Transformer substation electrical equipment comprehensive physical examination system based on cloud side end collaborative perception

A technology for collaborative sensing and electrical equipment, applied in the field of analysis, processing systems, and monitoring of electrical equipment in substations, it can solve the problems of lack of intelligent processing solutions, data sharing, and low utilization of abnormal analysis and accurate positioning, so as to reduce computing load. , to ensure real-time performance, improve the effect of data transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Best practice:

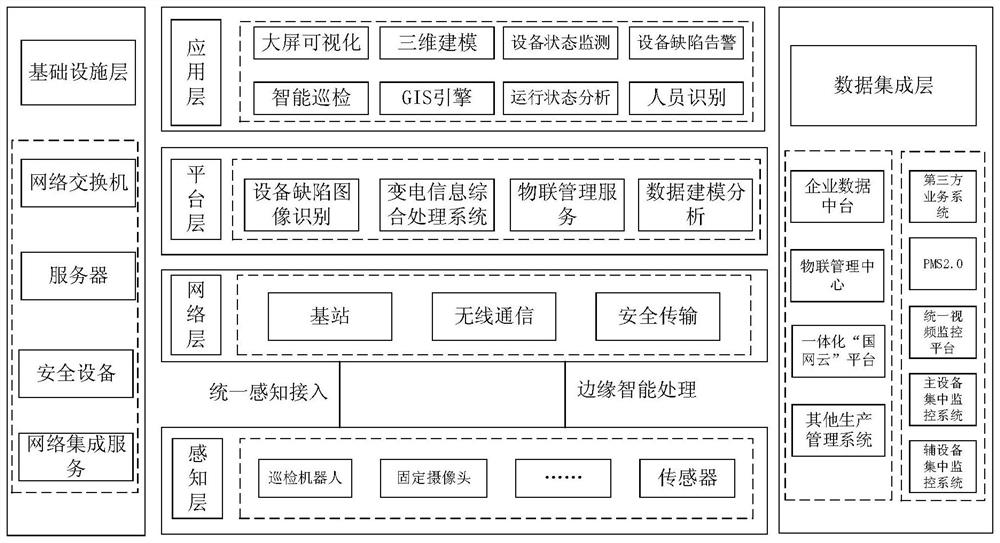

[0056] Refer to attached figure 1 , a comprehensive physical examination system for electrical equipment in substations based on cloud-edge-end collaborative perception. The overall design complies with the overall technical architecture of the Ubiquitous Power Internet of Things and is divided into four layers:

[0057] Perception layer: including inspection robots, fixed cameras in substations, partial discharge monitoring devices, iron core grounding current monitoring devices, SF6 gas component monitoring, voiceprint recognition and other devices, through various terminal sensing monitoring devices to collect on-site meters in substations Data information such as data display, equipment temperature, human face, foreign object intrusion, etc., monitor and identify potential faults of electrical equipment in substations, realize multi-node and all-round monitoring of substations, and apply edge computing technology to realize local intelligent process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com