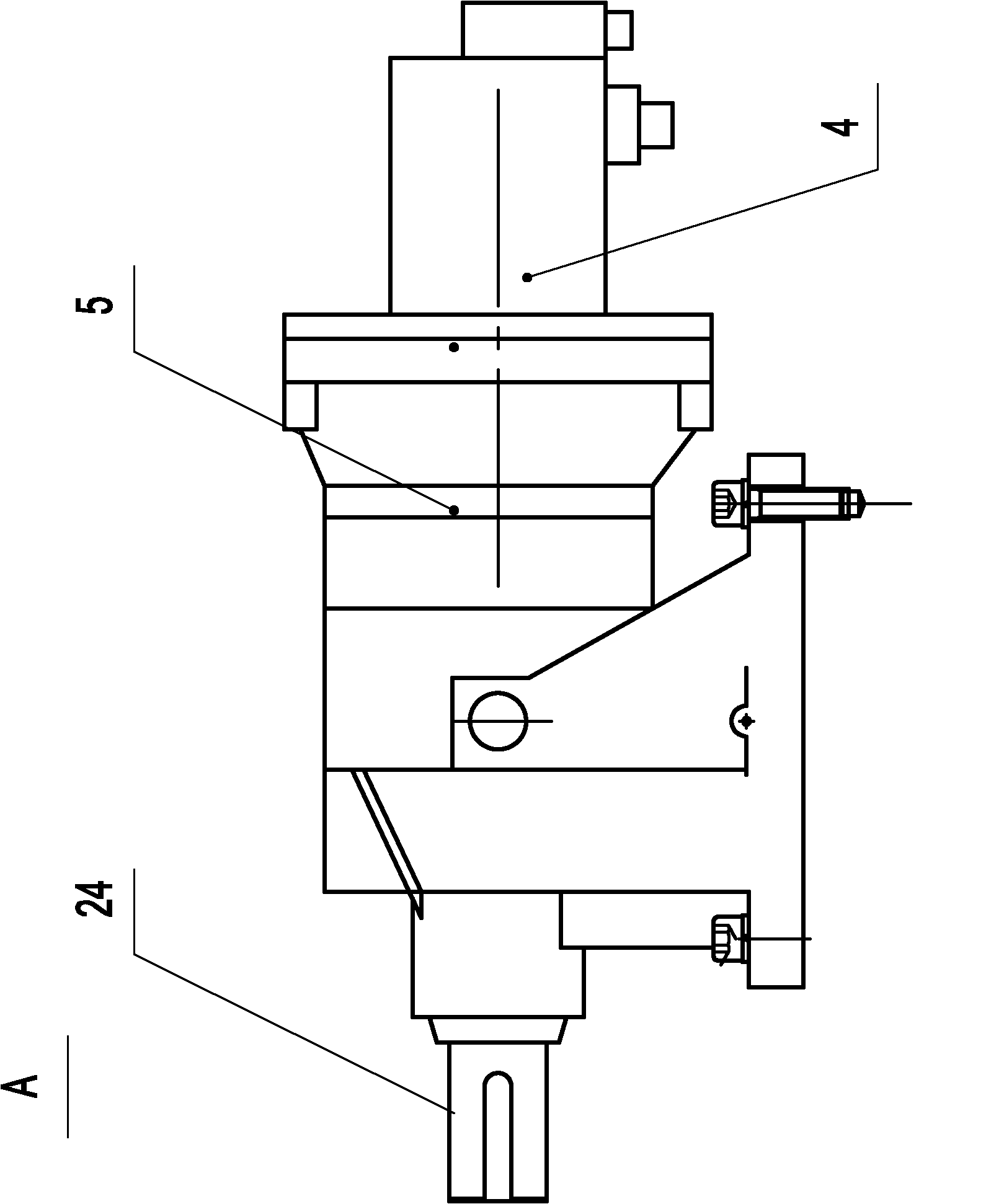

[0031] refer to image 3 , the motor reducer section A includes a motor (4) and a reducer (5), and the left shaft extension end 24 of the motor (4) is connected to the torque sensor 8 through the first shaft coupling 6 . The motor (4) is a servo motor, which has the characteristics of intelligent automatic gain adjustment, high speed and high response, and ultra-low vibration. The reducer (5) selects a planetary gear reducer, which has the advantages of less wear, smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com